Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64 results about "Reactive compatibilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reactive compatibilization is the process of modifying a mixed immiscible blend of polymers to arrest phase separation and allow for the formation of a stable, long-term continuous phase. It is done via the addition of a reactive polymer, miscible with one blend component and reactive towards functional groups on the second component, which result in the "in-situ" formation of block or grafted copolymers.

Stain repellent optical hard coating

ActiveUS20050249957A1Easy to cleanEasy to clean and stainSynthetic resin layered productsCoatingsReactive compatibilizationSurface layer

A hard coating composition for use as a stain repellent single layer on an optical display. The coating composition adds a monomer of a mono or multi(methyl)acrylate bearing at least one monovalent hexafluoropolypropylene oxide derivative and a free radically reactive compatibilizer consisting of either a fluoroalkyl-group containing acrylate compatibilizer or a fluoroalkylene-group containing acrylate compatibilizer to a conventional hydrocarbon-based hard coat formulation. The resultant coating is substantially smooth and forms a durable surface layer that has low surface energy that is stain and ink repellent.

Owner:3M INNOVATIVE PROPERTIES CO

Process for manufacturing a thermoformable plasticized composite containing cellulose fiber and a moldable polymer

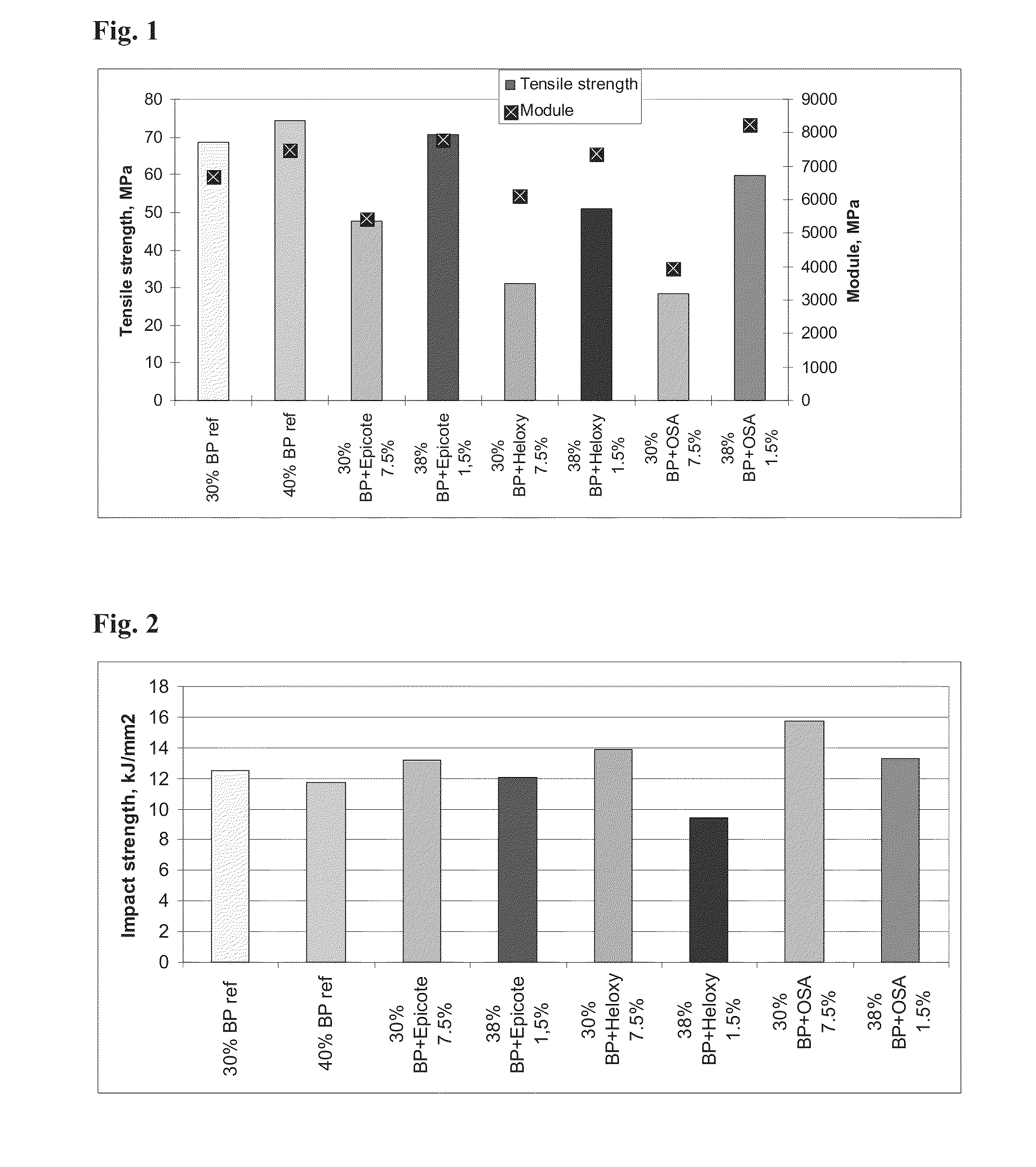

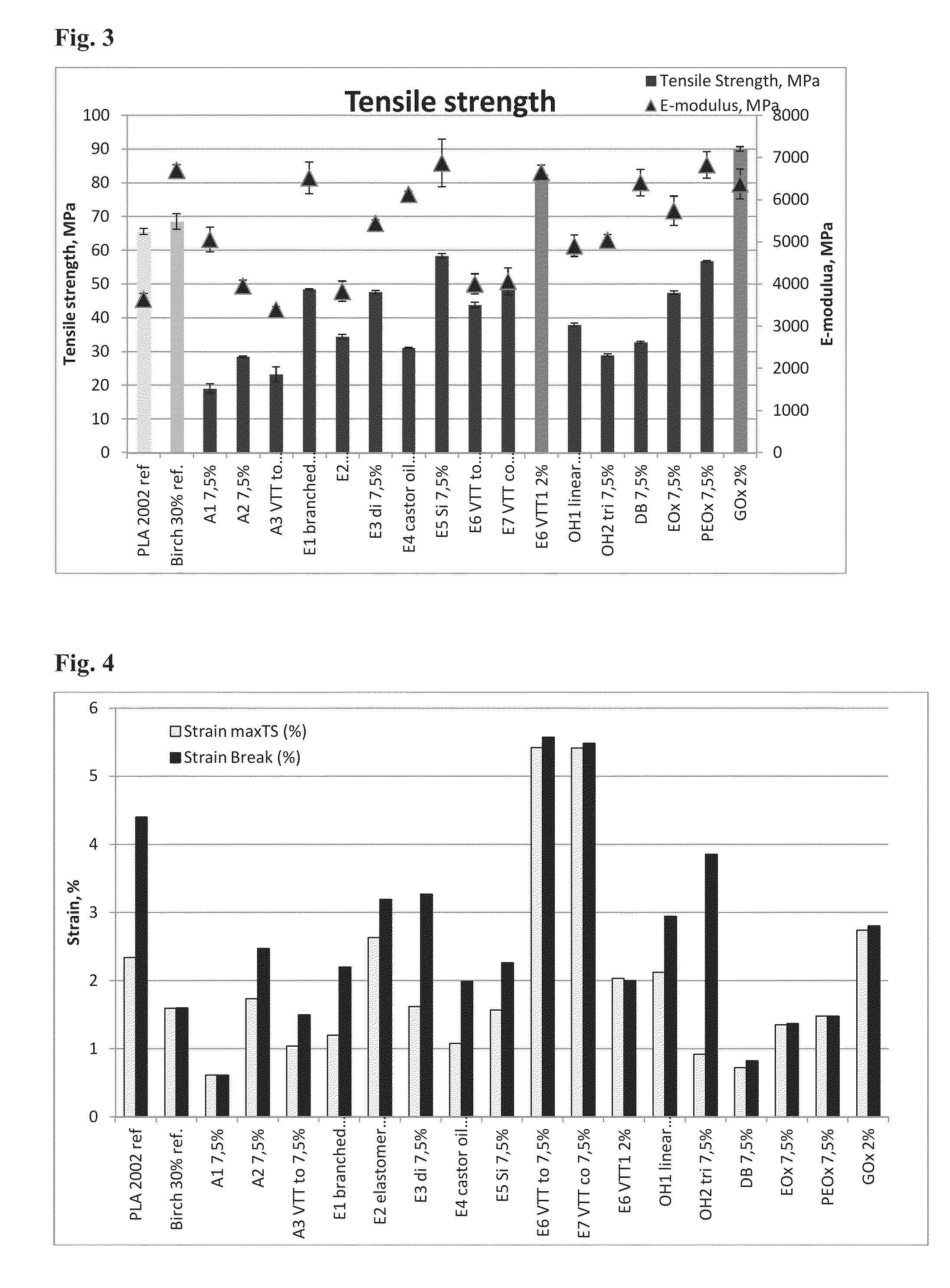

InactiveUS20130331518A1High strengthReduced impact strengthArtifical filament manufactureReactive compatibilizationPolymer science

The present invention concerns a process for manufacturing a thermoformable plasticized composite containing cellulose fiber and polylactide by blending the dry cellulose fiber and a compatibilizer in a compactor into pellets, and subsequently reacting the reactive compatibilizer and the mixture of cellulose fiber and polylactide by compounding. The invention also concerns a composite manufactured using said process, as well as further processed products.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

