Tooth removal device for metal zipper sizing and cleaning and tooth removal method thereof

A fixed-size teeth cleaning and metal zipper technology, which is applied in positioning devices, feeding devices, storage devices, etc., can solve problems such as accumulation speed, and achieve the effects of reducing labor costs, increasing production speed, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

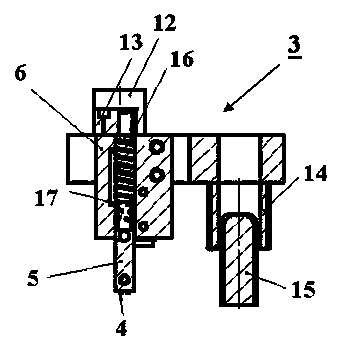

[0043] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

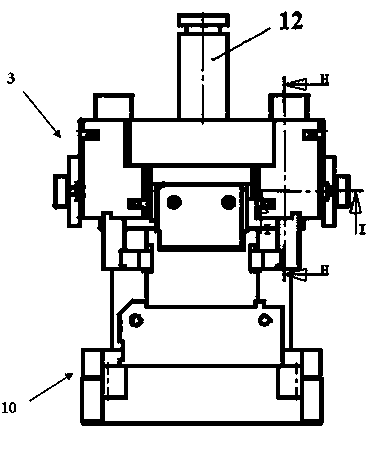

[0044] Such as figure 1 As shown, the present invention discloses a tooth extraction device for metal zipper fixed-size teeth cleaning, which is used to determine the length of the zipper and other technological requirements according to the needs of customers, and perform fixed-size tooth extraction on the zipper 1 that is fixed-size tooth extraction , Accurately extract the specified number and position of teeth.

[0045] The device comprises a correspondingly arranged upper die base 3 and a lower die base 10 , wherein the lower die base 10 is horizontally fixed on any plane, and the upper die base 3 is correspondingly arranged horizontally above the lower die base 10 .

[0046] A lower mold 11 is fixed on the top of the lower mold base 10 . The top of this lower mold 11 is used for placing the zipper 1 that is sized and extracted.

[0047] The bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com