Vertical steam removal device for residual solvent in rapeseed meal

A residual solvent and vertical technology, which is applied in the field of devices for vertical distillation and removal of residual solvent in rapeseed meal, can solve problems such as unsatisfactory results, and achieve the effects of complete desolubilization, high leaching dissolution consumption, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

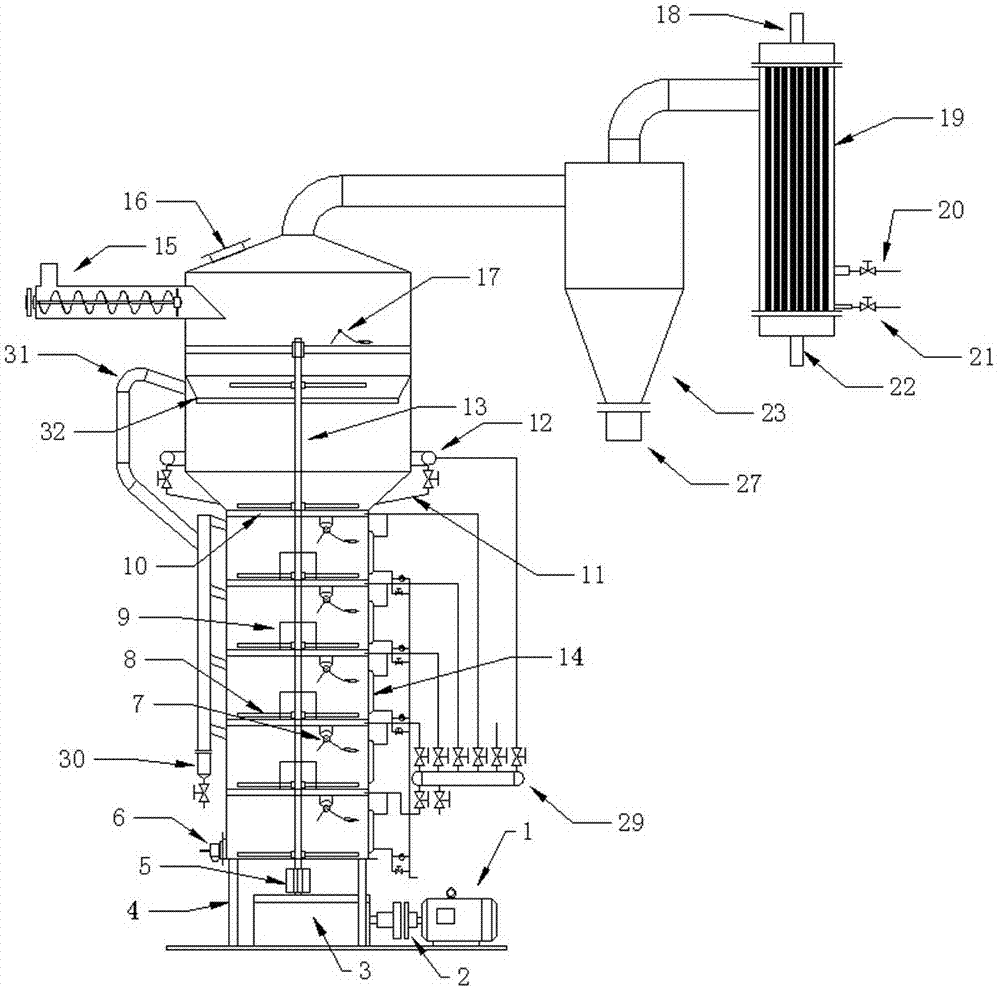

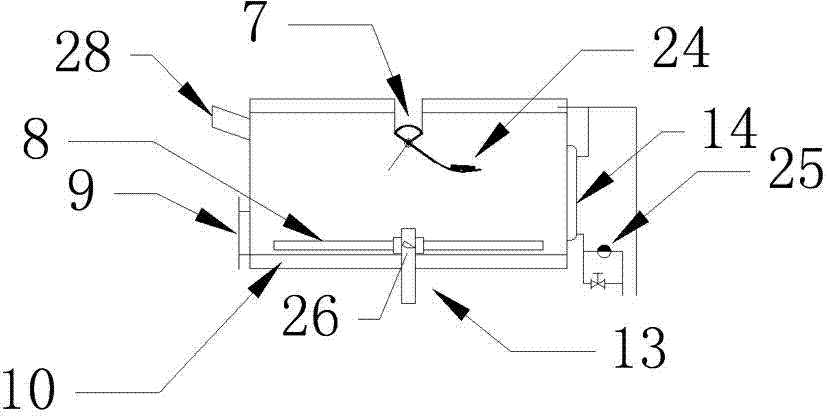

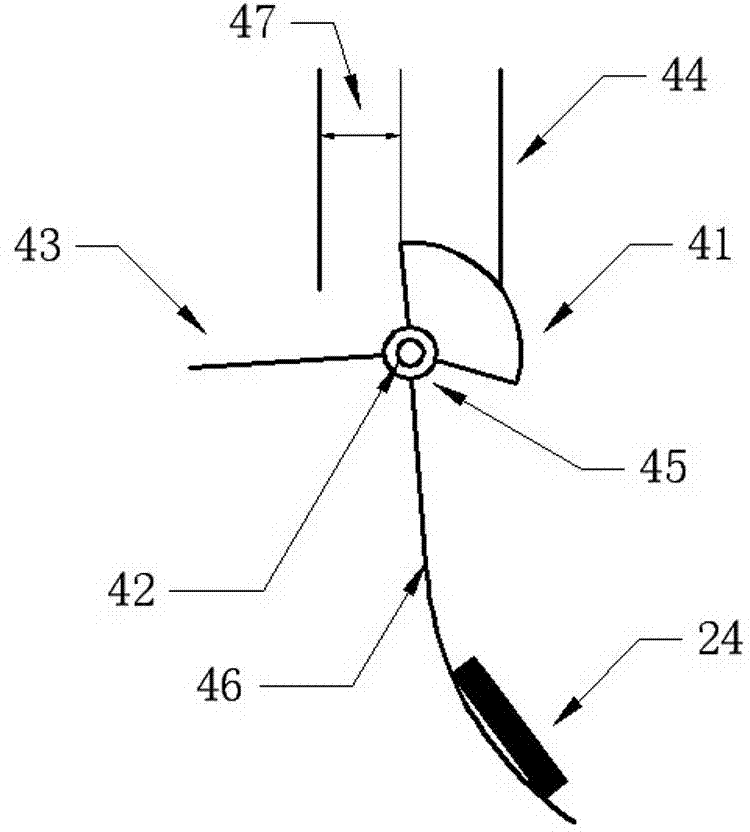

[0034] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0035] Such as figure 1 , figure 2 , image 3 and Figure 4 The device for vertical steaming and removing residual solvent in rapeseed meal shown includes a vertical steaming machine consisting of six layers of casings. The bottom plate and side walls of the lower five layers of casings are provided with heated steam jackets 10, 14. The bottom of the upper box is provided with an annular steam pipe 12, and several valves on the annular steam pipe 12 are connected with several inclined steam pipes 11 to realize direct heating of the material without being blocked by the material; each layer of the box is equipped with a material height indicator 17 and the automatic material door 7 that automatically adjusts the falling speed of the upper layer of material according to the material height of this layer; the material sealing and conveying winch cage 15 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com