Two-station isolating mechanism

An isolation mechanism and double-station technology, which is applied to metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems affecting the processing quality and precision of other workpieces, low processing efficiency, and high labor intensity, etc. The effects of wide range, less restrictions on use, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

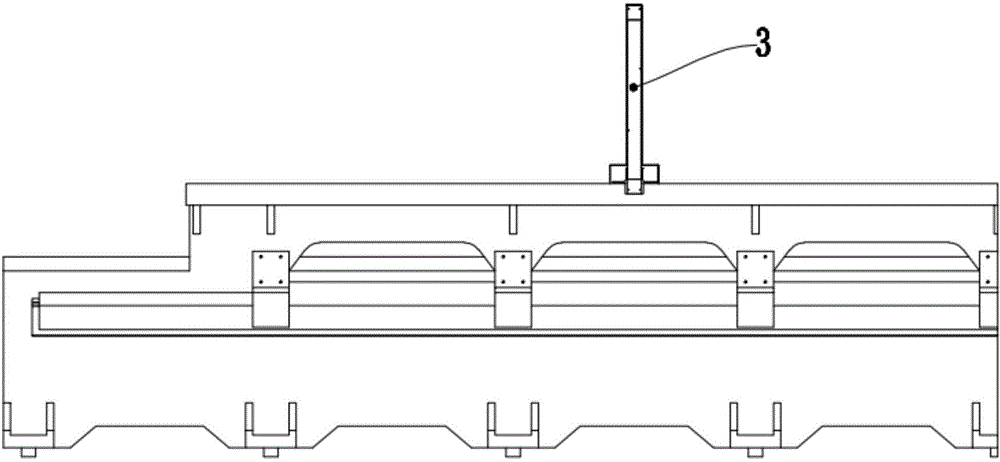

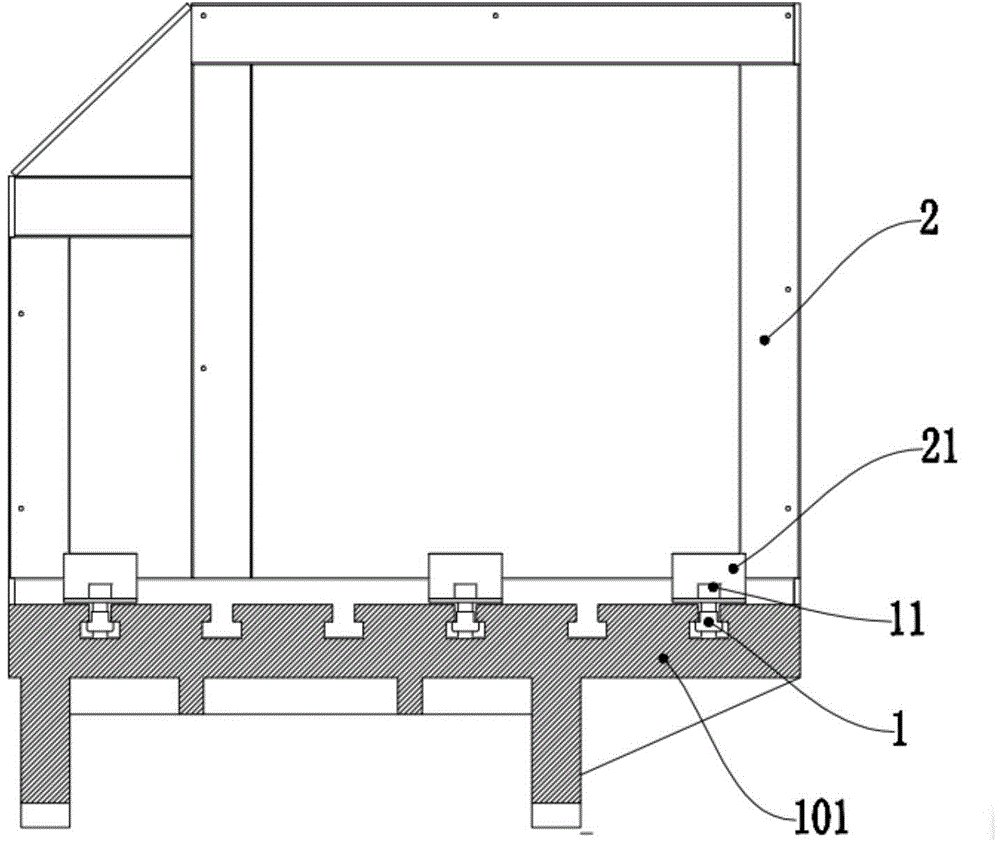

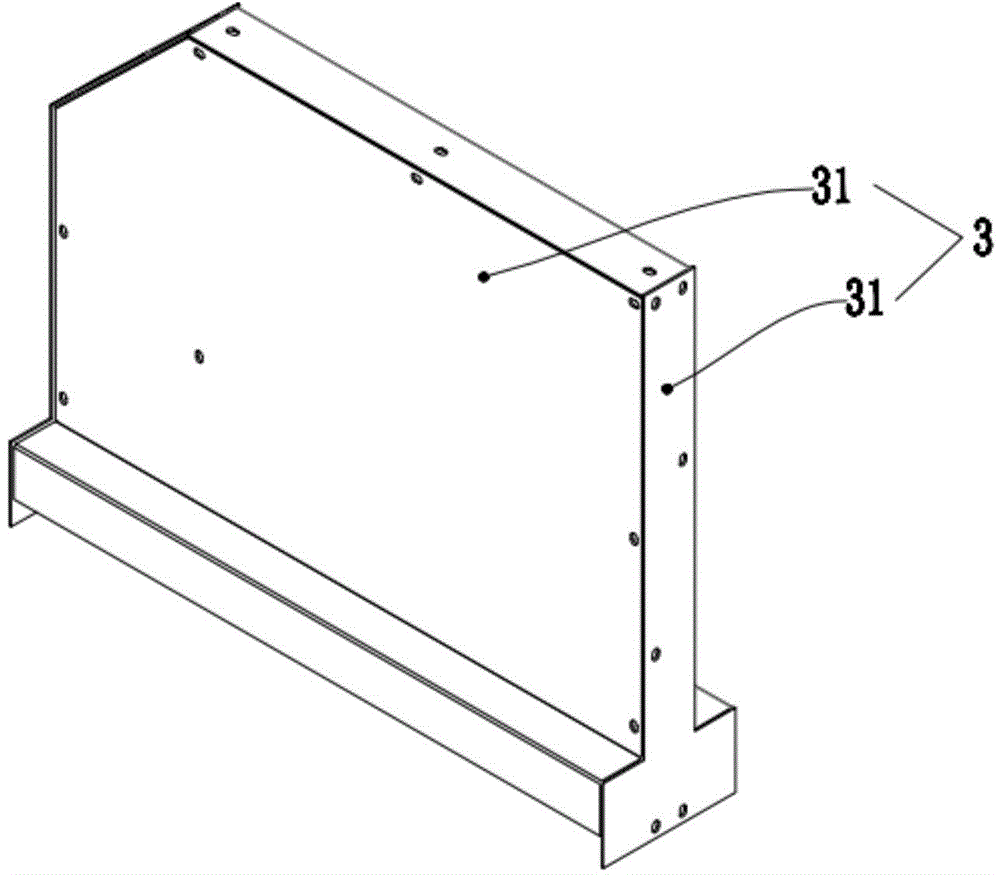

[0018] A double-station isolation mechanism installed on the worktable 101 of a CNC machine tool, including a T-shaped block 1 for positioning and installation, a fixing frame 2 for supporting and positioning, and a plurality of protective plates 31 for isolation;

[0019] The fixed frame 2 is installed in the groove of the work surface 101 through the T-shaped block 1 and the bolt 11, and the protective plate 31 is installed on the fixed frame 2 by screws, and forms a A protective cover3.

[0020] The double-station isolation mechanism of the present invention is installed on the work surface 101 of the lathe bed of numerically controlled machine tool, by erecting on the work surface 101 one or more fixed mounts 2 sealed by the protective plate 31, one on the original bed The processing area is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com