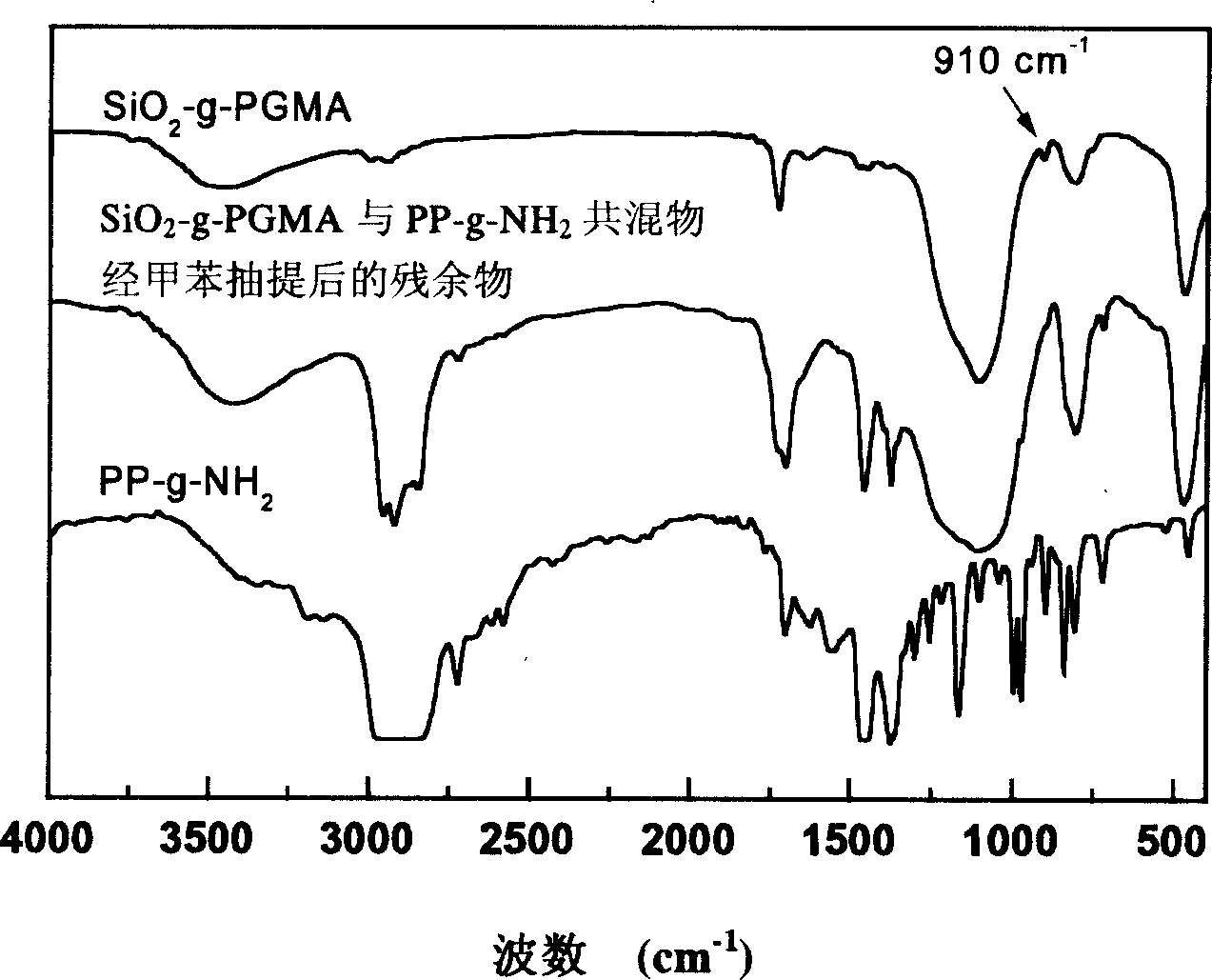

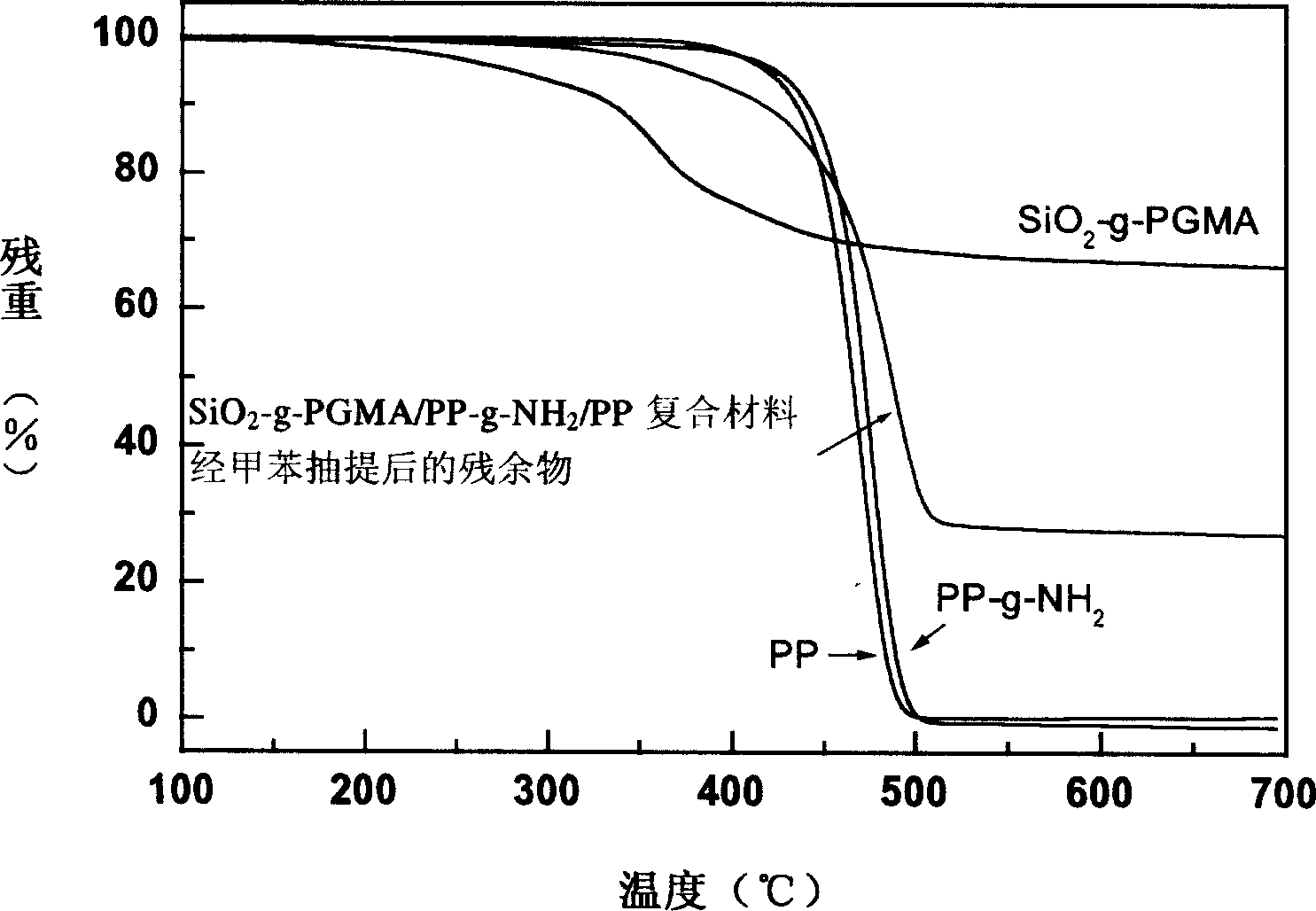

Reacting nano inorganic particle/polymer composite material

This invention discloses a kind of reactive inorganic nanoparticle / polymer composite materials which comprises 1~5wt% inorganic nanoparticles, 2.5~10wt% reactive compatilizers and 85~96.5wt% polymer matrix. In this invention, reactive compatilization technology is adopted, that is, inorganic nanoparticles react with polymer in situ during ordinary blending to produce grafted compounds, which greatly enhances the interfacial effect between inorganic nanoparticles and polymer matrix so that both the interfacial adhesion strength and the dispersion of inorganic nanoparticles in the matrix are greatly improved and mechanical properties of the prepared composite materials are effectively promoted. This invention requires no special apparatus or technique the composite materials with good comprehensive properties can be obtained with only common facilities.

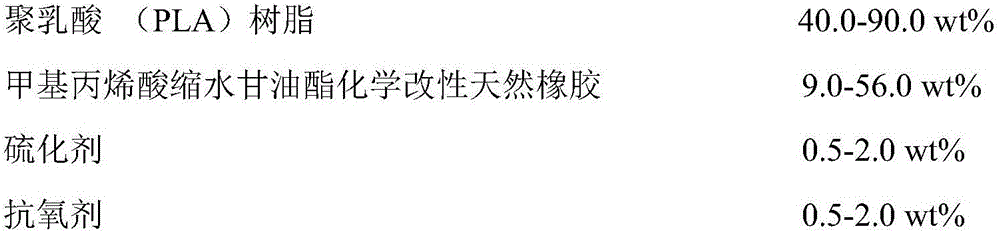

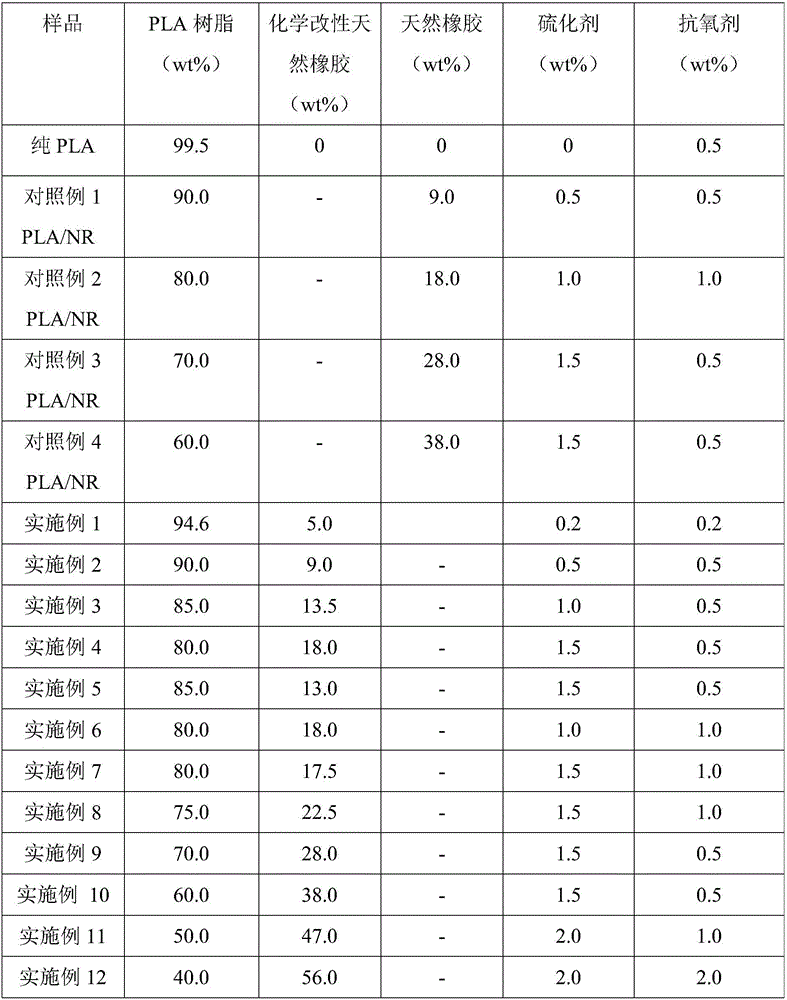

Polylactic acid/chemically modified natural rubber blend material and preparing method thereof

InactiveCN106366596AImprove interfacial adhesionHigh impact strengthGlycidyl methacrylatePolymer science

The invention relates to a polylactic acid / chemically modified natural rubber blend material and a preparing method thereof. The polylactic acid / chemically modified natural rubber blend material is mainly prepared from 30.0-94.6 wt% of polylactic resin, 5.0-66.0 wt% of glycidyl methacrylate chemically modified natural rubber, 0.2-2.0 wt% of vulcanizing agent and 0.2-2.0 wt% of antioxygen. According to the glycidyl methacrylate chemically modified natural rubber, the interfacial adhesive action between the polylactic acid and the modified natural rubber is improved through reactive compatibilization, and the polylactic acid is subjected to toughening modification through dynamic vulcanization of the modified natural rubber, thus tenacity and ductility of polylactic acid material can be improved greatly and the polylactic acid / chemically modified natural rubber blend material is obtained. The polylactic acid / chemically modified natural rubber blend material has an excellent mechanical property, which shows not only excellent impact strength but also excellent elongation at break, and thus the polylactic acid / chemically modified natural rubber blend material can be applied to the field of high polymer materials of packaging, electronic appliances, automobile industry and the like.

Owner:QINGDAO UNIV OF SCI & TECH

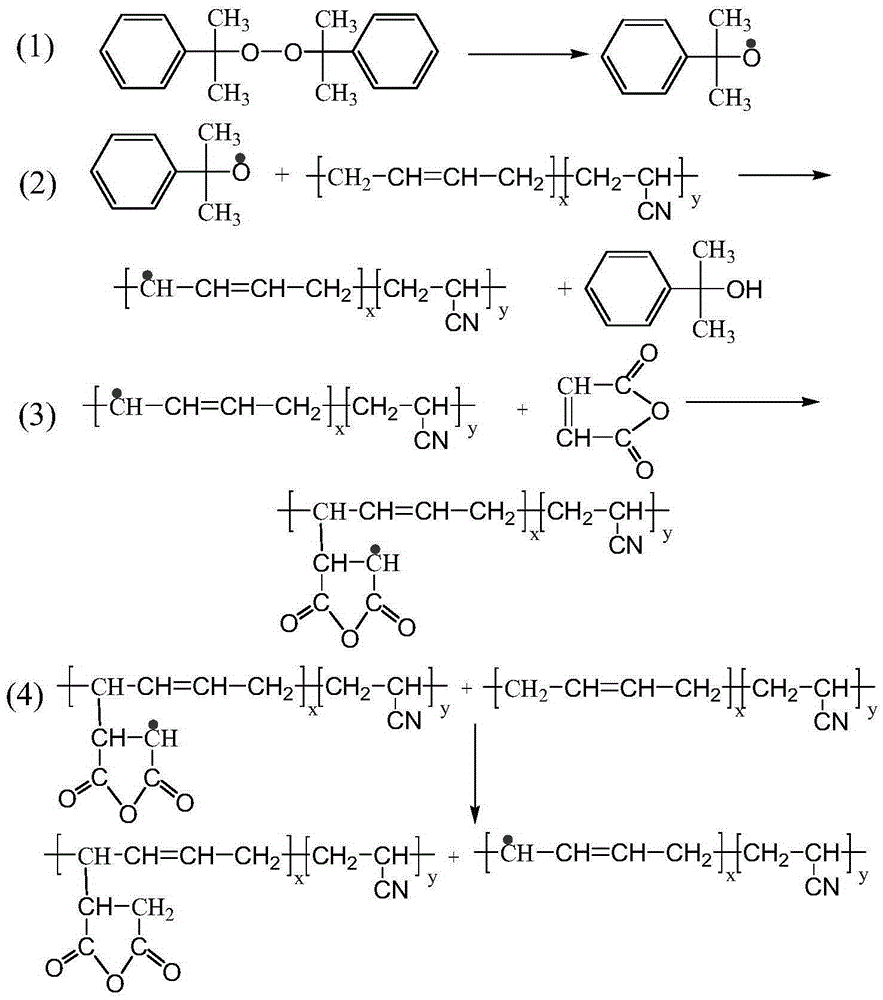

High-performance environment-friendly polypropylene blending material and preparation method thereof

The invention belongs to the field of processing modification of polymers, and provides a high-performance environment-friendly polypropylene blending material and a preparation method thereof. The preparation method is characterized in that: in the mixing process of a surface active rubber powder and polypropylene (PP), a small amount of maleic anhydride and polyene compounds are added, the in-situ reactive compatibilization is realized in a twin-screw extruder under the action of an initiator, and the shortcomings of the degradation of the polypropylene in the melt extrusion process and serious losses of other mechanical properties in a toughening system are overcome, accordingly, the high-strength and high-toughness PP / scrap tire rubber powder environment-friendly blending material is obtained. The process of the invention can be used to realize the functions of auxiliary materials in a material prescription, especially the reaction function, and ensure the comprehensive performances of the blending material. The special PP / scrap tire rubber powder material prepared by the invention meets the use requirements of the actual project, and has the advantages of simple preparation process, lower production cost, wide range of application, and very strong economic benefit and environmental benefit.

