Vacuum sewage-biodegradation dirt tank device for train and sewage disposal method

A sewage biological and biological pretreatment technology, applied in biological water/sewage treatment, water/sewage treatment, oxidized water/sewage treatment, etc. Second-level standards and other issues, to achieve the effect of eliminating the ground treatment system, prolonging the cleaning operation cycle, and ensuring efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

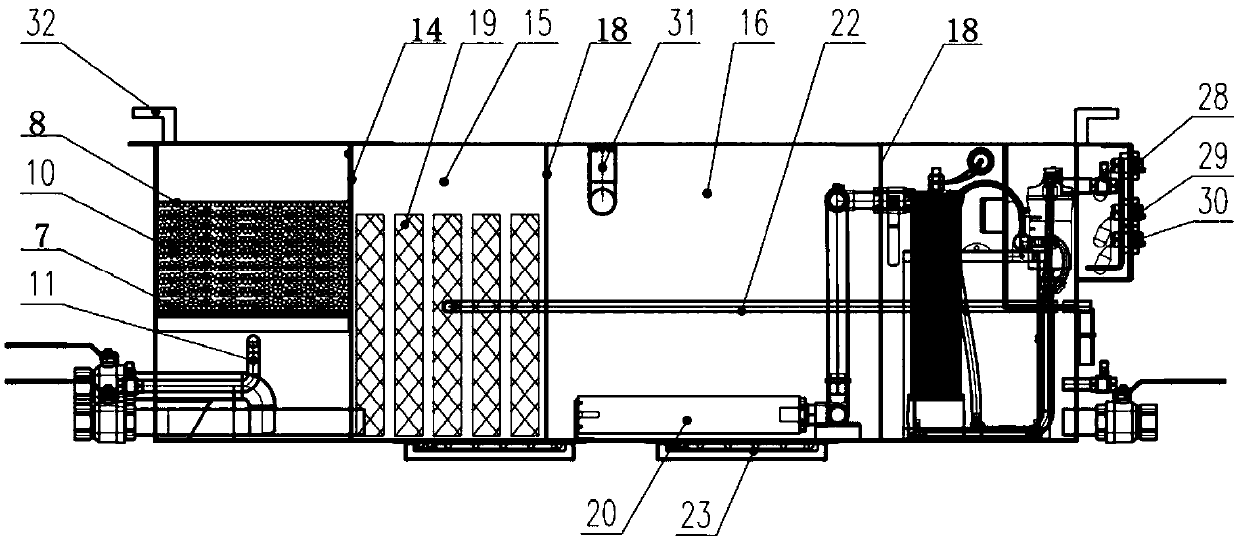

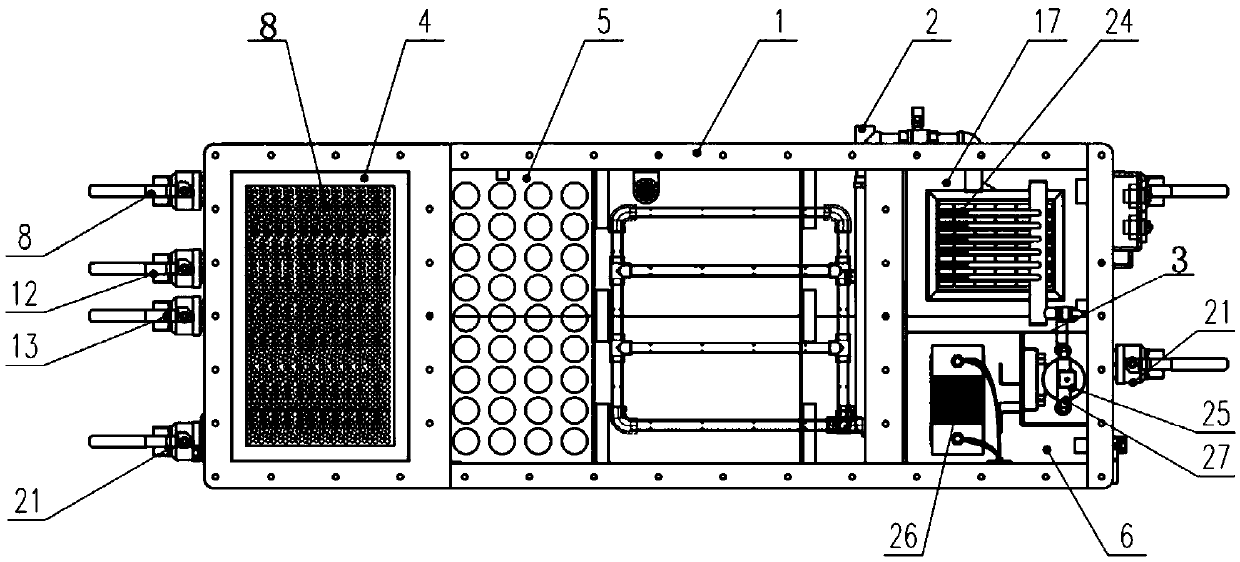

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] Such as figure 1 and figure 2 As shown, the present invention provides a vacuum sewage biodegradation dirt tank device for trains, including a dirt tank 1 and a control system. The waste water and dirt discharged from washing basins, toilets and other equipment all flow into the dirt box 1. Hanging lugs 32 are arranged at the top four corners of the dirt box 1, and the dirt box 1 is hung on the vehicle body chassis through the lifting lugs 32. below.

[0028] The dirt tank 1 has a biological pretreatment chamber and an advanced oxidation chamber 6 which communicate with each other, and the biological pretreatment chamber and the advanced oxidation chamber 6 are separated by a first partition 3 . The biological pretreatment chamber is used for preliminary degradation of the dirt entering the dirt tank 1, and the pollutant index is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com