Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Oxygen Content Measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The value represents the extent to which oxygen is removed from the blood as it passes through the body. Usually, the arterial oxygen concentration is measured in blood from the femoral, brachial, or radial artery, and the oxygen content of mixed venous blood is measured from blood withdrawn from the pulmonary artery.

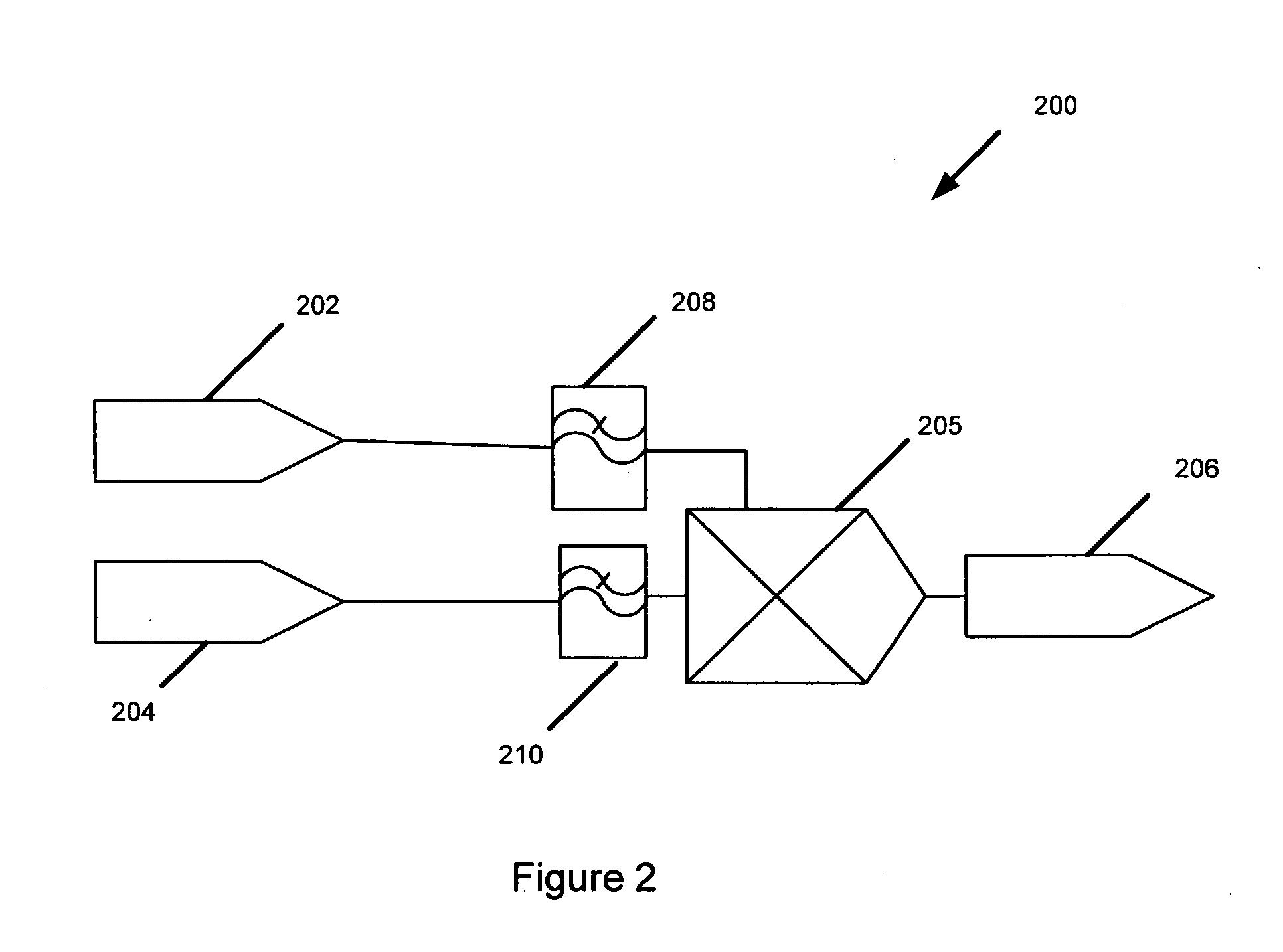

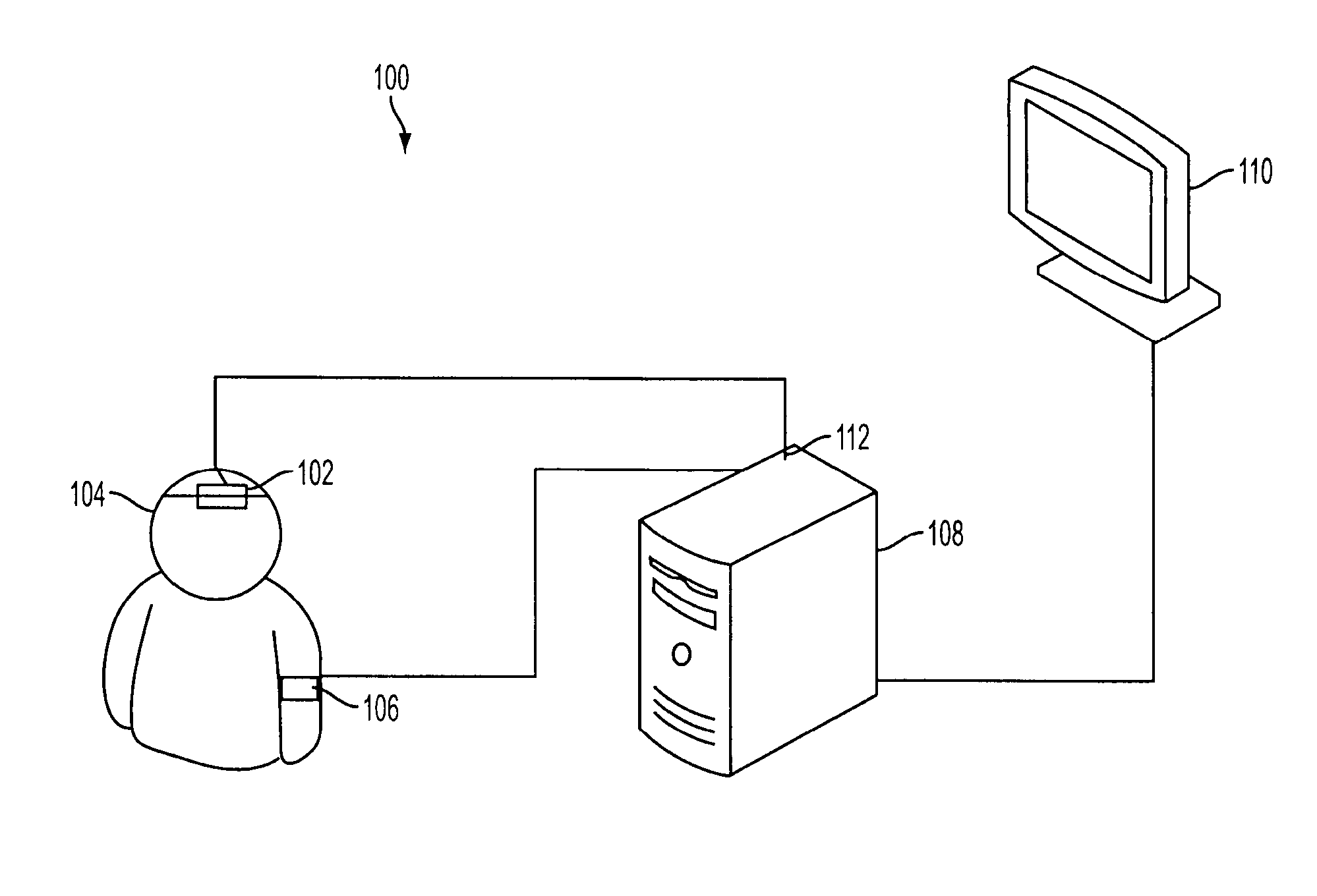

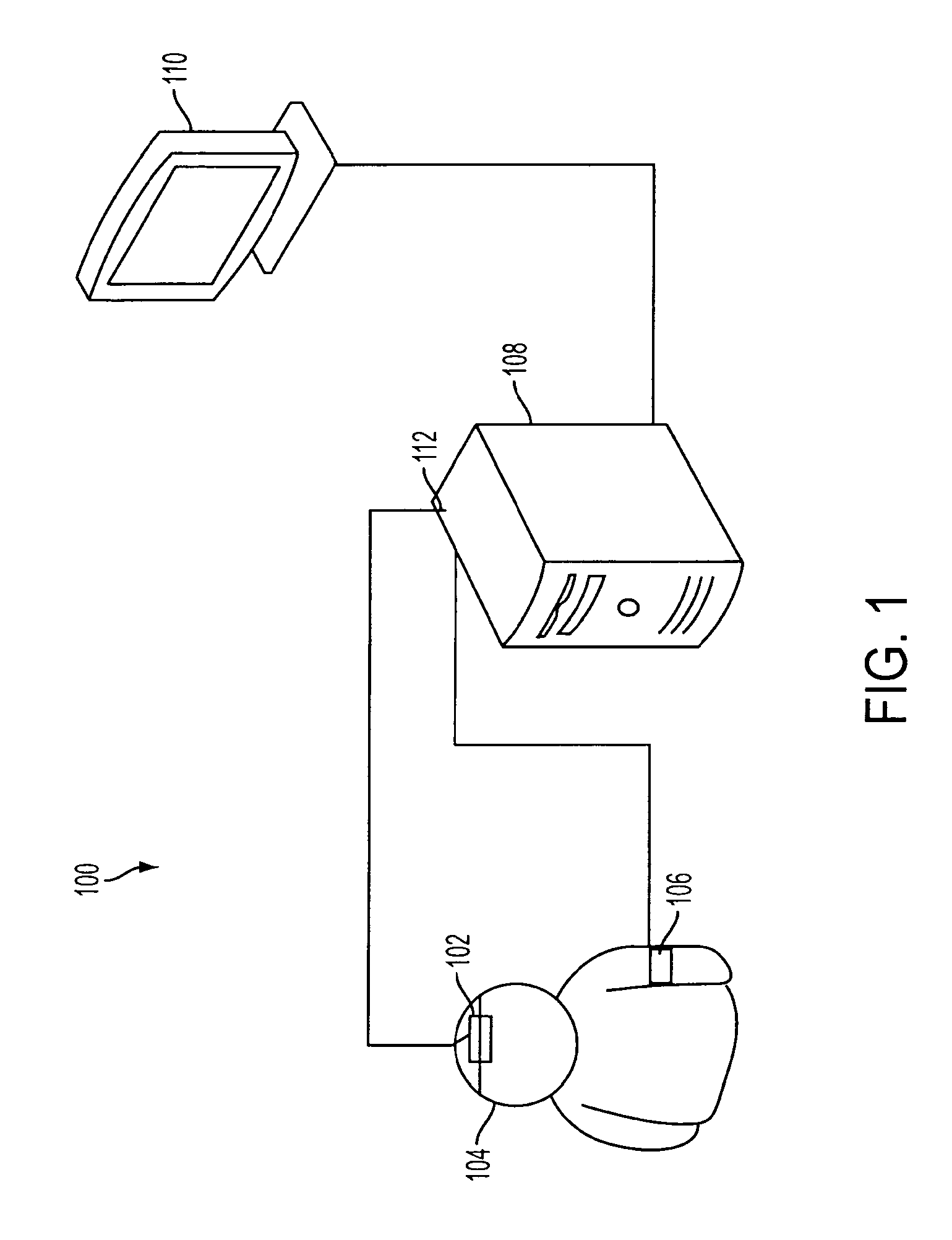

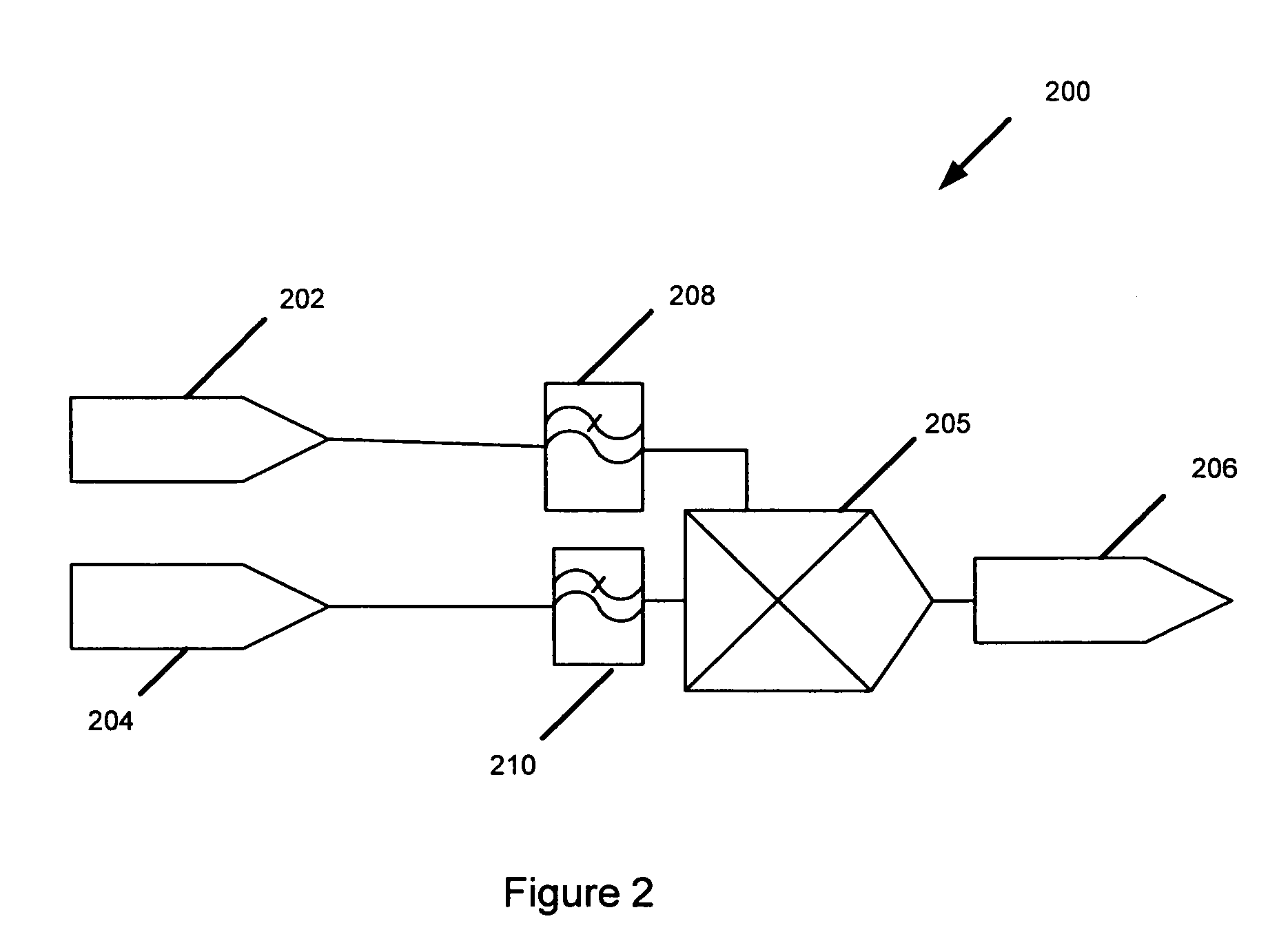

Method and system for determining a cerebrovascular autoregulation state of a patient

A method of diagnosing cerebrovascular autoregulation in a patient includes measuring blood pressure of the patient, measuring, non-invasively, venous oxygen content of the patient's brain substantially simultaneously with the measuring blood pressure, correlating the blood pressure and the venous oxygen content measurements in a time domain, and determining a cerebrovascular autoregulation state of the patient based on the correlating the blood pressure and the venous oxygen content measurements.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Method and system for determining a cerebrovascular autoregulation state of a patient

A method of diagnosing cerebrovascular autoregulation in a patient includes measuring blood pressure of the patient, measuring, non-invasively, venous oxygen content of the patient's brain substantially simultaneously with the measuring blood pressure, correlating the blood pressure and the venous oxygen content measurements in a time domain, and determining a cerebrovascular autoregulation state of the patient based on the correlating the blood pressure and the venous oxygen content measurements.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Sample preparation method of oxygen content measurement of steels

InactiveCN101769835AMeet measurement needsOvercome limitationsPreparing sample for investigationHardnessManufacturing enterprises

The invention relates to a sample preparation method of the oxygen content measurement of steels, which comprises sample preparation methods of pipes, sheets and high-hardness steels and can satisfy the requirements on the oxygen content measurement on the steels in a bearing manufacturing enterprise according the technical requirements of products. Especially for thin-wall pipes, thin sheets, high-hardness steels, and other steels, samples can not be manufactured according to rules in a standard, therefore, the oxygen content of steels at key parts of a bearing can not be measured; and the samples can be manufactured by adopting the sample preparation method in the invention, and the oxygen content can also be measured according to procedures, devices, and methods in an GB / T11261-2006 standard. The samples manufactured by using the sample preparation method can not only be used for measuring the steels, but also be used for measuring the oxygen contents of other metals, thereby overcoming limitations of the sample preparation method in the standard, broadening the usable range and ensuring that more steel products can be all subjected to the oxygen content measurement by using the standard method; and the sample preparation method provides reliable basis and guarantees especially for analyzing and searching early failure reasons of bearing products.

Owner:胡先根

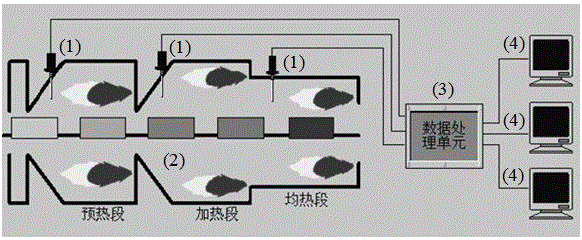

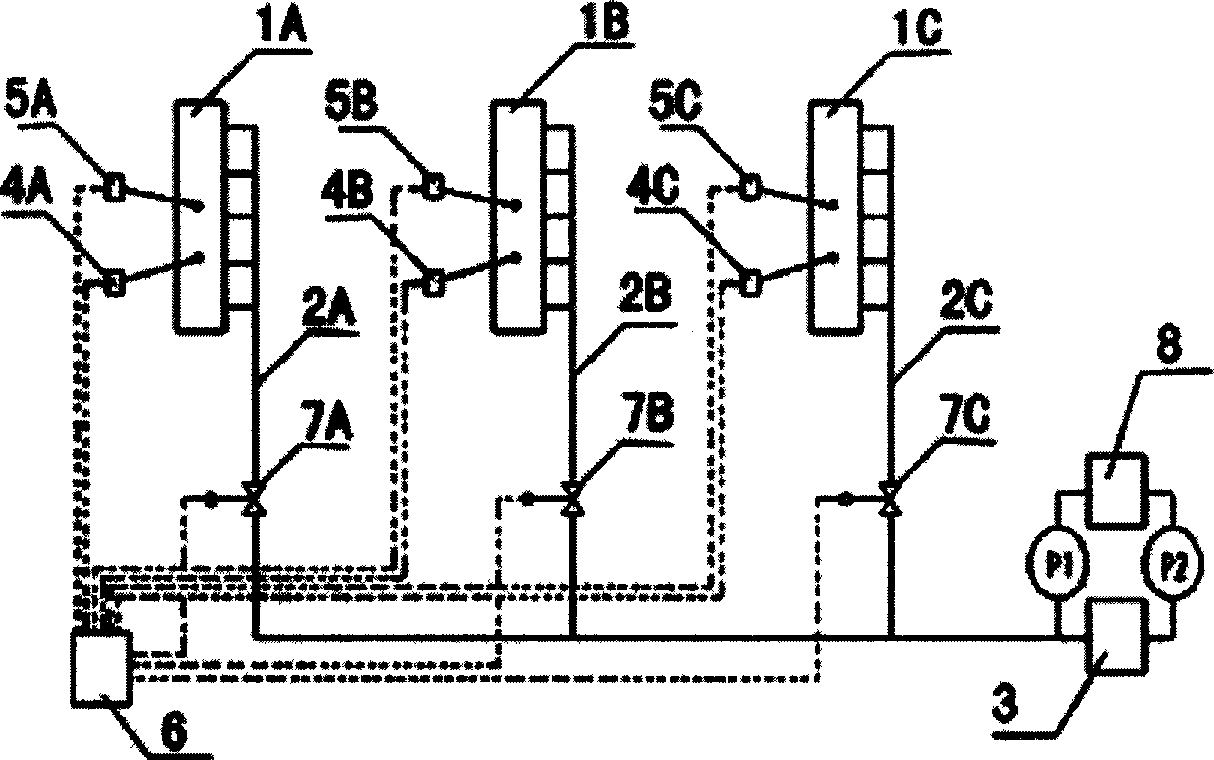

Online measuring and controlling system for combustion condition of steel rolling heating furnace

InactiveCN105734264AAchieve independent controlFurnace typesHeat treatment process controlCombustionControl system

The invention relates to an online measurement and control method for the combustion status of a steel rolling heating furnace. Aiming at the method of detecting the residual oxygen in the flue of the traditional heating furnace, it is difficult to independently control the combustion atmosphere in different sections of the heating furnace, the combustion efficiency is low, and the billet is oxidized and burned too much. Many more questions. The present invention installs the oxygen analyzer at the combustion gas outlet of each section on the top of the heating furnace to measure the oxygen content of the combustion atmosphere in different sections of the furnace online, and then based on the oxygen content measurement value, the excess air in the corresponding section The coefficient is adjusted online to realize the precise control of the oxygen content in the combustion atmosphere in different sections of the heating furnace. The invention can help the operator to automatically operate the combustion status of the heating furnace within the required range, realize accurate measurement and control of the combustion status of different sections, improve the combustion efficiency of the heating furnace, reduce the oxidation and burning loss of the billet, and improve the performance and yield of the product. Important engineering application promotion value.