Owner:CHANGZHOU UNIV

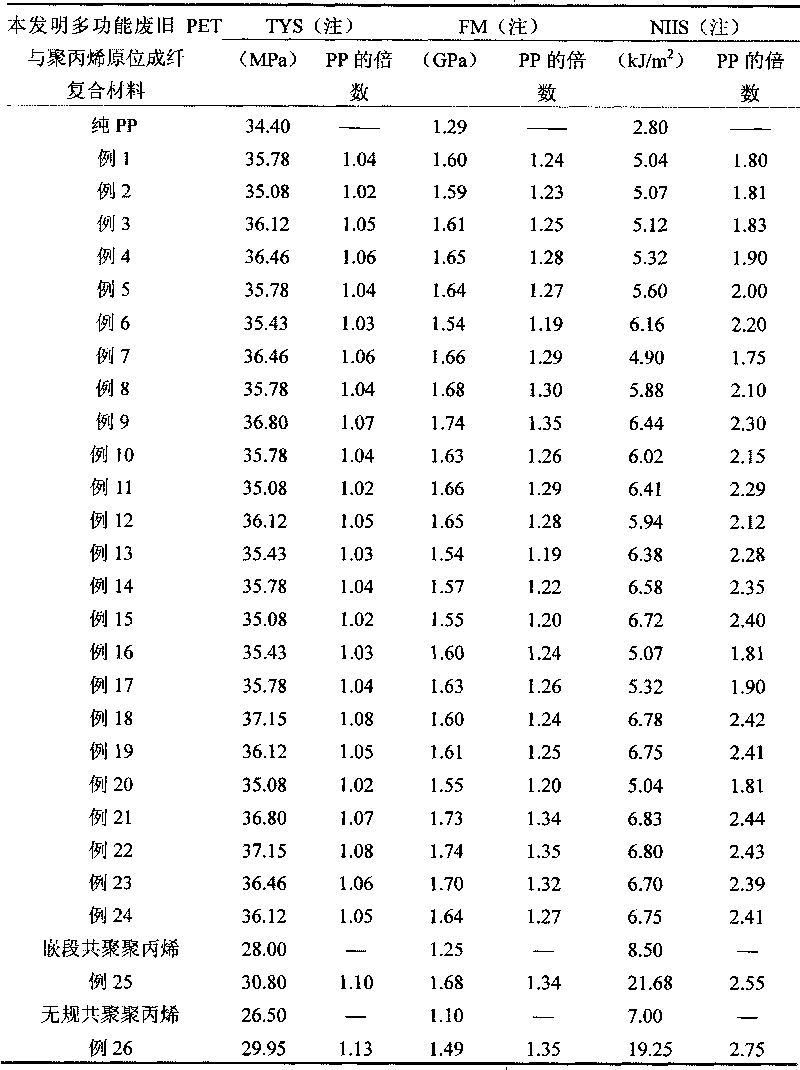

Multifunctional waste PET and polypropylene in-site fiber-forming composite material prepared by multi-component compatiblizing and toughening agent

InactiveCN101717476ACompatibleGood compatibilityMonocomponent polyesters artificial filamentFiberElastomer

The invention discloses multifunctional waste PET and polypropylene in-site fiber-forming composite material prepared from a multi-component compatiblizing and toughening agent. The multi-component controllable reactive compatiblizing and toughening agent is prepared from polypropylene, an elastomer 1, an elastomer 2, a difunctional group reactive monomer, a second monomer and a peroxide initiator. Then, multifunctional waste PET is prepared from an antioxidant and the prepared multi-component controllable reactive compatiblizing and toughening agent and waste PET; and finally, the in-site fiber-forming composite material is prepared by compounding the prepared multifunctional waste PET with polypropylene. The in-site fiber-forming composite material prepared by the technical scheme of the invention has obviously improved toughness (the notch impact strength of a cantilever beam) and rigidity (tensile yield stress and bending elastic modulus) in comparison with the raw material polypropylene and has relatively good reproducibility of mechanical performance; meanwhile, the invention also changes a great amount of waste which mainly refers to waste PET domestically generated every year into resources, thereby having remarkable economic and social benefits.

Owner:洛阳石化吉润化工有限责任公司 +1

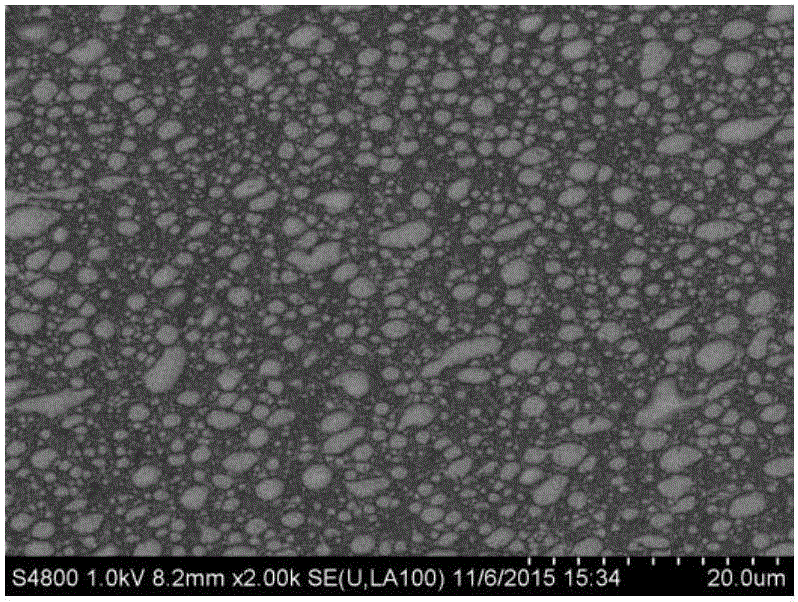

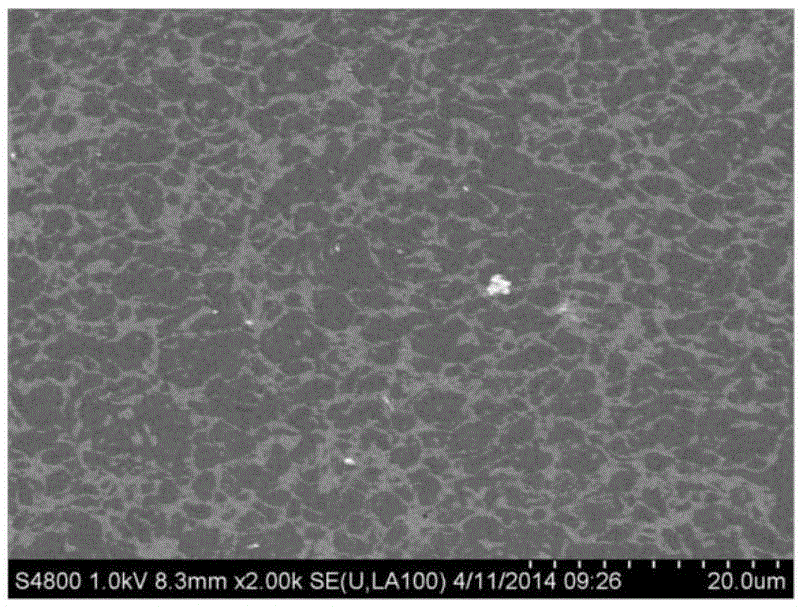

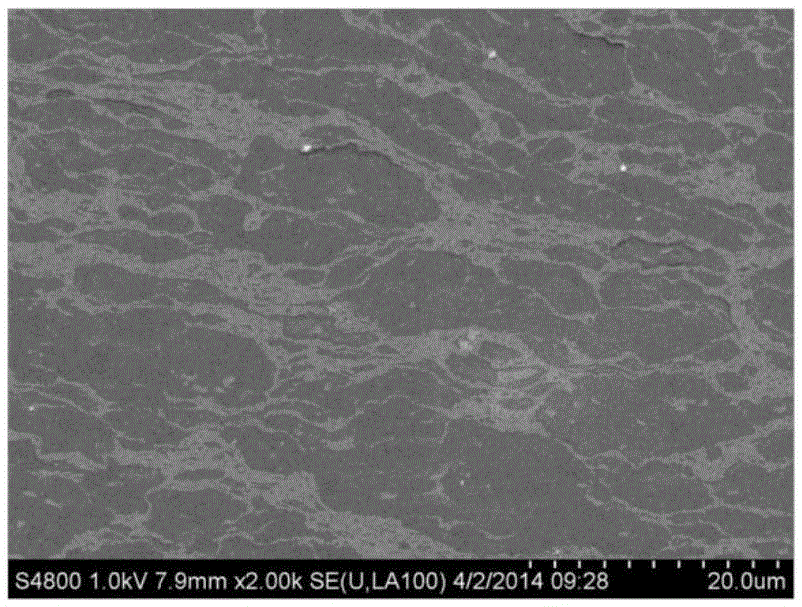

Method for preparing silicone rubber/polyamide thermoplastic vulcanized rubber by virtue of reactive compatibilization

InactiveCN105885423AImprove physical and mechanical propertiesGood oil resistancePolymer scienceInsulation layer

The invention discloses a method for preparing silicone rubber / polyamide thermoplastic vulcanized rubber by virtue of reactive compatibilization. According to the method, the raw materials (parts by weight) are as follows: 100 parts of silicone rubber, 20-90 parts of polyamide, 1-20 parts of a self-made solubilizer, 0.5-2 parts of an antioxidant, 1-5 parts of a vulcanizing agent and 0.5-2 parts of a polymerization inhibitor, wherein the self-made solubilizer is epoxidized silicone rubber obtained by epoxidation reaction of peroxy acid and vinyl-terminated silicone rubber. The method comprises the steps of carrying out shearing blending on the silicone rubber, polyamide, the self-made solubilizer and the antioxidant at 170-260 DEG C to obtain a mixture, uniformly mixing the mixture with the vulcanizing agent and the polymerization inhibitor at the room temperature, and finally carrying out high-temperature high-speed dynamic vulcanizing, so as to obtain the silicone rubber / polyamide thermoplastic vulcanized rubber. The thermoplastic vulcanized rubber has the characteristics of fine microcosmic phase state structure, excellent physical and mechanical properties, excellent high temperature resistance and oil resistance and the like and can be applied to automotive fuel rubber pipes, conveying belts, cable insulation layers, tool handles and the like.

