Method for preparing silicone rubber/polyamide thermoplastic vulcanized rubber by virtue of reactive compatibilization

A thermoplastic vulcanizate, reactive compatibilization technology, applied in the field of polymer material processing, can solve the problems of high temperature resistance, poor oil resistance, limited compatibilization effect, inability to achieve complete compatibility between polyolefin and silicone rubber, etc. The effect of excellent performance and good physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

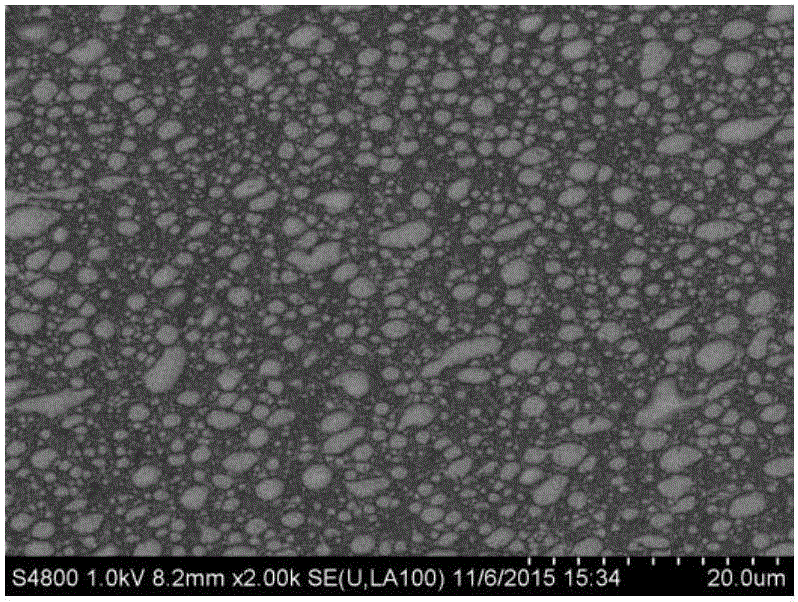

Image

Examples

Embodiment 1

[0028] The selected raw material composition and mass parts are as follows:

[0029]

[0030] Wherein the raw material composition and mass parts of self-made compatibilizer are as follows:

[0031] Methyl vinyl silicone rubber 100;

[0032] Glycidyl methacrylate 0.01;

[0033] Dicumyl peroxide 1

[0034] According to the above formula, the preparation steps are as follows:

[0035] (1) Preparation of self-made solubilizer: Melt and mix methyl vinyl silicone rubber, glycidyl methacrylate, and dicumyl peroxide in a Haake mixer at 150°C for 5 minutes to obtain graft modified permanent silicone rubber;

[0036] (2) Rubber and plastic premixing: Add the dried polyamide 6, methyl silicone rubber, grafted modified silicone rubber and antioxidant 1010 into the internal mixer, mix at 220°C, and discharge after mixing evenly Cool to room temperature; at room temperature, mix with 2,5-dimethyl-2,5-bis(tert-butyl peroxide)hexane and 2,2,6,6-tetramethylpiperidine-nitrogen - The o...

Embodiment 2

[0042] The selected raw material composition and mass parts are as follows:

[0043]

[0044]

[0045] The raw material composition and mass fraction of the self-made compatibilizer are as follows:

[0046] Terminated vinyl silicone rubber 100;

[0047] Peroxybenzoic acid 2.

[0048] According to the above formula, the preparation steps are as follows:

[0049] (1) Preparation of self-made solubilizer: Dissolve vinyl-terminated silicone rubber and peroxybenzoic acid in chloroform, react for 96 hours at a temperature of 30°C, and a stirring paddle speed of 70rpm to prepare a epoxy-terminated Epoxy silicone rubber;

[0050] (2) Rubber and plastic premixing: add the dried polyamide 12, methyl vinyl silicone rubber, epoxy silicone rubber and antioxidant 1010 into the internal mixer, mix at 180°C, and leave after mixing evenly. The material is cooled to room temperature; at room temperature, use an open mill to mix with dicumyl peroxide and 2,2,6,6-tetramethylpiperidine-n...

Embodiment 3

[0056] The selected raw material composition and mass parts are as follows:

[0057]

[0058] Wherein the raw material composition and mass parts of self-made compatibilizer are as follows:

[0059] Methyl vinyl silicone rubber 100;

[0060] 1,2-epoxybutene 5;

[0061] Dibenzoyl peroxide 0.01.

[0062] According to the above formula, the preparation steps are as follows:

[0063] (1) Preparation of self-made solubilizer: Melt and mix methyl vinyl silicone rubber, 1,2-epoxybutene, and dibenzoyl peroxide in a Haake internal mixer at 180°C for 15 minutes to obtain grafted Modified silicone rubber;

[0064] (2) Rubber and plastic premixing: add the dried polyamide 6, methyl silicone rubber, graft-modified methyl vinyl silicone rubber and antioxidant 1010 into the internal mixer, mix at 260°C, and wait for mixing After uniformity, the discharge material is cooled to room temperature; at normal temperature, use an open mill to mix with dicumyl peroxide and 2,2,6,6-tetramethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com