Owner:SHANGHAI UNIV

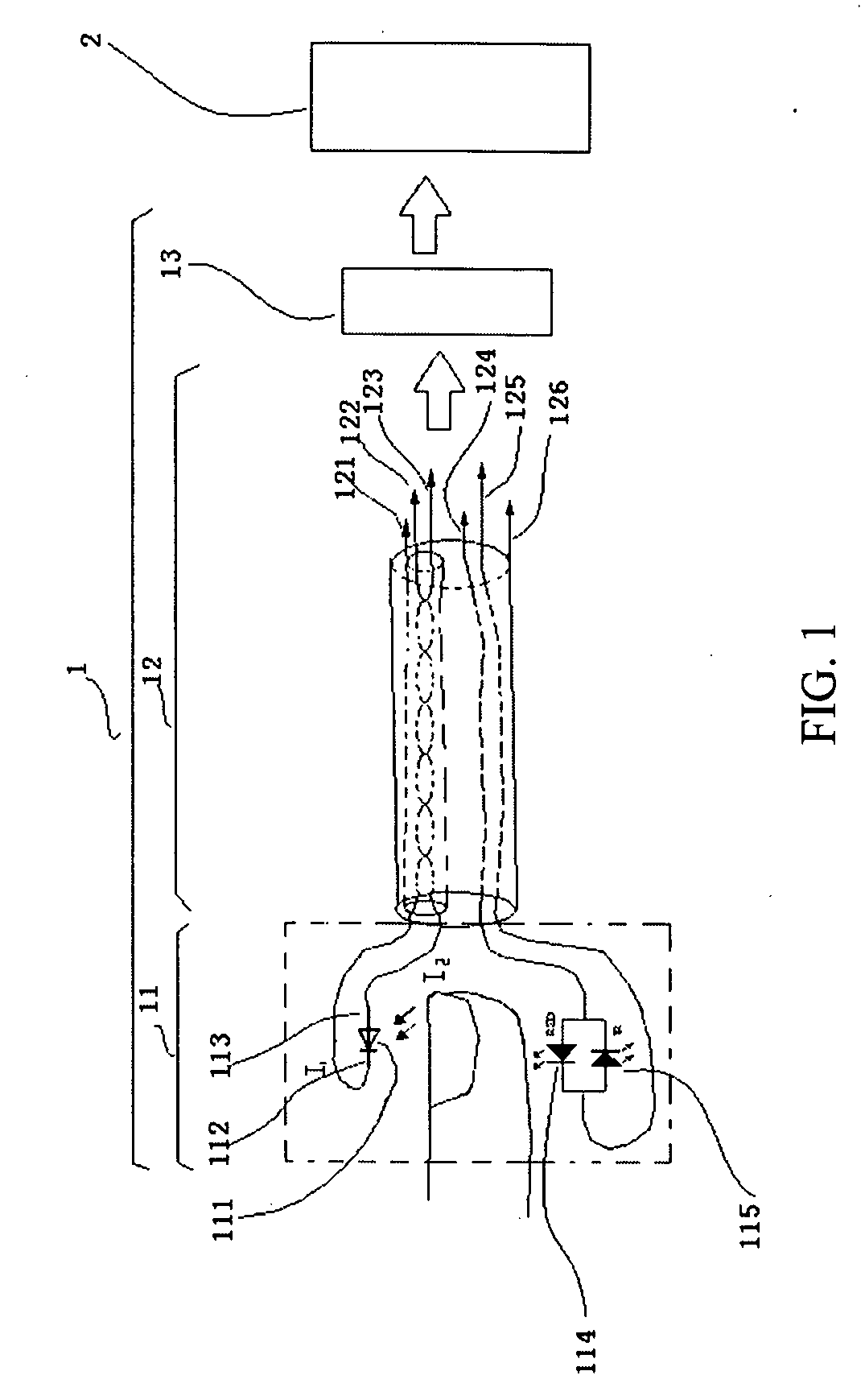

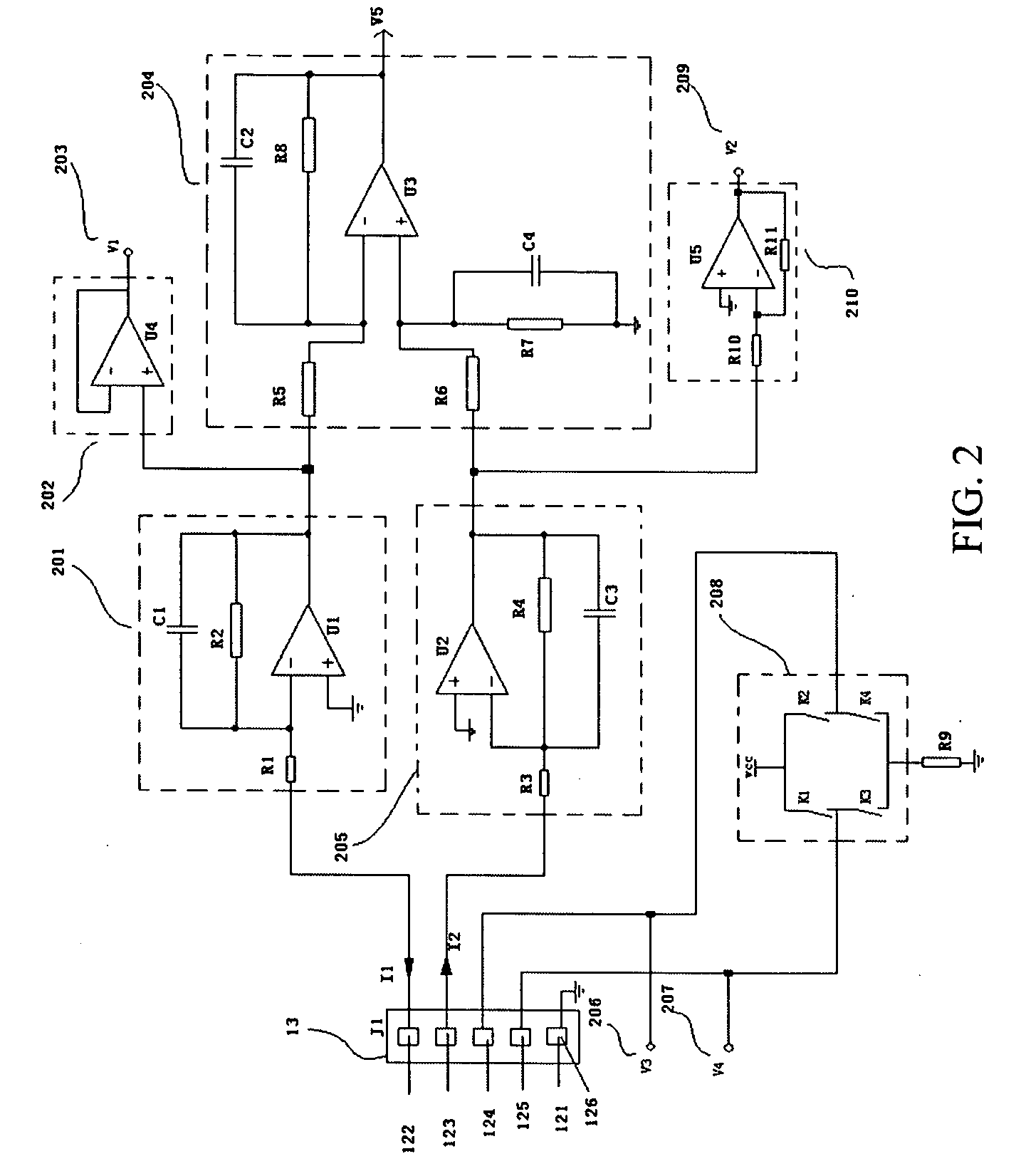

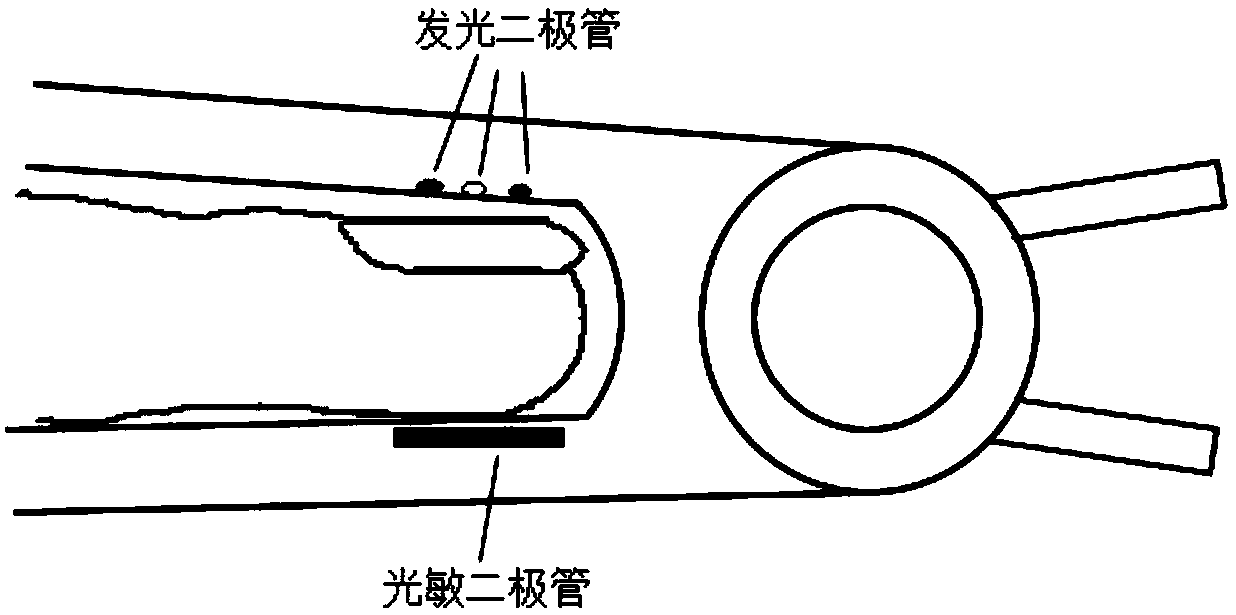

Method and device for detecting fault in a blood oxygen sensor

ActiveUS20060206020A1Accurate detectionImprove reliabilityCalibration apparatusDiagnostic recording/measuringOxygen sensorProcessing element

A device for measuring blood oxygen content comprises a blood oxygen sensor interface, a signal processing unit, and a plurality of voltage sampling points. A method for detecting fault in a blood oxygen sensor comprises the steps of: connecting the blood oxygen sensor to the signal processing unit; providing voltage signals by the signal processing unit via a pair of testing terminals, for alternately driving two LEDs connected in inverse-parallel with each other in the blood oxygen sensor; sampling the voltages of the pair of testing terminals, respectively, and determining the fault relevant to the LEDs based on the relationship of the voltages; receiving current signals from a photodiode in the blood oxygen sensor by the signal processing unit via another pair of terminals, converting the received current signals into voltage signals, and outputting positive voltage signals via a reverser and a follower, respectively; and sampling the positive voltage signals respectively for determining the fault relevant to the photodiode. Thus, the fault of the sensor can be detected and determined by employing a plurality of sampling points without the tissue to be measured of the human body, thereby the output error due to the faults of the sensor can be avoided, and the device can be maintained conveniently.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

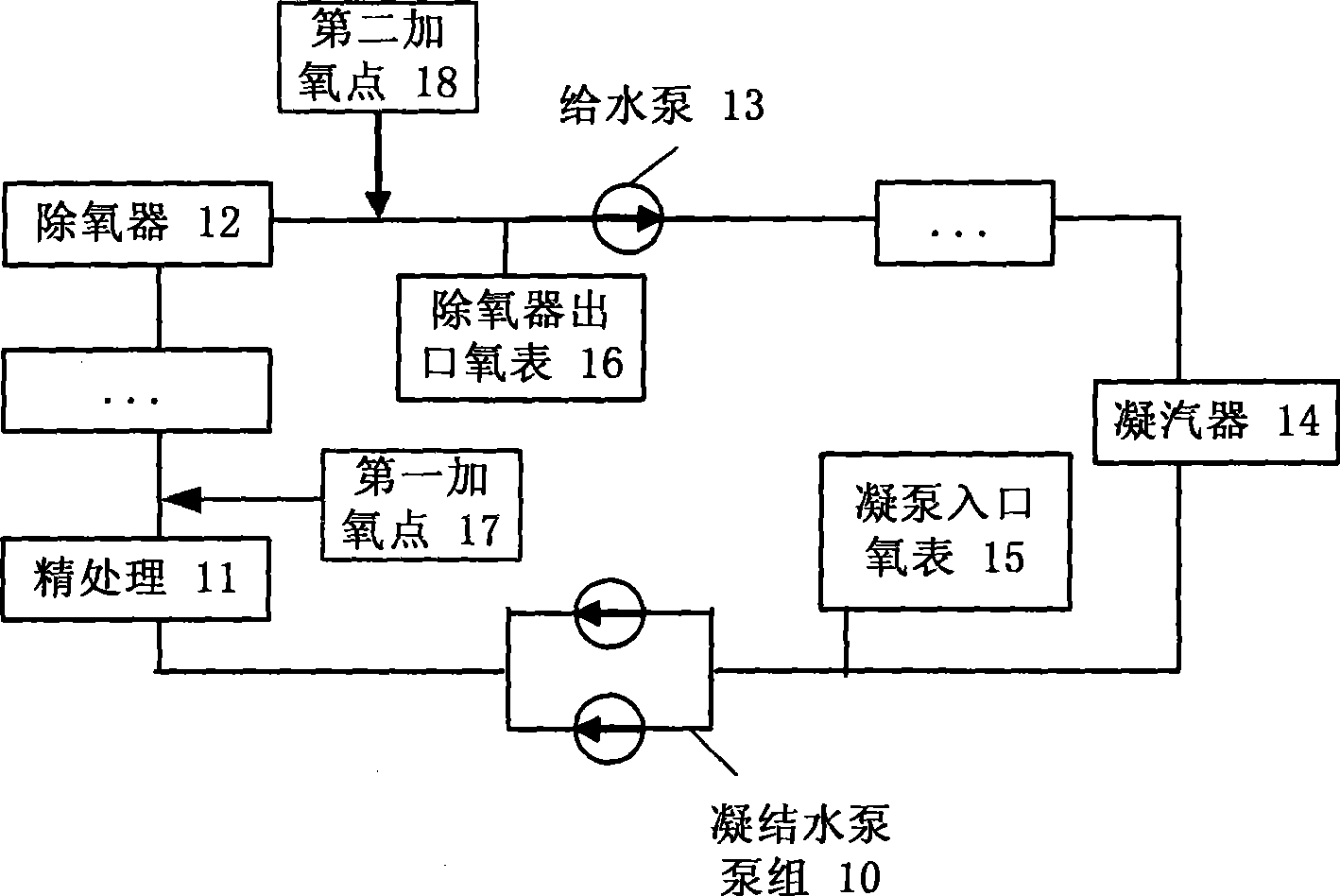

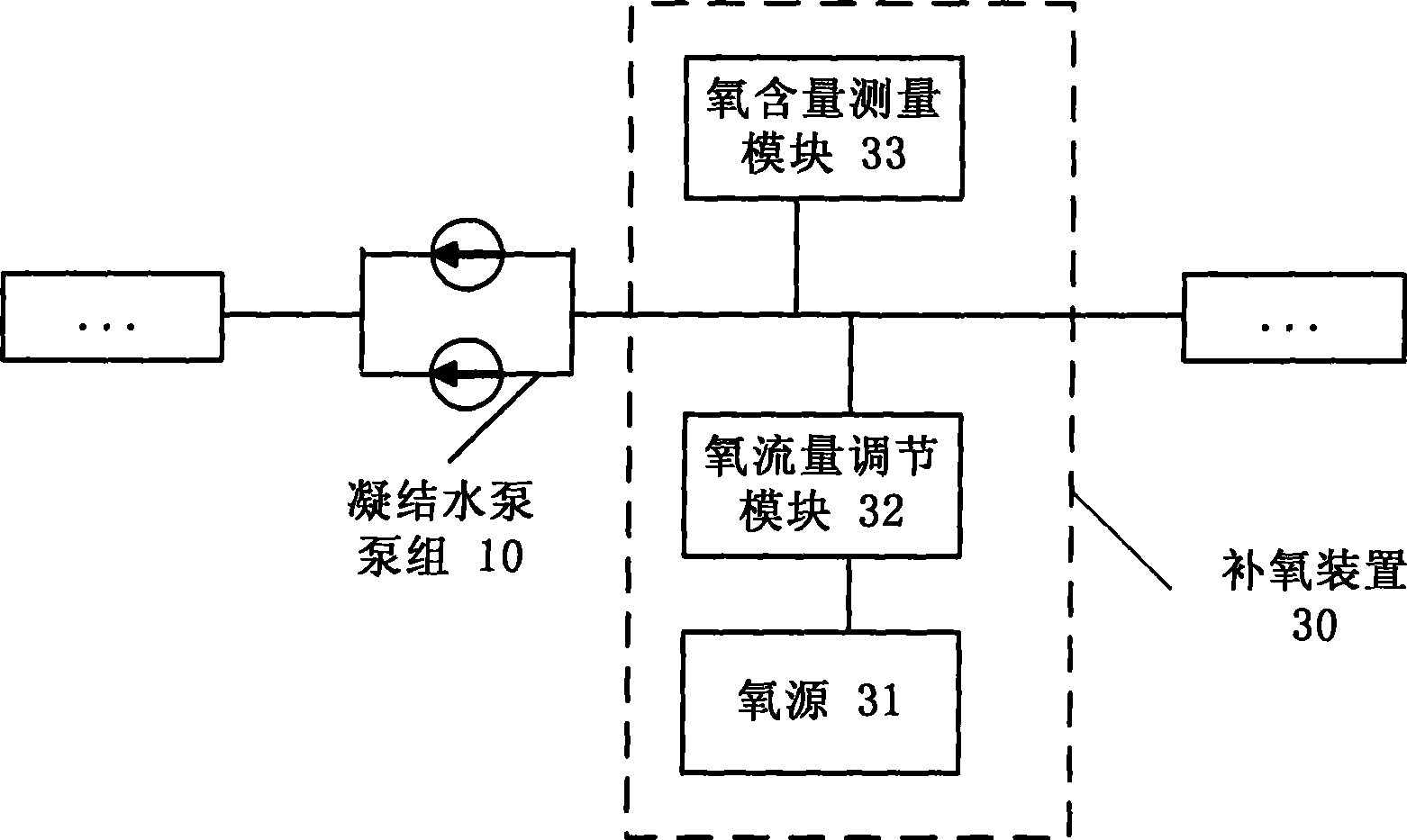

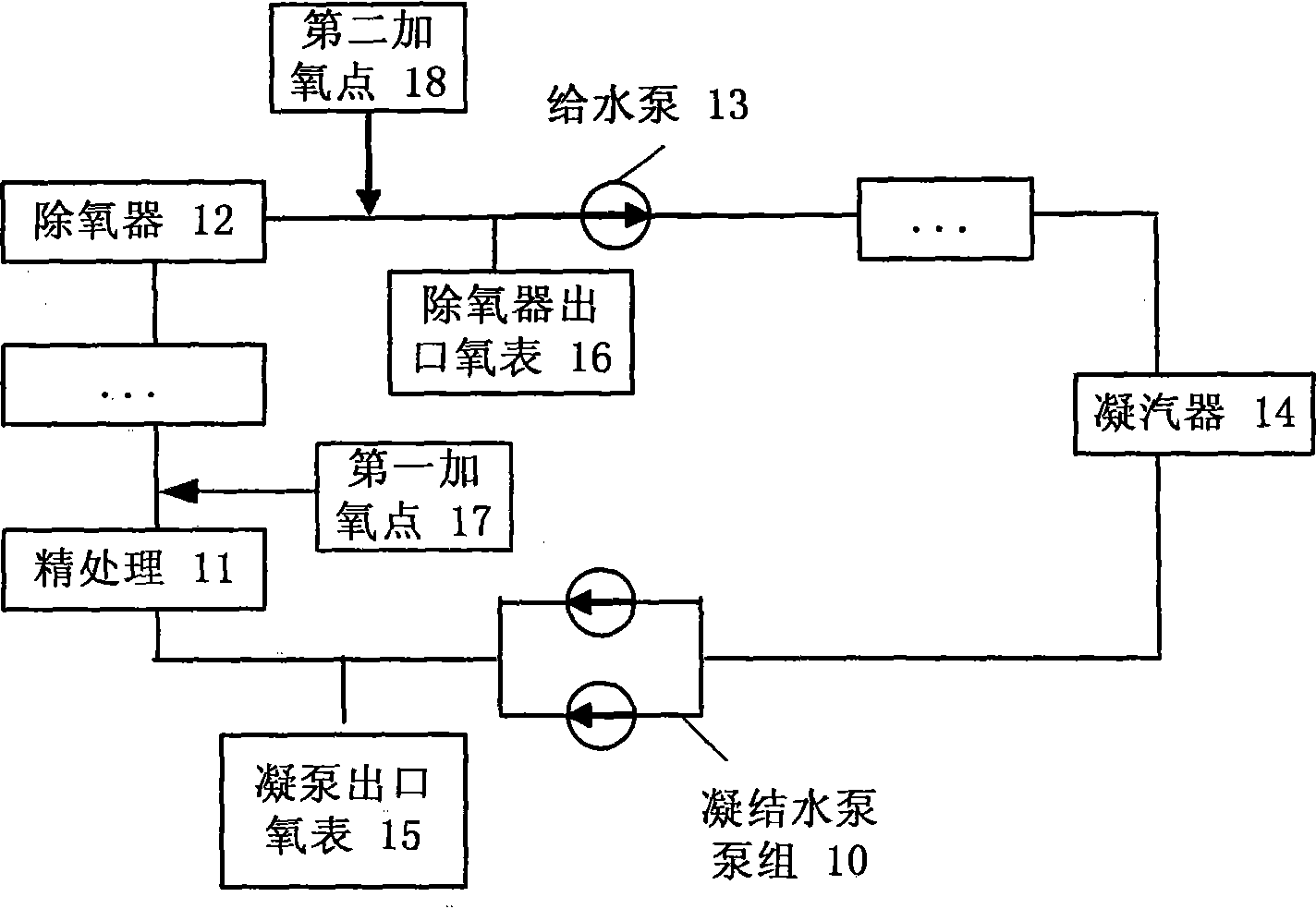

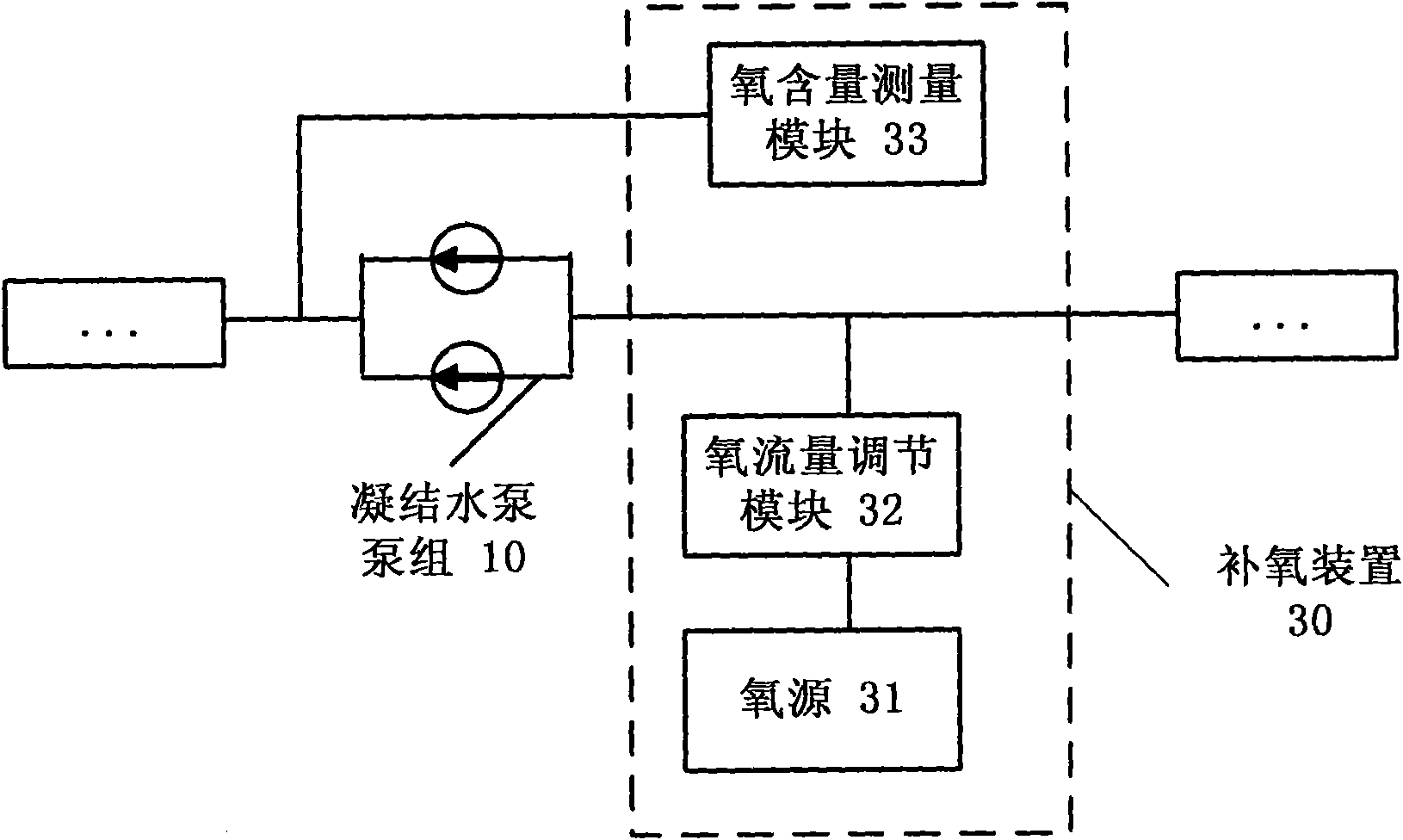

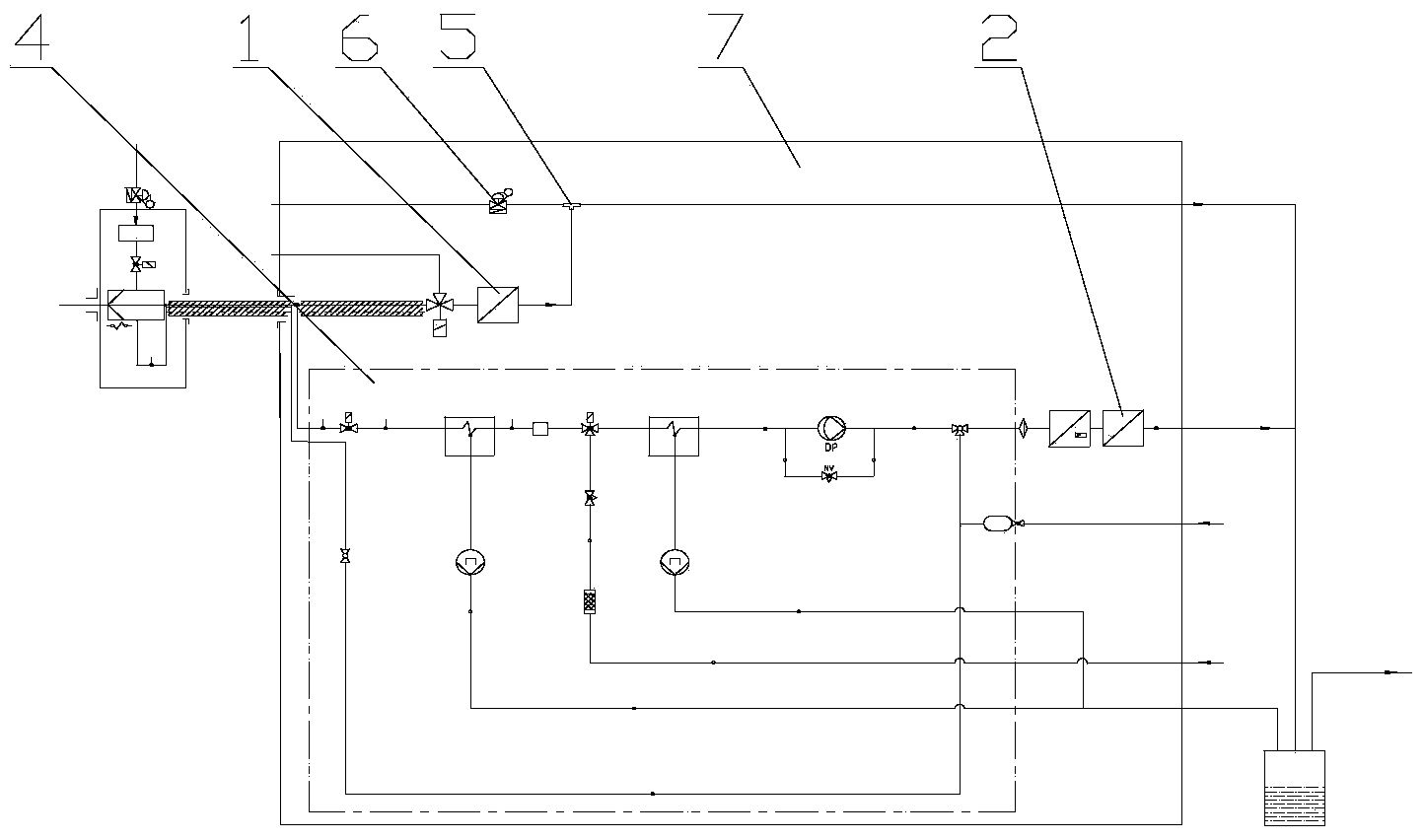

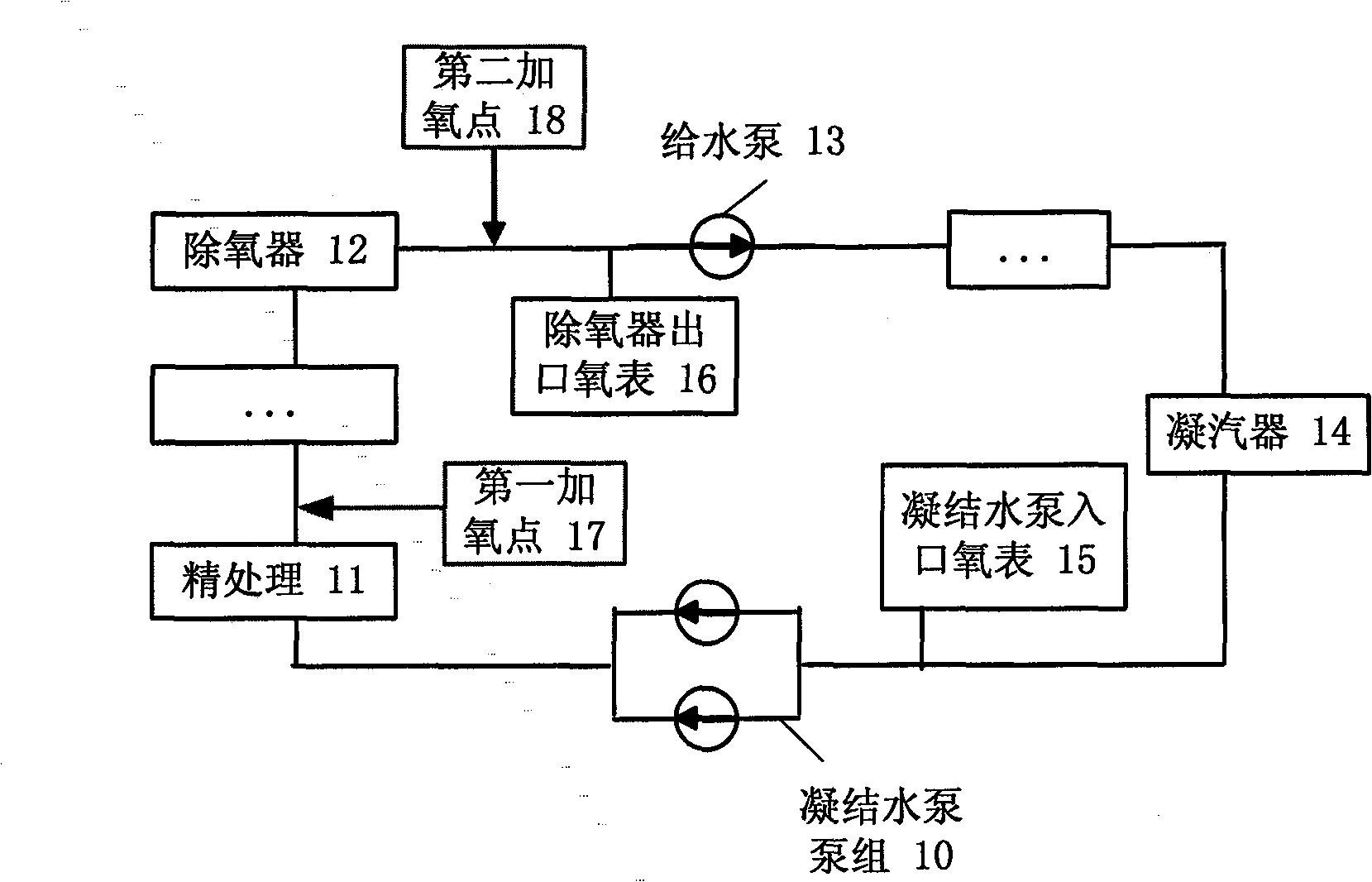

Station boiler and water and oxygen supply apparatus and method thereof

ActiveCN101423282AImprove securityWater/sewage treatment by substance additionDifferential pressureEconomizer