Owner:BEIJING UNIV OF CHEM TECH

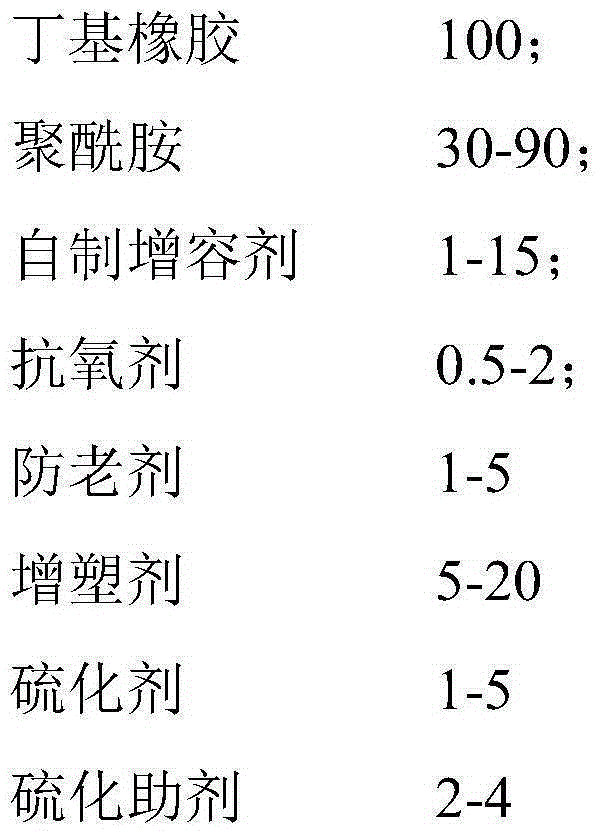

Reactively compatibilized butyl rubber/polyamide TPV (thermoplastic vulcanzate) and preparation method thereof

ActiveCN105255026AImprove physical and mechanical propertiesImprove air tightnessThermoplasticPolymer science

The invention relates to reactively compatibilized butyl rubber / polyamide TPV (thermoplastic vulcanzate) and a preparation method thereof. The butyl rubber, a bifunctional compound and a radical initiator are mixed at a high temperature, bifunctional compound graft-modified butyl rubber is prepared and taken as a compatibilizer, and the butyl rubber / polyamide TPV with excellent physical and mechanical properties, air tightness, hardness and the like is prepared with rubber and plastic premixing and dynamic vulcanization technologies.

Owner:BEIJING UNIV OF CHEM TECH

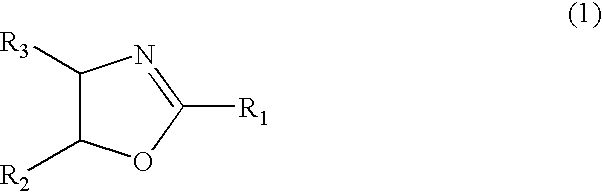

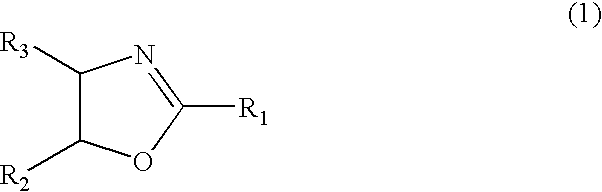

Continuous process for the preparation of a reactive polymer

A continuous process for the reactive compatibilization of polymers includes I. processing monooxazoline, bisoxazoline or a mixture thereof together with a first polymer, to give a reactive polymer; and II. adding the reactive polymer to one or more second polymers. In addition, a reactive polymer contains I. a first polymer; and II. at least 5% by weight of chemically unbound monooxazoline, bisoxazoline or a mixture thereof.

Owner:EVONIK DEGUSSA GMBH

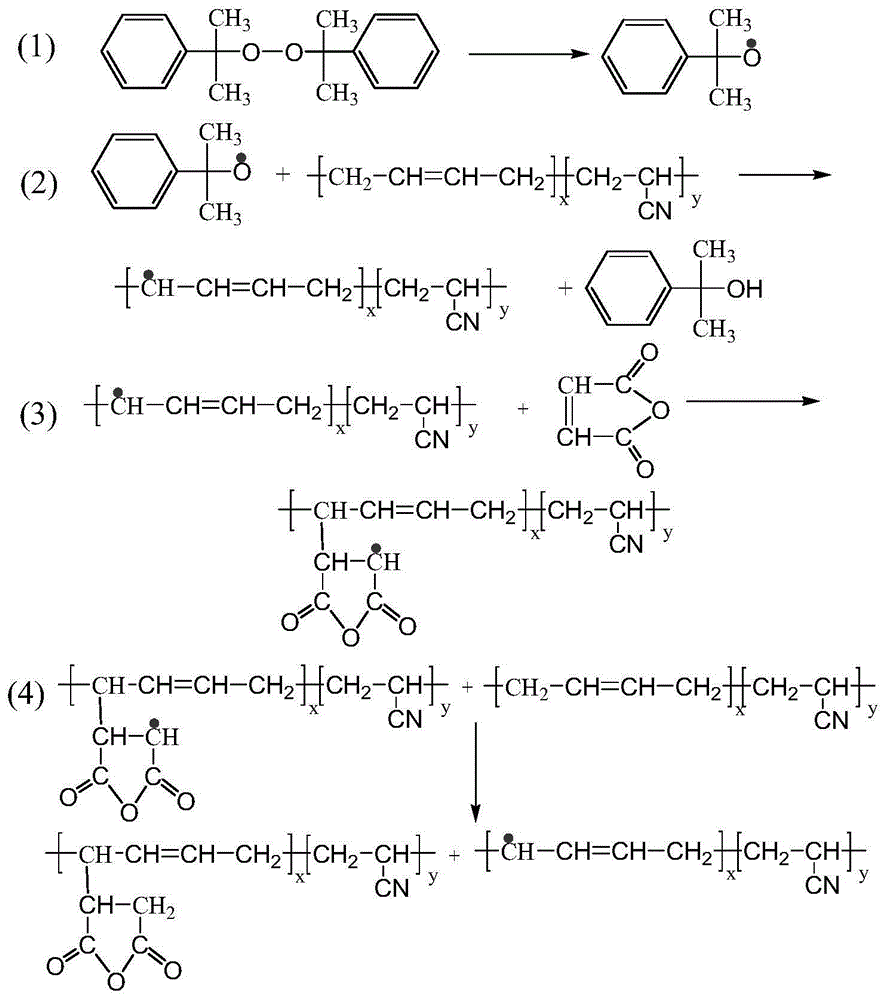

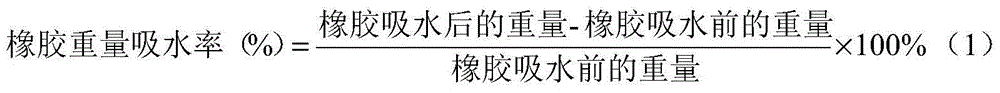

Method for preparing reactive compatibilization-type nitrile water-swelling rubber

The invention relates to a method for preparing reactive compatibilization-type nitrile water-swelling rubber. The method comprises the following steps: sequentially adding an active agent A, an active agent B, a vulcanizing agent, an anti-aging agent, a water absorbing additive and a bulking agent after plastifying nitrile rubber on an open mill by adopting a thinning coating roll; adding water-absorbing resin to evenly mix after mixing evenly, and then adding reinforcing filler carbon black and white carbon black; milling, and finally adding a vulcanization accelerator A and a vulcanization accelerator B to evenly mix; packaging into a triangular packet; thinning, batching off and standing for later use; putting the mixed nitrile rubber into a tabletting mold; vulcanizing, opening the mold, taking out the vulcanized water-swelling nitrile rubber, standing and cutting. The method has the advantages and beneficial effects that the preparation method is simple, and low in requirement on equipment, so as to save the cost. The method can be widely applied to tunnels, culverts, swimming pools, basements, underwater engineering, downhole oil recovery, water supply facilities, civil construction and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Preparation method of ABS (acrylonitrile butadiene styrene) composition for 3D printing

ActiveCN105524401AReduce interfacial tensionIntegrity guaranteedAdditive manufacturing apparatusGlass fiberReactive compatibilization

The invention discloses a preparation method of ABS (acrylonitrile butadiene styrene) composition for 3D printing. The composition comprises, in parts by mass, 45-55 parts of ABS, 8-14 parts of an SEBS (styrene-ethylene-butylenes-styrene) graft, 23-34.4 parts of a PC-PPO (polycarbonate-polyphenylene oxide) segmented copolymer, 0.3-0.7 parts of an amino silane coupling agent, 5-9 parts of nano filler, 5-12 parts of glass fibers, 0.6-1.1 parts of an antioxidant and 0.3-0.7 parts of a light stabilizer. The ABS composition for 3D printing is prepared through extrusion and blending of elongational flows as well as reactive compatibilization. The composition has good melt processing stability, good tensile strength, good rigidity and good anti-impact strength, and can guarantee customization precision of printed products and product strength and guarantee that a patient uses 3D printed products safely in the recovery process when the composition is applied to 3D printing aiding medical instruments.

