A method for determining the oxygen content of steam methane reforming hydrogen production unit

A technology for reforming a hydrogen production device and water vapor, which is applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as increasing production costs and reducing heat utilization, and achieves increased fuel utilization, wide applicability, and calculation. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

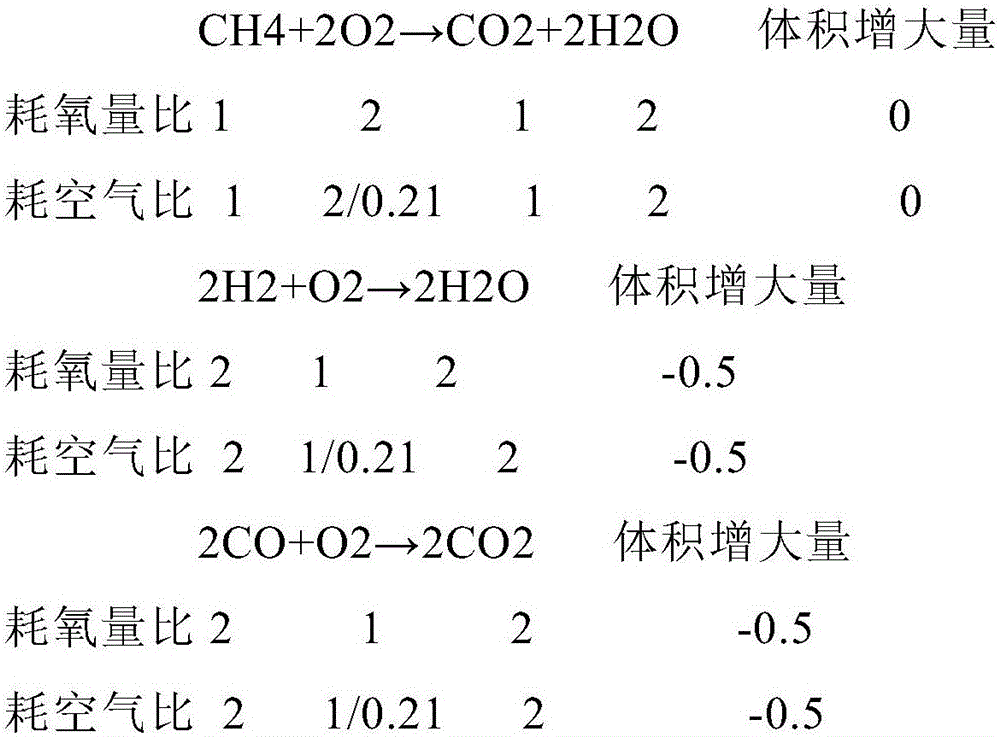

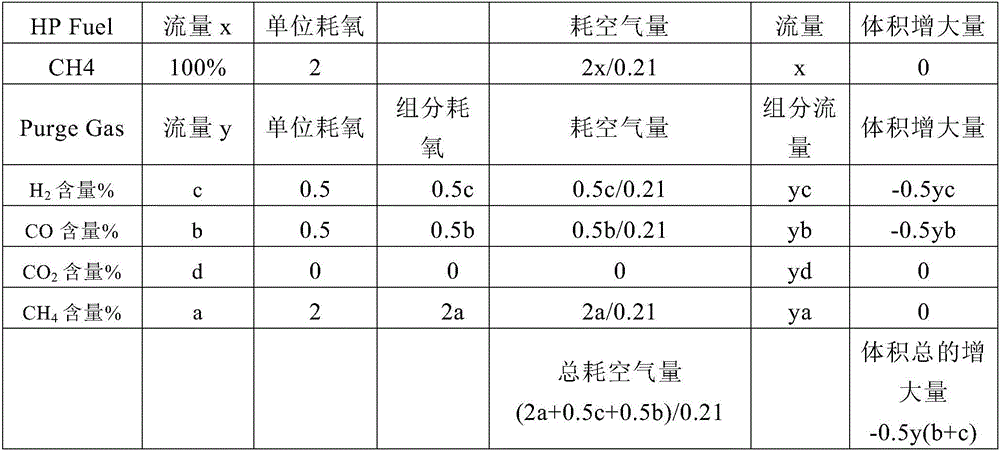

Method used

Image

Examples

Embodiment 1

[0032] The load of HYCO unit is hydrogen production 6800Nm3 / h, water-carbon ratio 3.619, air excess coefficient 1.24, natural gas flow rate 122Nm3 / h, analytical gas flow rate 4629Nm3 / h, PSA operation factor 0.644, air coefficient required for analytical gas 1.982.

[0033] The calculated oxygen content is 3.11%, the actual 3.15%, and the difference is less than 0.1%. Due to the error of the instrument and other air blowing equipment, it can be determined that the instrument is accurate and the combustion utilization rate is high.

Embodiment 2

[0035] The load of HYCO unit is 16000Nm3 / h hydrogen production, 2.743 water-carbon ratio, 1.3 excess air coefficient, 256Nm3 / h natural gas flow rate, 9136Nm3 / h analytical gas flow rate, 1.05 PSA operation factor, and 2.48 air coefficient for analytical gas

[0036] The calculated oxygen content is 1.738%, the actual 1.64%, and the difference is less than 0.1%. Due to the existence of instrument errors and other blast equipment errors, it can be determined that the instrument is accurate and the combustion utilization rate is high.

Embodiment 3

[0038] The load of HYCO unit is 18786Nm3 / h hydrogen production, 2.723 water-carbon ratio, 1.253 excess air coefficient, 299Nm3 / h natural gas flow rate, 10633Nm3 / h analytical gas flow rate, 1.05 PSA operation factor, and 2.48 air coefficient for analytical gas

[0039] The calculated oxygen content is 1.25%, the actual 1.16%, and the difference is less than 0.1%. Due to the existence of instrument errors and other blast equipment errors, it can be determined that the instrument is accurate and the combustion utilization rate is high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com