The invention discloses an oxygenating device for a station boiler and water supply and an oxygenating method thereof. The oxygenating device comprises an oxygen content measurement module, an oxygen supply and an oxygen flow regulation module, wherein, the oxygen content measurement module is used for measuring the dissolved oxygen content of condensed water at an entrance of a pump package of a condensed water pump for a station boiler; the oxygen supply is used for supplying oxygen required by oxygen supplementation; and the oxygen flow regulation module is connected with the oxygen supply, can be inserted into the entrance of the pump package of a condensed water pump, and is used for controlling the flow oxygenating to condensed water according to the dissolved oxygen content output by the oxygen content measurement module. The method and the device are used in the mode of water supply weak oxidizing treatment (or AVT(O)) of a high parameter machine set of a station so as to supply, regulate and control the dissolved oxygen of the condensed water and economizer supply water, which is in accordance with the requirements of weak oxidizing treatment. By the regulation and the design of oxygenating points and flow, the invention simplifies a system, increases the safe reliability of the system, stabilizes the oxygenation differential pressure and simplifies control.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

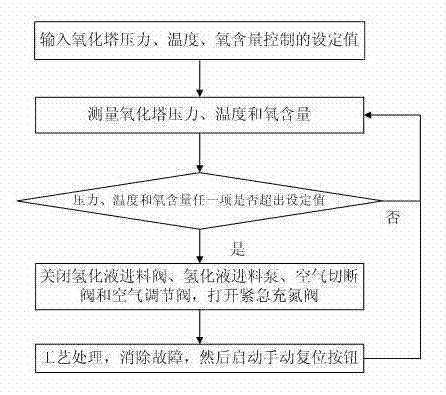

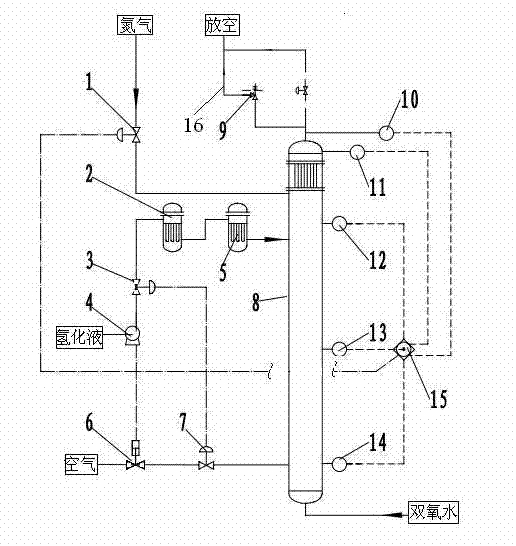

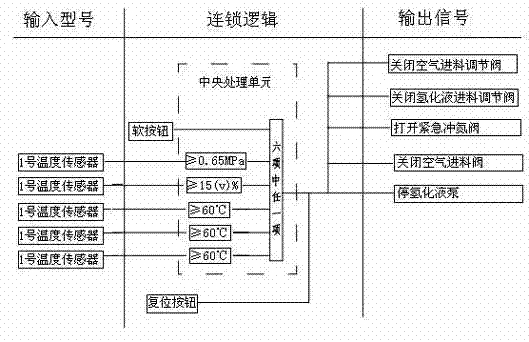

Safety interlock control method and system for slurry reactor hydrogen peroxide device oxidation tower

ActiveCN103677023AImprove securityReduce operational riskSimultaneous control of multiple variablesSlurry reactorAir conditioning

The invention relates to a safety interlock control method and system for a slurry reactor hydrogen peroxide device oxidation tower. The system is composed of a pressure sensor, an oxygen content sensor, a first temperature sensor, a second temperature sensor, a third temperature sensor, a hydrogenated liquid feed valve, a hydrogenated liquid feed pump, an air regulating valve, an air shut-off valve and an emergency nitrogen charging valve. The method includes the control steps that first, set control values are input through a central processing unit; second, instructions of the central processing unit are measured; third, whether pressure, temperature and oxygen content measurement values exceed the set values or not are detected, if the pressure, temperature and oxygen content measurement values exceed the set values, the fourth step is executed, and if not, the second step is executed again; fourth, the hydrogenated liquid feed valve, the hydrogenated liquid feed pump, the air shut-off valve and the air regulating valve are closed, and the emergency nitrogen charging valve is opened; fifth, process treatment is performed, faults are removed, a manual reset button is started, and the second step is executed again. With the method, interlocking among temperature, pressure and oxygen content measurement instruments, the hydrogenated liquid feed valve, an air valve and a nitrogen valve is achieved through the central processing unit, and production safety of hydrogen peroxide is improved.

Owner:河北都邦石化工程设计有限公司

Special transport box for living aquatic products and transport method

InactiveCN102084841AReduce contact densityAvoid mechanical damageClimate change adaptationPisciculture and aquariaTemperature controlAquatic product

The invention discloses a special transport box for living aquatic products and a transport method. The method is characterized in that: the living aquatic products are treated at a low temperature so that the living aquatic products are transported in a dormancy state, the temperature of the transport box adopted during transporting is regulated through a cold-hot exchanger, and the aquatic products are partitioned by using layered trays to reduce the contact density of the aquatic products and avoid mechanical injury. The transport box consists of a box body, a temperature detector, a temperature control electromagnetic valve, a heat exchange valve, a cold exchange valve, the cold-hot exchanger, the layered trays, tray pores, an oxygen content measurement instrument, an oxygen inlet, an air exhaust port, an air inlet, an air inlet electromagnetic valve, an exhaust port electromagnetic valve and an oxygen generator. After the aquatic products are transported to the site, the aquatic products are resuscitated by adding oxygen and fresh seawater. The transport box has the characteristics of reasonable design, high transport number, little mechanical injury of the aquatic products, high survival rate and low cost.

