Method and system for processing coal tar

A processing method, coal tar technology, applied in the petroleum industry, hydrogenation treatment process, hydrocarbon oil treatment, etc., can solve problems such as restricting the operation cycle of hydrogenation units, achieve improved production efficiency and economic benefits, low price, and remove high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

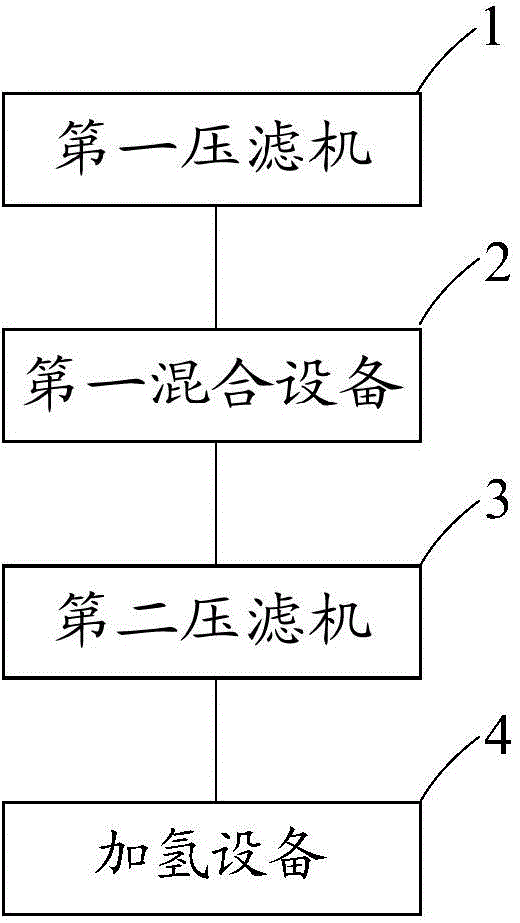

[0048] A kind of processing method of coal tar, comprises the following steps:

[0049] The first step: filter with a filter press to remove impurities with a diameter of 20-50 μm in the whole fraction of coal tar to obtain the first effluent;

[0050] The second step: mixing the first effluent with the diesel fraction at room temperature at a volume ratio of 1:0.1 to obtain a mixed oil;

[0051] Step 3: Use a filter press to filter and remove particles wrapped with impurities with a diameter of 1-20 μm in the mixed oil to obtain the second effluent.

[0052] The fourth step: hydrocracking the second effluent, the reaction conditions are: temperature 300°C, pressure 8MPa, space velocity 0.5, hydrogen oil volume ratio 500:1.

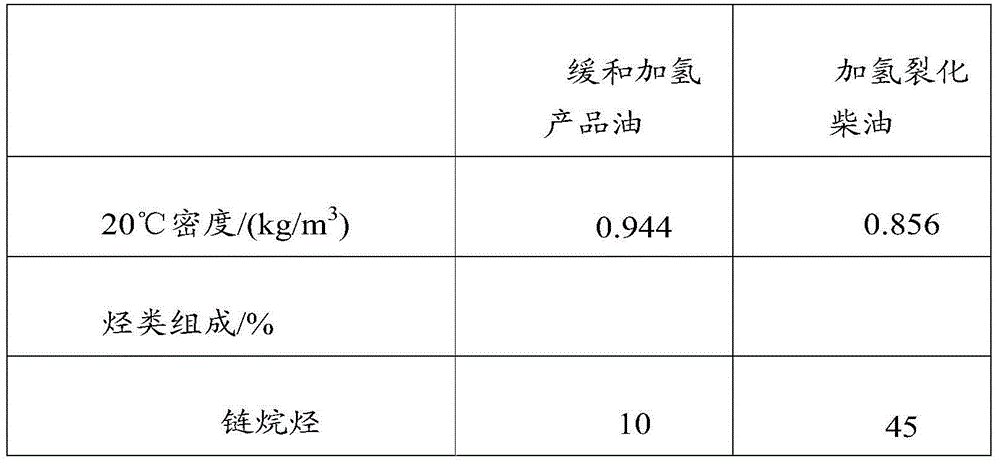

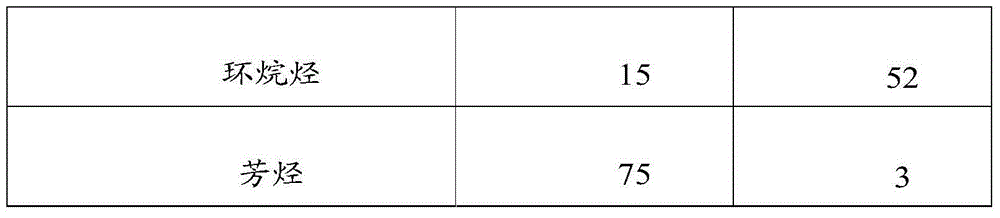

[0053] The diesel fraction in the second stage has an aromatics content of 6% and a paraffinic content of 45%.

Embodiment 2

[0056]A kind of processing method of coal tar, comprises the following steps:

[0057] The first step: filter with a filter press to remove impurities with a diameter of 20-50 μm in the whole fraction of coal tar to obtain the first effluent;

[0058] The second step: mixing the first effluent with the diesel fraction at room temperature at a volume ratio of 1:0.2 to obtain a mixed oil;

[0059] Step 3: Use a filter press to filter and remove particles wrapped with impurities with a diameter of 1-20 μm in the mixed oil to obtain the second effluent.

[0060] The fourth step: hydrocracking the second effluent, the reaction conditions are: temperature 350°C, pressure 10MPa, space velocity 1, hydrogen to oil volume ratio 800:1.

Embodiment 3

[0062] A kind of processing method of coal tar, comprises the following steps:

[0063] The first step: filter with a filter press to remove impurities with a diameter of 20-50 μm in the whole fraction of coal tar to obtain the first effluent;

[0064] The second step: mixing the first effluent with the diesel fraction at room temperature at a volume ratio of 1:1 to obtain a mixed oil;

[0065] Step 3: Use a filter press to filter and remove particles wrapped with impurities with a diameter of 1-20 μm in the mixed oil to obtain the second effluent.

[0066] The fourth step: hydrocracking the second effluent, the reaction conditions are: temperature 400°C, pressure 15MPa, space velocity 2, hydrogen to oil volume ratio 1100:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com