Preparation method of reaction-compatibilizing nitrile water-swellable rubber

A technology of water-swelling rubber and reaction compatibilization, applied in the field of sealing materials, can solve the problems of complex preparation method of compatibilizer, complex compatibilizer synthesis process, large mass loss rate, etc. Loss rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

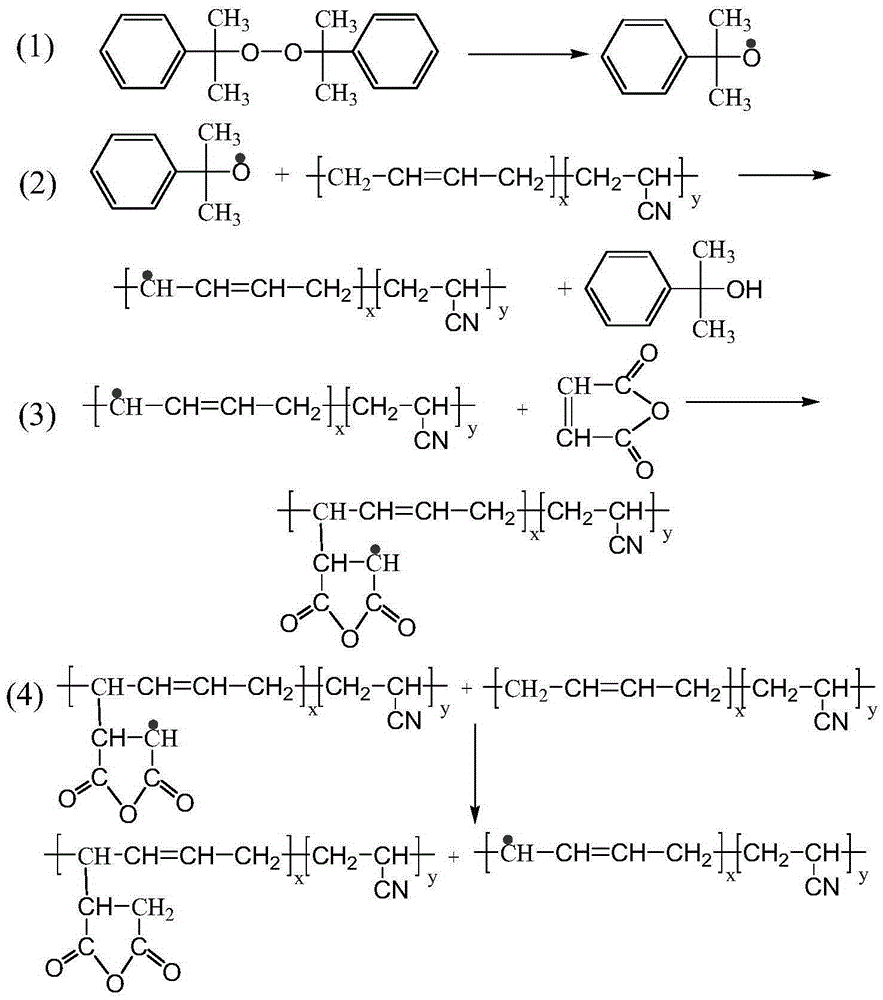

[0033] The preparation steps of reactive compatibilizer are as follows:

[0034] Add 30g of NBR to the torque rheometer, and then add a mixture of 0.3g of maleic anhydride and 3g of dicumyl peroxide. °C, the third section is 110 °C, and the reaction is 5 minutes. After the grafting reaction was completed, the grafted product was taken out and placed in a Soxhlet extractor for extraction with tetrahydrofuran for 24 hours, and the unreacted initiator, maleic anhydride, and maleic anhydride homopolymer were extracted to obtain the compatibilizer Ma Toric anhydride / nitrile rubber graft copolymer.