Owner:SOUTH CHINA UNIV OF TECH

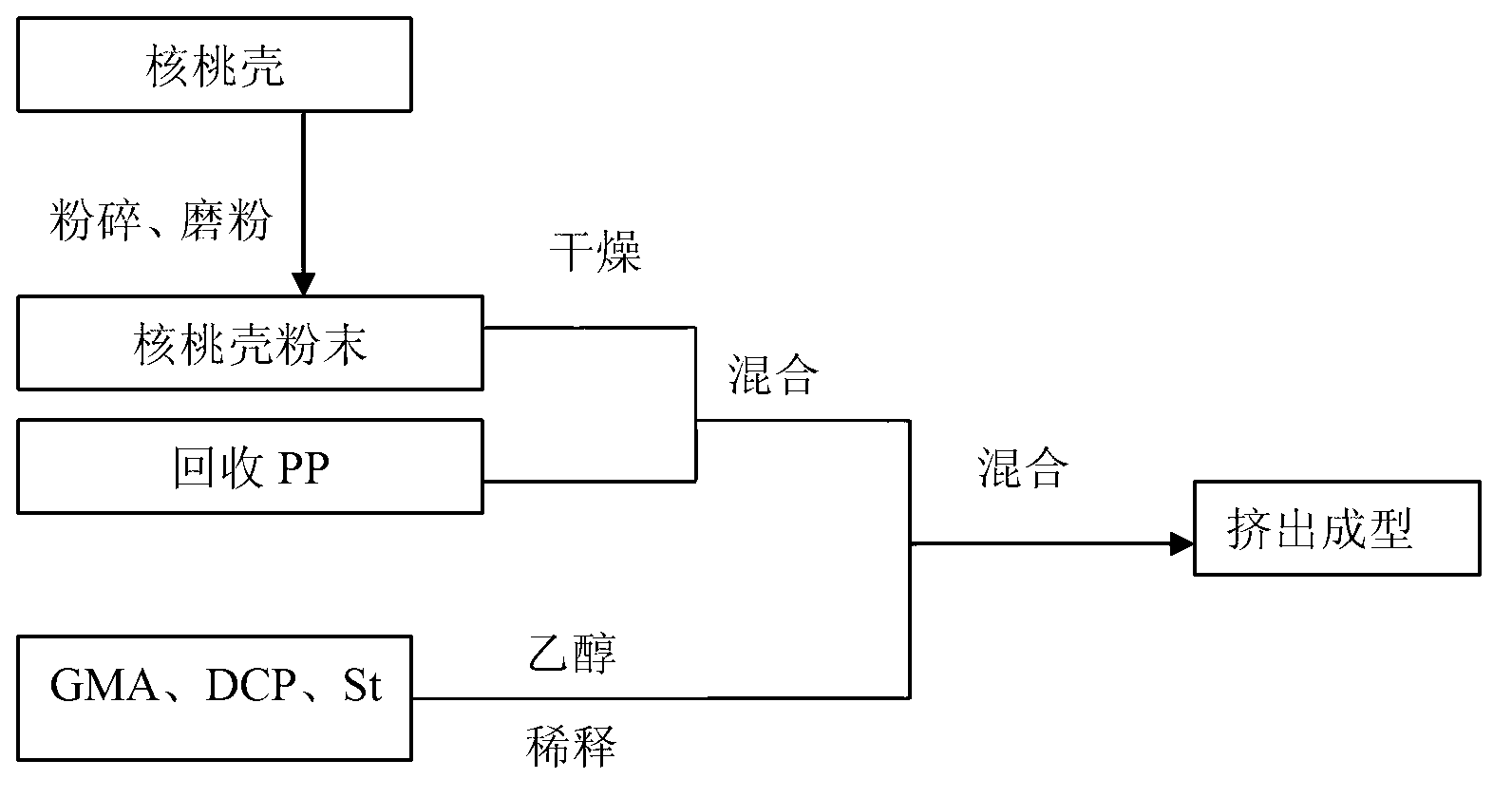

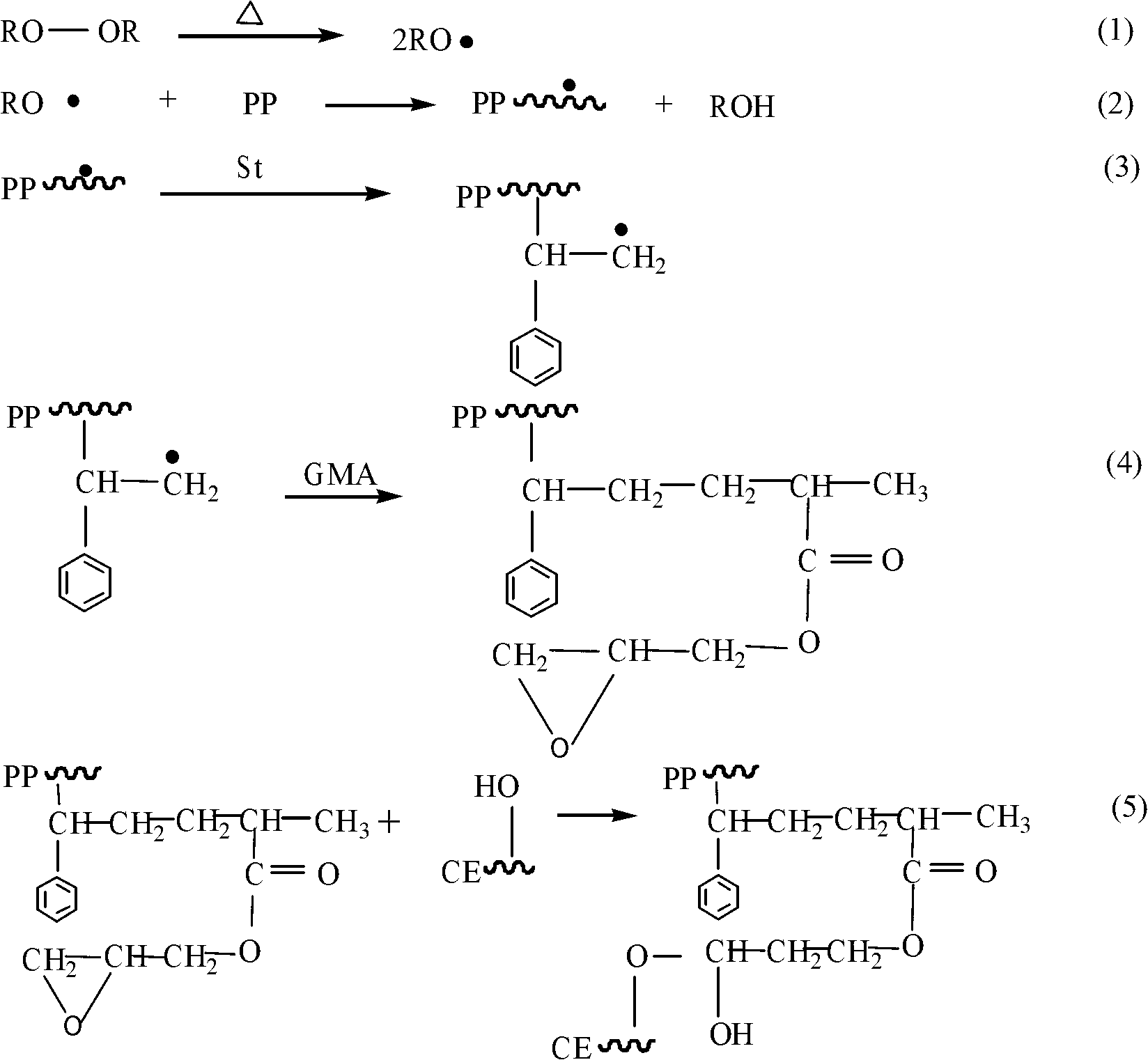

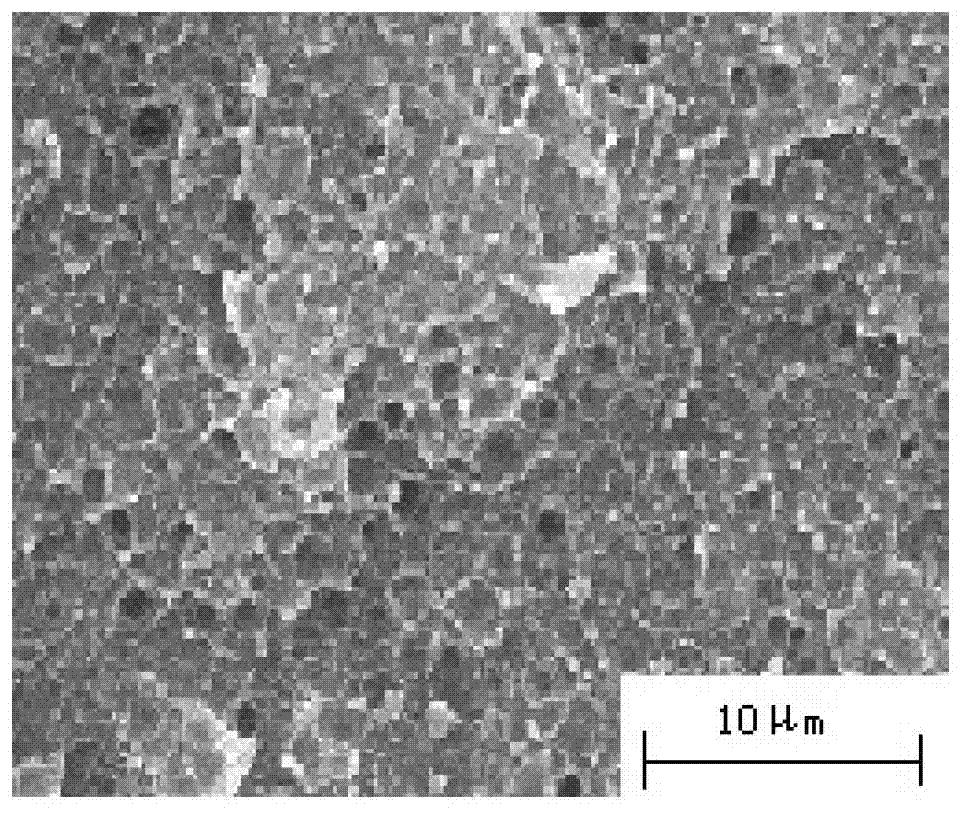

Reclaimed polypropylene (PP)-based wood-plastic composite material and preparation method thereof

The invention discloses a reclaimed polypropylene (PP)-based wood-plastic composite material and a preparation method thereof. The wood-plastic composite material comprises the raw materials by weight: 50 to 70 parts of reclaimed PP, 30 to 50 parts of natural plant fiber, 0.1 to 0.3 part of initiator, 0.1 to 6 parts of glycidyl methacrylate and 0.1 to 3 parts of styrene, wherein the sum of the weight parts of the reclaimed PP and the natural plant fiber is 100. By double monomer melt grafting in-situ reactive compatibilization, the compatibility of the reclaimed PP and the natural plant fiber is effectively improved, the interface bounding force between two phases is enhanced and the comprehensive performance of the material is improved. Various sectional materials can be extruded by different dies, so that industrialized production of the materials such as automobile internal lining panels, windows, doors and the like is realized.

Owner:SINOPLAST NEW MATERIAL

Preparation method of high-density polyethylene/polyamide 66 laminar barrier materials using in-situ reactive compatibilization method

ActiveCN102786633AGood capacity increaseImprove interfacial adhesionLow-density polyethylenePolyamide

The invention discloses a preparation method of high-density polyethylene / polyamide 66 laminar barrier materials using an in-situ reactive compatibilization method. By the preparation method, compatibility between the high-density polyethylene and the polyamide 66 is improved. The high-density polyethylene / polyamide 66 laminar barrier materials comprise, by weight, 65-95 parts of high-density polyethylene, 5-35 parts of polyamide 66, 0.01-1 part of initiator, 0.1-4 parts of maleic anhydride, and 1-7 parts of montmorillonite. The high-density polyethylene / polyamide 66 laminar barrier materials are evident in compatibilization, high in interface adhesion, excellent in barrier performance, applicable to hose packing of pesticide bottle production, paint bucket and diluent bottle production, and cosmetic production or to packing films or hose packing of food production.

Owner:SINOPLAST NEW MATERIAL

Vinyl blocked poly(trifluoropropyl)methylsiloxane fluororubber compatibilizer and preparation method thereof

The invention belongs to the technical field of rubber materials. By introducing vinyl blocked poly(trifluoropropyl)methylsiloxane on a main chain of fluororubber, the purpose of improving the compatibility of blend of fluororubber and fluorinated silicone rubber is realized by means of the characteristic that vinyl blocked poly(trifluoropropyl)methylsiloxane is compatible with fluororubber and fluorinated silicone rubber. Meanwhile, crosslinking reaction is carried out on unreacted vinyl and fluorinated silicone rubber, so that reactive compatibilization is realized. The invention relates to a fluororubber-vinyl blocked poly(trifluoropropyl)methylsiloxane compatibilizer which at least comprises the following materials in parts by weight: 100 parts of fluororubber, 3-15 parts of vinyl blocked poly(trifluoropropyl)methylsiloxane, 0.5-2 parts of an initiator and 0.2-1.5 parts of an accelerant. The fluororubber-vinyl blocked poly(trifluoropropyl)methylsiloxane compatibilizer prepared by using a high-temperature mechanochemical grafting method has good compatibility with fluororubber and fluorinated silicone rubber, so that the compatibilization effect is obvious and stable.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Novel high-softness polylactic acid fiber composite material and preparation method thereof

ActiveCN104695047AImprove high temperature stabilityGood compatibilityArtificial filament heat treatmentMelt spinning methodsFiberTrans esterification

The invention relates to a novel high-softness polylactic acid fiber composite material and a preparation method thereof. The composite material comprises the following components in parts by weight: 70-90 parts of polylactic acid (PLA), 1-3 parts of poly(1,2-propylene glycol adipate) (PPA), 0.1-1 part of polycarbodiimide (PCDI), and 0.1-1 part of tetrabutyl titanate. The PLA / PPA blend is modified by taking multifunctional PCDI and TT-01 as reactive compatibilizers, the high-temperature stability and compatibility of the material can be well improved by PCDI, and the processing performance is better. After PCDI is added, the breaking strength and elastic modulus of the PLA / PPA blend fiber are reduced, the breaking elongation is obviously improved, and the softness is improved. The transesterification reaction between PLA and PPA can be promoted through the addition of TT-01, so that the stability and compatibility of the product are further improved.

Owner:HEFEI GENIUS NEW MATERIALS

Fluororubber-grated-maleic anhydride bulking agent and preparing method thereof

InactiveCN102936319AHigh grafting rateGood capacity increasePolymer scienceReactive compatibilization

The invention discloses a fluororubber-grated-maleic anhydride bulking agent and a preparing method thereof. The preparing method is that: raw fluororubber, fluororubber, initiating agents, vulcanizing agents and accelerants are filled into an internal mixer for reacting for 10-30min at temperature of 120-160 DEG C and with rotating speed to be 50-100r / min to obtain the fluororubber-grated-maleic anhydride (KFM-g-MAH) bulking agent. KFM-g-MAH performance of the bulking agent and carbonyl groups / carboxyl groups and other polar groups in polar acrylic polymer have strong interaction, and simultaneously can react with polar groups (amino groups and carboxyl groups) of acrylic polymer (ACM) and epoxy groups to achieve the reactive compatibilization effect. By aid of selection of the initiating agents, reactant activation energy is reduced, and accordingly high grating efficiency is achieved. The fluororubber-grated-maleic anhydride bulking agent and the preparing method thereof have the advantages that grating efficiency is obviously improved and compatibilization effect is good and stable.

