Safety interlock control method and system for slurry reactor hydrogen peroxide device oxidation tower

A safety interlocking, oxidation tower technology, applied in the control/regulation system, non-electric variable control, simultaneous control of multiple variables, etc., can solve the problems such as the interlocking control technology of the oxidation tower of the hydrogen peroxide device that has not been found, and achieve optimal production. Benefit, improve safety, prolong the effect of the start-up cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

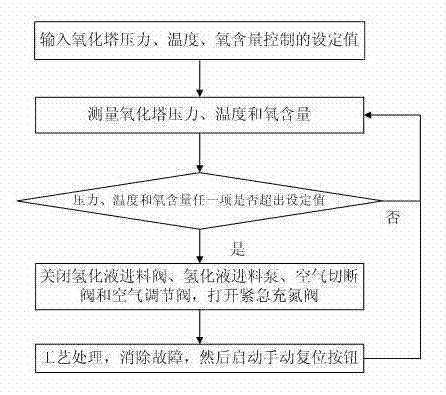

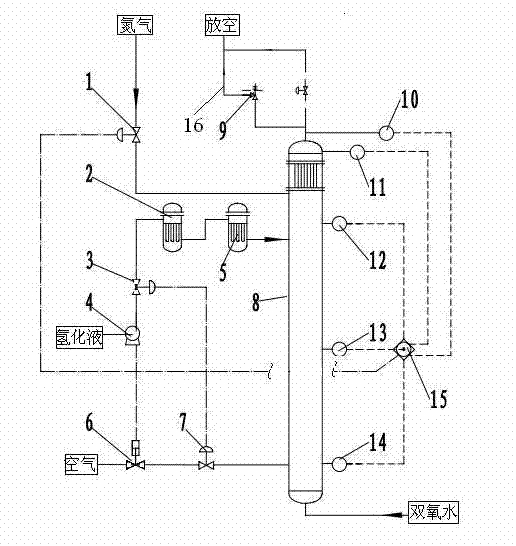

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

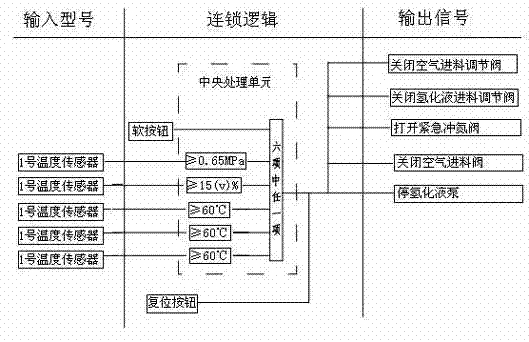

[0020] The system for the safety interlock control of the oxidation tower of the slurry bed hydrogen peroxide device in the present invention, such as figure 2 As shown, it is mainly composed of a central processing unit 15, a pressure sensor 11, an oxygen content sensor 10, a No. 1 temperature sensor 12, a No. 2 temperature sensor 13, a No. 3 temperature sensor 14, a hydrogenation liquid feed valve 3, and a hydrogenation liquid feed pump 4 , air regulating valve 7, air cut-off valve 6 and emergency nitrogen filling valve 1. The pressure sensor is located at the oxidation tower top of the oxidation tower 8, the oxygen content sensor is installed at the tower top venting line 16, and No. 1 temperature sensor, No. 2 temperature sensor and No. 3 temperature sensor are respectively installed at the upper section, middle section and lower section of the oxidation tower. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com