[0035] The compatibilizer maleic anhydride grafted acrylonitrile-butadiene rubber prepared in the last step is applied in water-swellable acrylonitrile-butadiene rubber, and its steps are as follows:

[0036] 1) After plasticizing 100 parts of nitrile rubber on the open mill for 1 min with a thin open roll, add 1.5 parts of stearic acid, 5 parts of ZnO, 1.5 parts of sublimed sulfur, 1...

Embodiment 6~10

[0047] 1) After plasticizing 100 parts of nitrile rubber on the open mill for 1 min with a thin open roll, add 1.5 parts of stearic acid, 5 parts of ZnO, 1.5 parts of sublimed sulfur, 1 part of anti-aging agent D, 10 parts PEG-8000, after rolling evenly (about 3min) at a roller distance of 2 mm, then add 30 to 70 parts of sodium polyacrylate and 8 parts of compatibilizer and mix evenly, then add 20 parts of carbon as a reinforcing filler Black and 20 parts of white carbon black were kneaded for 10 minutes at a roll distance of 3 mm. Finally, 2 parts of vulcanization accelerator DM and 2 parts of vulcanization accelerator CZ were added and mixed evenly. Triangular bag 6 times, thin pass, sliced, and stand for 4 hours for later use.

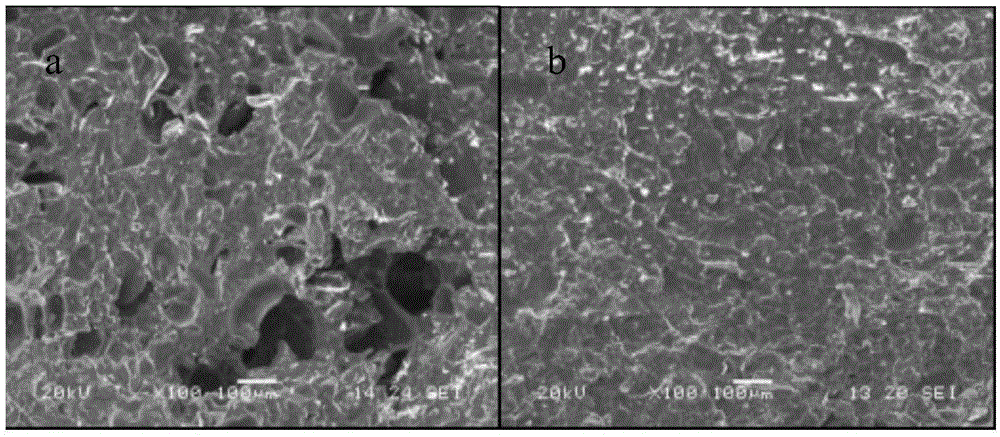

[0048] 2) Place the kneaded nitrile rubber in a tableting mold, vulcanize it on a flat vulcanizer at 160°C for 15 minutes (pressure is 10Mpa), open the mold, take out the vulcanized water-swellable nitrile rubber, and let it stand for 24 hours , c...

Embodiment 11~15

[0051] 1) After 100 parts of nitrile rubber is masticated on the open mill with a thin open roll for 1 min, 1.5 parts of stearic acid, 5 parts of ZnO, 1.5 parts of sublimed sulfur, 1 part of anti-aging agent 4010NA, 0~ 12 parts of PEG-6000, after the roller distance is 2mm, knead evenly (about 3min), then add 50 parts of polypropylene lithium, 8 parts of compatibilizer (the compatibilizer prepared in Example 1) and knead After uniformity, add 20 parts of carbon black and 20 parts of white carbon black as reinforcing fillers, and knead for 10 minutes on a roller distance of 3 mm. Finally, add 2 parts of vulcanization accelerator DM and 2 parts of vulcanization accelerator CZ to mix. Evenly smelted, with a roller distance of 0.4 mm, bagged 6 times, thinly passed, and then sliced, and left to stand for 4 hours for later use.

[0052] 2) Place the kneaded nitrile rubber in a tableting mold, vulcanize it on a flat vulcanizer at 160°C for 10 minutes (pressure is 10Mpa), open the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com