Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

75results about How to "Improve the level of automatic control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

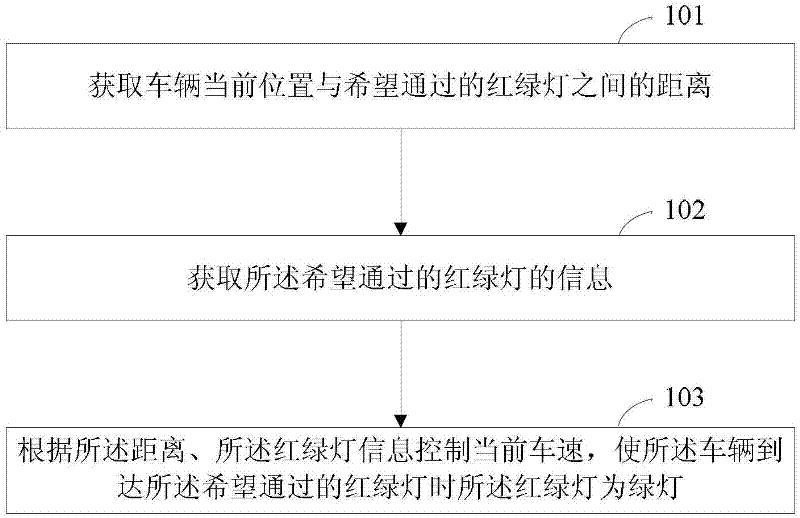

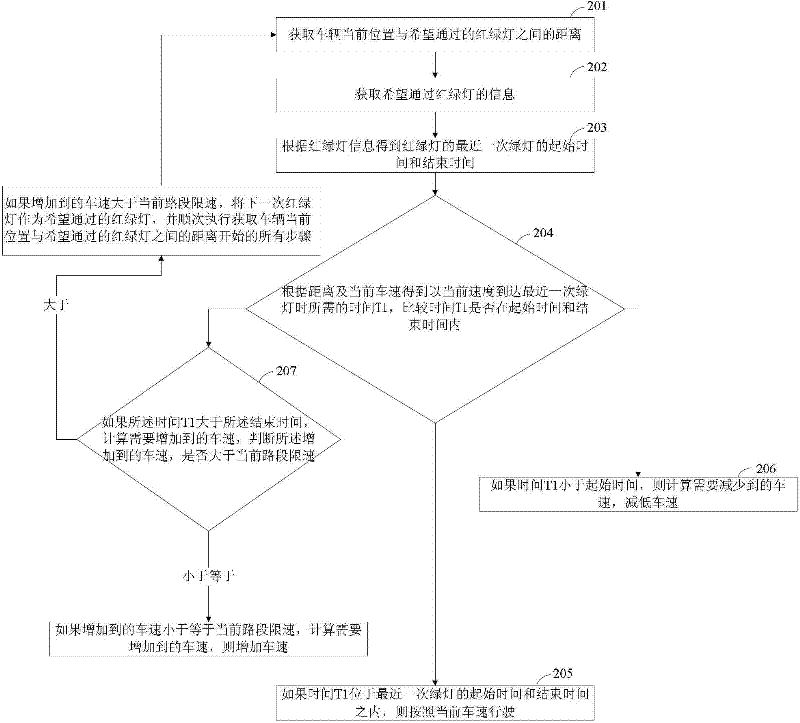

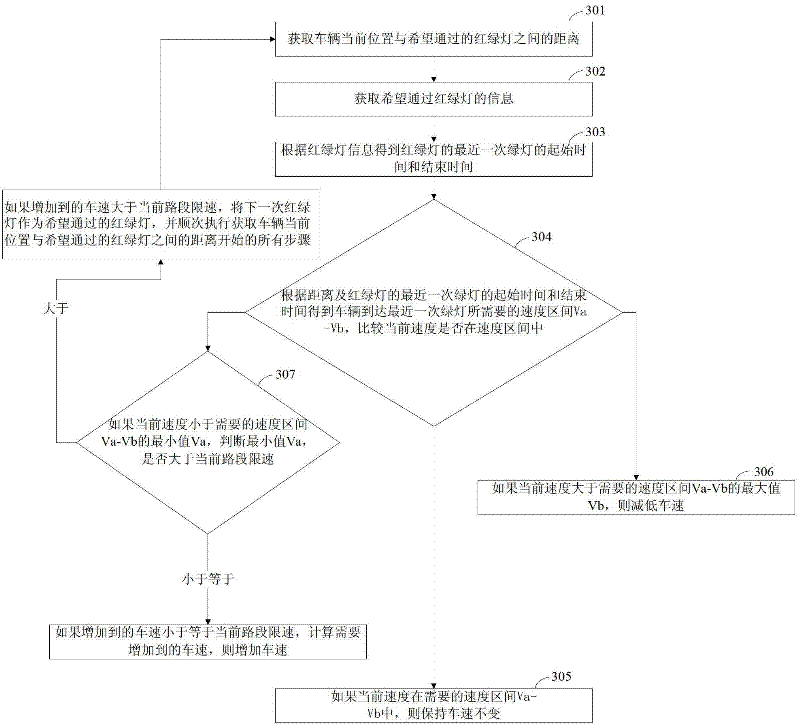

Vehicle speed control method and system

ActiveCN102649432AAvoid congestionImprove the level of automatic controlAutomatic controlSpeed control system

The embodiment of the invention discloses a vehicle speed control method and a vehicle speed control system and belongs to the field of automobile control. The method comprises the following steps that: the distance from the current position of a vehicle to a traffic light expected to pass is obtained; the traffic light information of the traffic light expected to pass is obtained; and the current vehicle speed is controlled according to the distance and the traffic light information so that the traffic light is green when the vehicle reaches the traffic light expected to pass. The system comprises a distance obtaining module, a traffic light information obtaining module and a vehicle speed feedback module. The embodiment of the invention has the advantages that through the comprehensive processing on the traffic light information, the absolute position of the traffic light and the vehicle and parameters of the vehicle per se, the vehicle is automatically controlled, the vehicle speed regulation is realized, the condition of crowding at traffic light crossings is avoided to a certain degree, and the traffic condition is optimized.