Owner:DALIAN BAIJIA TECH

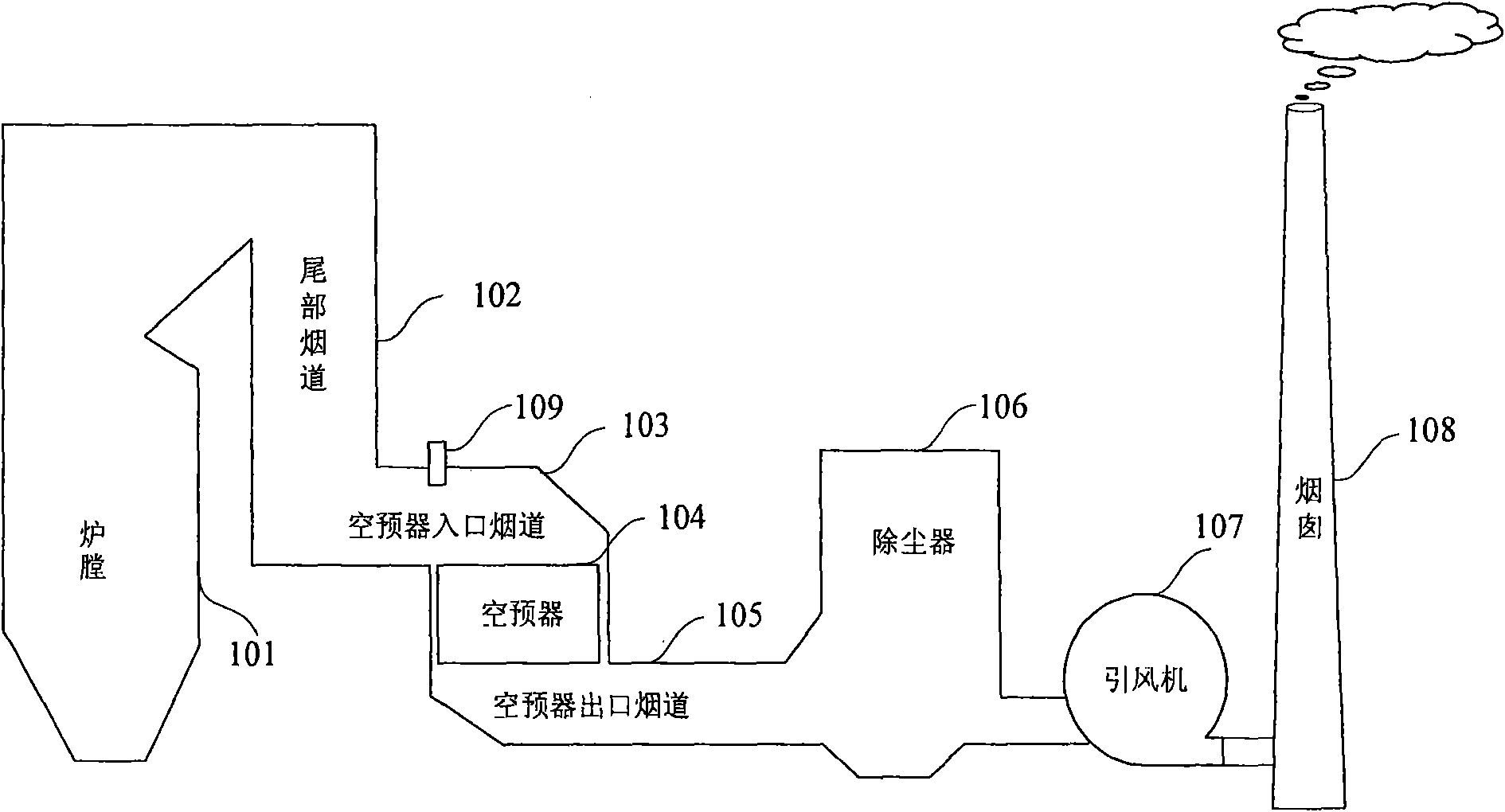

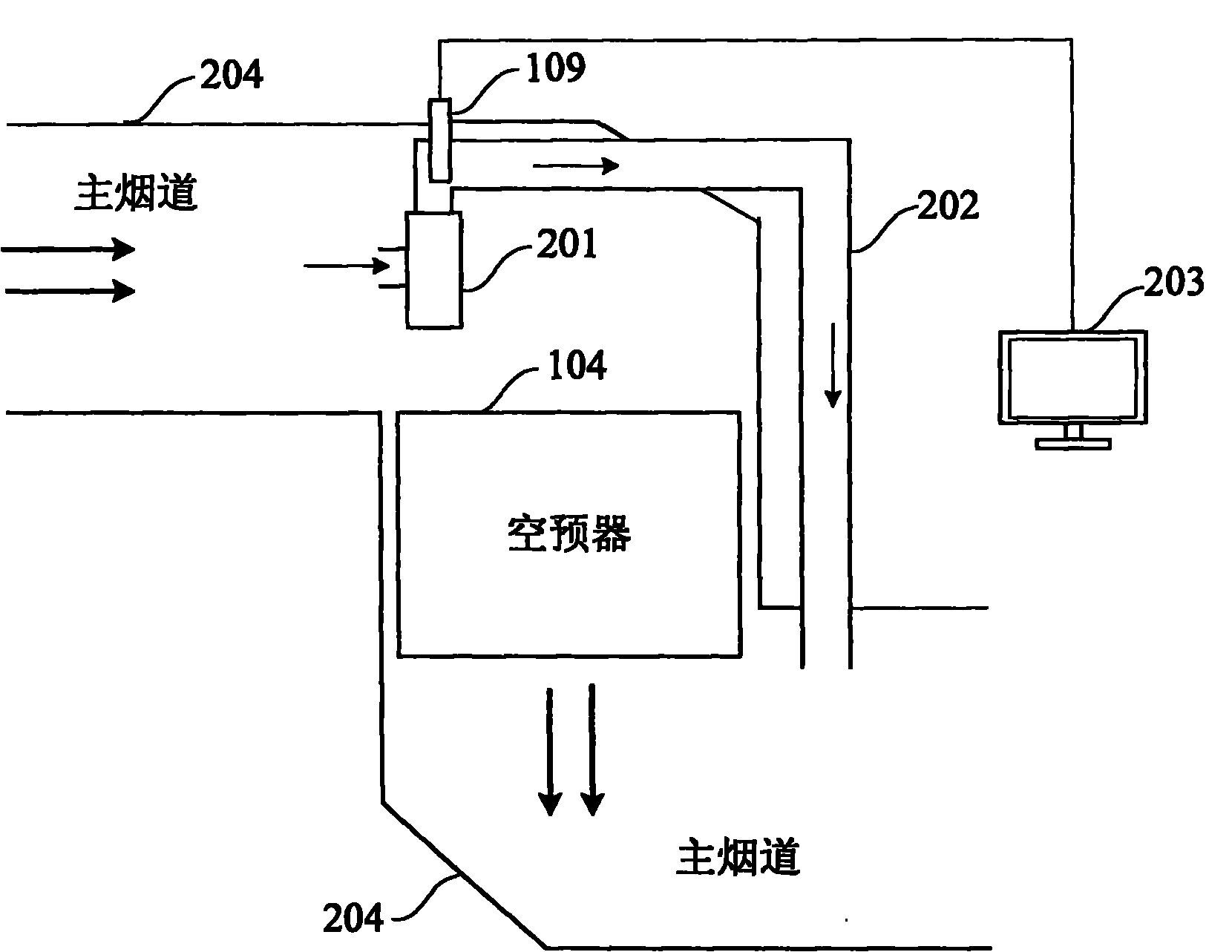

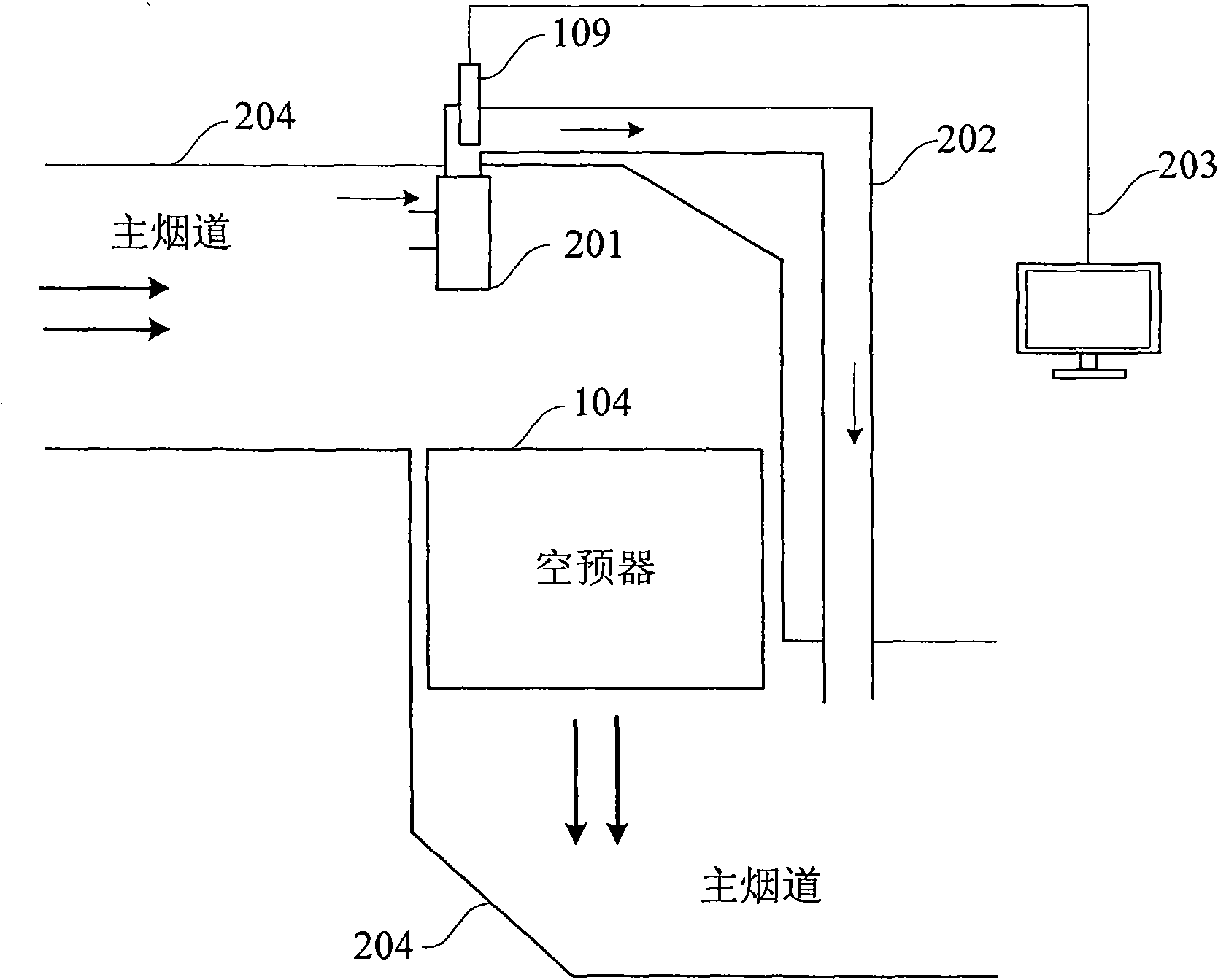

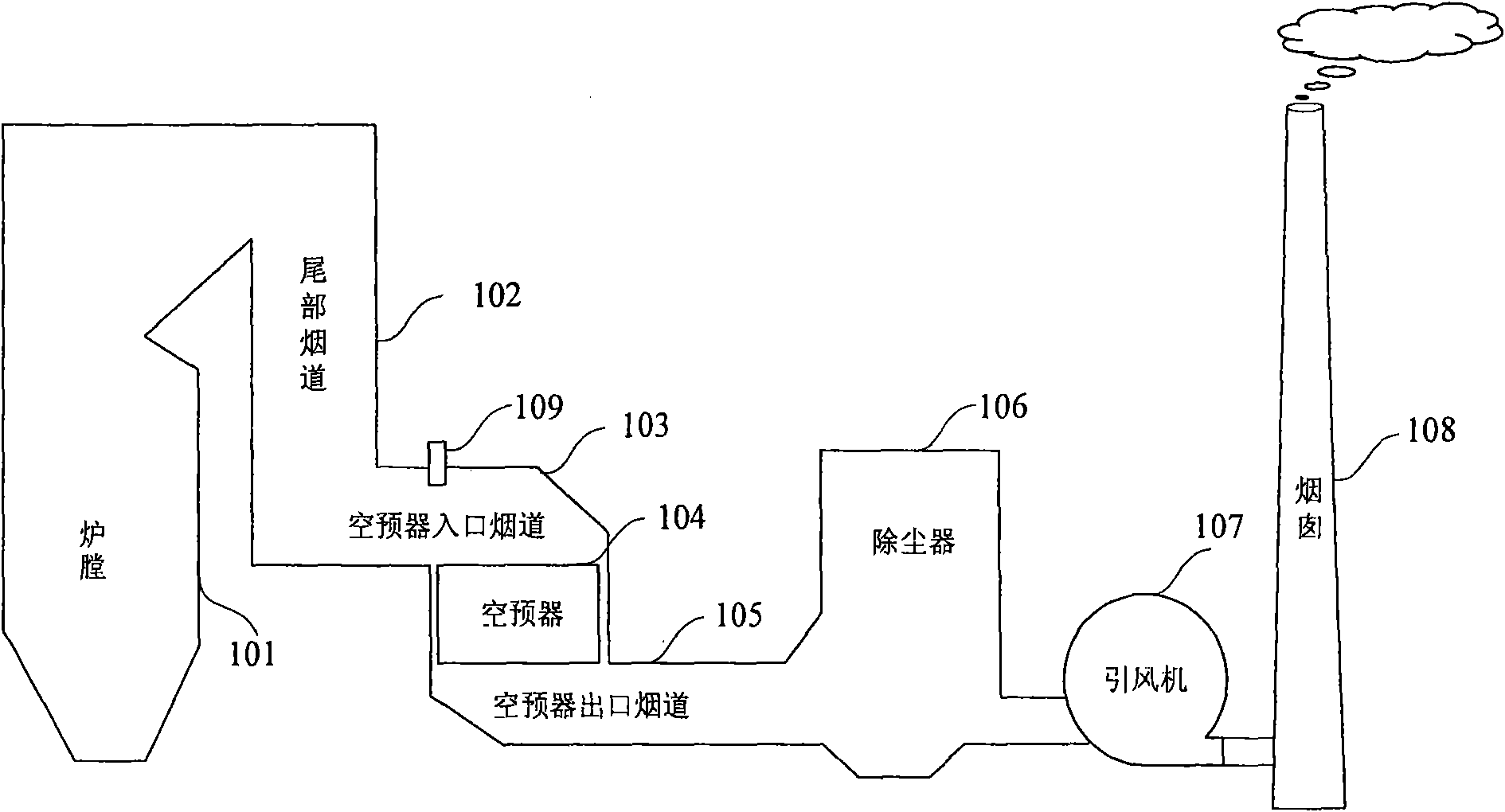

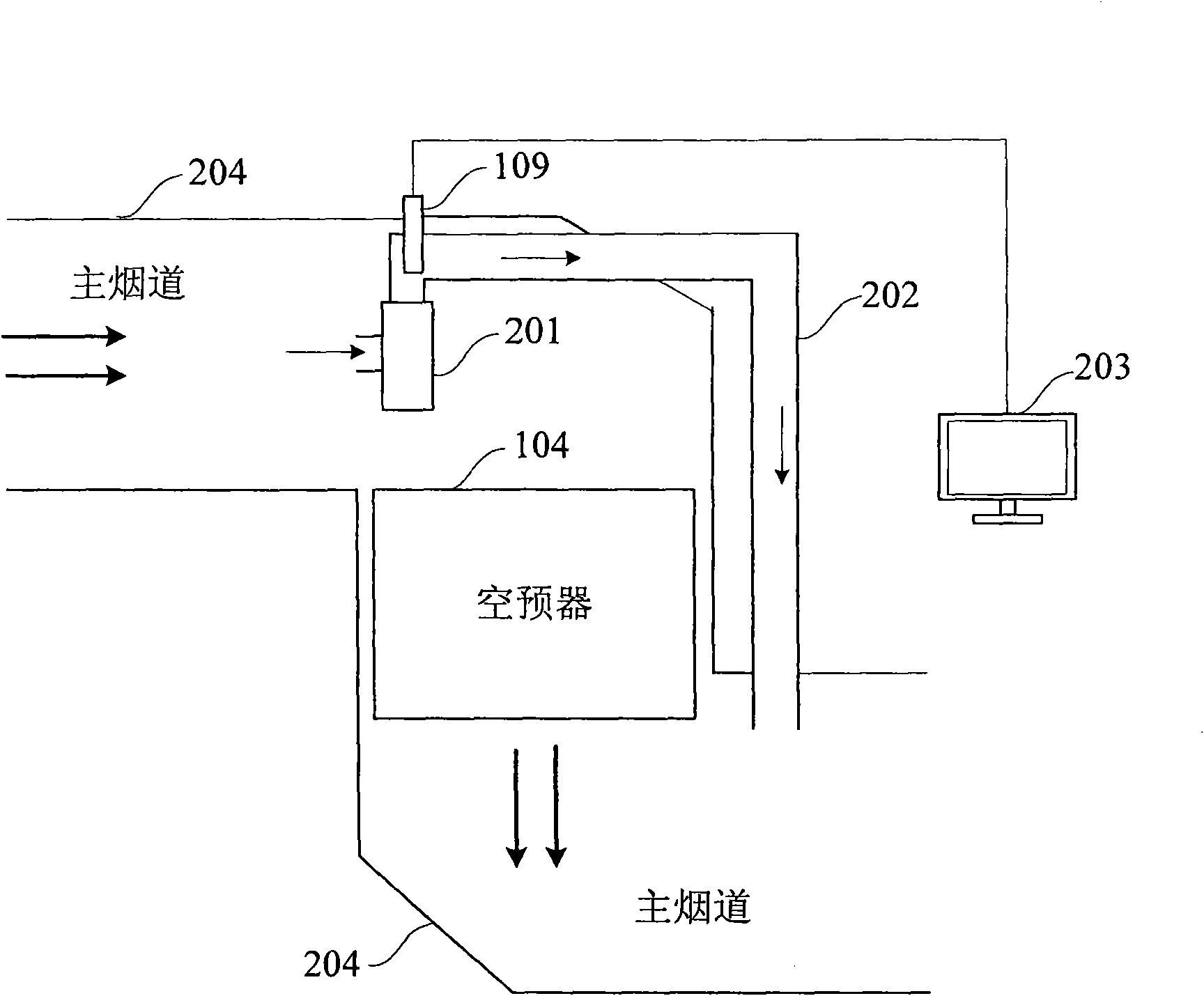

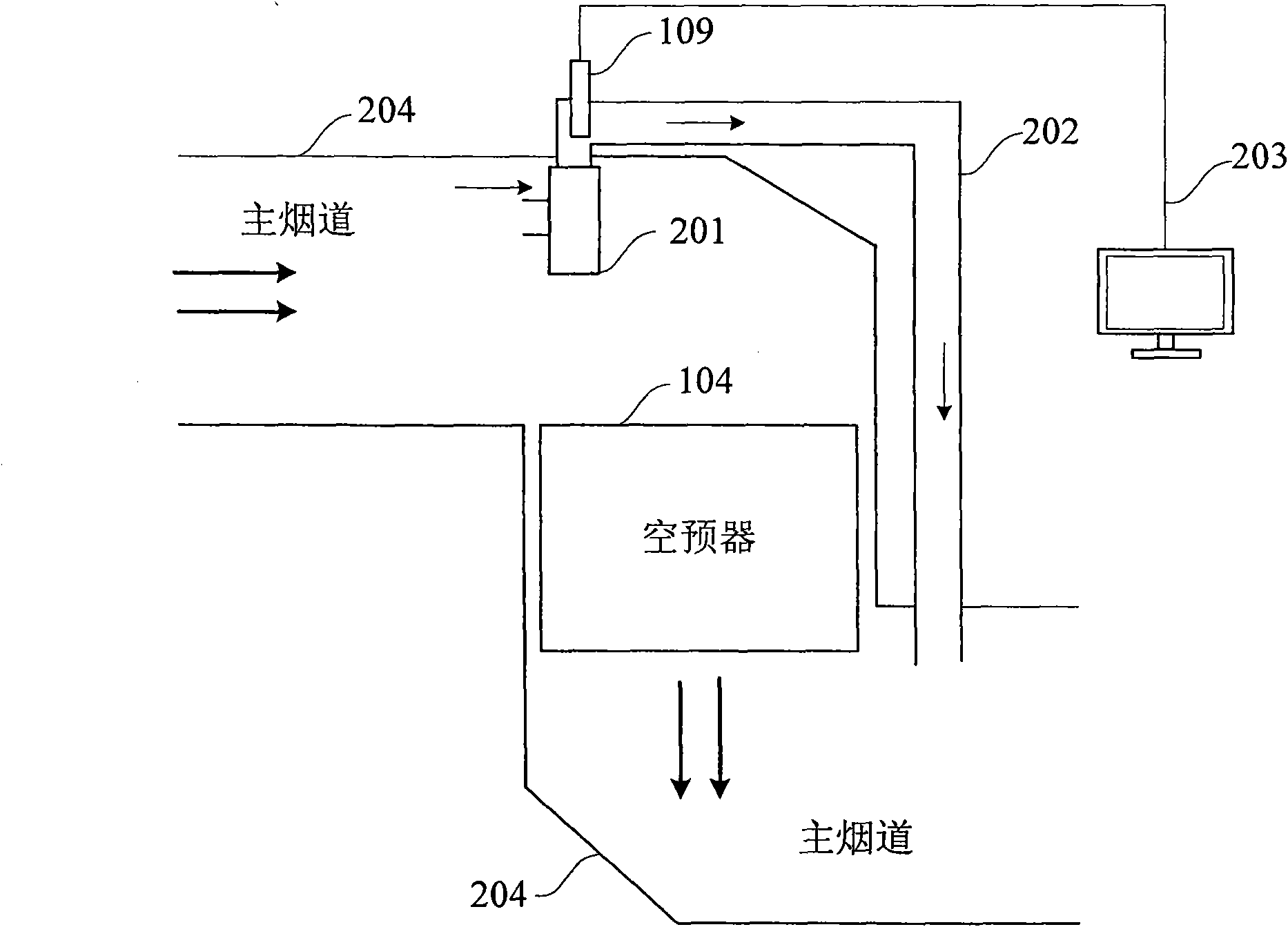

Smoke oxygen content measurement method and system

ActiveCN102095773AAvoid contaminationMeasure precise measurePreparing sample for investigationMaterial analysis by electric/magnetic meansAir preheaterEngineering

The invention provides a smoke oxygen content measurement method and system. The system comprises a main flue, an air preheater, a dust collector, a bypass flue and an oxygen content measurement device, wherein the air preheater is arranged in the main flue; the dust collector is used for collecting smoke to be tested from the main flue at the front end of the air preheater and carrying out dust removal treatment on the smoke to be tested; the bypass flue is used for sending the smoke to be tested, subjected to the dust removal treatment by the dust collector, to the main flue at the rear endof the air preheater; and the oxygen content measurement device is used for detecting the oxygen content of the smoke to be tested in the bypass flue and outputting detected oxygen content data. Based on the technical scheme of the invention, a zirconium oxide probe can be prevented from being contaminated by dust, and the smoke oxygen content can be accurately measured.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

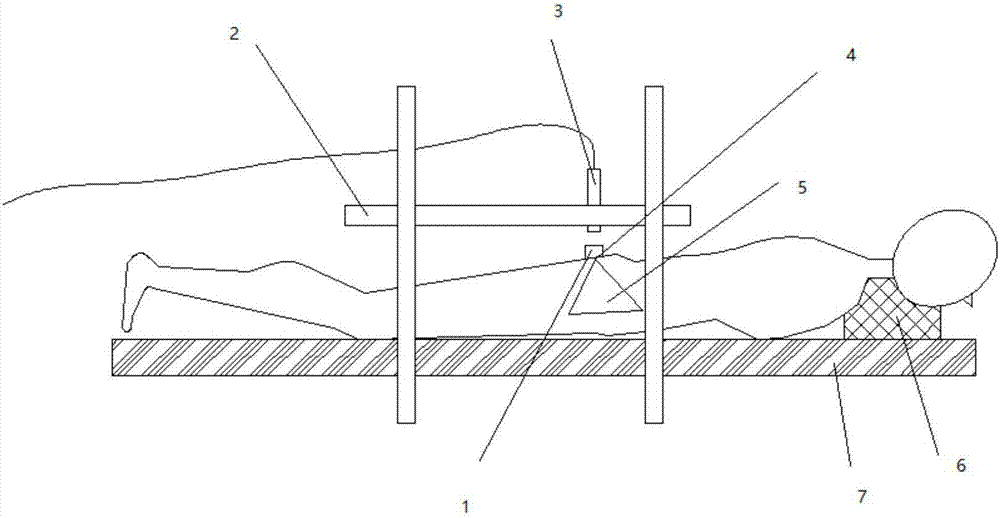

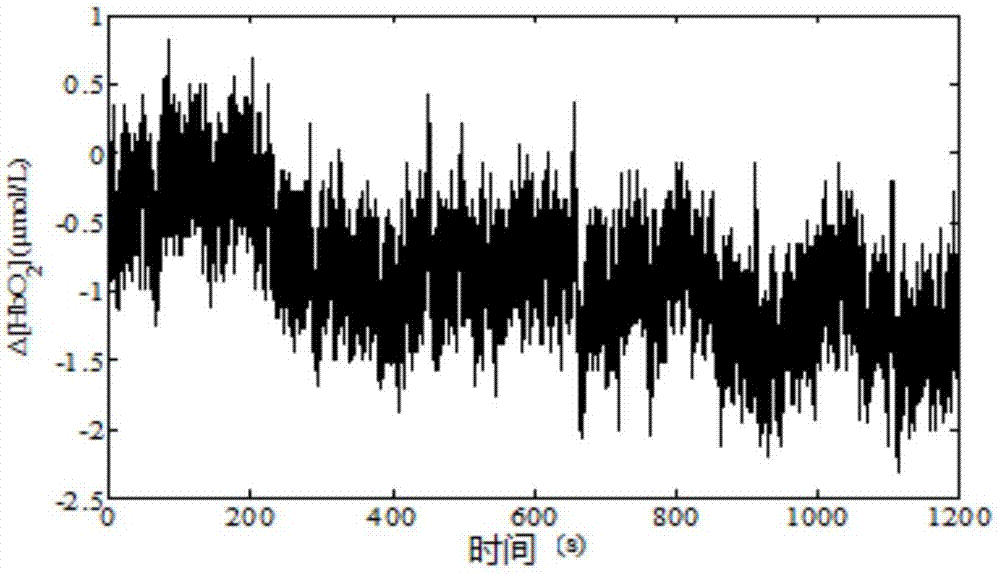

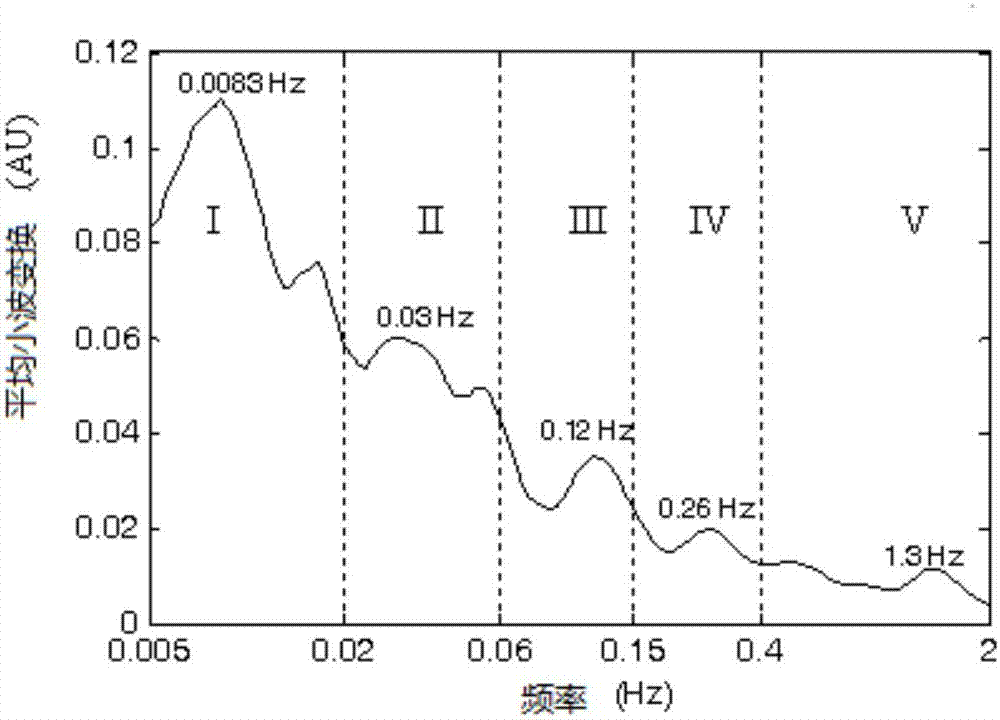

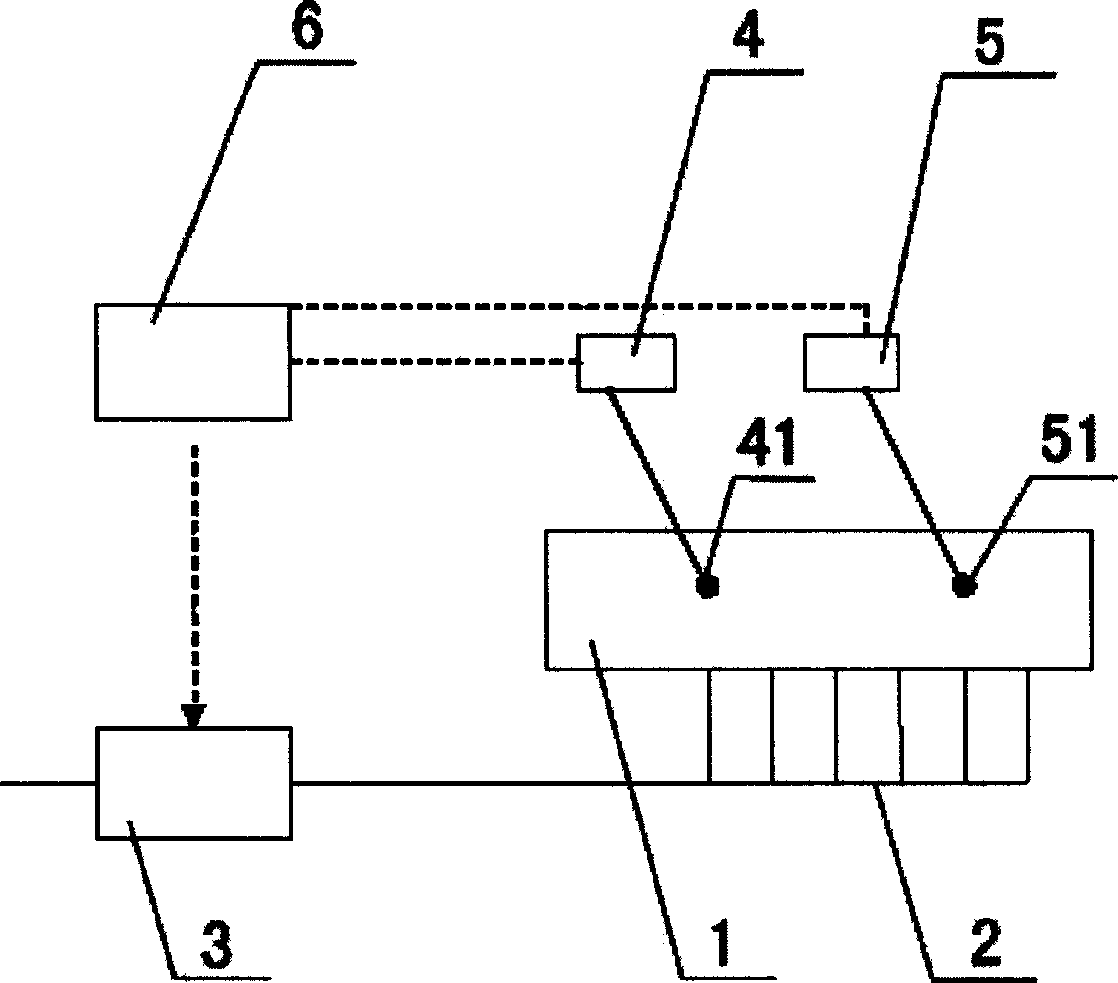

Pressure sore risk assessment method and system based on near-infrared spectrum muscle oxygen content measurement

InactiveCN107280682AImprove portabilityEasy to monitor in real timeDiagnostic recording/measuringSensorsPressure sore riskPressure ulcer risk evaluation

Provided is a pressure sore risk assessment method and system based on near-infrared spectrum muscle oxygen content measurement. The method includes the steps of (1) in a resting state, monitoring the muscle oxygen parameter content of a pressure sore risk area; (2) applying 10-30 kPa of pressure for 1-10 minutes to the pressure sore risk area; (3) after pressure interruption, measuring the muscle oxygen parameter content of the pressure sore area for 5-15 minutes; (4) processing the muscle oxygen parameter content signals collected by step (1) and (3) to show the risk probability of the occurrence of pressure sores. According to the pressure sore risk assessment method and system, the muscle oxygen content can be non-invasively detected, and the equipment has good portability, which facilitates real-time monitoring.

Owner:国家康复辅具研究中心

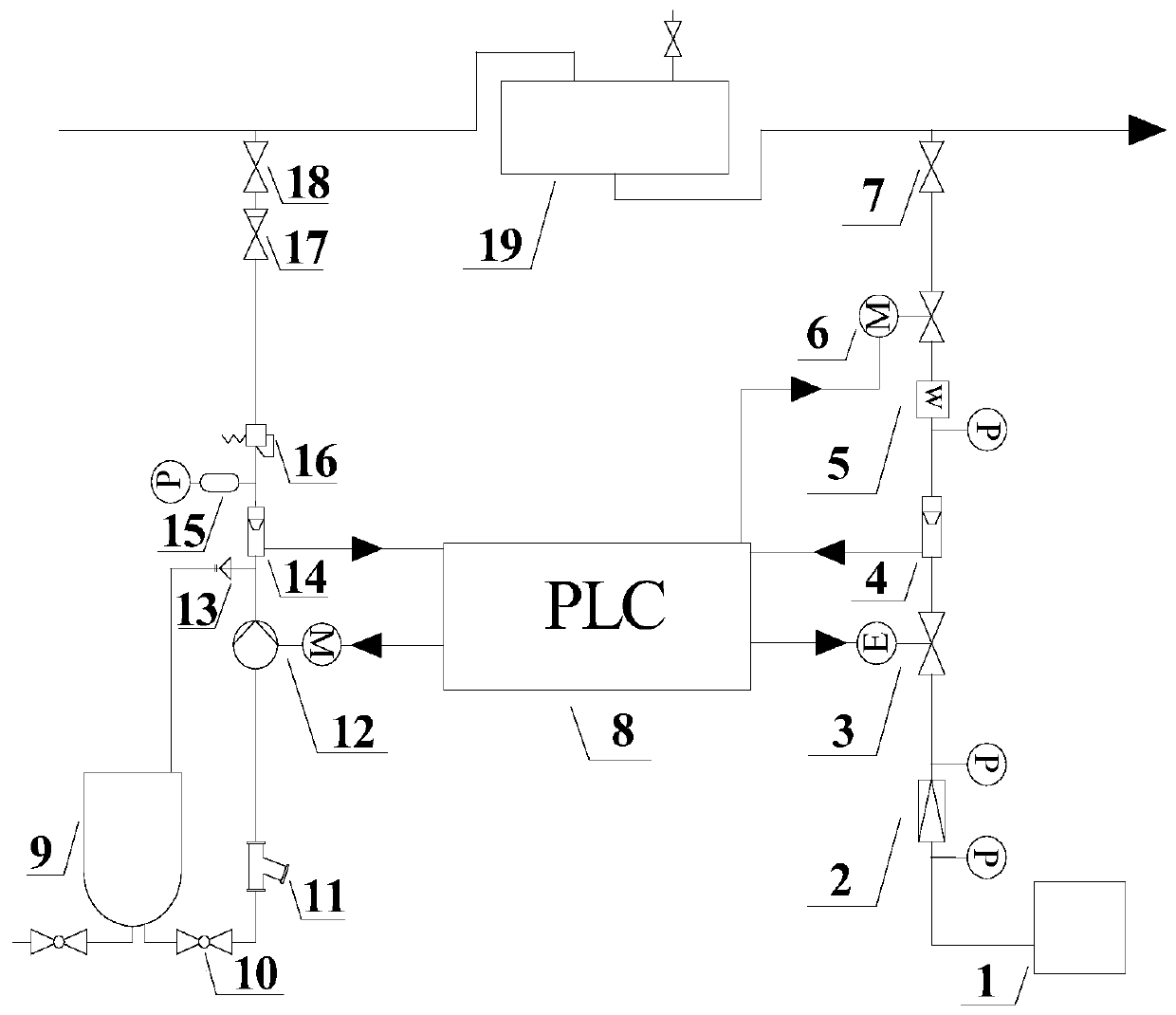

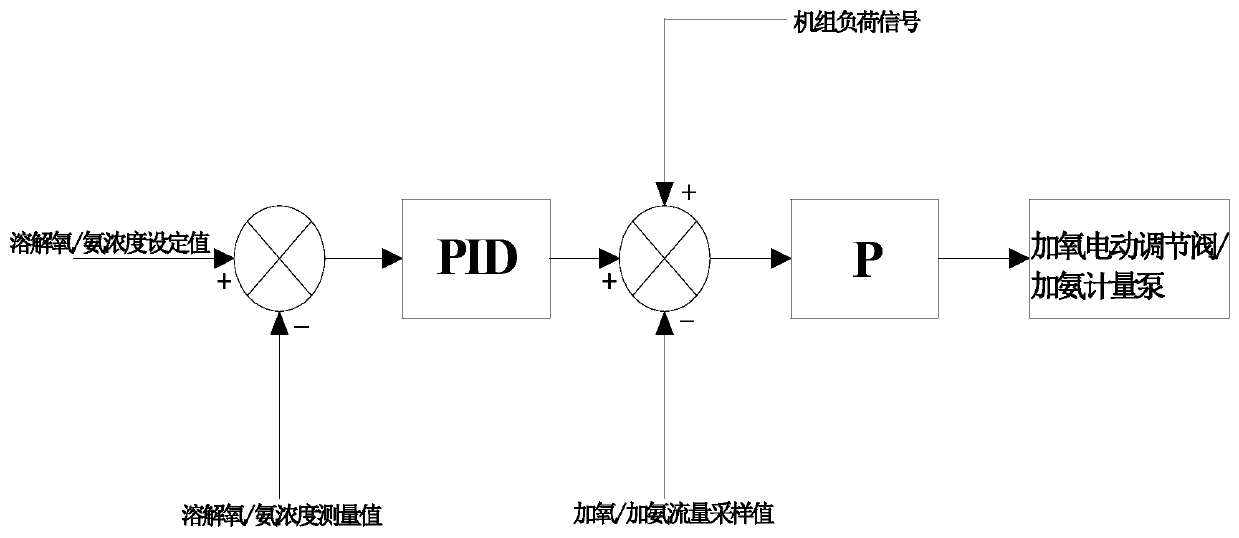

Synergistic precise control device and method for automatic oxygen addition and ammonia addition for water supply in power plant

ActiveCN110217900AGuaranteed safe operationAvoid corrosionWater treatment parameter controlTreatment using complexing/solubilising chemicalsPower stationHydrogen

A synergistic precise control device and method for automatic oxygen addition and ammonia addition for water supply in a power plant are disclosed. The device includes an automatic oxygen addition andammonia addition synergistic controller, a fed water oxygen addition system and a condensed water ammonia addition system, and mainly includes a PLC automatic oxygen addition and ammonia addition synergistic controller, an oxygen addition pressure reducing valve, an oxygen addition electromagnetic regulating valve, an oxygen addition pressure stabilizer, an ammonia addition metering pump, and other components. A fed water hydrogen conductivity signal is inputted to the PLC automatic oxygen addition and ammonia addition synergistic controller; when the fed water hydrogen conductivity is less than 0.15 [mu]S / cm, the appropriate oxygen amount and ammonia amount are controlled; when the fed water hydrogen conductivity is higher than 0.15 [mu]S / cm, an oxygen addition electric turn-off valve isturned off to stop oxygen addition and the ammonia amount is properly increased. Feedforward PID regulation is performed on oxygen addition according to a result of comparing a measured value of thedissolved oxygen content in fed water with a set value of the dissolved oxygen content by adopting a unit load as feedforward, thus achieving precise oxygen addition control. Feedforward PID regulation is performed on ammonia addition according to a result of comparing a measured value of conductivity of a deaerator inlet with a set value of the conductivity by adopting a unit load as feedforward,thus achieving precise ammonia addition control.

