Station boiler and water and oxygen supply apparatus and method thereof

A power plant boiler and oxygen replenishment technology, which is applied in the direction of adding substances to water/sewage treatment, etc., can solve the problems of high pressure at the oxygenation point, selection of oxygenation system components, difficulty in calibration and flow adjustment control, and unfavorable adjustments to achieve high safety. sexual effect

Active Publication Date: 2010-12-01

STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

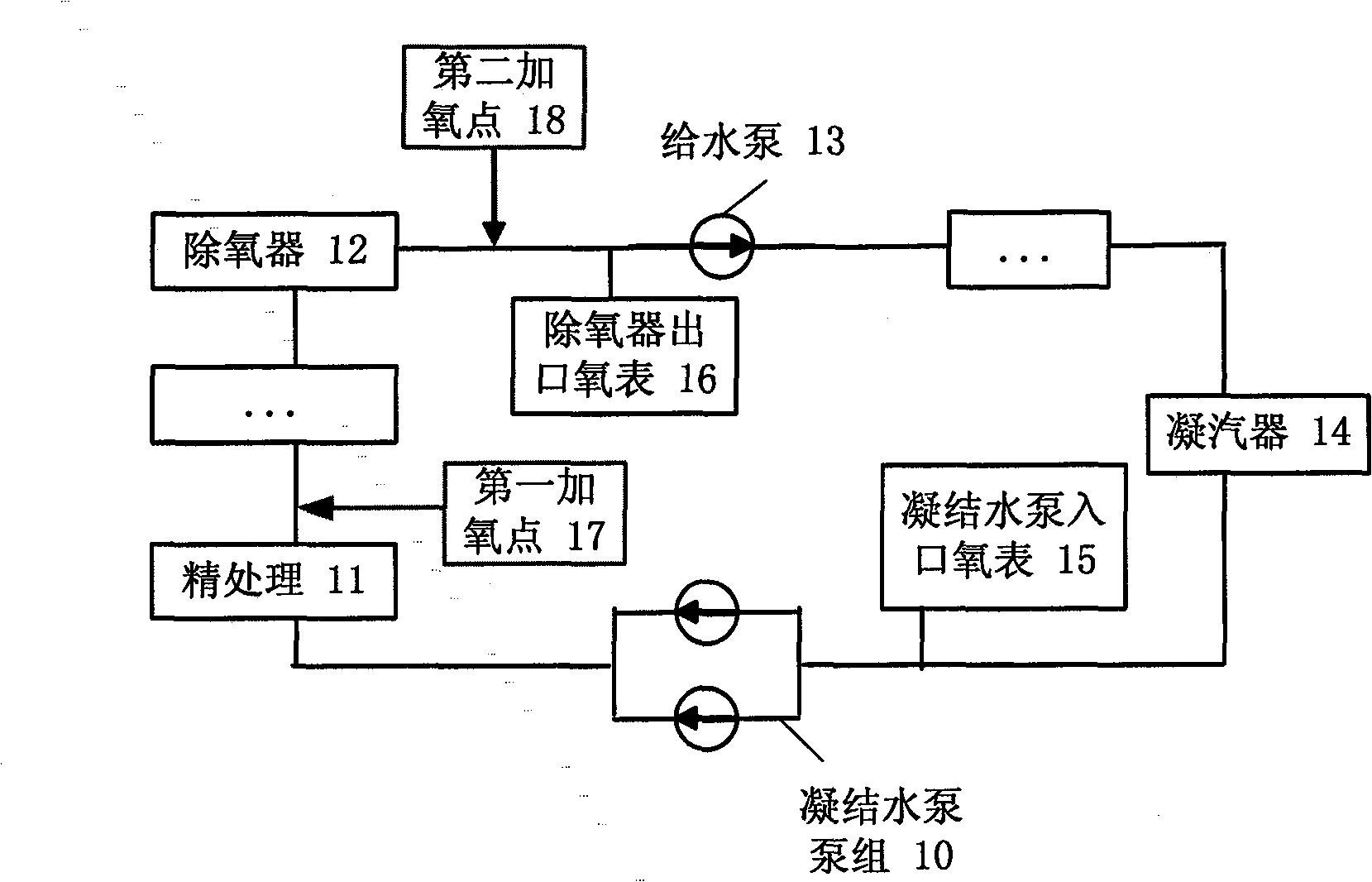

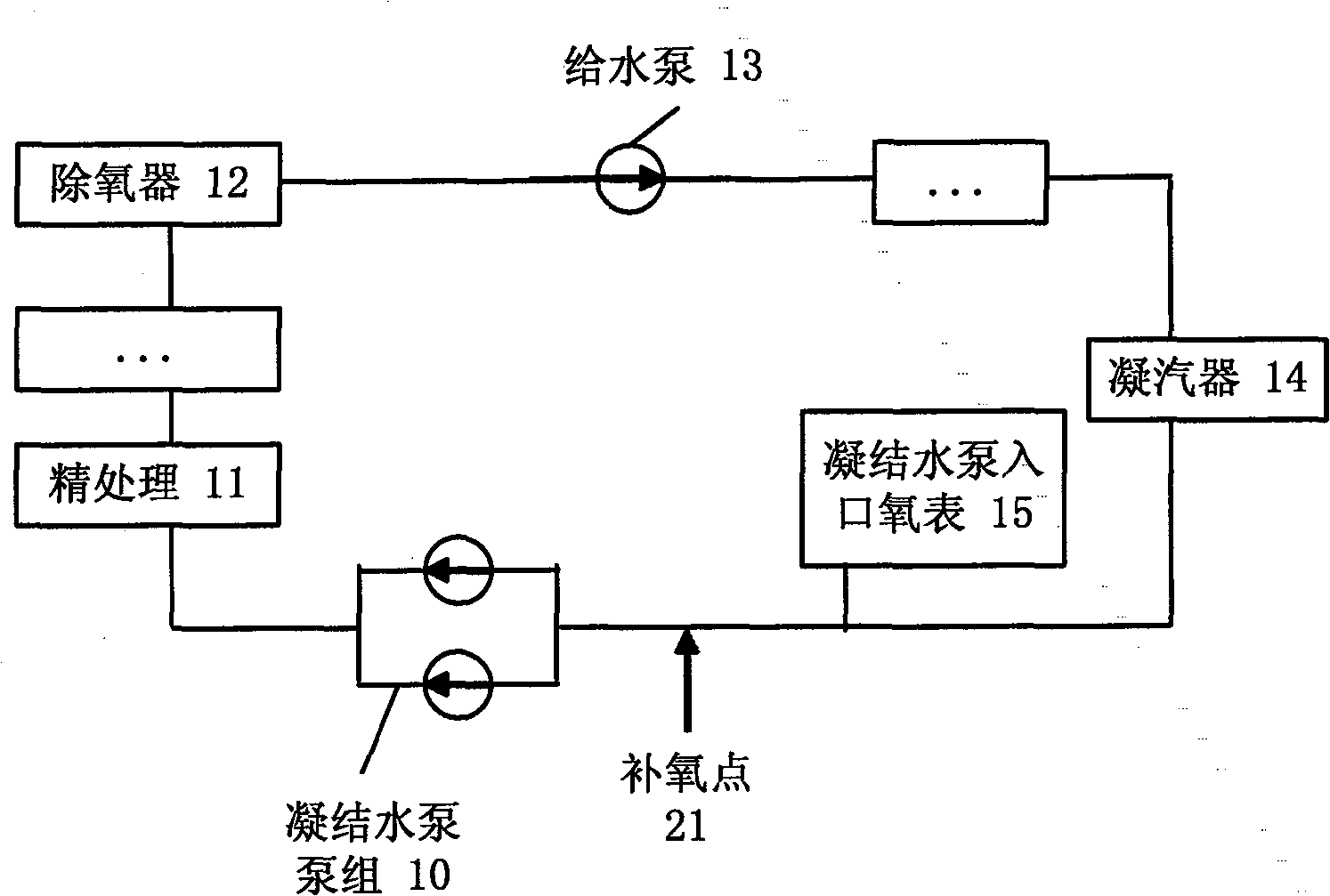

However, the OT method in the prior art is not applicable or cannot be used in the AVT (O) method in many aspects. For example, 1) the pressure of the oxygen addition point is relatively high, the system design and installation requirements are correspondingly increased, and the safety factor is reduced; 2) the oxygen addition point is relatively high, and the safety factor is reduced; After the point pressure is increased, the volume flow rate decreases by an order of magnitude for the trace amount of oxygen required by the AVT(O) method, which brings obvious difficulties to the selection, calibration and flow adjustment control of the oxygenation system components; 3) for accurate detection and control For two-point oxygenation, it is necessary to add an oxygen meter and its sampling points between the first and second oxygenation points; 4) The operating pressure of the oxygenation point changes significantly with the load, and the trend of the pressure difference between it and the oxygenation system is the same as that of the oxygenation system. The change in the required direction is just the opposite, which is unfavorable for adjustment; 5) To adjust the oxygen addition in time and accurately with the load, it is necessary to design a more complex linkage measurement and control system