Owner:CHERY AUTOMOBILE CO LTD

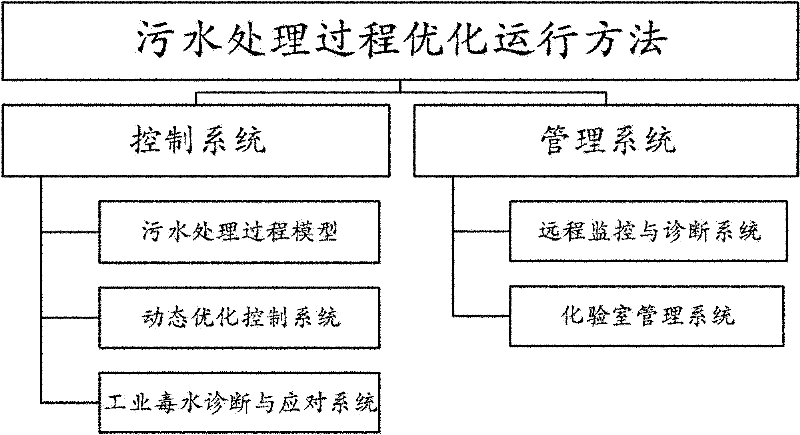

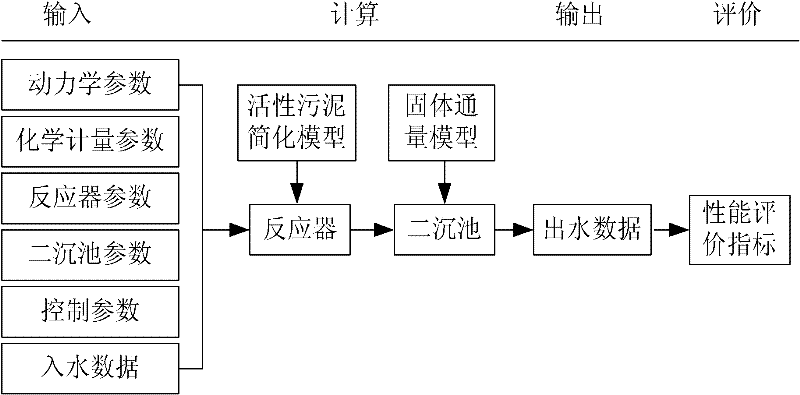

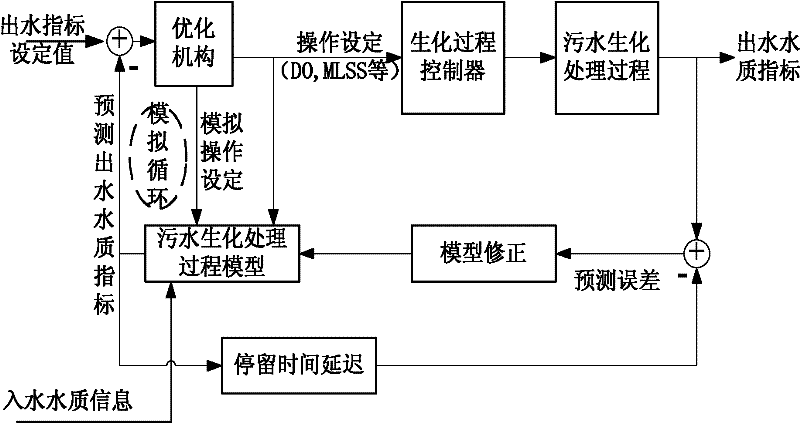

Sewage treatment process optimizing operation method

InactiveCN102681498AImprove the level of automatic controlRealize energy saving and consumption reductionEnergy industryTotal factory controlAutomatic controlControl system

The invention relates to a sewage treatment process optimizing operation method. The method comprises the following steps of: establishing a sewage treatment process model and predicating outlet water quality of a sewage treatment system so as to obtain an outlet water quality predicated value of the sewage treatment system; establishing a dynamic optimizing control system; establishing an industrial poisonous water diagnosis and response system so as to produce an alarm for invasive industrial poisonous water; establishing a sewage treatment process remote monitoring and diagnosis system so as to transmit local real-time monitoring data of a sewage treatment plant to enterprise managers and upstream authorities for making decisions; establishing a testing laboratory management system so as to test and measure the water quality and industrial parameters in the sewage treatment process and then analyze various testing laboratory measurement data; and introducing the various testing laboratory measurement data into the dynamic optimizing control system so as to correct set values of sludge concentration and dissolved oxygen concentration. According to the invention, the automatic control level of the sewage treatment plant is enhanced, the energy conservation and consumption reduction in the sewage treatment process are achieved, the safety of sewage treatment is improved and the human resource cost of the sewage treatment is reduced.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +2