Owner:XIAN THERMAL POWER RES INST CO LTD

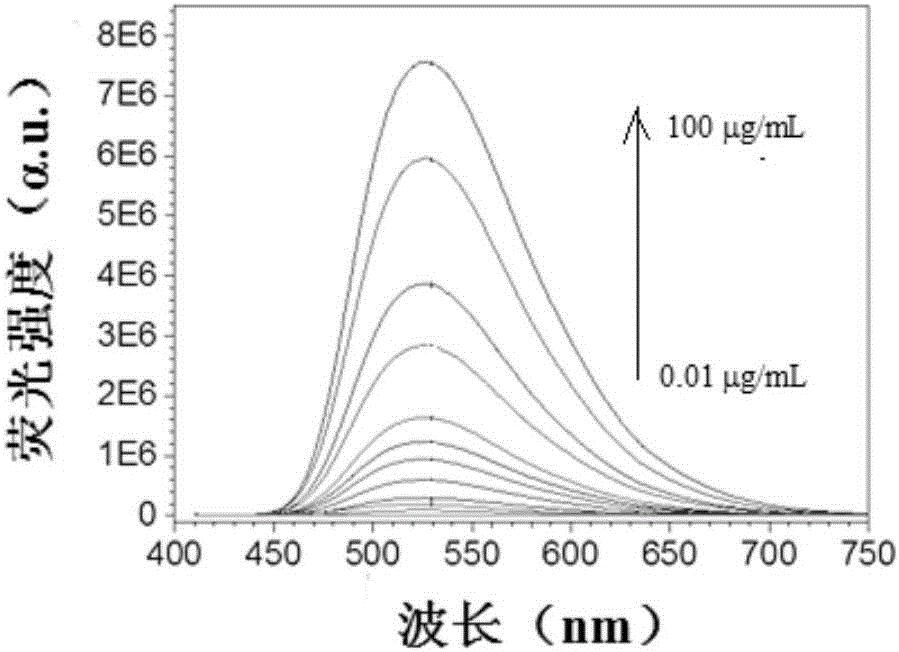

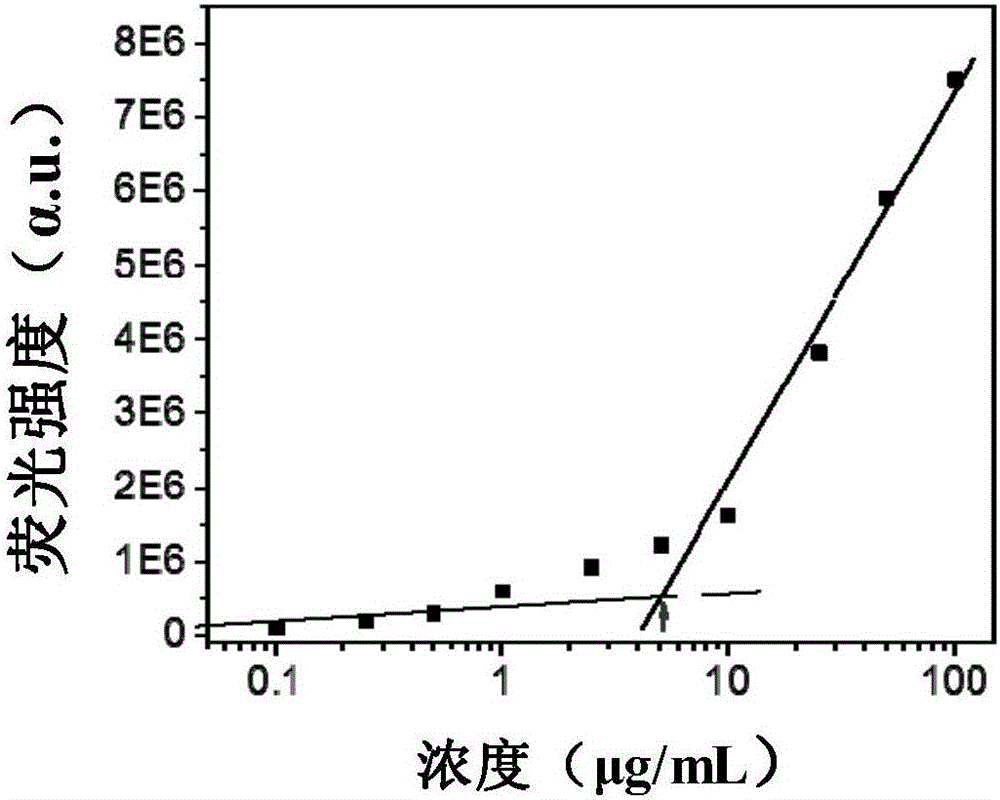

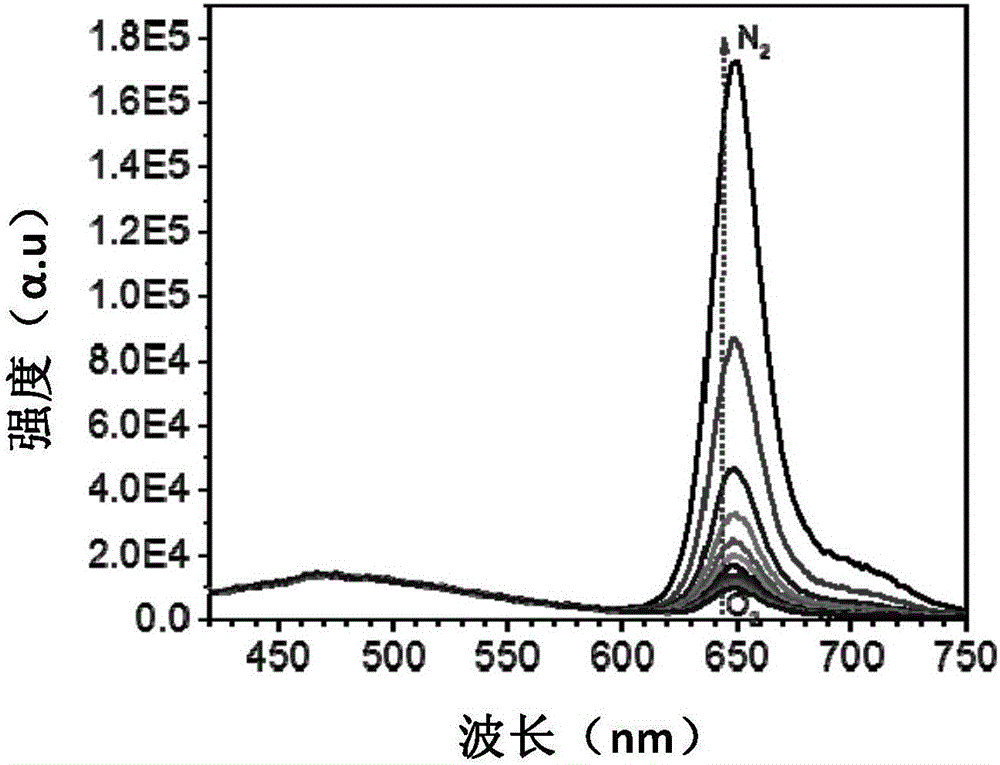

Extracellular ratio-type oxygen sensing probe, and preparation method and applications thereof

ActiveCN106634965AHigh Oxygen Sensing EfficiencyHigh fluorescence intensityFluorescence/phosphorescenceLuminescent compositionsEscherichia coliDisease

The invention provides an extracellular ratio-type oxygen sensing probe, and a preparation method and applications thereof. The ratio-type oxygen sensing probe comprises a carrier and an oxygen sensitive compound, which is wrapped in the carrier. The carrier is composed of an amphiphilic graft polymer and aggregation-induced luminous groups connected to the amphiphilic graft polymer. The provided ratio-type oxygen sensing probe can measure the oxygen consumption amounts of escherichia coli and GM12878 human B lymphocyte under different cell concentrations; at the same time, can in-situ measure at least 100 cfu / mL of cells within 7 hours, can also applied to drug screening, does not have any cytotoxicity, and is safe and reliable. Furthermore, due to the extremely high quantum efficiency of PtTFPP probe micelles, the oxygen sensing probe can be used to measure the oxygen content of water solution; and the probe can be widely applied to commercial instruments such as ELISA reader, and assists the high throughput measurement, disease diagnosis, metabolism research, and the like.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

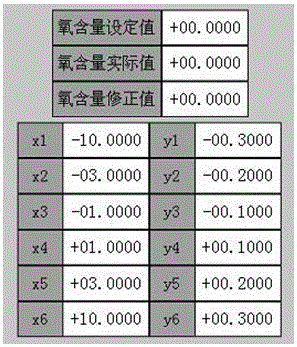

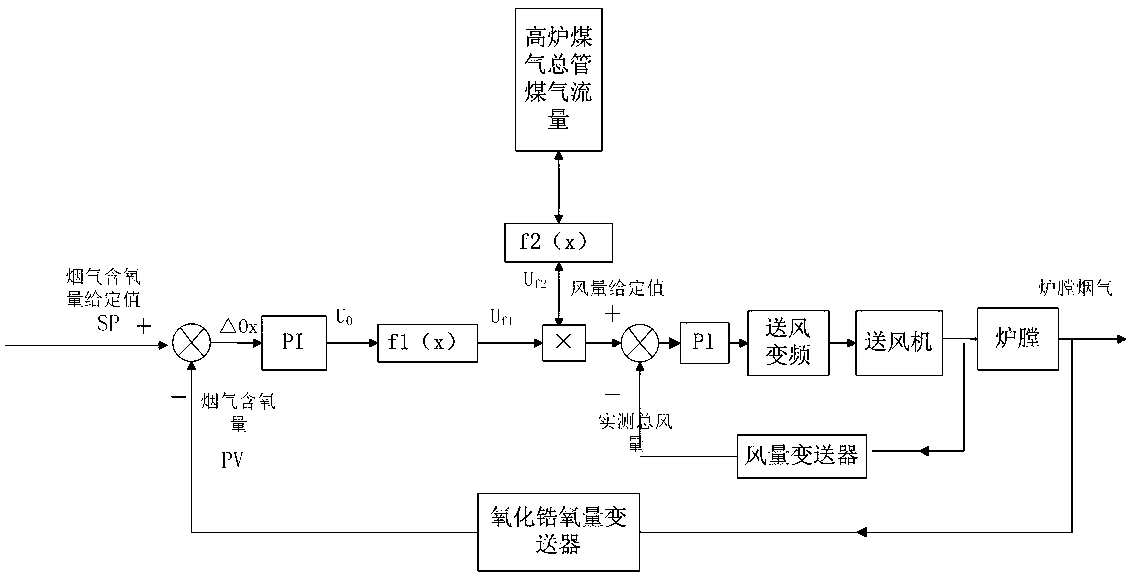

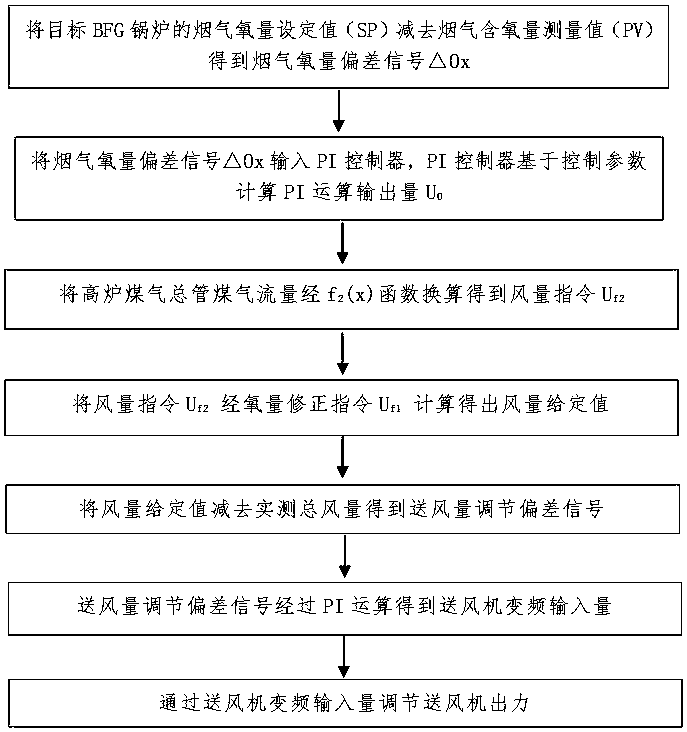

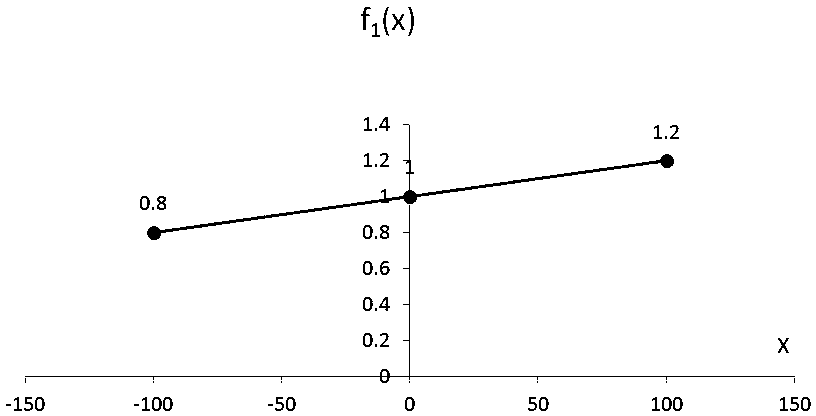

BFG boiler air supply optimization control method

InactiveCN110145760ASuppress occasional interferenceSuppress internal disturbanceCombustion regulation systemsAir volumeStreamflow

The invention relates to a BFG boiler air supply optimization control method. The BFG boiler air supply optimization control method comprises the following steps that a flue gas oxygen content settingvalue of a target BFG boiler subtracts a flue gas oxygen content measurement value to obtain a flue gas oxygen amount deviation signal; the flue gas oxygen amount deviation signal is input into a PIcontroller, and the PI controller calculates the PI operation output amount based on control parameters; an air volume command is obtained through conversion of the blast furnace coal gas header coalgas flow rate; the air volume command is calculated through an oxygen amount correction command to obtain an air volume given value; the air volume given valve subtracts the actual measurement total air volume to obtain an air supply volume adjustment deviation signal; the air supply volume adjustment deviation signal is subjected to PI operation to obtain the blower variable frequency input quantity; and the blower variable frequency input quantity is used for adjusting the blower output. The BFG boiler air supply optimization control method enables air supply frequency conversion control torespond to the flue gas oxygen content deviation change to conduct continuous adjustment, quick response to the amount of the fuel quantity can be achieved, boiler combustion is stabilized, the systeminternal disturbance is suppressed, and the operational stability of a generator set is improved.

Owner:JIANGSU FRONTIER ELECTRIC TECH

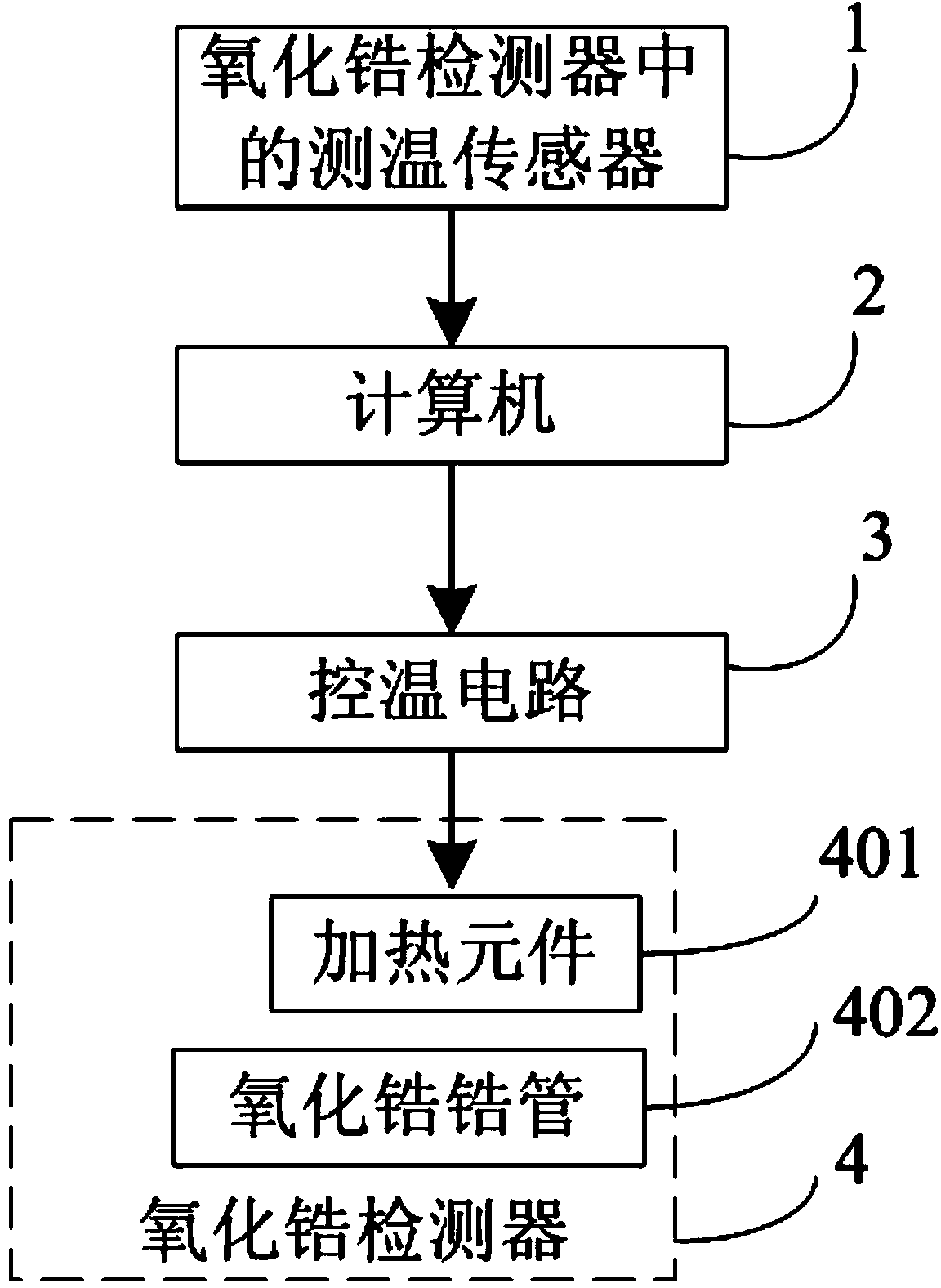

Oxygen content measurement device and oxygen content measurement method for zirconium oxide

InactiveCN103808784AHigh measurement accuracyExtended service lifeMaterial analysis by electric/magnetic meansWorking temperatureOperating temperature range

The invention discloses an oxygen content measurement device and an oxygen content measurement method for zirconium oxide. The oxygen content measurement device for zirconium oxide comprises a temperature measurement sensor, a computer, a temperature control circuit and an zirconium oxide detector which are connected with one another in sequence, wherein the temperature measurement sensor is arranged in the zirconium oxide detector. According to the oxygen content measurement method for the zirconium oxide, the zirconium oxide detector works within a stable working temperature range by a fuzzy control method and then outputs oxygen potential and a temperature value of gas to be detected; the oxygen concentration of the gas to be detected by the zirconium oxide detector is calculated through a transformation formula of a nernst formula. The oxygen content measurement device and the oxygen content measurement method have the beneficial effects that the fuzzy control method replaces the conventional PID (proportion, integration and differentiation) temperature control method, so that the problem that the oxygen concentration of the detected gas, which is measured by an instrument, is inaccurate due to the influence on a control result of a PID temperature control algorithm, caused by the change of an environment factor of an object characteristic of an electric heating furnace of the conventional oxygen concentration instrument for the zirconium oxide, is solved; the measurement precision of the zirconium oxide instrument is improved, and the service life of the zirconium oxide instrument is prolonged.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