Owner:GUANGZHOU GLORYSTAR CHEM

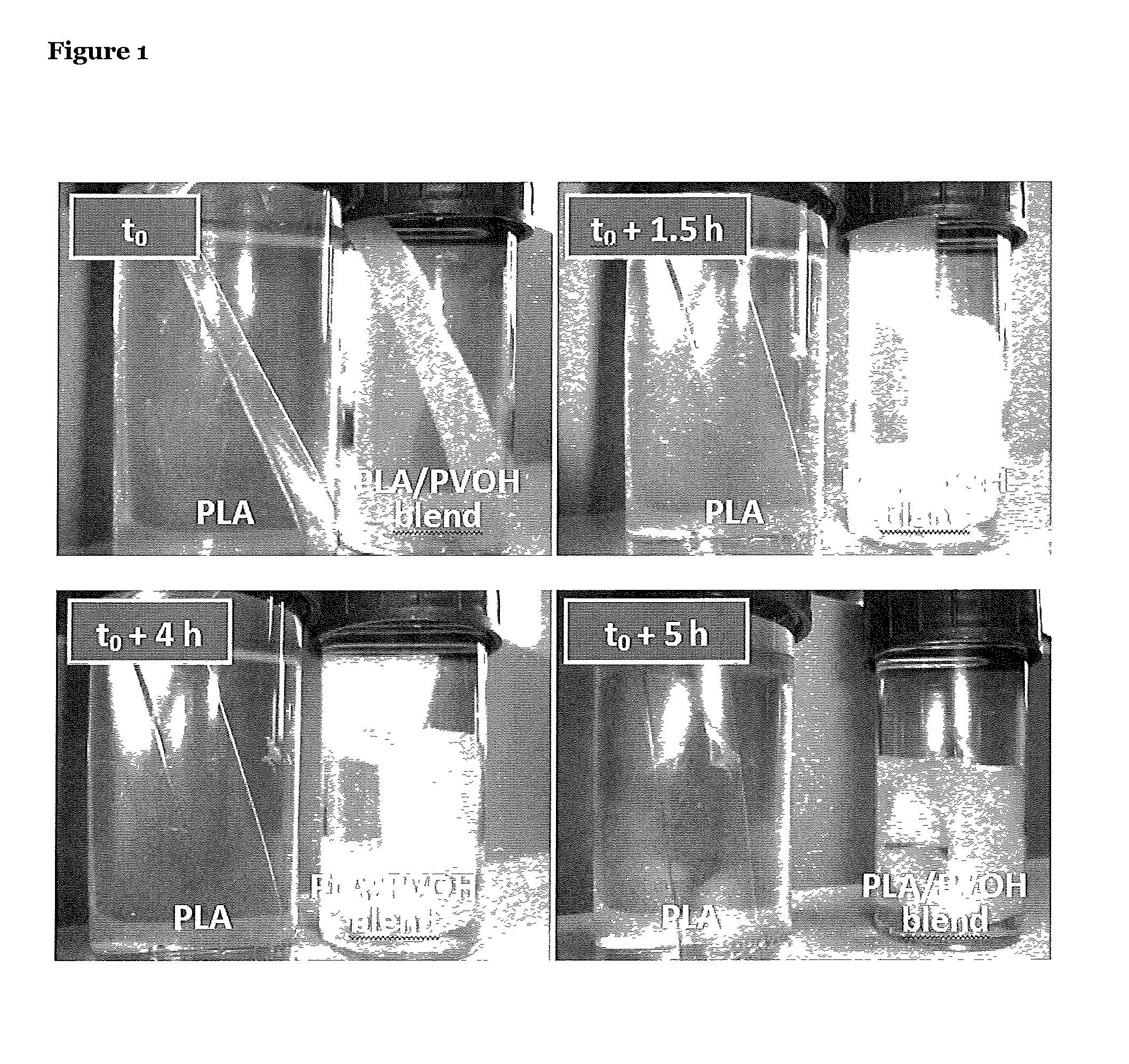

Blends of a Polylactic Acid and a Water Soluble Polymer

The present invention relates to water-dispersive biodegradable compositions which may be formed into films and fibres. The present invention also relates to polymer blends comprising polylactide and water-soluble polymers. More particularly, the present invention relates to the use of grafted copolymers (PLA-grafted water-soluble polymers) for the compatibilization of PLA and water-soluble polymers. Such reactive compatibilization of immiscible polymer blends is achieved in such a way that main blend components are covalently bonded. In addition, such reactive compatibilization can be carried out by reactive extrusion.

Owner:NICOVENTURES TRADING LTD

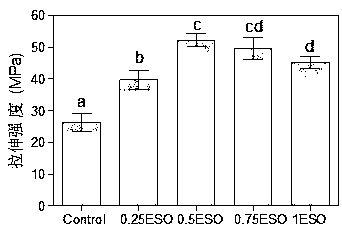

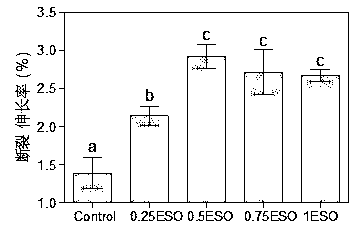

Reactive compatibilized bamboo fiber/polylactic acid composite material and preparation method thereof

The invention belongs to the technical field of fiber-reinforced resin composite materials and particularly relates to a reactive compatibilized bamboo fiber / polylactic acid composite material and a preparation method thereof. The preparation method comprises the following steps: coating bamboo fibers by adopting a vegetable oil prepolymer, uniformly mixing the obtained bamboo fibers and a polylactic acid resin, mixing by a twin screw mixer to induce a vegetable oil prepolymer reaction so as to obtain a reactive compatibilized bamboo fiber / polylactic acid mixture, and performing hot press molding on the mixture in a mold, so as to obtain the environmental-friendly and biodegradable bamboo fiber / / polylactic acid composite material. The prepared composite material has excellent tensile strength, tensile modulus and elongation at break.

Owner:FUJIAN AGRI & FORESTRY UNIV

PC (Polycarbonate)/PET (Polyethylene Terephthalate) composition and preparation method thereof

ActiveCN103951954AGood compatibilityImprove mechanical propertiesPolyethylene terephthalate glycolToluene diisocyanate

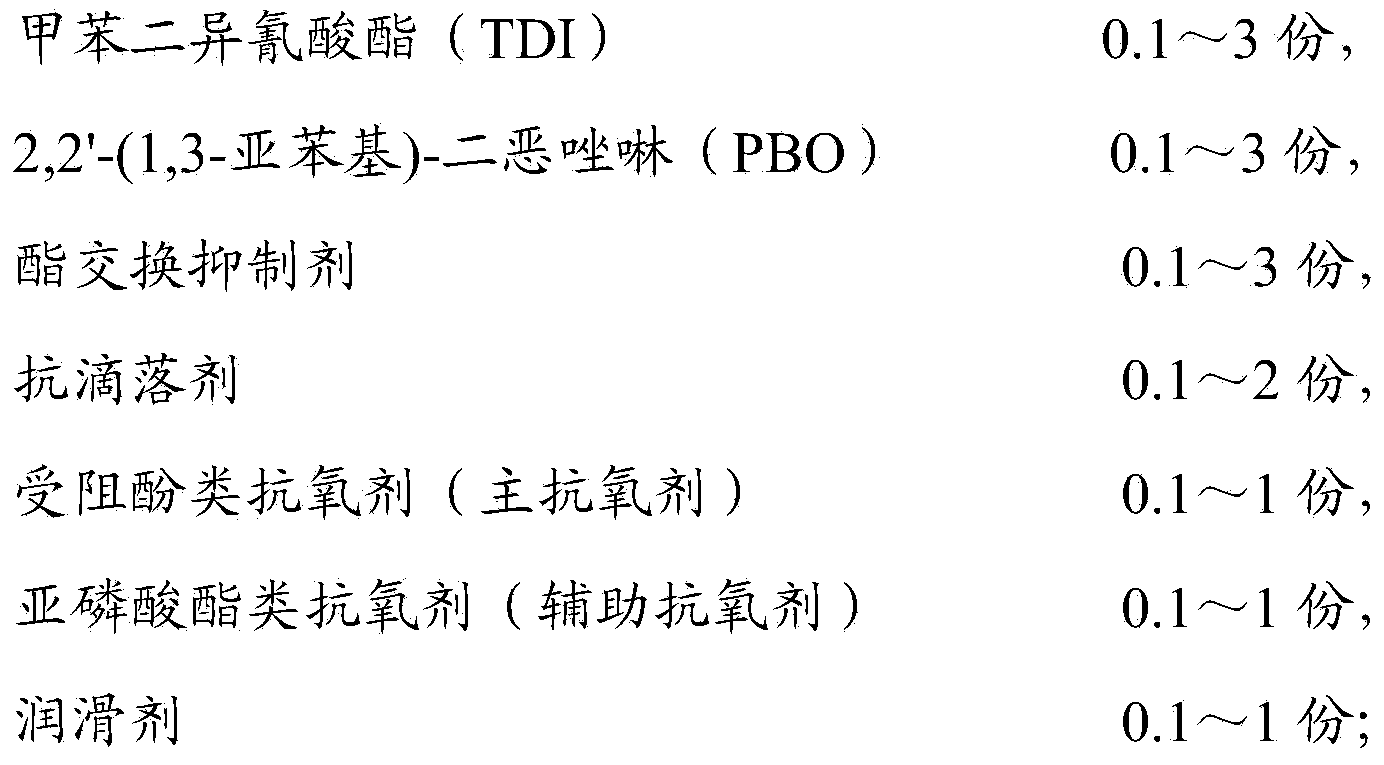

The invention discloses a PC (Polycarbonate) / PET (Polyethylene Terephthalate) composition and a preparation method thereof. The PC / PET composition is prepared from the following raw materials in parts by weight: 70-95 parts of PC, 5-30 parts of PET, 0.1-3 parts of toluene diisocyanate, 0.1-3 parts of 2, 2'-(1, 3-phenylene)-bisoxazoline, 0.1-3 parts of ester exchange inhibitor, 0.1-2 parts of anti-dripping agent, 0.1-1 part of hindered phenol antioxidant, 0.1-1 part of phosphite ester antioxidant and 0.1-1 part of lubricating agent, wherein the weight part sum of PC and PET is 100. The PC / PET composition with good mechanical properties, high flame retardance, chemical resistance and processability is prepared by using an in-situ reactive compatibilization method and can be applied to outer decorating parts of automobiles, office equipment, communication equipment parts and the like.

