High-temperature high-humidity flue gas bag type dust collection and ash removal method and device thereof

A high-temperature, high-humidity, bag-type dust removal technology, applied in separation methods, dry gas layout, chemical instruments and methods, etc., can solve the problems of bag-type dust collectors not working normally, inability to clean dust, and filter bag dust blocking, etc. Achieve the effect of improving dust removal effect and dust removal efficiency, reducing dust removal difficulty and cost, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings to facilitate a clearer understanding of the present invention, but they do not limit the present invention.

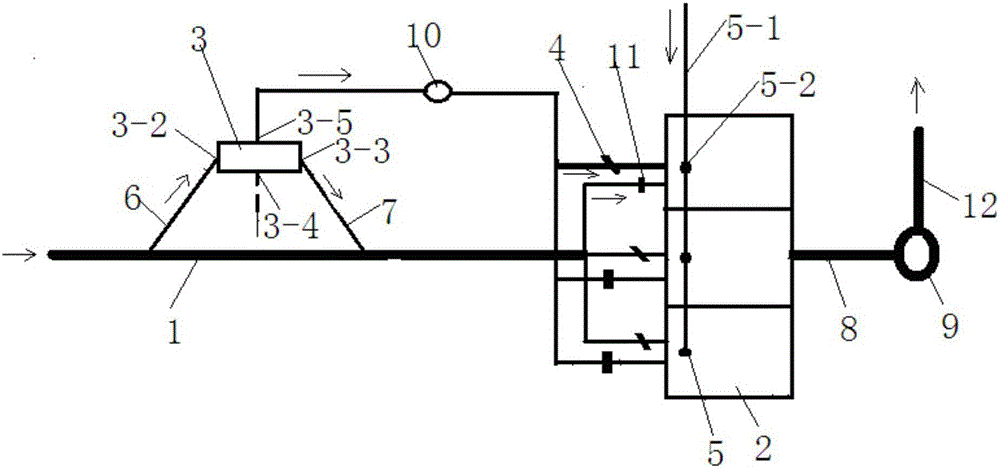

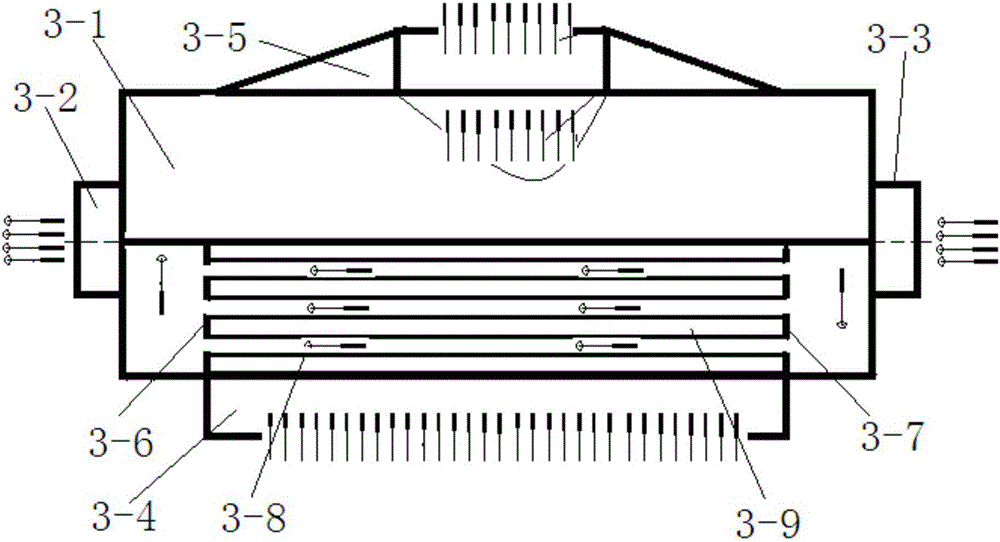

[0022] like figure 1 As shown, a high-temperature and high-humidity flue gas bag-type dust removal device includes a flue gas main pipe 1 and a bag filter 2, and the front end of the flue gas main pipe 1 is connected to an air preheater 3; combined with figure 2 As shown, the air preheater 3 is a tubular heat exchanger, which includes a box body 3-1. The front end of the box body 3-1 has a flue gas inlet 3-2, and the rear end has a flue gas outlet 3-3. There is a preheating air inlet 3-4, and a preheating air outlet 3-5 on the top. The front orifice plate 3-6, the heat exchange tube bundle 3-8 and the rear orifice plate are arranged in sequence from front to back in the box body 3-1. 3-7. The heat exchange tube bundle 3-8 is a thin-walled steel tube b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com