Oxygen content prediction method based on real-time measurement data

A technology of real-time measurement and prediction method, applied in prediction, neural learning method, data processing application, etc., can solve problems such as inability to change, inability to obtain measurement results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

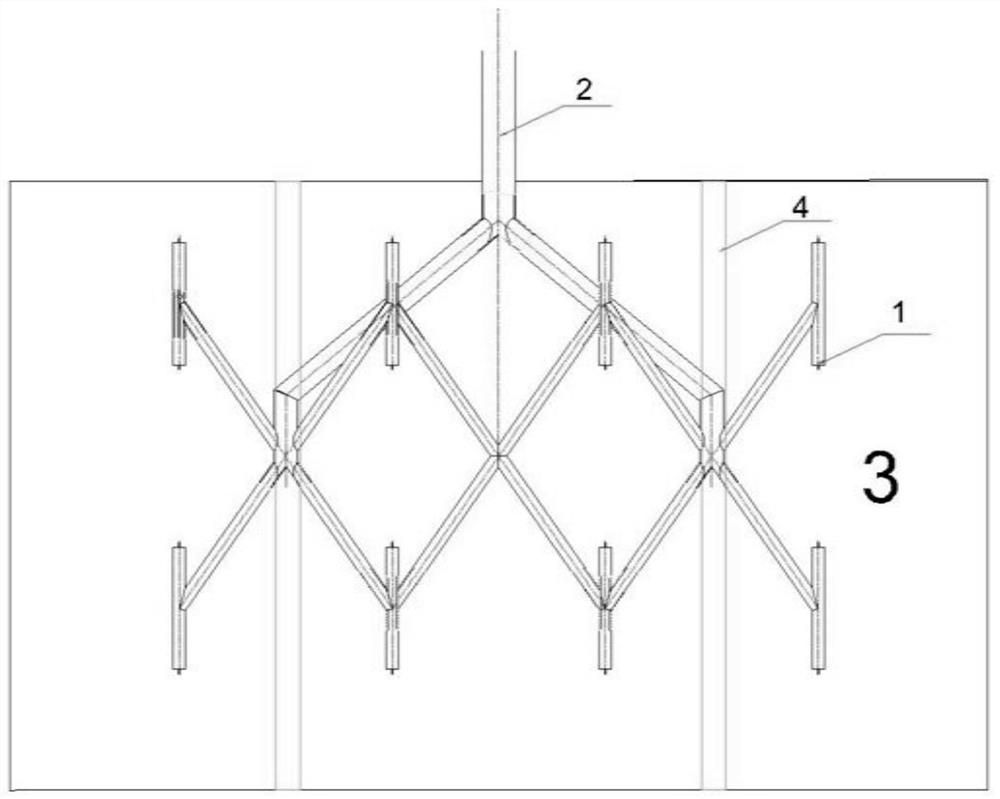

[0033] Such as figure 1 As shown, a grid multi-point measuring device is installed at the outlet flue 3 of the SCR flue gas denitrification system on the flue A side. The flue gas enters the sampling device from 16 grid multi-point sampling ports 1. After the gas is combined, it flows into the subsequent oxygen measurement device from the total sampling port 2. Before the soft measurement is put into use, upload the multi-point oxygen measurement data to DCS.

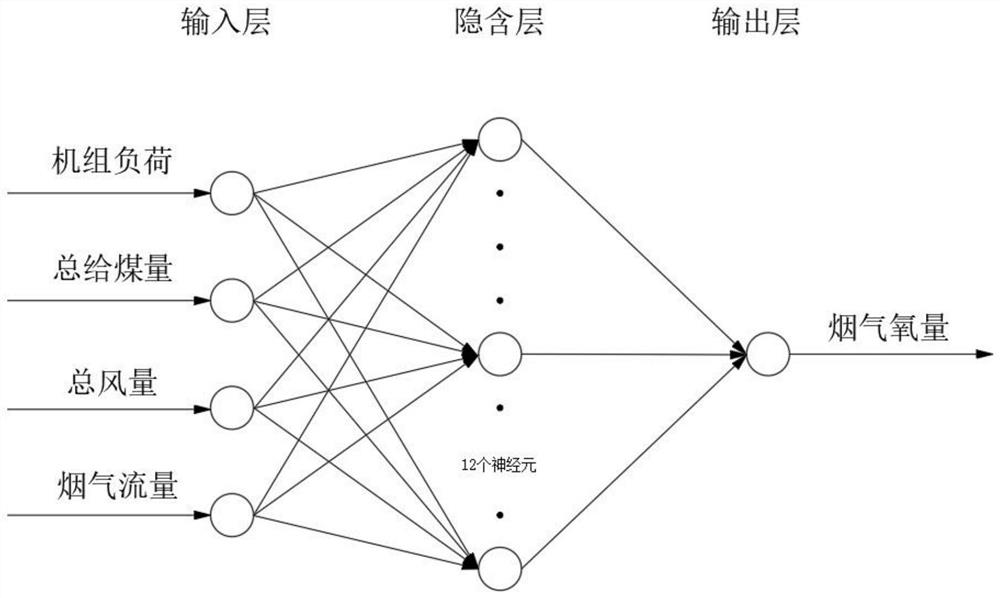

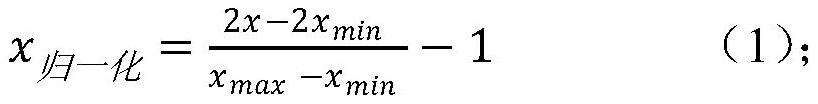

[0034] Then collect the real-time unit load (power generation power), coal volume, primary and secondary air volume, in-situ measuring point oxygen volume, and grid multi-point oxygen volume data of the power plant boiler operation within 14 days. These data should cover most of the operating conditions of the boiler. . Then according to different working conditions, 80% of the data...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com