Owner:SINOPLAST NEW MATERIAL

Preparation method of hyperbranched polybutylene adipate terephthalate material

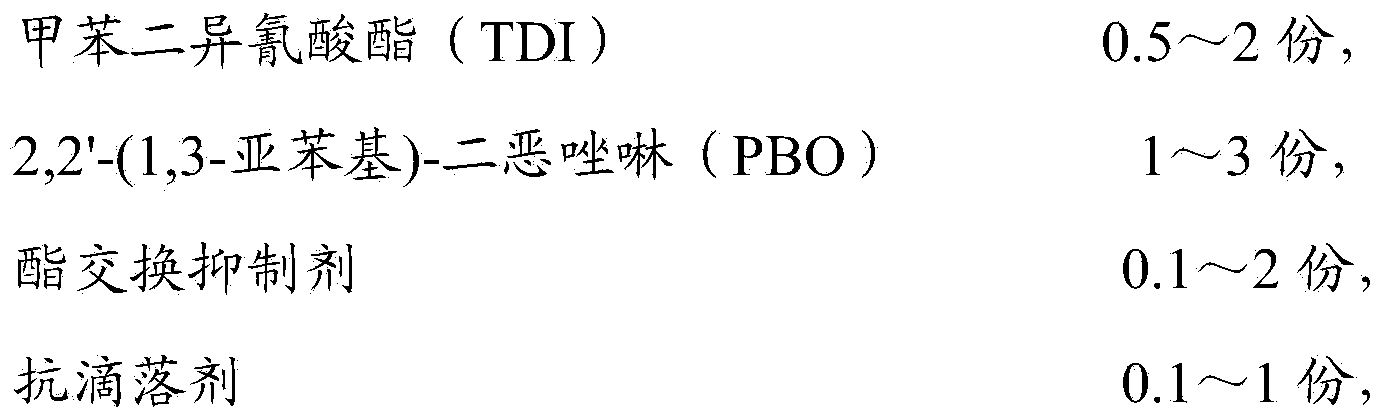

The invention belongs to the field of high polymer materials, and particularly relates to a preparation method of a hyperbranched polybutylene adipate terephthalate material, which adopts cyanuric chloride, ethylenediamine and the like as raw materials to gradually react to generate a triazine ring branching agent, the PBAT, the triazine ring branching agent and an antioxidant are put into a double-screw extruder according to a weight part ratio, the materials are uniformly mixed, extruded and granulated, and then the product is prepared by using an injection molding machine; -NH-groups of thebranching agent can react with terminal hydroxyl groups of PBAT to generate the hyperbranched PBAT material with a core-shell structure, so that the comprehensive performance of the material is further improved. Meanwhile, the -NH-group of the branching agent can also react with carboxyl generated by degradation and aging of the waste plastic, so that molecular chain repair and reactive compatibilization are realized. The method provided by the invention has the characteristics of simple operation, mild reaction conditions, high branching agent purity, environmental friendliness, wide application range and the like, and has wide application prospects in the fields of branching of polyester and high valuation of waste plastics.

Owner:ZHONGBEI UNIV

Preparation method of high-bonding-strength EVA film for glass fiber reinforced plastic interlayer

PendingCN113817105AImprove adhesionGood compatibilityFilm/foil adhesives without carriersGraft polymer adhesivesEpoxyElastomer

The invention discloses a preparation method of a high-bonding-strength EVA (Ethylene Vinyl Acetate) film for a glass fiber reinforced plastic interlayer, and belongs to the technical field of EVA interlayer glues. GMA (Glycidyl Methacrylate) is subjected to melt grafting, GMA (Glycidyl Methacrylate) contains a strong-activity epoxy group, and a macromolecular coupling agent is used, so that a good reactive compatibilization effect can be achieved in a blending reaction, the elasticity is high, the EVA film is rubbery and includes enoughpolyethylene crystals which play a physical crosslinking point erole, the EVA film has the characteristics of thermoplastic elastomer, large cohesive force, small surface tension during melting and high thermal bonding force to the surface of epoxy glass fiber reinforced plastic, such as a 3240 epoxy board, and further the chemical resistance, the thermal stability, the weather resistance and the electrical performance are excellent.

Owner:安徽省阳明达新材料科技有限公司

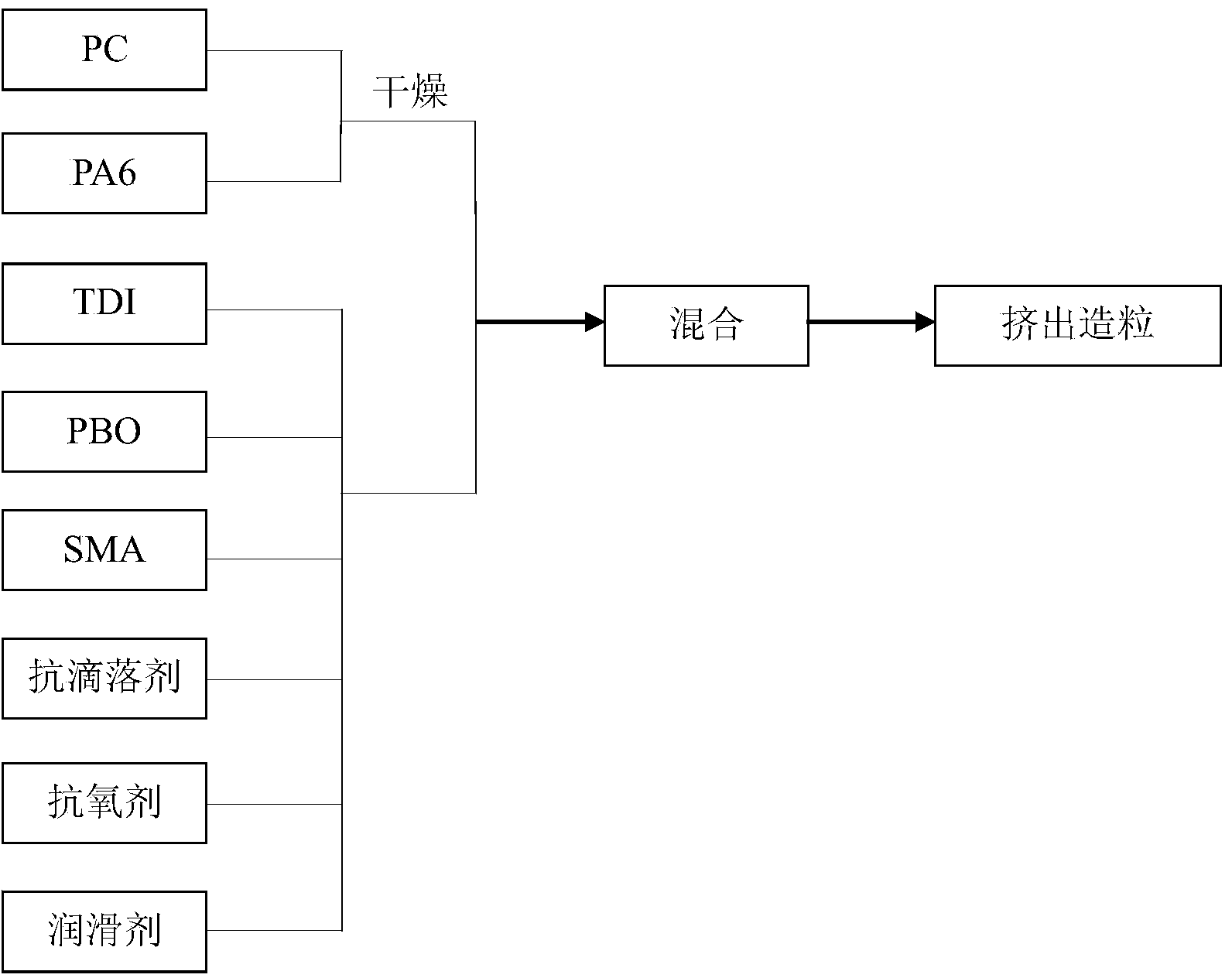

PC/PA6 composition and preparation method for same

ActiveCN103951955AImprove mechanical propertiesImprove flame retardant performancePolyamidePolycarbonate

The invention discloses a PC / PA6 composition and a preparation method for the same. The PC / PA6 composition is prepared from the following raw materials in parts by weight: 65-90 parts of polycarbonate, 10-35 parts of polyamide 6, 0.1-3 parts of toluene diisocynate, 0.1-3 parts of 2,2'-(1,3-phenylene)-dioxazoline, 0.1-6 parts of styrene-maleic anhydride copolymer, 0.1-2 parts of anti-drip agent, 0.1-1 part of hindered phenol antioxidant, 0.1-1 part of phosphite ester antioxidant and 0.1-1 parts of lubricant, wherein the sum of the parts by weight of polycarbonate and polyamide 6 is 100 parts. The PC / PA6 composition disclosed by the invention, which is good in mechanical property, and high in flame retardance, chemical resistance and processability, is prepared by a method of in-situ reactive compatibilization, and can be applied to the industries such as automobiles and electronics and electrical appliances.

Owner:SINOPLAST NEW MATERIAL

Fibrilia-reinforced polypropylene engineering composite as well as preparation method and application of fibrilia-reinforced polypropylene engineering composite

The invention discloses a fibrilia-reinforced polypropylene engineering composite, a preparation method thereof and application of the fibrilia-reinforced polypropylene engineering composite to preparation of automobile parts. The composite is prepared from the following raw materials in percentage by weight: 59-80% of polypropylene, 19-30% of fibrilia, 1-5% of epoxy furan, 1-10% of a toughening agent and 0.1-3% of lauroyl peroxide, wherein both the fibrilia and epoxy furan are from renewable biomasses and meet the requirements of low carbon, environment friendliness and sustainable economic development. According to the fibrilia-reinforced polypropylene engineering composite, epoxy furan can reactively improve the interfacial compatibility of polypropylene and fibrilia under the initiating action of lauroyl peroxide, so that the composite is kept to have excellent mechanical property and processability and can be used for preparing the automobile parts. The preparation method of the composite, disclosed by the invention, can be used for preparing the composite through one-step extrusion and is simple, easy to operate and suitable for industrial production.

Owner:ZHEJIANG XINLI NEW MATERIAL CO LTD

Novel anti-precipitation flame retardant PA6 composite material and preparation method thereof

InactiveCN110408199AImprove mechanical propertiesReduce precipitationReactive compatibilizationPolymer science

The invention relates to the field of high-molecular materials, and discloses a novel anti-precipitation flame retardant PA6 composite material and a preparation method thereof. The novel anti-precipitation flame retardant PA6 composite material of the invention comprises PA6, an amino group-containing flame retardant and a phosphate radical-containing flame retardant, wherein the PA6 accounts for90-96% of the total mass of the composite material. The simultaneous reaction of phosphate groups having a flame retarding effect with amino groups in the PA6 and the flame retardant is utilized to carry out reactive compatibilization, so the compatibility of the flame retardant with the PA6 is improved, the uniform dispersion of the flame retardant in a matrix is promoted, and the emigration ofthe flame retardant is inhibited. The compatibility of the flame retardant with the PA6 matrix is good, so the mechanical properties of the product are improved to a certain extent. The vertical burning level of the PA composite material can reach V-0 level by only adding the flame retardant accounting 10% of the mass of the material, and the composite material can be formed at one time, so the cost is low.

Owner:横店集团得邦工程塑料有限公司

Continuous process for the preparation of a reactive polymer

A continuous process for the reactive compatibilization of polymers includes I. processing monooxazoline, bisoxazoline or a mixture thereof together with a first polymer, to give a reactive polymer; and II. adding the reactive polymer to one or more second polymers. In addition, a reactive polymer contains I. a first polymer; and II. at least 5% by weight of chemically unbound monooxazoline, bisoxazoline or a mixture thereof.

Owner:EVONIK DEGUSSA GMBH

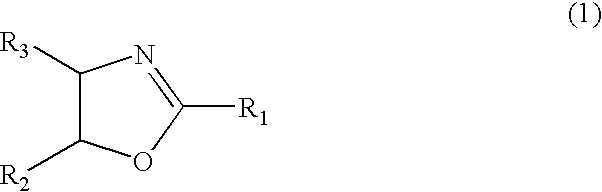

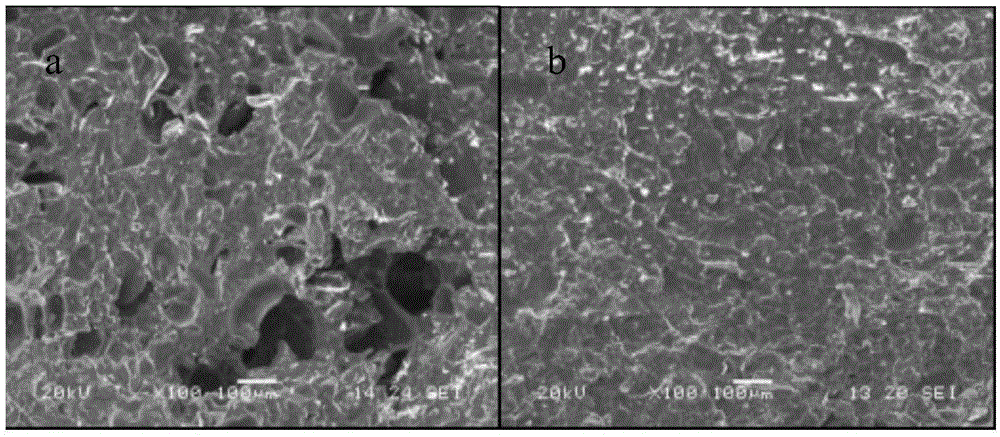

PBT/ABS (polybutylene terephthalate/acrylonitrile-butadiene-styrene) alloy material and preparation method thereof

The invention discloses a PBT / ABS (polybutylene terephthalate / acrylonitrile-butadiene-styrene) alloy material and a preparation method thereof. The PBT / ABS alloy material comprises the following components in percentage by mass: 20-40% of PBT, 70-50% of ABS, 2-8% of MAG, 0.2-3% of a lubricant and 0.2-0.5% of an antioxidant. The PBT / ABS alloy material disclosed by the invention has the beneficial effects that MGE (methyl methacrylate-glycidyl methacrylate-ethyl acrylate) is added to perform reactive compatibilization and blending compatibilization on the PBT / ABS alloy material to ensure that the performance of the PBT / ABS alloy material is effectively improved, system phases are dispersed more uniformly, and the phase morphology is more stable to obtain more benefits for molding processing, then the PBT / ABS alloy material has the characteristics of both PBT and ABS, the ABS has the function of improving the impact strength of PBT, the PBT has the function of better improving the processability and chemical reagent resistance of the ABS at the same time, so that the PBT / ABS alloy material has the characteristics of stable size, high strength, good appearance, high chemical reagent resistance and the like.

