Windshield support arm integrated type central positioning block mechanism

A technology for supporting arms and windscreens, applied in the directions of roofs, transportation and packaging, vehicle parts, etc., can solve the problems of difficult installation, disassembly and maintenance, affecting user experience, and prone to abnormal noise when reversing. The effect of fitting the fixed effect, improving the user experience, and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

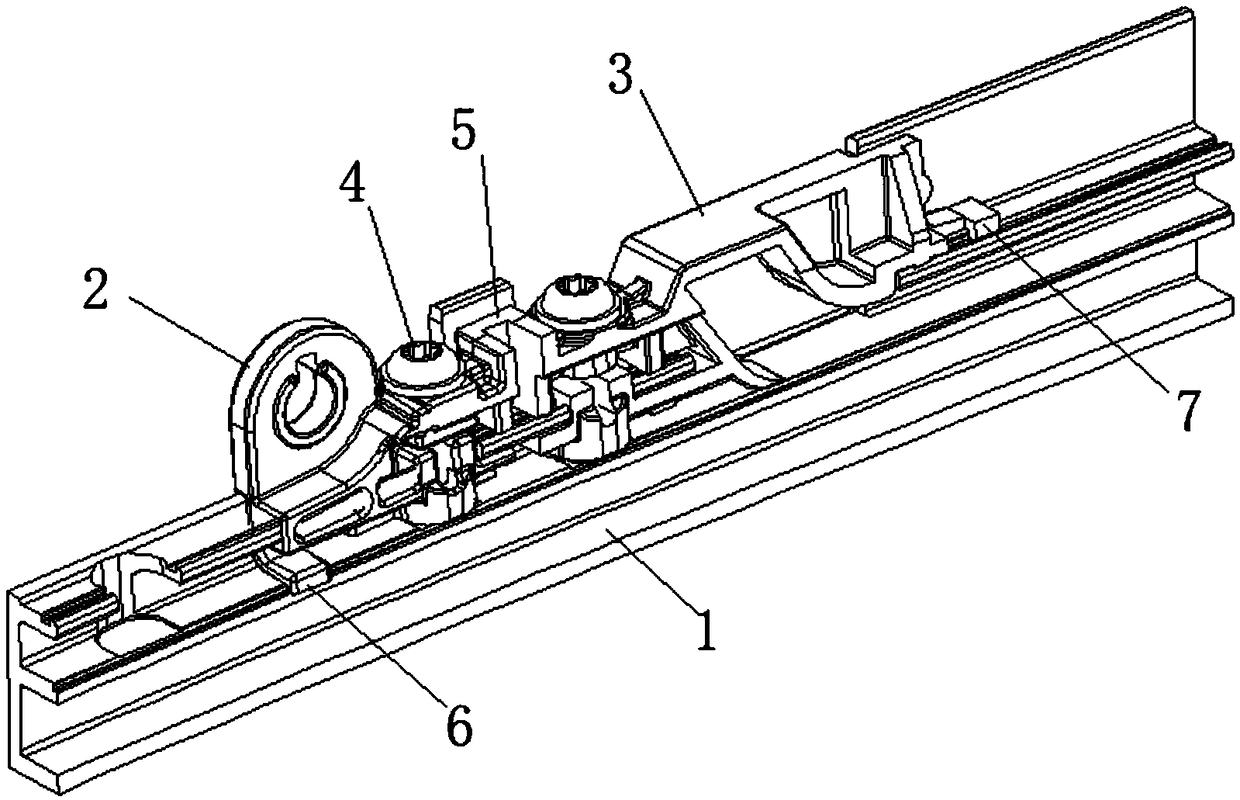

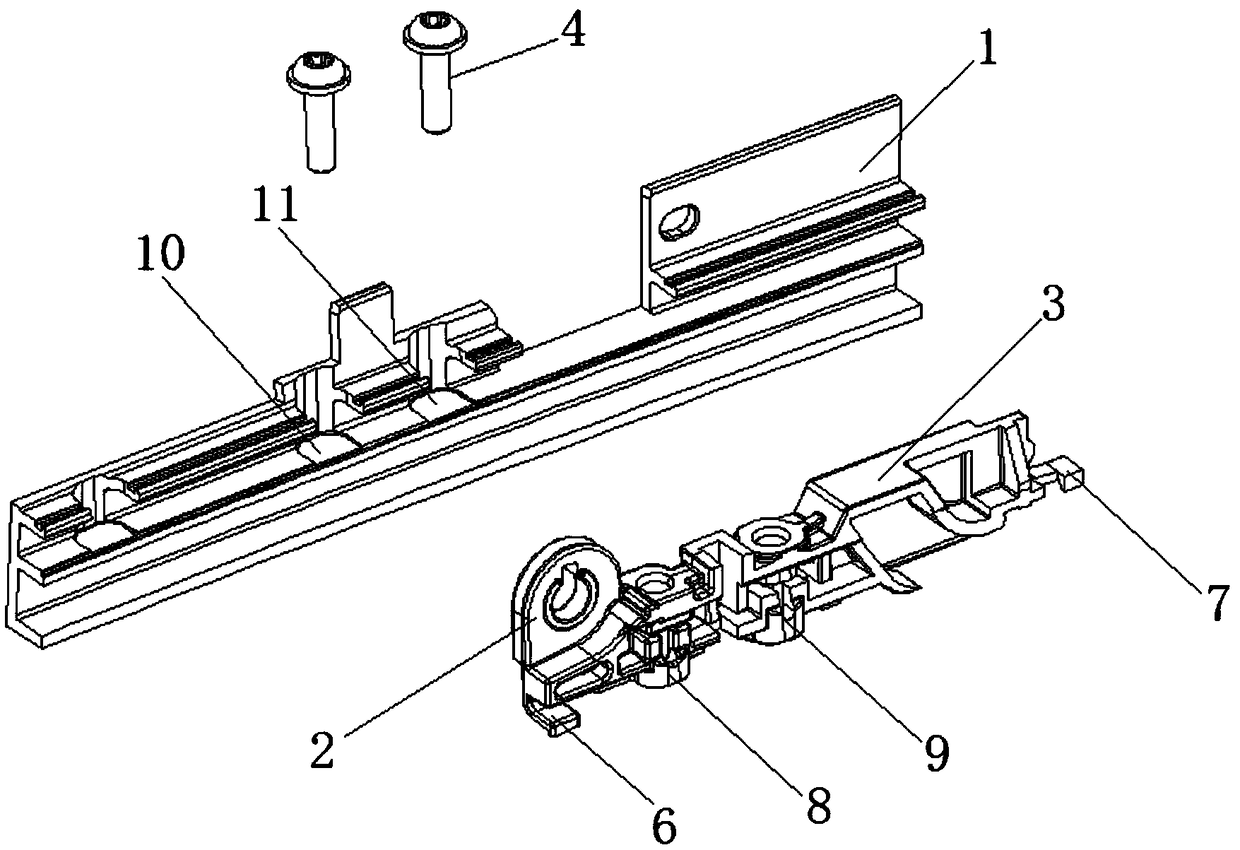

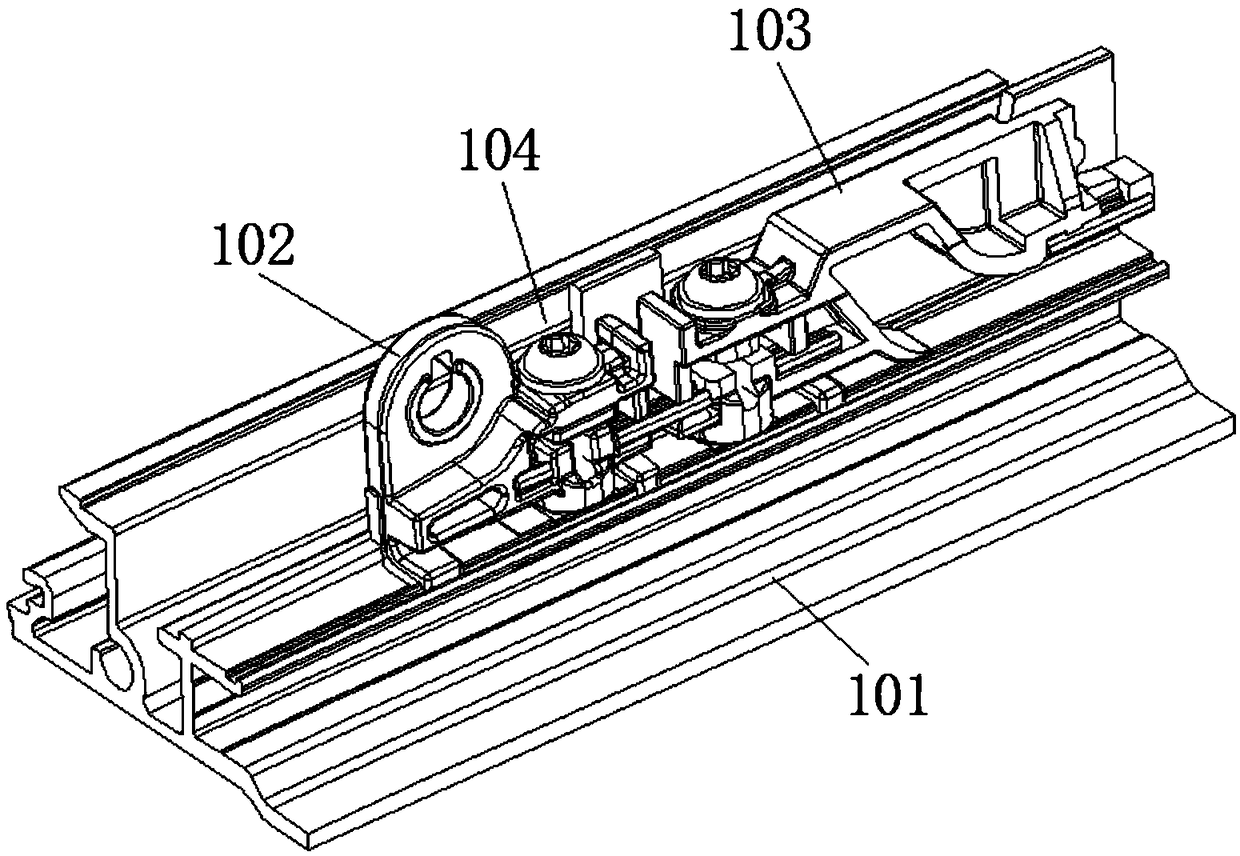

[0043] see figure 1 , a windshield net support arm integrated positioning block mechanism, including a multi-track slide rail reference plate 1, the multi-track slide rail reference plate 1 is dug in sequence from left to right with a first semi-circular groove 10 and a second paste The half-circle groove 11, the multi-track slide rail reference plate 1 is clamped with a middle positioning block 2 at one end close to the first laminating half-circle groove 10, and the right side of the middle positioning block 2 is provided with a windshield net support arm 3, and the windshield net support arm 3 Through the second laminating semicircular groove 11 and the multi-track slide rail reference plate 1, there is an integrated interconnection block 5 between the middle positioning block 2 and the windshield net support arm 3, and the left and right ends of the integrated interconnection block 5 are respectively It is fixedly connected with the middle positioning block 2 and the winds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com