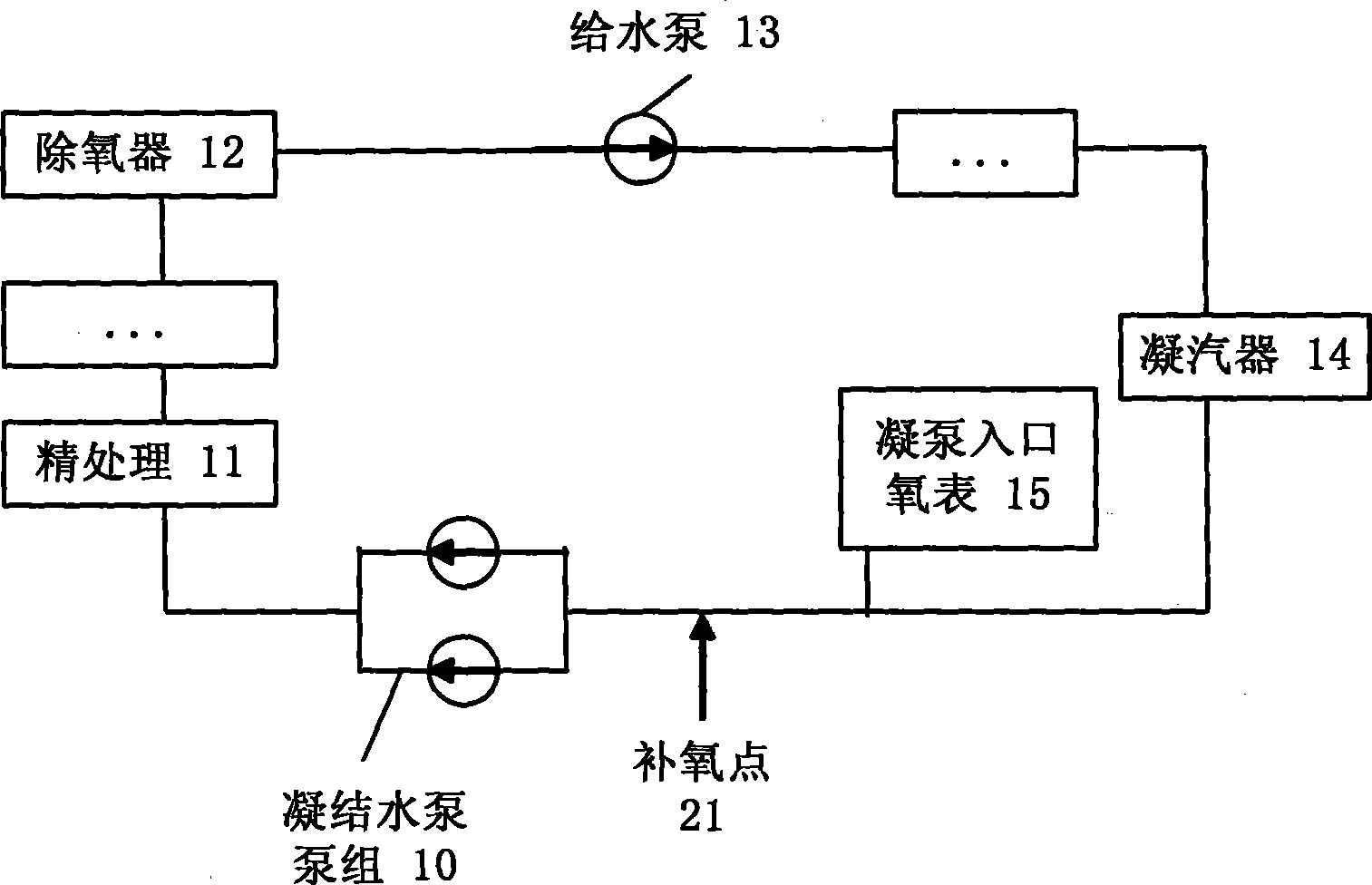

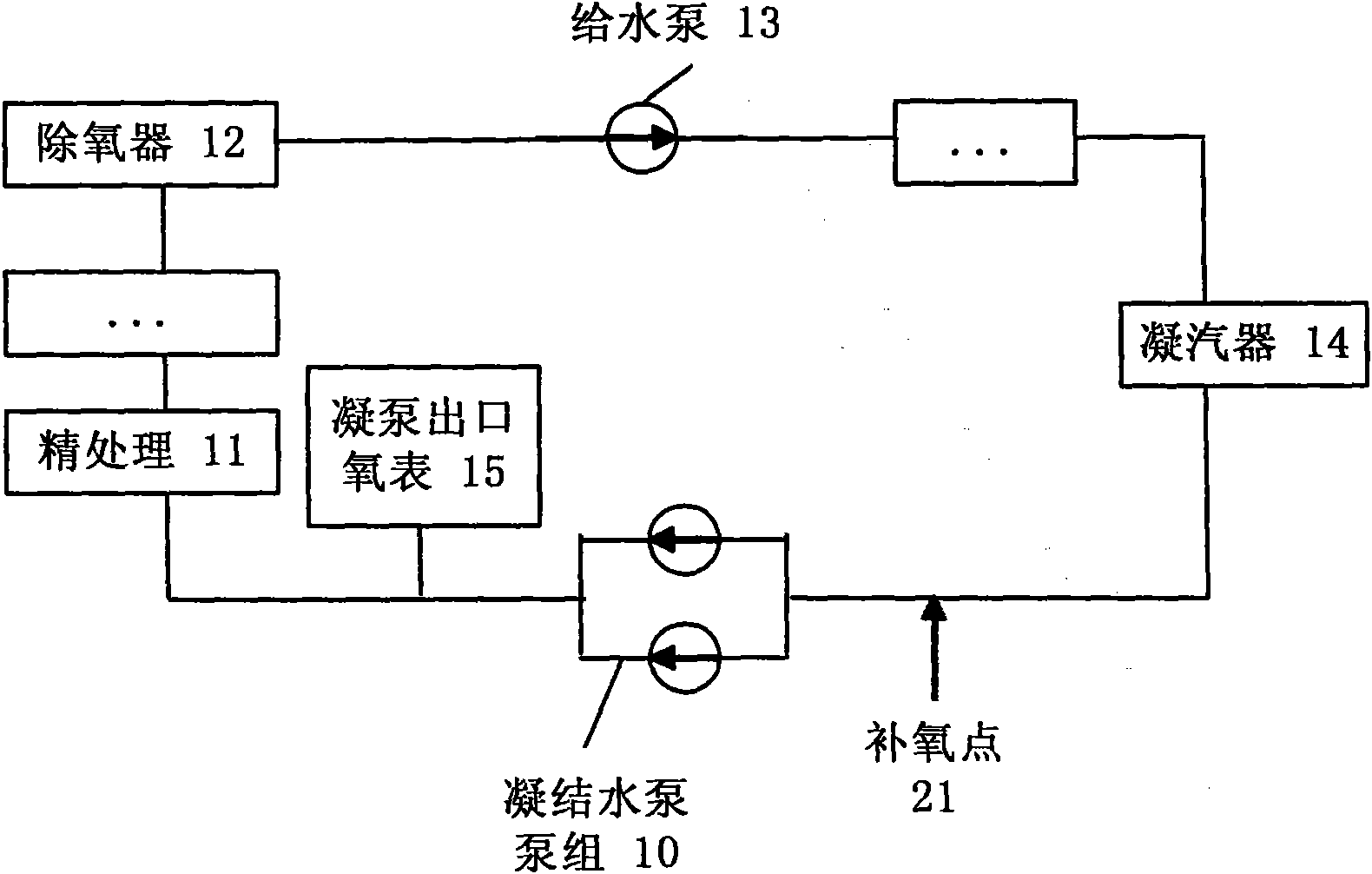

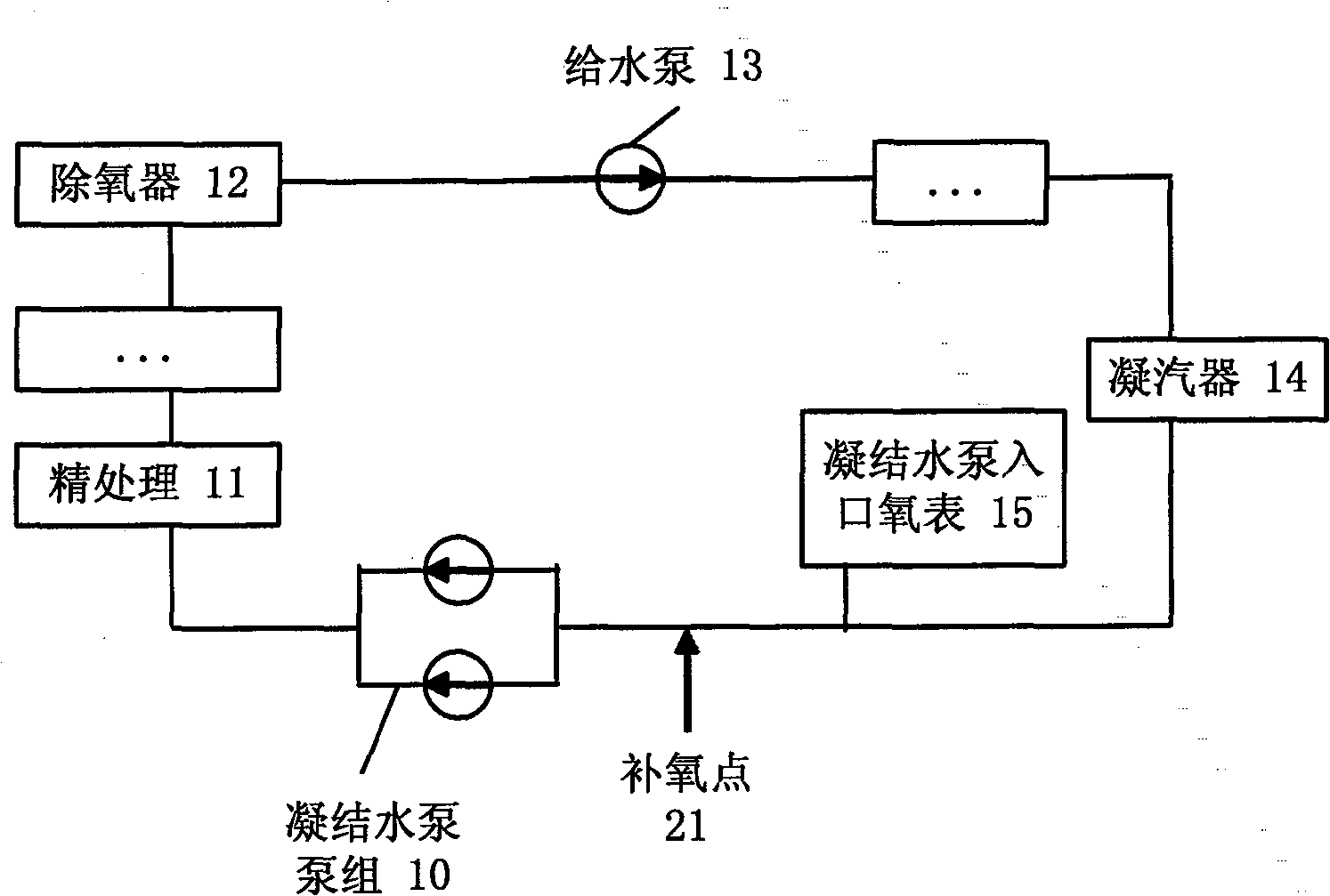

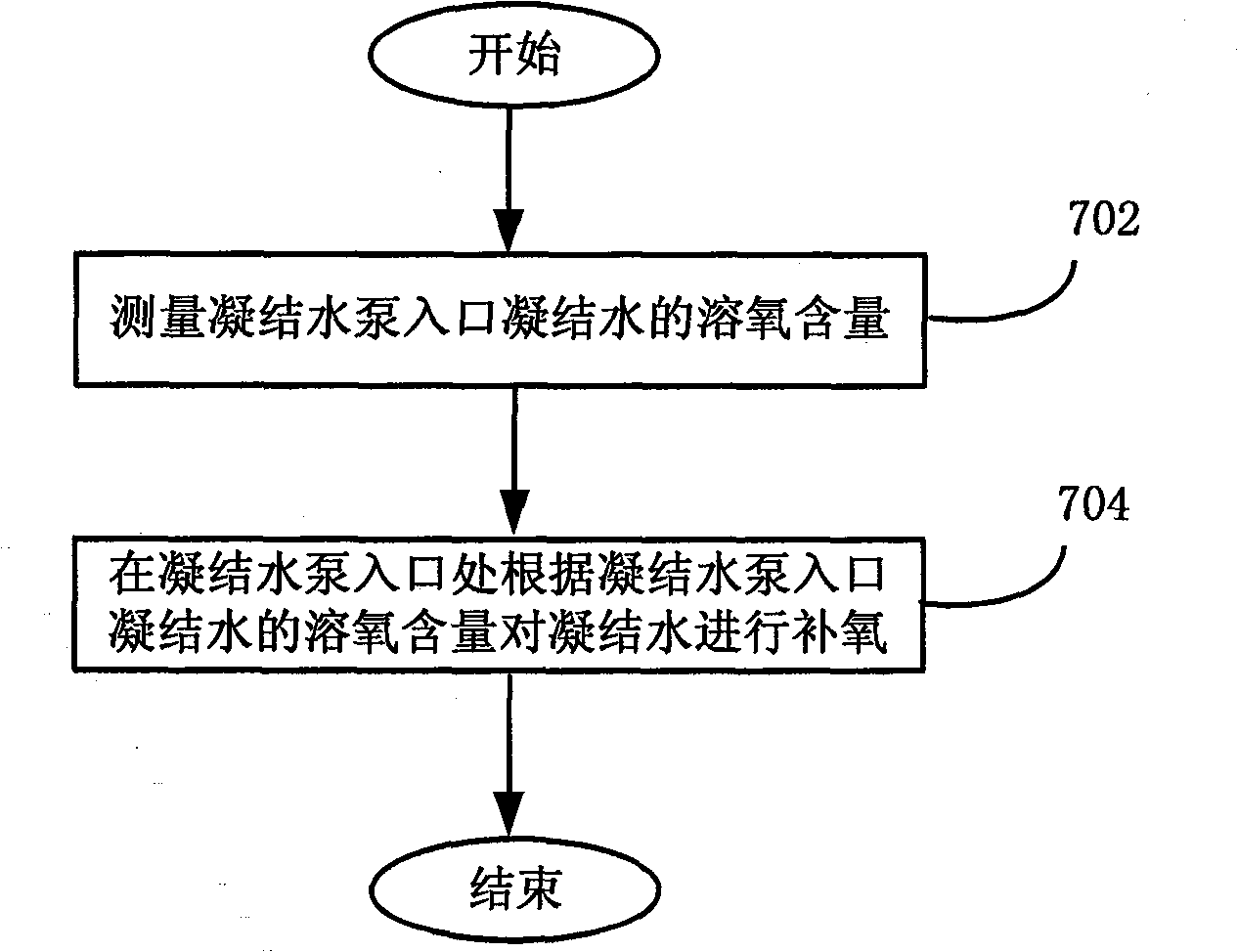

Power station boiler and water-supply oxygen supplementing device and method thereof

InactiveCN101830526AImprove securityWater/sewage treatment by substance additionPower stationPressure difference

The invention discloses a power station boiler and water-supply oxygen supplementing device and method thereof. The water-supply oxygen supplementing device comprises an oxygen content measuring module, an oxygen source and an oxygen flow regulating module, wherein the oxygen content measuring module is used for measuring the dissolved oxygen content of condensation water positioned on an outlet of a condensation water pump set of the power station boiler; the oxygen source is used for supplying oxygen needed by oxygen supplementation; and the oxygen flow regulating module is connected with the oxygen source, can be connected with an inlet of the condensation water pump set, and is used for controlling the oxygen supplementing flow of the condensation water according to the dissolved oxygen content output by the oxygen content measuring module. The condensation water constant-pressure oxygen supplementing device and method of the power station boiler are used for a water-supply weak oxidation treatment mode of a high-parameter set of a power plant and supplementing, regulating and controlling the dissolved oxygen of the condensation water and economizer supplying water and accords with the requirements for weak oxidation treatment (WOT). The invention simplifies a system and enhances the safety and the reliability of the system through oxygen supplementing point and flow regulation design, stabilizes the oxygen supplementing pressure difference, and simplifies the control.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

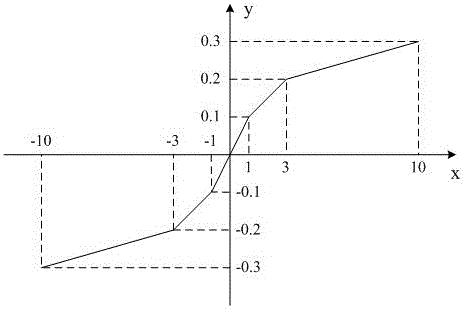

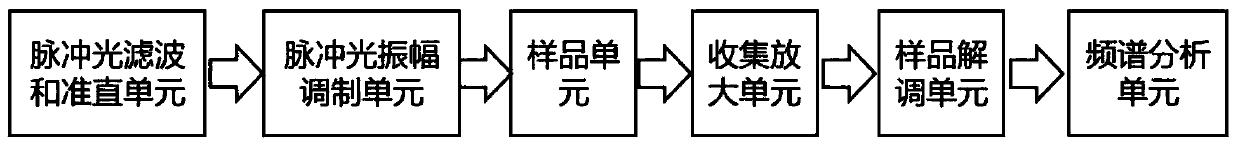

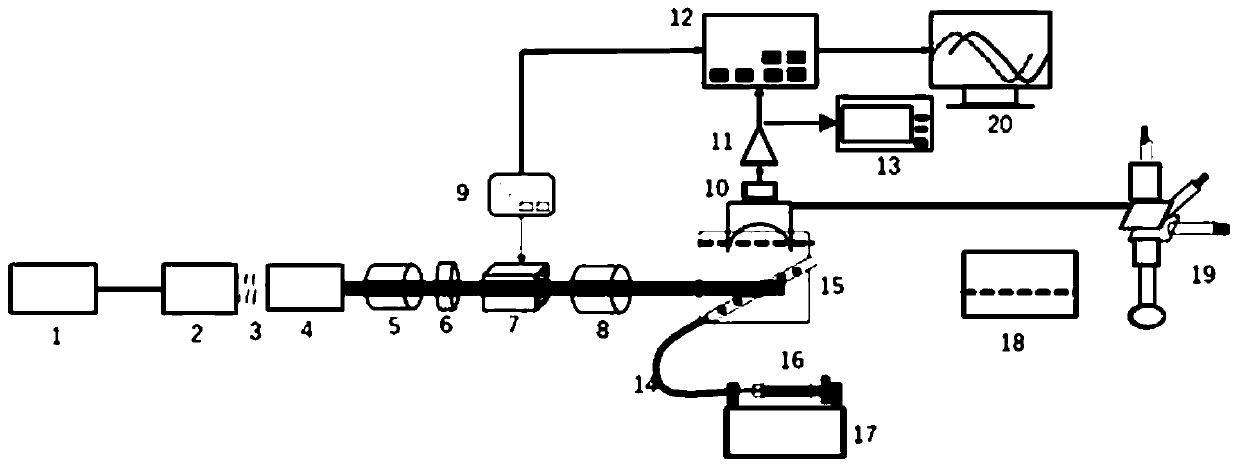

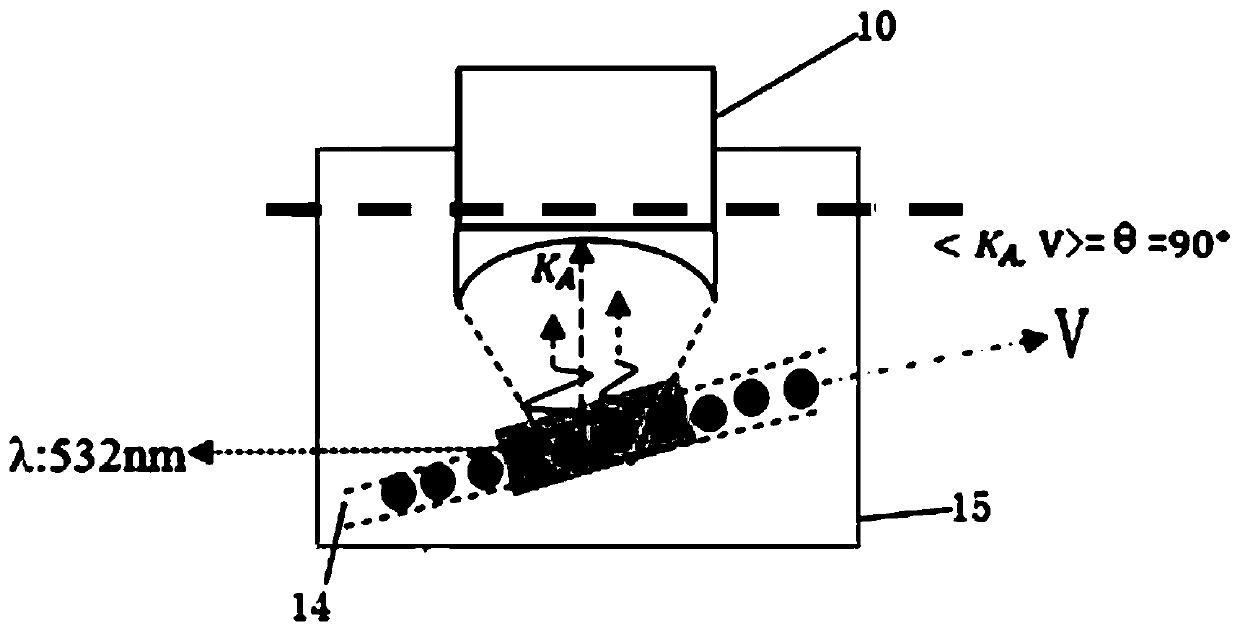

Photoacoustic Doppler blood flow velocity and blood oxygen content measuring system and measuring method

PendingCN111297346AEnhanced light absorptionHigh light absorption coefficientMeasurement devicesSensorsMaterials scienceDoppler flow

The invention discloses a photoacoustic Doppler blood flow velocity and blood oxygen content measuring system. The system comprises a pulsed light filtering and collimating unit, a pulsed laser amplitude modulation unit, a sample unit, a collecting and amplifying unit, a signal demodulation unit and a spectrum analysis unit. The invention further discloses a measuring method adopting the measuringsystem. The photoacoustic Doppler blood flow velocity and blood oxygen content measuring system and the measuring method have the advantages of being high in measuring precision, large in measurableflow velocity range, large in measurable depth, small in spectrum broadening, high in spectrum resolution, large in wavelength selection range, high in detection bandwidth and high in system sensitivity.

Owner:SHENZHEN UNIV

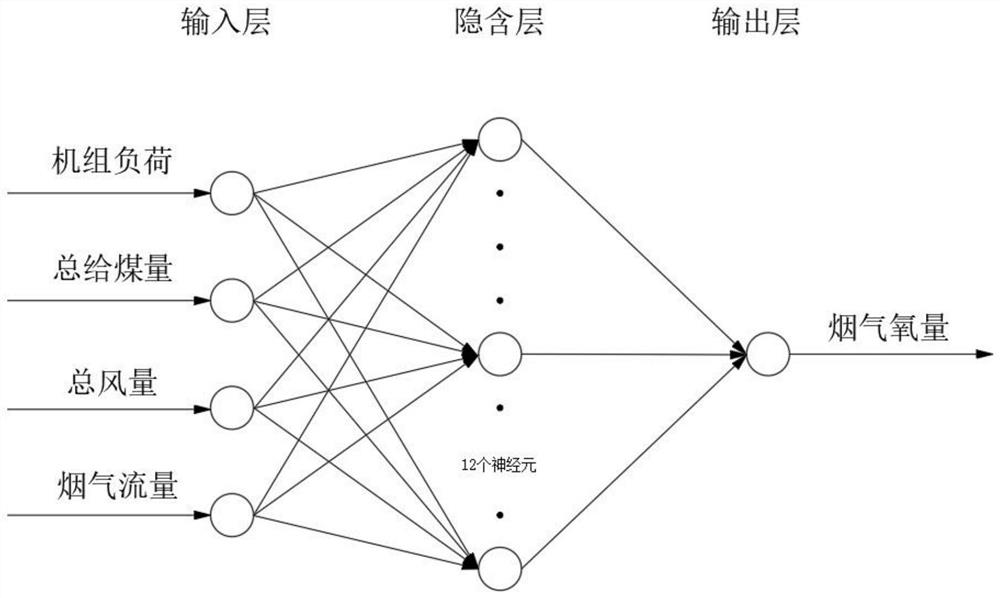

Oxygen content prediction method based on real-time measurement data

PendingCN114187976AAccurately reflect the oxygen content of flue gasAccurate predictionMolecular entity identificationForecastingAir volumeSimulation

The invention discloses an oxygen content prediction method based on real-time measurement data. The oxygen content prediction method comprises the following steps: (1) additionally arranging a grid multi-point oxygen content measurement device behind a flue in-situ oxygen content measurement point; (2) collecting operation data of the power station boiler; (3) extracting a part of data as a training sample of the artificial neural network, and taking the remaining data as a verification sample; (4) the prediction time advance is set to be t0, and training is carried out with the unit loads, the total coal feeding amount, the total air volume and the flue gas flow sample data at the multiple different moments t as input and the grid multi-point oxygen amount sample data at the moment t + t0 as prediction output; (5) testing the trained artificial neural network through a verification sample; and (6) embedding the verified artificial neural network serving as an oxygen compensation prediction model into a measurement system to be responsible for oxygen prediction. The method has the advantages of accuracy of actual oxygen amount hard measurement and soft measurement prediction, and can better meet the requirement of oxygen amount auxiliary adjustment in automatic air supply.

Owner:国家能源蓬莱发电有限公司 +1

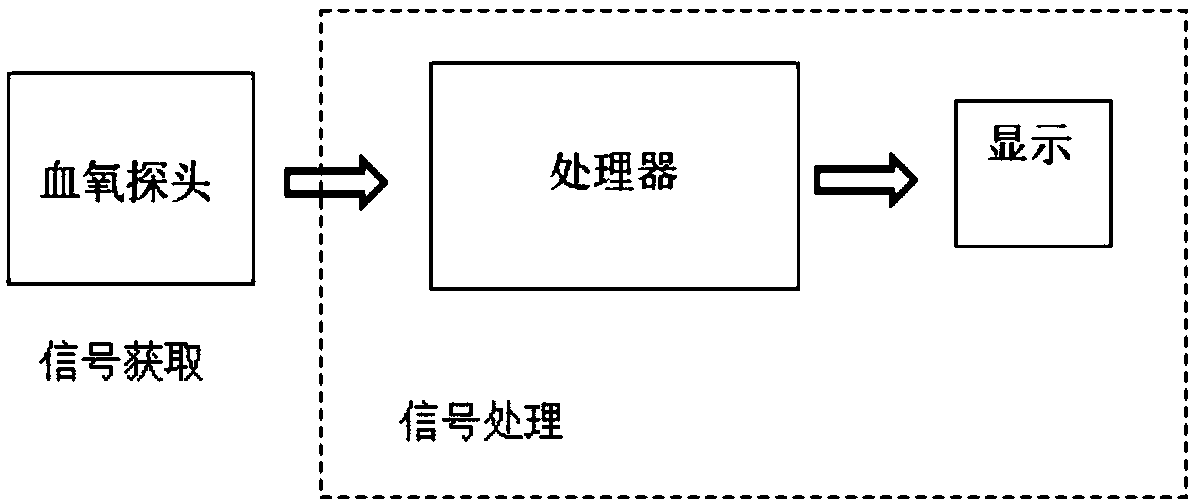

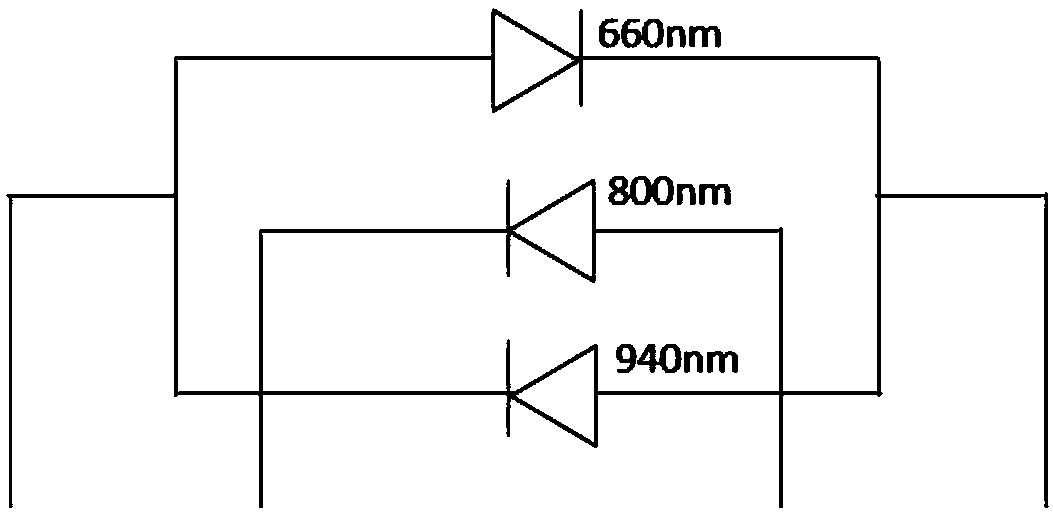

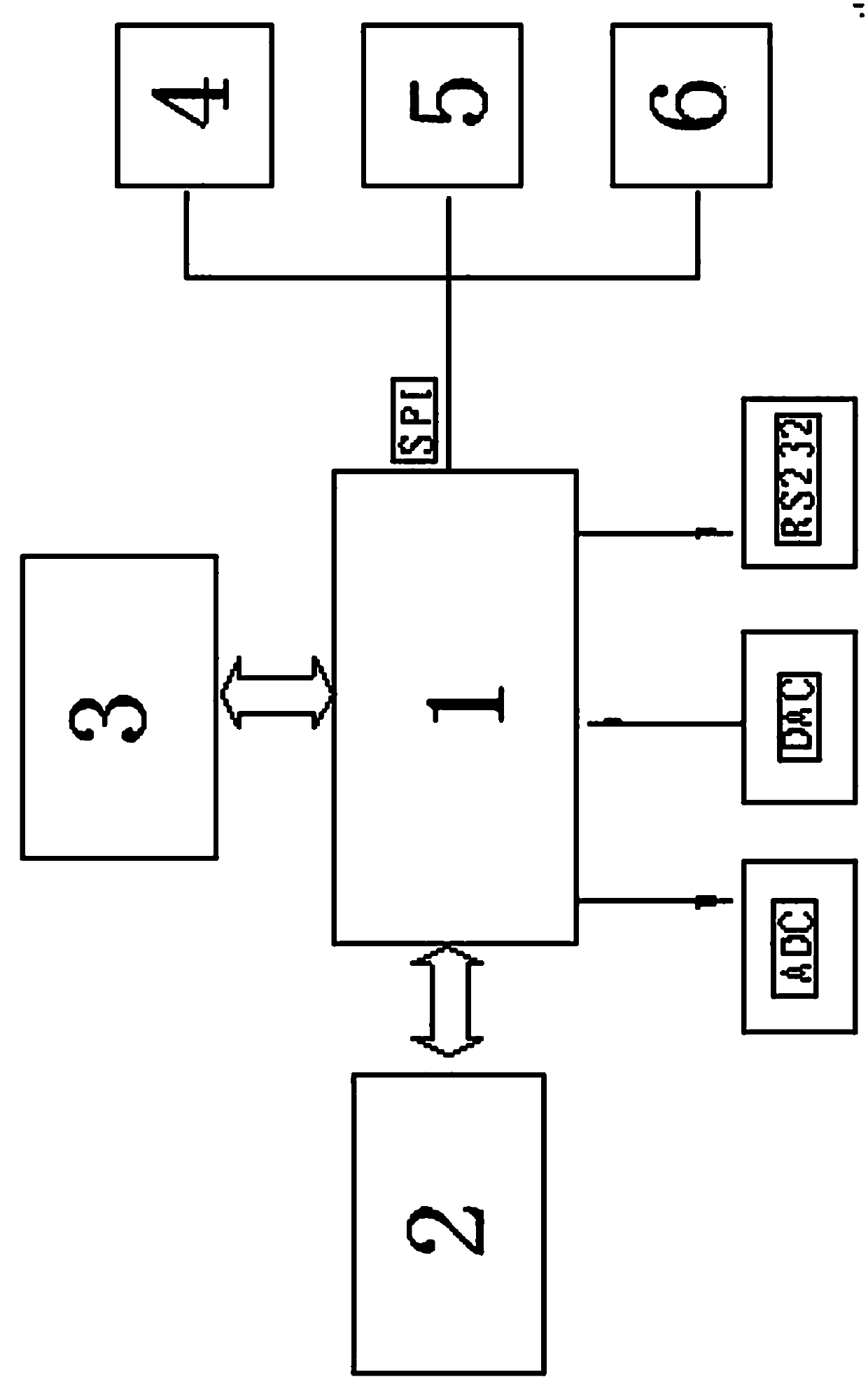

A pulse blood oxygen monitoring system with added reference light source calibration and method thereof

ActiveCN109157224APrecise system parametersReduce mistakesDiagnostic recording/measuringSensorsInformation processingOxygen monitoring

The invention discloses a pulse blood oxygen monitoring system and a pulse blood oxygen monitoring method for realizing more accurate calibration by adding a reference light source, belonging to the technical field of pulse blood oxygen monitoring. It can solve the problem of low precision caused by approximate processing in the existing calculation process. Methodology used: On the basis of 660 nm and 940 nm light sources used in blood oxygen probe, A reference light source with the wavelength of 800 nm is added to calibrate the system. The improved three light source probe is used in the signal acquisition part of the system calibration to avoid the approximate treatment in the formulated simplification of the calculation process of the information processing part, which makes the calculation formula of blood oxygen saturation more accurate. 800 nm and 660 nm, 800 nm and 940 nm, 660 nm and 940 nm light source were used for calibration, respectively, and 660 nm and 940 nm light sourcewere still used for actual measurement. The invention has the advantages that more accurate system parameters are obtained, and the blood oxygen content measurement value is more accurate.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Zirconium oxide oxygen content analysis instrument with paperless recording instrument

InactiveCN103424432AMaterial analysis by electric/magnetic meansRecording measured valuesLiquid-crystal displayDisplay device

The invention relates to a zirconium oxide oxygen content analysis instrument with a paperless recording instrument. The zirconium oxide oxygen content analysis instrument is characterized by comprising a microprocessor, wherein the microprocessor is connected with display equipment, a gas path unit and storage equipment. The instrument adopts a color liquid crystal display as the display equipment to display the measured real-time oxygen content in the form of characters. The display has a touch function, an operator can touch a press key of the display to switch into a recording state, the instrument displays the history record of oxygen content measurement in the form of a curve, the sampling interval is one second, the recording length is about 5.8 days, and a user can quickly browse the history record by operating a touch screen. The recorded data can be exported by an upper computer through a computer interface.