Owner:QINGDAO XINZHAN PLASTIC

Polypropylene composite material and preparation method and application thereof

The invention relates to the field of composite materials, and particularly relates to a polypropylene composite material and a preparation method and application thereof. The polypropylene compositematerial contains polypropylene, hemp fibers, itaconic acid epoxy, a flexibilizer and an initiator. The method of the polypropylene composite material comprises the following steps: uniformly mixing the polypropylene, the hemp fibers, the itaconic acid epoxy, the flexibilizer and the initiator, and melting, blending and extruding the mixture. The application of the polypropylene composite materialrelates to the application of the polypropylene composite material in the preparation of automobile parts. In the polypropylene composite material, dilauroyl peroxide is used as the initiator, so that the itaconic acid epoxy can reactively compatibilize the interfacial compatibility of the polypropylene and the hemp fibers, is beneficial to improving the compatibility of polypropylene and plant fibers, and has the effect of promoting fiber dispersion, thereby ensuring that the polypropylene composite material has excellent mechanical properties and processability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of reaction-compatibilizing nitrile water-swellable rubber

The invention relates to a method for preparing reactive compatibilization-type nitrile water-swelling rubber. The method comprises the following steps: sequentially adding an active agent A, an active agent B, a vulcanizing agent, an anti-aging agent, a water absorbing additive and a bulking agent after plastifying nitrile rubber on an open mill by adopting a thinning coating roll; adding water-absorbing resin to evenly mix after mixing evenly, and then adding reinforcing filler carbon black and white carbon black; milling, and finally adding a vulcanization accelerator A and a vulcanization accelerator B to evenly mix; packaging into a triangular packet; thinning, batching off and standing for later use; putting the mixed nitrile rubber into a tabletting mold; vulcanizing, opening the mold, taking out the vulcanized water-swelling nitrile rubber, standing and cutting. The method has the advantages and beneficial effects that the preparation method is simple, and low in requirement on equipment, so as to save the cost. The method can be widely applied to tunnels, culverts, swimming pools, basements, underwater engineering, downhole oil recovery, water supply facilities, civil construction and the like.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Super-nylon 66 alloy prepared by in-situ reactive compatibilization method and preparation method thereof

InactiveCN102796229AImprove performanceImprove notched impact strengthReactive compatibilizationNylon 66

The invention discloses super-nylon 66 alloy prepared by an in-situ reactive compatibilization method and a preparation method thereof, and the preparation method is used for improving the compatibility of nylon 66 and POE (poly ortho ester), and preparing the super-nylon 66 alloy with high toughness, low temperature resistance and low water absorption rate. The super-nylon 66 alloy comprises the following compounds in parts by weight: 55 to 95 parts of nylon 66, 5 to 45 parts of POE, 0.01 to 1 part of initiating agent, and 0.1 to 4 parts of maleic anhydride, wherein the initiating agent is organic peroxide. The super-nylon 66 alloy provided by the invention has excellent comprehensive performance, in particular high notch impact strength, excellent low temperature impact resistance and low water absorption rate; and the product can be used in producing various automobile parts, mechanical parts, electronic appliances, package materials and the like with high toughness, abrasion resistance and excellent self-lubrication performance.

Owner:SINOPLAST NEW MATERIAL

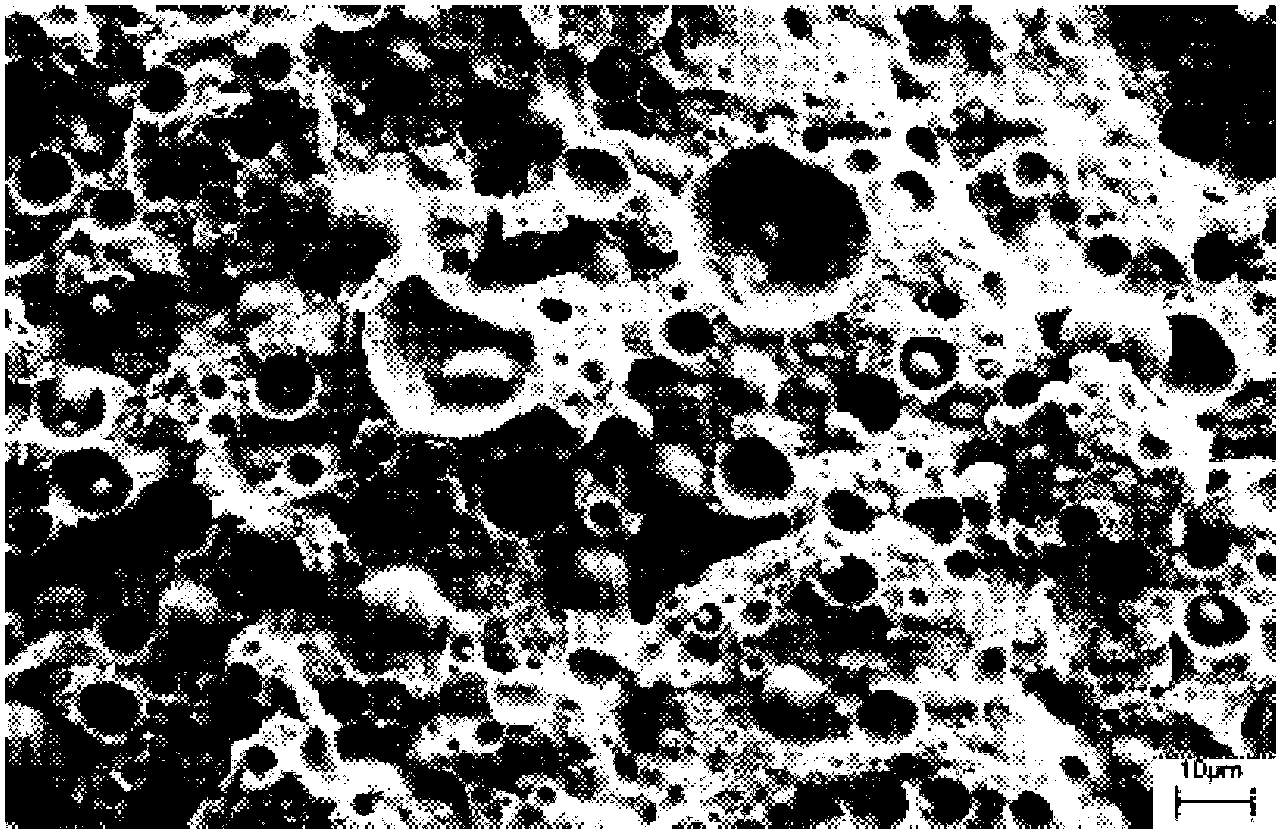

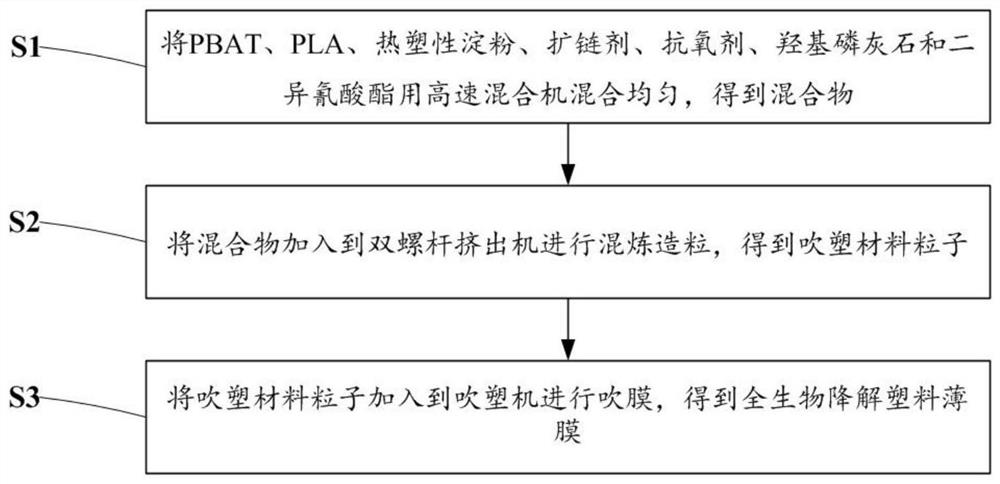

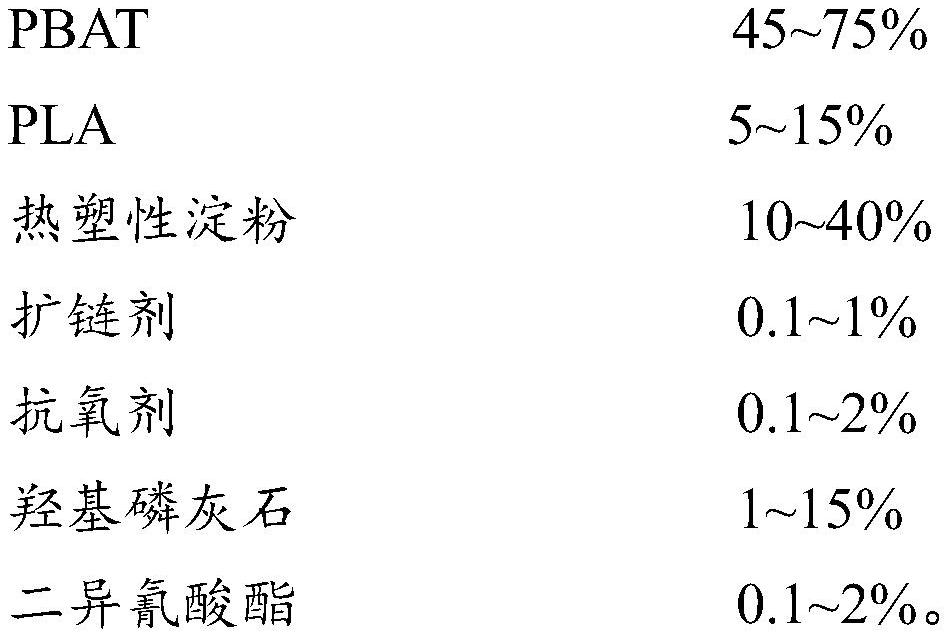

Fully biodegradable plastic film and preparation method thereof

The invention discloses a fully biodegradable plastic film and a preparation method thereof. The fully biodegradable plastic film comprises the following components in percentage by weight: 45-75% ofPBAT, 5-15% of PLA, 10-40% of thermoplastic starch, 0.1-1% of a chain extender, 0.1-2% of an antioxidant, 1-15% of hydroxyapatite and 0.1-2% of diisocyanate. According to the invention, the thermoplastic starch is adopted to replace native starch, so that the dispersity of the starch can be remarkably improved, and a film with higher mechanical properties is obtained while the material cost is greatly reduced; and by selecting diisocyanate as a compatibilizer and hydroxyapatite as a reinforcing agent, the effects of organic reactive compatibilization and toughening, inorganic particle reinforcement and crystallization promotion can be combined, and the comprehensive performance of the film is further improved due to the synergistic effect of diisocyanate and hydroxyapatite.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com