Guide device for nuclear power driving pipe seat deep hole machining

A guide device and pipe seat technology, applied in metal processing equipment, drilling molds for workpieces, manufacturing tools, etc., can solve problems such as poor strength and rigidity, deviation and vibration, and difficulty in chip discharge to ensure product size Requirements for precision and surface roughness, solve the problems of deviation and vibration, and ensure the effect of processing progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the examples.

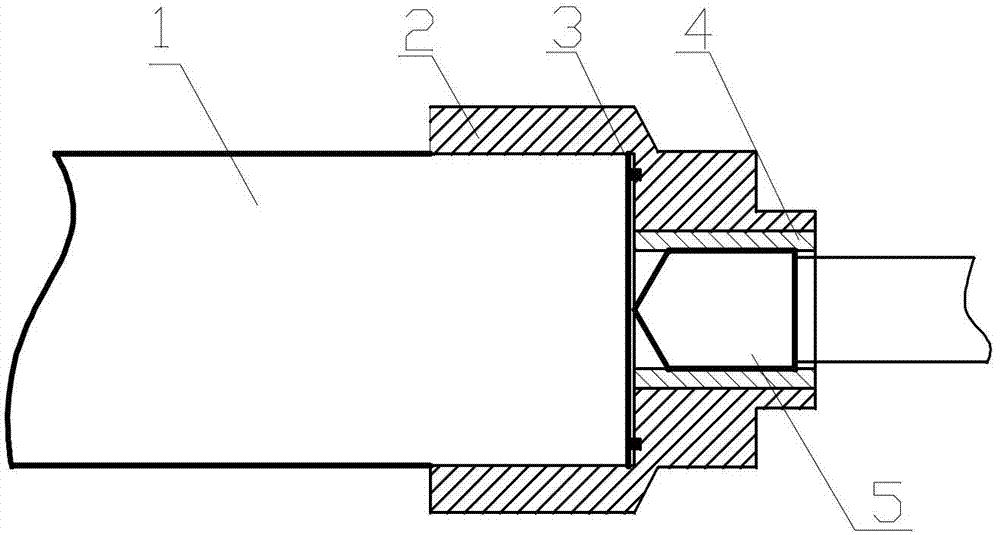

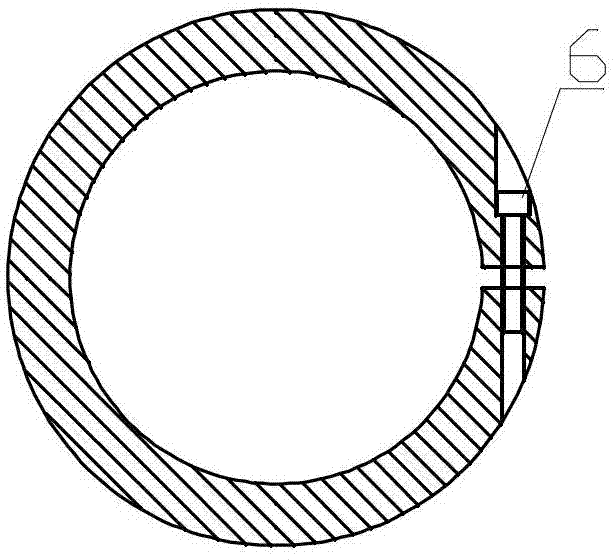

[0014] Such as Figure 1~2 As shown, the guide device for deep hole processing of nuclear power drive tube socket provided by the present invention includes a bushing and a bushing, one end of the bushing is tightly fitted to the workpiece, the other end of the bushing is provided with a bushing, and the contact end surface of the bushing and the workpiece is arranged Oil seal; the drill bit is inserted into the bushing for guiding processing; the shaft sleeve is provided with tightening bolts. The device is fixed on the main shaft of the machine tool when installed. Select the appropriate bushing according to the size of the deep hole of the drive pipe seat to be processed, insert the selected bushing into the bushing, and confirm whether the bushing is installed in place; check whether the oil seal is damaged. After confirming that the oil seal is not damaged, install the bush...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com