Owner:上海可贵固态离子导体有限责任公司

Flue gas treatment system and dry-wet oxygen measurement apparatus thereof

InactiveCN103399057AImprove working conditionMaterial electrochemical variablesFlue gasPre treatment

The present invention discloses a dry-wet oxygen measurement apparatus for a flue gas treatment system. The dry-wet oxygen measurement apparatus comprises a wet oxygen measurement instrument and a dry oxygen measurement instrument, wherein gas paths of the wet oxygen measurement instrument and the dry oxygen measurement instrument are arranged in a side-by-side manner, an inlet of the wet oxygen measurement instrument is communicated with a flue channel through a pipeline, and an inlet of the dry oxygen measurement instrument is communicated with an outlet of a pretreatment device. During online monitoring, flue gas in the flue channel concurrently enters the gas path of the wet oxygen measurement instrument and the gas path of the dry oxygen measurement instrument, the wet oxygen measurement instrument detects wet oxygen content of the initial flue gas in the flue channel, and the dry oxygen measurement instrument detects dry oxygen content of the flue gas treated through the pretreatment device so as to calculate to obtain humidity of the flue gas, such that concurrent wet oxygen content and dry oxygen content measurement is achieved, delayed quantity between the two measurement values is reduced, and measurement precision of the flue gas humidity is improved. The present invention further discloses a flue gas treatment system comprising the dry-wet oxygen measurement apparatus.

Owner:BEIJING SDL TECH

Smoke oxygen content measurement method and system

ActiveCN102095773BAvoid contaminationMeasure precise measurePreparing sample for investigationMaterial analysis by electric/magnetic meansAir preheaterEngineering

The invention provides a smoke oxygen content measurement method and system. The system comprises a main flue, an air preheater, a dust collector, a bypass flue and an oxygen content measurement device, wherein the air preheater is arranged in the main flue; the dust collector is used for collecting smoke to be tested from the main flue at the front end of the air preheater and carrying out dust removal treatment on the smoke to be tested; the bypass flue is used for sending the smoke to be tested, subjected to the dust removal treatment by the dust collector, to the main flue at the rear endof the air preheater; and the oxygen content measurement device is used for detecting the oxygen content of the smoke to be tested in the bypass flue and outputting detected oxygen content data. Based on the technical scheme of the invention, a zirconium oxide probe can be prevented from being contaminated by dust, and the smoke oxygen content can be accurately measured.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

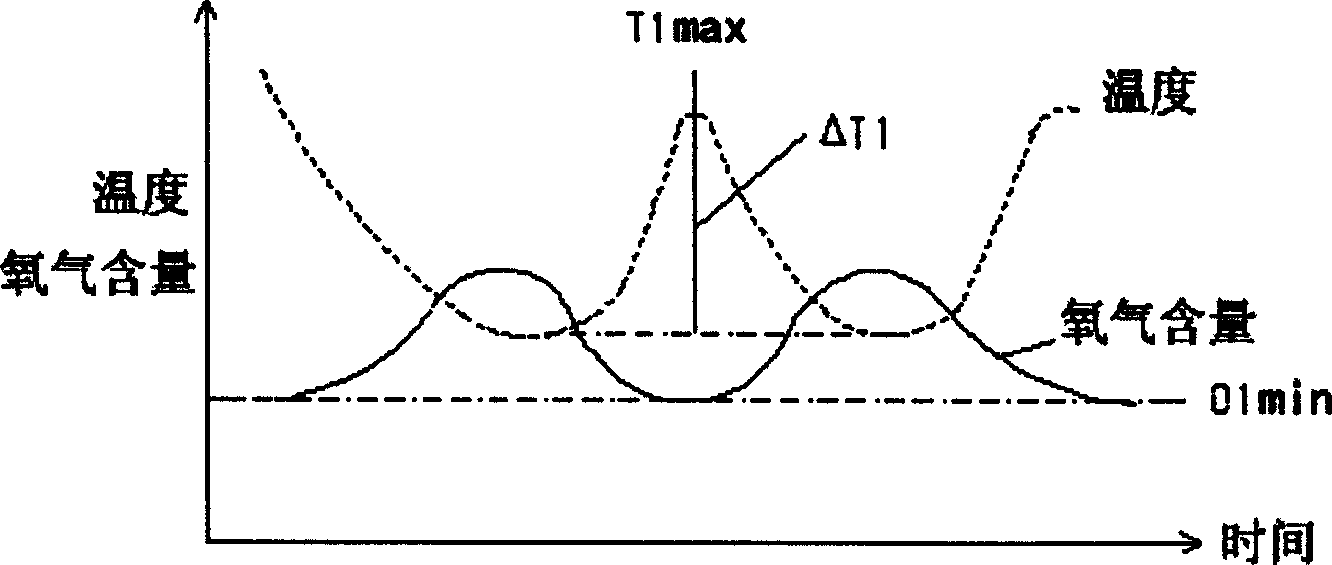

Refuse biochemical aerobic treatment device and its control method

InactiveCN1702060ASmall footprintShorten fermentation timeBio-organic fraction processingOrganic fertiliser preparationMeasuring instrumentAir content

An aerobic garbage disposal device setting draught fan beside garbage heap and its control method comprise the following steps: connecting ventilating duct with air outlet of fan; setting air outlet of fan in garbage heap; equipping air content measuring apparatus and temperature measuring apparatus in garbage heap; sending measurement result of measuring instrument into data input pin of controller; control pin of said controller connecting with switch of fan. Said air content measuring apparatus is oxygen measurement set or carbon dioxide measurement set. The invention reduces bad odour from garbage heap, accelerates biochemical aerobic reaction, decreases secondary garbage pollution, increases heating value of garbage, decreases energy consumption of burning plant and decreases cost of garbage disposal system.

Owner:ENVIROSYST BEIJING ENVIRONMENTAL ENG & TECH CO LTD

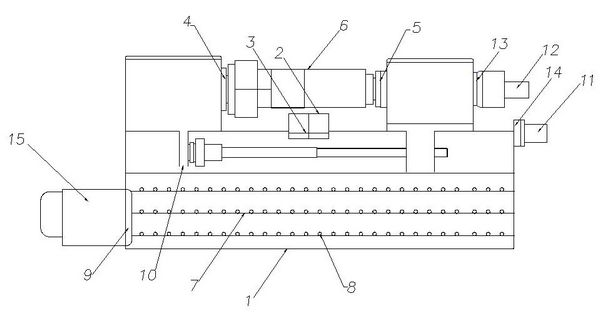

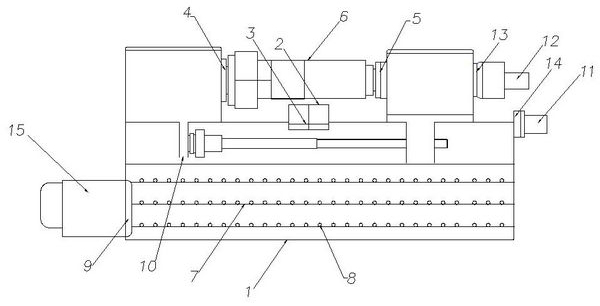

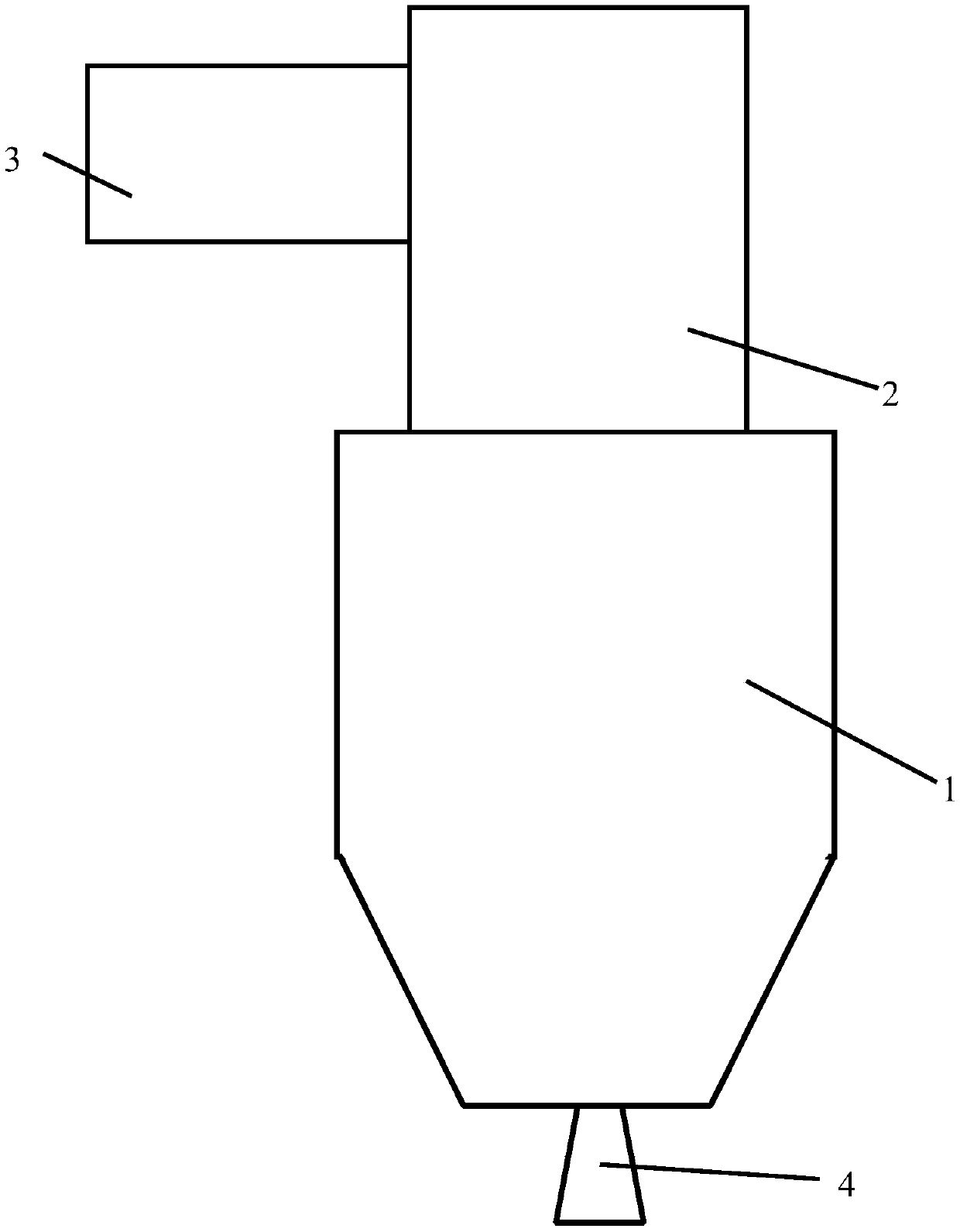

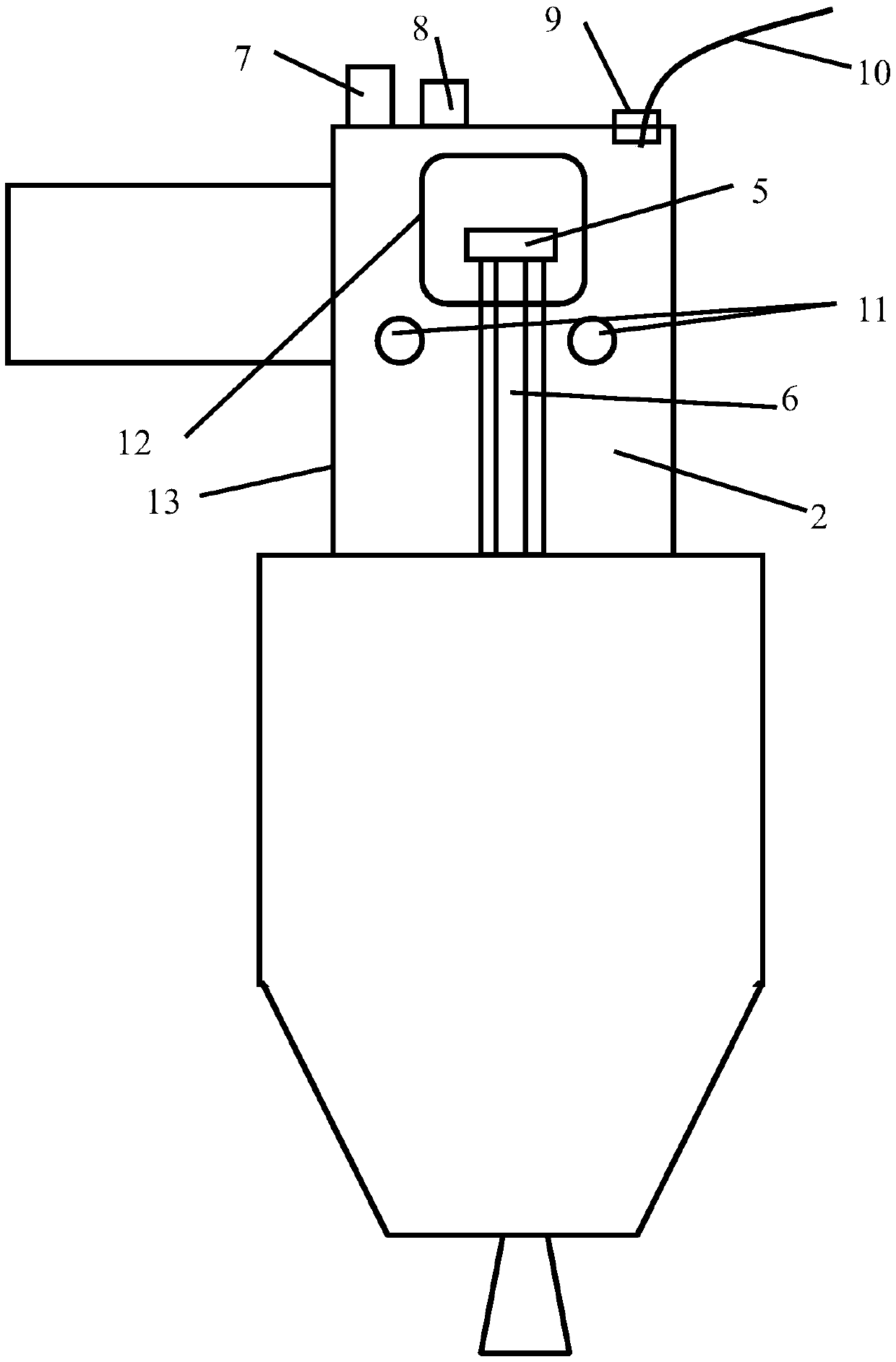

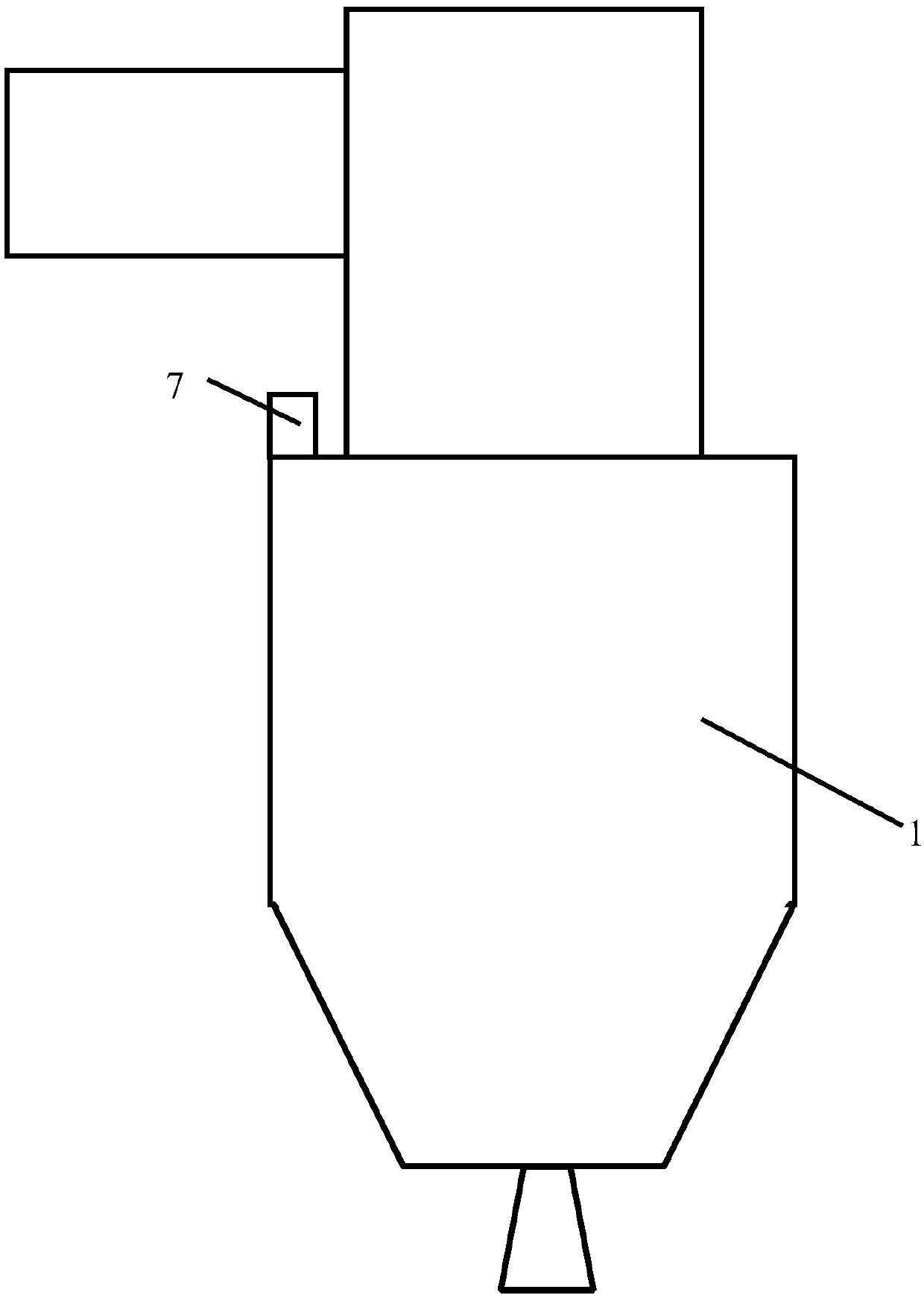

Novel ultrafine metal powder preparation equipment

PendingCN109550967AImprove protectionReduce consumptionAdditive manufacturing apparatusMetallurgyMetal powder

The invention discloses novel ultrafine metal powder preparation equipment. The novel ultrafine metal powder preparation equipment comprises an atomizing chamber, the upper portion of the atomizing chamber communicates with a seal material feeding bin, the lower portion of the atomizing chamber is connected with a powder collecting device, the side face of the seal material feeding bin is connected with a material feeding transition seal bin, the top ends of the atomizing chamber, the seal material feeding bin and the material feeding transition seal bin are all provided with oxygen content measurers, and the top ends of the seal material feeding bin and the material feeding transition seal bin are further provided with pressure sensors. The purpose of the invention is to provide the novelultrafine metal powder preparation equipment, and the problems of seal of the material feeding bin and the atomizing chamber and the low powder making efficiency in the aerosol polarization method preparation process of existing metal powder are solved.

Owner:XIAN BRIGHT ADDTIVE TECH CO LTD

Method for measuring oxygen content in iron powder

ActiveCN103529187AConducive to oxygen content measurement researchAvoid correlationTesting metalsIron powderMaterials testing

The invention discloses a method for measuring oxygen content in iron powder. The method comprises the following steps: preparing testing materials, manufacturing a pressed blank, sintering, measuring and calculating the oxygen content. The method needs no relevant professional operators, and only ordinary instruments such as a material testing machine, a sintering furnace, a carbon sulfur analyzer and the like in a powder metallurgy plant need to be adopted, so that the method is convenient to operate and economic and practical. Oxygen content standard exceeding in iron powder can be effectively detected at any time, so that the phenomenon that relevant property of a final product is reduced is prevented; the invention disclose a novel testing method which is beneficial to study on oxygen content measurement in iron powder.

Owner:ZHEJIANG QUZHOU YONGFENG METAL PROD

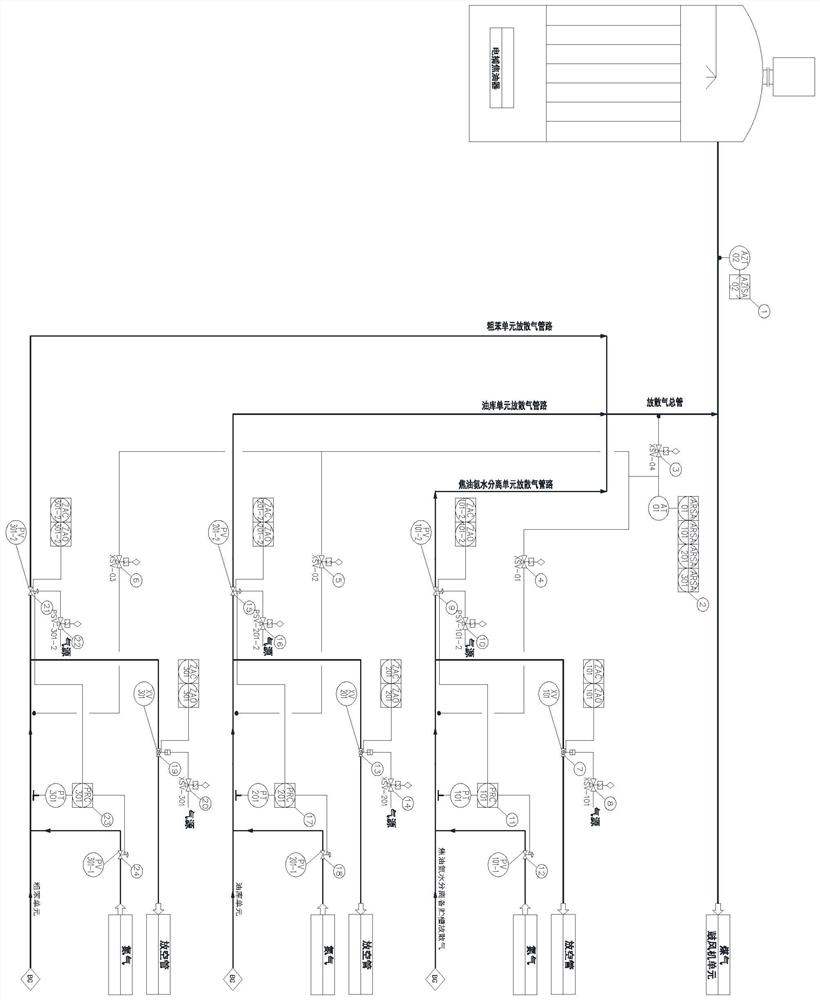

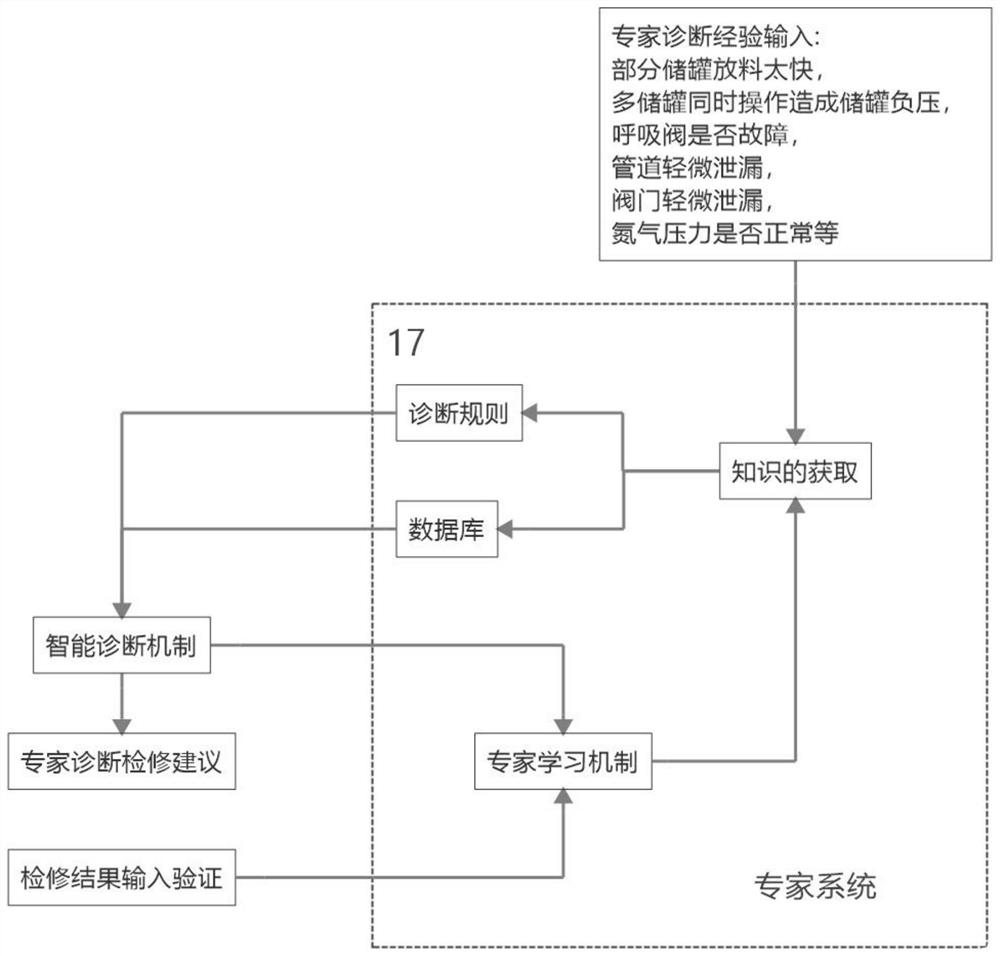

Intelligent control and diagnosis system and method for oxygen content of diffused gas at top of coking tank