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

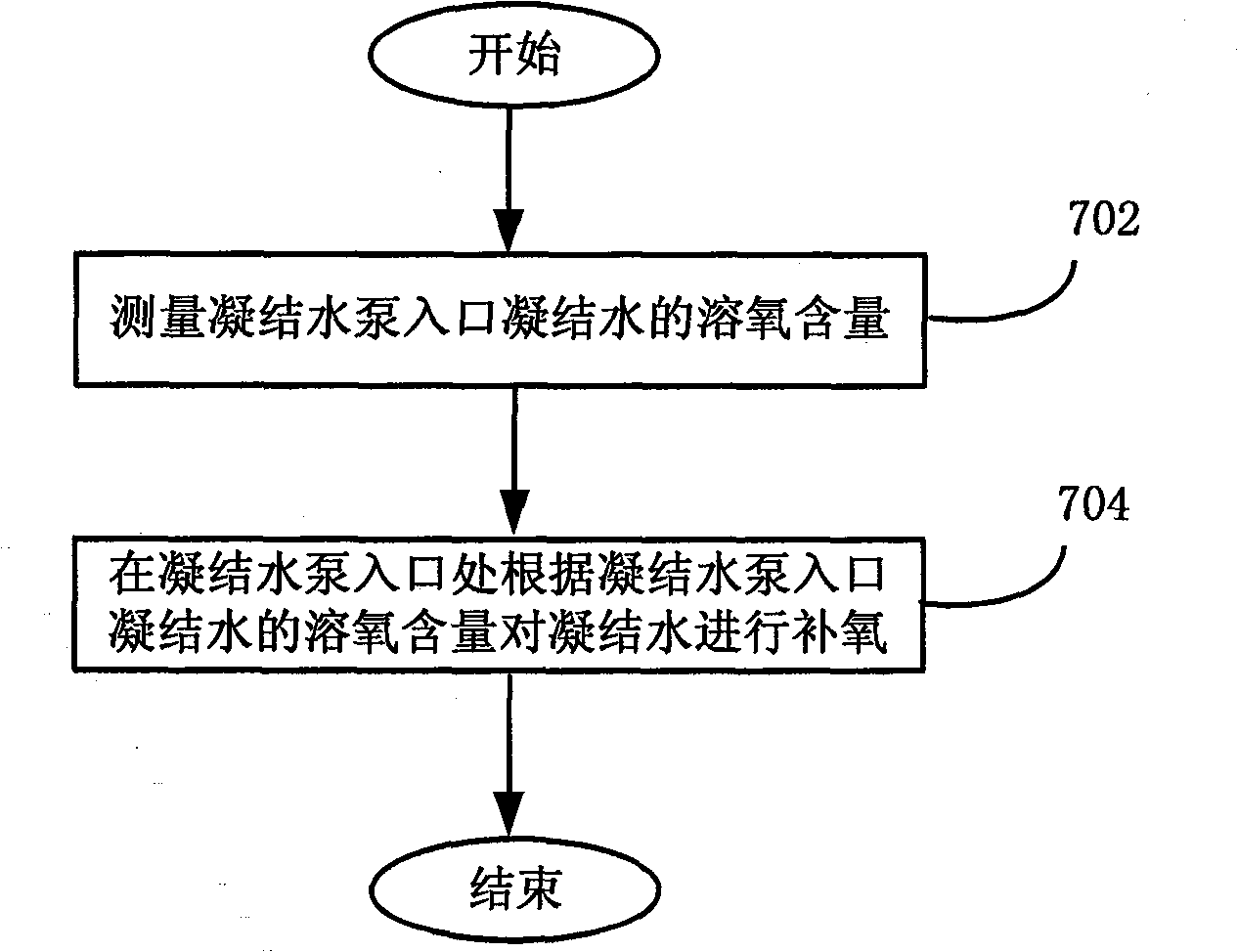

The invention discloses an oxygenating device for a station boiler and water supply and an oxygenating method thereof. The oxygenating device comprises an oxygen content measurement module, an oxygen supply and an oxygen flow regulation module, wherein, the oxygen content measurement module is used for measuring the dissolved oxygen content of condensed water at an entrance of a pump package of acondensed water pump for a station boiler; the oxygen supply is used for supplying oxygen required by oxygen supplementation; and the oxygen flow regulation module is connected with the oxygen supply, can be inserted into the entrance of the pump package of a condensed water pump, and is used for controlling the flow oxygenating to condensed water according to the dissolved oxygen content output by the oxygen content measurement module. The method and the device are used in the mode of water supply weak oxidizing treatment (or AVT(O)) of a high parameter machine set of a station so as to supply, regulate and control the dissolved oxygen of the condensed water and economizer supply water, which is in accordance with the requirements of weak oxidizing treatment. By the regulation and the design of oxygenating points and flow, the invention simplifies a system, increases the safe reliability of the system, stabilizes the oxygenation differential pressure and simplifies control.

Description

A power plant boiler and its feedwater oxygenation device and method technical field The invention relates to power plant boiler feed water treatment technology, in particular to a power plant boiler and its feed water oxygenation device and method. Background technique Dissolved oxygen is considered to be an important chemical indicator in the monitoring of water vapor cycle in power plants. Chemical methods for boiler feed water treatment include Reducing All-Volatile Treatment (AVT(R)), Oxidizing All-Volatile Treatment (AVT(O)), and Oxygenated Treatment (OT). The system using OT and AVT(O) is currently the most reliable and well-operated feedwater treatment system in the world. Under aerobic conditions, the pores of the Fe3O4 protective layer will be filled by some low-solubility ferric oxide hydrate (FeOOH) or ferric oxide (Fe2O3). Sometimes ferric oxide even covers the entire protective layer of ferric oxide. In this way, the concentration of iron ions in the feed ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C02F1/68

Inventor 李长鸣何俊峰

Owner STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com