PendingCN114113489AAvoid import cutoffEmission reductionProgramme total factory controlMaterial analysisThermodynamicsAir blower

The invention provides a coking tank top diffused gas oxygen content intelligent control diagnosis system and method, and the system comprises a tar ammonia water separation unit diffused gas pipeline, an oil depot unit diffused gas pipeline, a crude benzene unit diffused gas pipeline, a diffused gas main pipeline, and a diffused gas pipeline oxygen content measurement instrument. The outlet of the diffused gas main pipeline is connected to the gas pipeline between the electrical tar precipitator and the inlet of the air blower; and sampling points of the diffused gas pipeline oxygen content measuring instrument are respectively arranged on a diffused gas main pipeline, a diffused gas pipeline of the tar and ammonia water separation unit, a diffused gas pipeline of the oil depot unit and a diffused gas pipeline of the crude benzene unit. The mode that three branch pipes of a traditional bleeder enter the gas pipeline respectively is changed, and the tail ends of the three branch pipes of the bleeder are gathered to one bleeding gas header pipe and then enter the gas pipeline in a unified mode. The oxygen content of the main pipe of the diffused gas is monitored, so that the confluence cut-off of the diffused pipe in a certain area caused by the fluctuation of the oxygen content of a certain branch pipe of the diffused pipe is effectively avoided.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

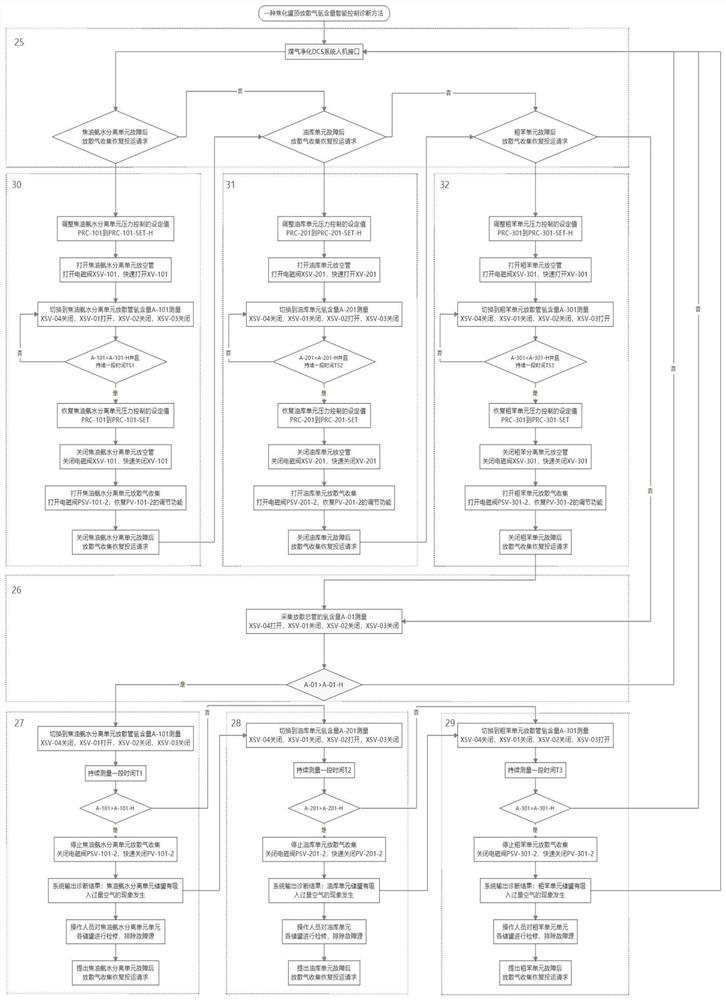

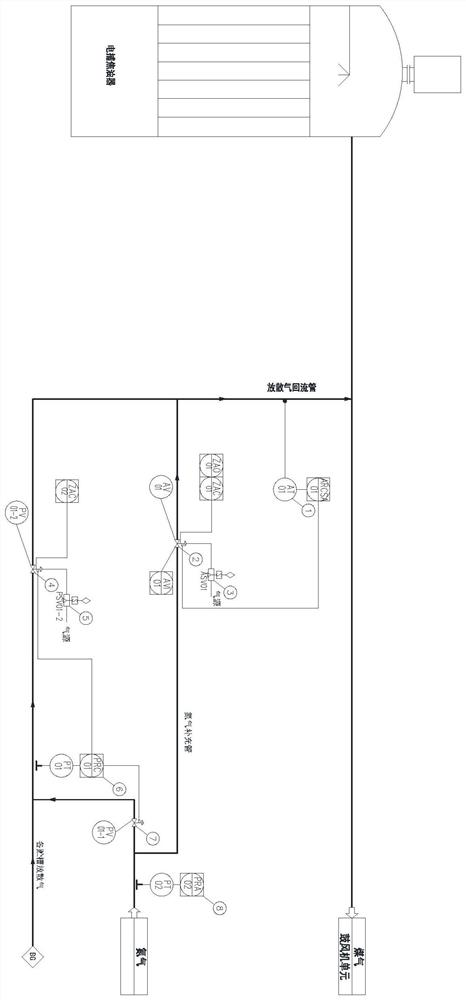

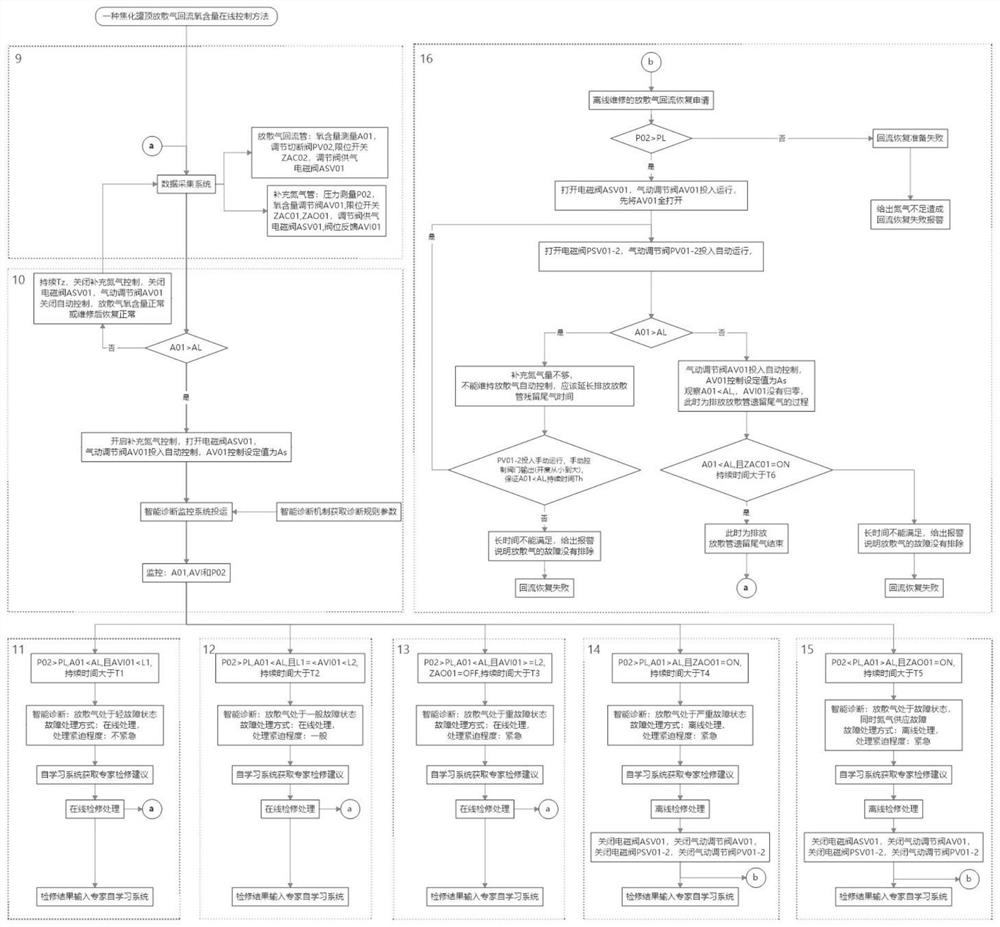

On-line measurement system and method for backflow oxygen content of diffused gas at top of coking tank

PendingCN114236059AEasy to troubleshootImprove the level of automatic controlFluid pressure measurementMaterial analysisAutomatic controlThermodynamics

The invention provides an online measurement system and method for the backflow oxygen content of diffused gas at the top of a coking tank. The system comprises a diffused gas pipeline oxygen content measurement instrument AT01 arranged on a diffused gas backflow pipe; the system further comprises a nitrogen supplementing pipe and a nitrogen supplementing pipeline adjusting valve AV01 arranged on the nitrogen supplementing pipe. Before a diffused gas backflow pipeline enters a gas pipeline, the oxygen content control in a tank top diffused gas fault state is realized by adding a mode of automatically controlling the nitrogen supplement amount, so that the diffused gas backflow oxygen content is controlled within an allowable emission range, and the online maintenance of the diffused gas fault becomes possible. An intelligent analysis method is adopted to monitor the oxygen content control process amount of diffused gas in real time, intelligent diagnosis results of diffused gas faults under different conditions are timely and accurately given out, corresponding fault maintenance suggestions are given out according to the intelligent results given out by an expert system, and the quantification degree of the faults is given out. And the bleeding gas fault diagnosis and automatic control level in the gas purification process is improved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

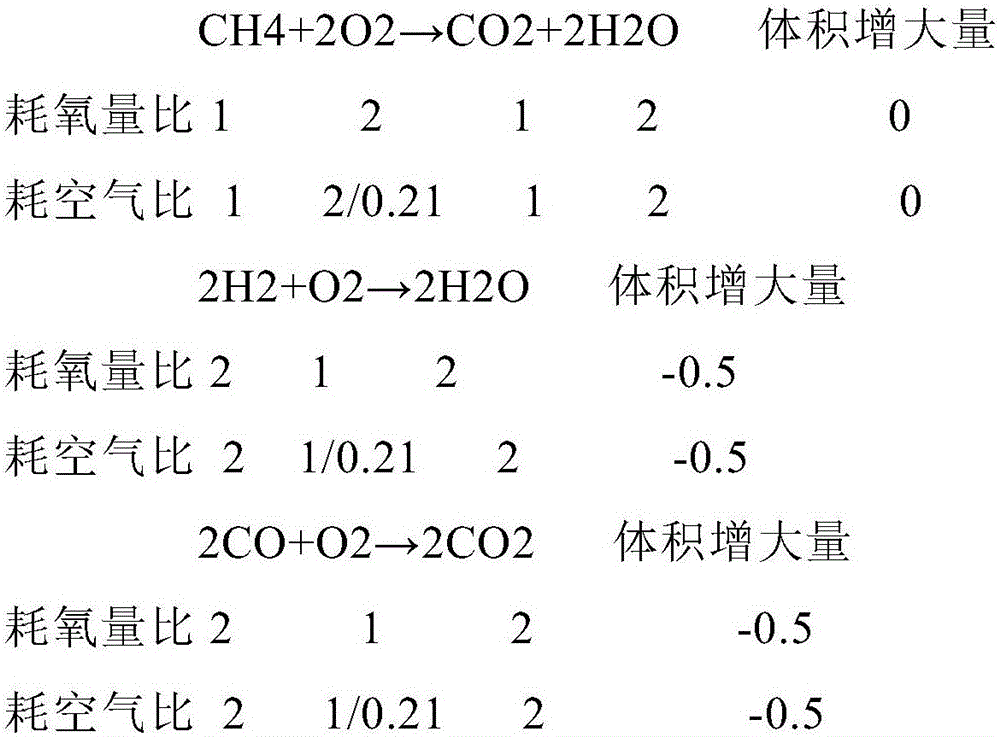

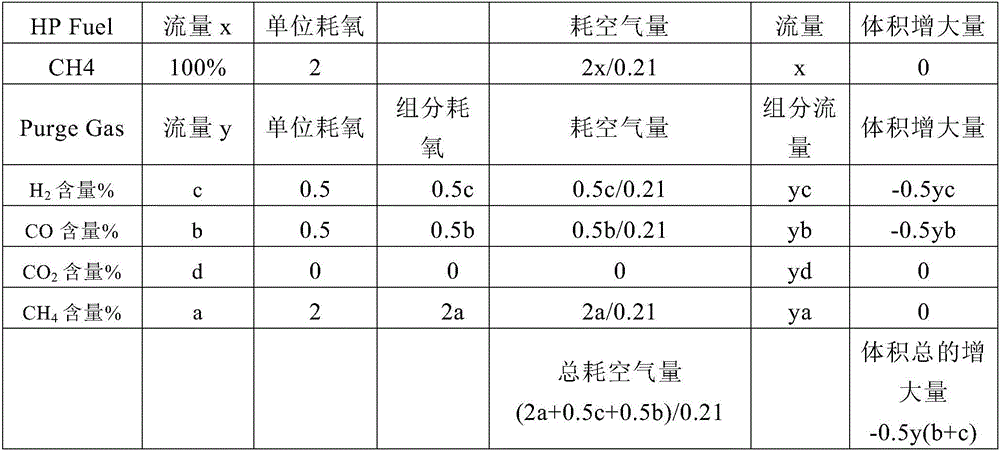

A method for determining the oxygen content of steam methane reforming hydrogen production unit

InactiveCN104807956BIncrease profitAccurate calculationMaterial analysisCombustionMeasuring instrument

The invention relates to a method for determining the oxygen content of a device for steam-methane reforming for hydrogen production. The method is as below: collecting the flow of natural gas and analytical gas in the device for steam-methane reforming for hydrogen production; calculating the amount of air needed for combustion by using the flow of natural gas and analytical gas; calculating the oxygen content by using the amount of air needed for combustion; and comparing the calculated oxygen content and the data detected by an oxygen content measuring instrument, so as to finish the determination of the oxygen content of the device for steam-methane reforming for hydrogen production. Compared with the prior art, the method provided by the invention gives comprehensive consideration of the influence factors and accurately calculates, can accurately obtain the accuracy of the oxygen content measuring instrument, increases fuel utilization rate and can be used in the calculation of the existing conversion furnace. Once the air quantity changes in the operation, the reason of fault can be determined rapidly.

Owner:SHANGHAI HUALIN IND GASES

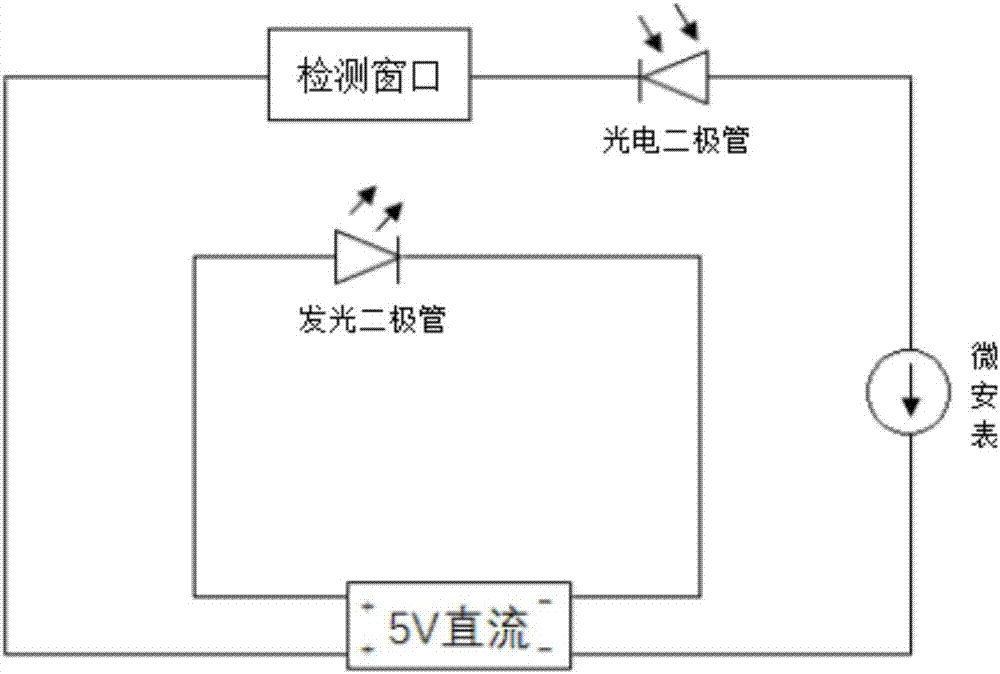

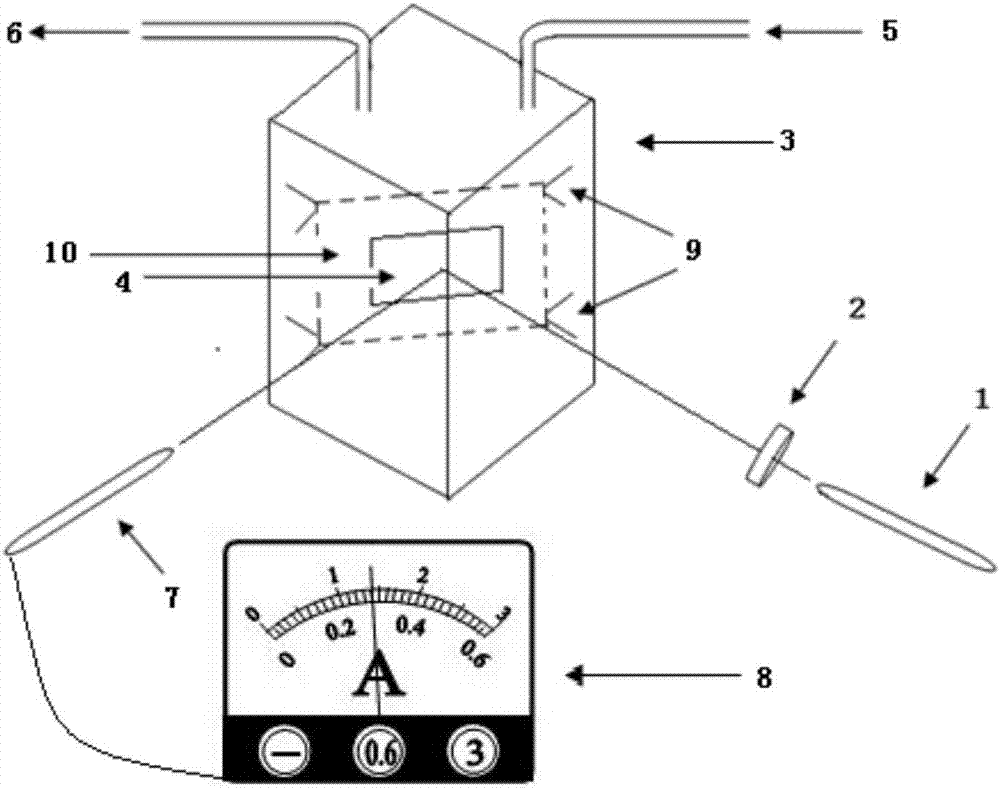

Portable oxygen content quick detector

InactiveCN107132220AHigh detection sensitivityHigh resolutionMaterial analysis by observing effect on chemical indicatorGalvanometerPhotoelectric conversion

The invention discloses a portable oxygen content quick detector, which belongs to the field of photoelectricity. The portable oxygen content quick detector comprises an LED (Light Emitting Diode) light source group and a detection window, wherein the LED light source group is connected with a collimating mirror; a collimating system is arranged in the LED light source group; an air inlet and an air outlet are arranged above the detection window; four attaching clamps and a photoelectric conversion device are arranged in the detection window; the photoelectric conversion device is connected with a galvanometer; the detection window is subjected to shading treatment; a membrane sensor is a detection membrane which contains hemoglobin; the membrane sensor is fixed on a white backboard through the attaching clamps, and ray is reflected to the photoelectric conversion device. According to the portable oxygen content quick detector disclosed by the invention, detection cost is greatly lowered, in addition, a complex step of the oxygen content measurement of a traditional method is avoided, oxygen contents can be quickly and accurately measured, and in addition, pollution caused to environment by chemical reagent in a traditional method is avoided.

Owner:DALIAN UNIV

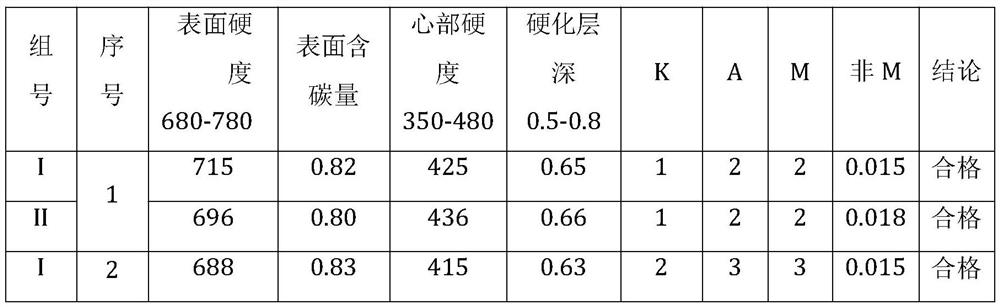

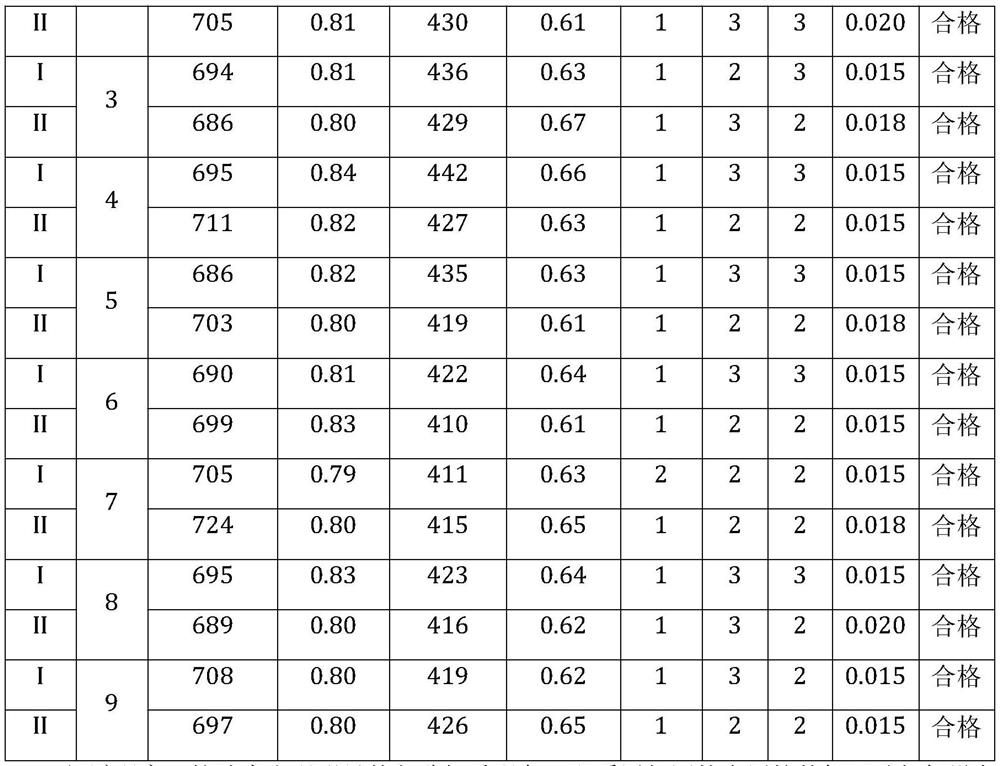

Carburizing method capable of adjusting nitrogen-methanol atmosphere proportion

PendingCN114481006AReduce consumptionReduce usageSolid state diffusion coatingCarbon potentialEnvironmental engineering

The invention relates to a carburizing method capable of adjusting the nitrogen-methanol atmosphere ratio, which comprises the following steps: reducing the introduction amount of nitrogen from 4.5 m < 3 > / h to 3.4 m < 3 > / h under the condition of keeping the methanol flow at 4.0 L / h, namely adjusting the ratio of CH3OH to N2 in pyrolysis gas from 1: 1.1 to 1: 0.9; meanwhile, after the CO value of the oxygen probe is adjusted and corrected to be 23%, variable oxygen content measurement is carried out, and the carbon potential is controlled in a mode of adding propane or air. On the premise that the original carburizing speed is guaranteed, the using amount of nitrogen can be saved by 30% or above.

Owner:SHANGHAI AUTOMOBILE GEAR WORKS

Station boiler and water and oxygen supply apparatus and method thereof

ActiveCN101423282BImprove securityWater/sewage treatment by substance additionDifferential pressureEconomizer

The invention discloses an oxygenating device for a station boiler and water supply and an oxygenating method thereof. The oxygenating device comprises an oxygen content measurement module, an oxygen supply and an oxygen flow regulation module, wherein, the oxygen content measurement module is used for measuring the dissolved oxygen content of condensed water at an entrance of a pump package of acondensed water pump for a station boiler; the oxygen supply is used for supplying oxygen required by oxygen supplementation; and the oxygen flow regulation module is connected with the oxygen supply, can be inserted into the entrance of the pump package of a condensed water pump, and is used for controlling the flow oxygenating to condensed water according to the dissolved oxygen content output by the oxygen content measurement module. The method and the device are used in the mode of water supply weak oxidizing treatment (or AVT(O)) of a high parameter machine set of a station so as to supply, regulate and control the dissolved oxygen of the condensed water and economizer supply water, which is in accordance with the requirements of weak oxidizing treatment. By the regulation and the design of oxygenating points and flow, the invention simplifies a system, increases the safe reliability of the system, stabilizes the oxygenation differential pressure and simplifies control.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com