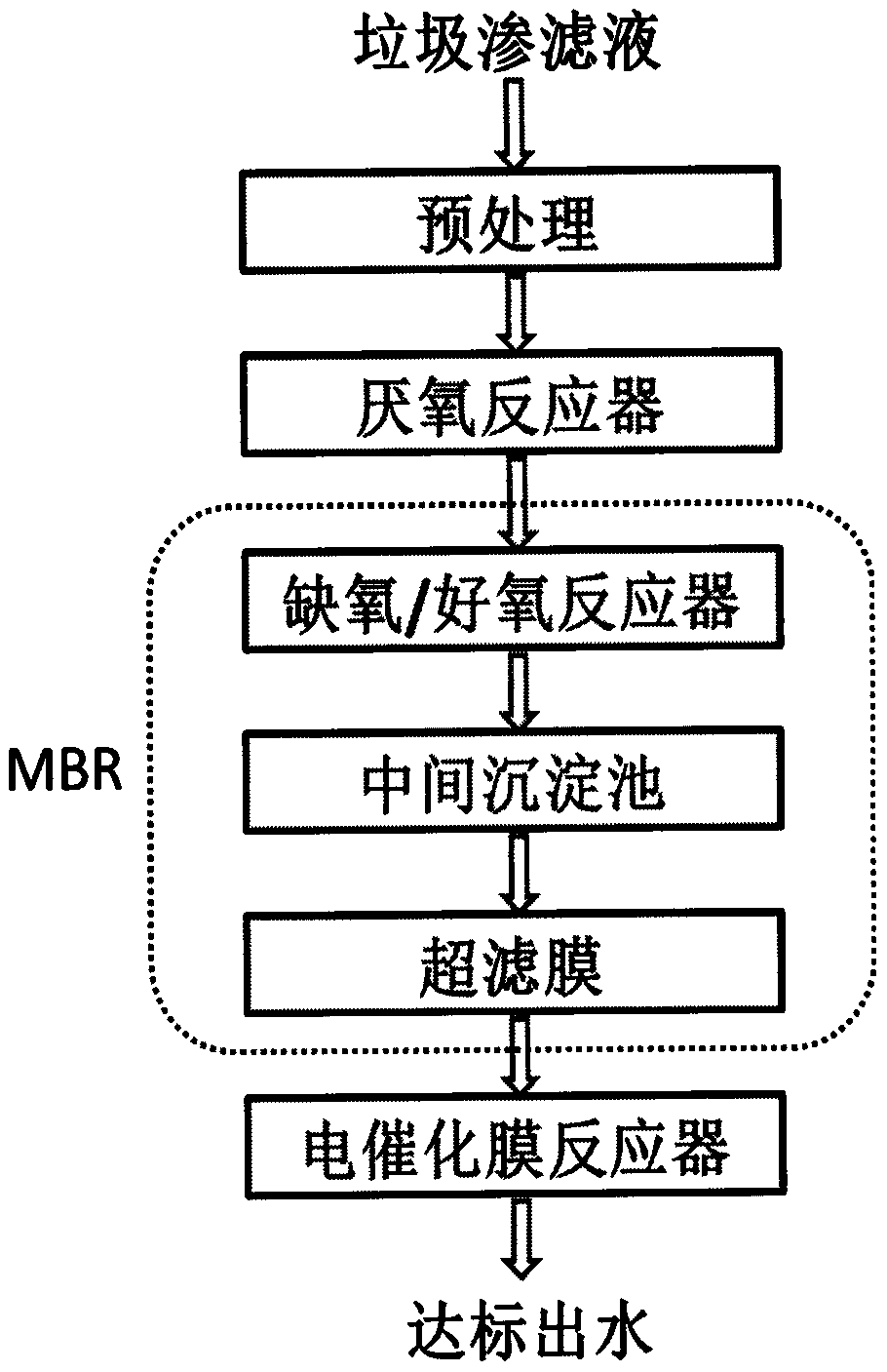

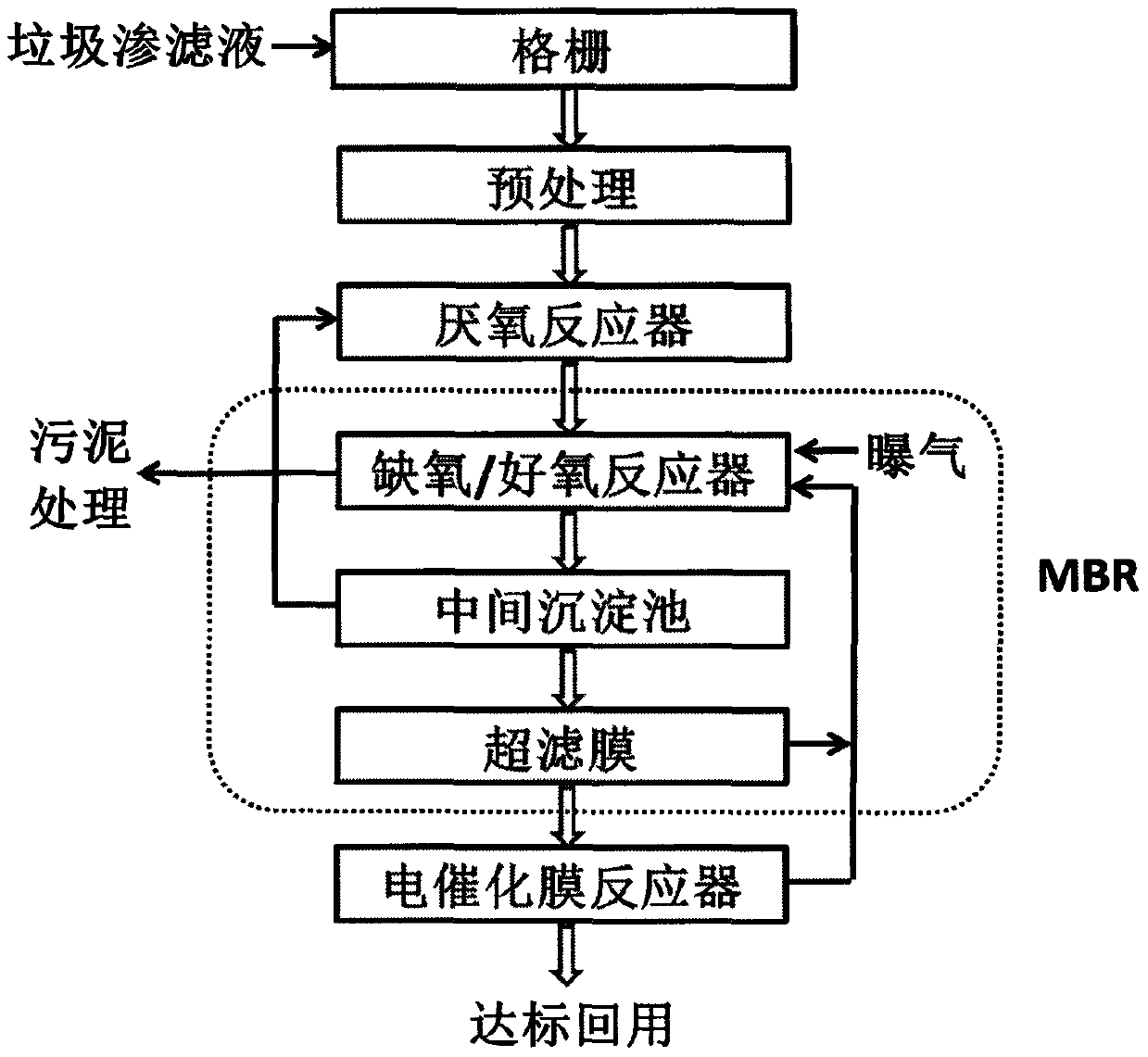

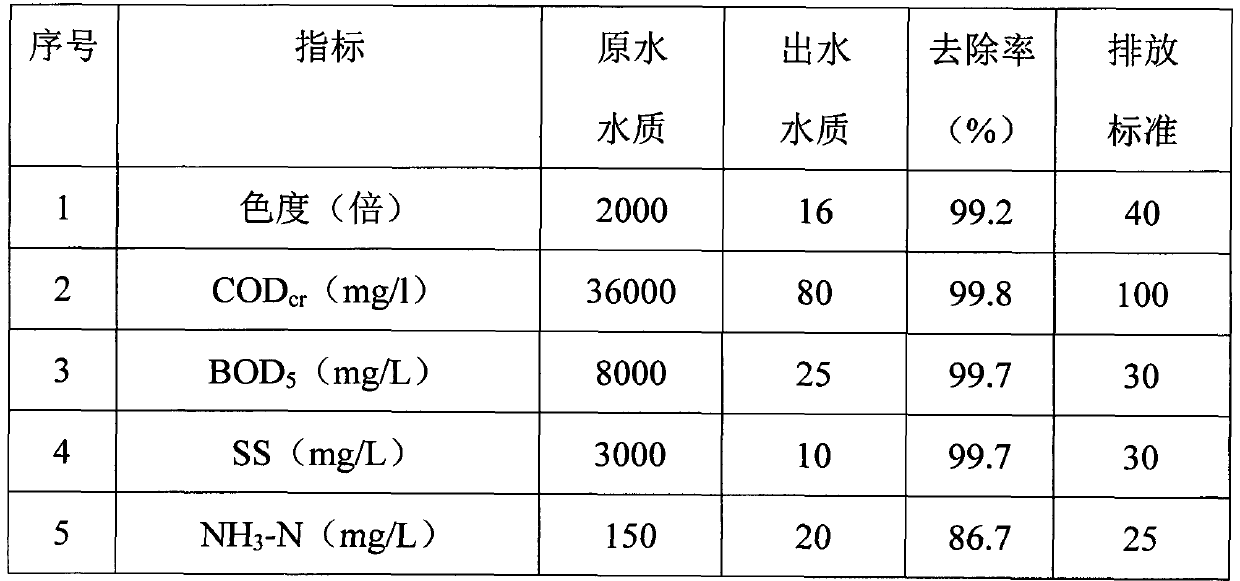

Treatment method for municipal domestic waste penetrating fluid

PendingCN107814458AAchieving processing powerLow biological toxicityFatty/oily/floating substances removal devicesTreatment with anaerobic digestion processesHigh concentrationUltrafiltration

The invention discloses a treatment method for municipal domestic waste penetrating fluid. The method is integrated and developed through techniques of pretreatment devices, anaerobic reactors, membrane bioreactors, electro-catalysis membrane reactors and the like aiming at the proprieties that the waste penetrating fluid is high in organic substance concentration and degradation-resistant. The treatment method comprises the steps of carrying out pretreatment such as coagulating sedimentation on landfill leachate so as to remove colloids or oil, suspends and most heavy metals in the landfill leachate, introducing the landfill leachate into an anaerobic reactor, removing organic pollutants under the effect of anaerobic microorganisms, converting organic amine into inorganic amine, and carrying out anoxic de-digestion, aerobic digestion, ultrafiltration membrane separation and the like by virtue of an external membrane bioreactor, so as to effectively remove high-concentration ammonia nitrogen, COD, BOD, SS and the like; and carrying out electrochemical oxidation and reduction reaction by virtue of an electro-catalysis membrane reactor, so as to decompose organic matters into organicsmall molecules or CO2 and water, decompose ammonia nitrogen into nitrogen, reduce heavy metals for realizing further removal, so that effluent quality reaches national or industrial relevant standards, and the effluent can be discharged or reused.

Owner:TIANJIN POLYTECHNIC UNIV

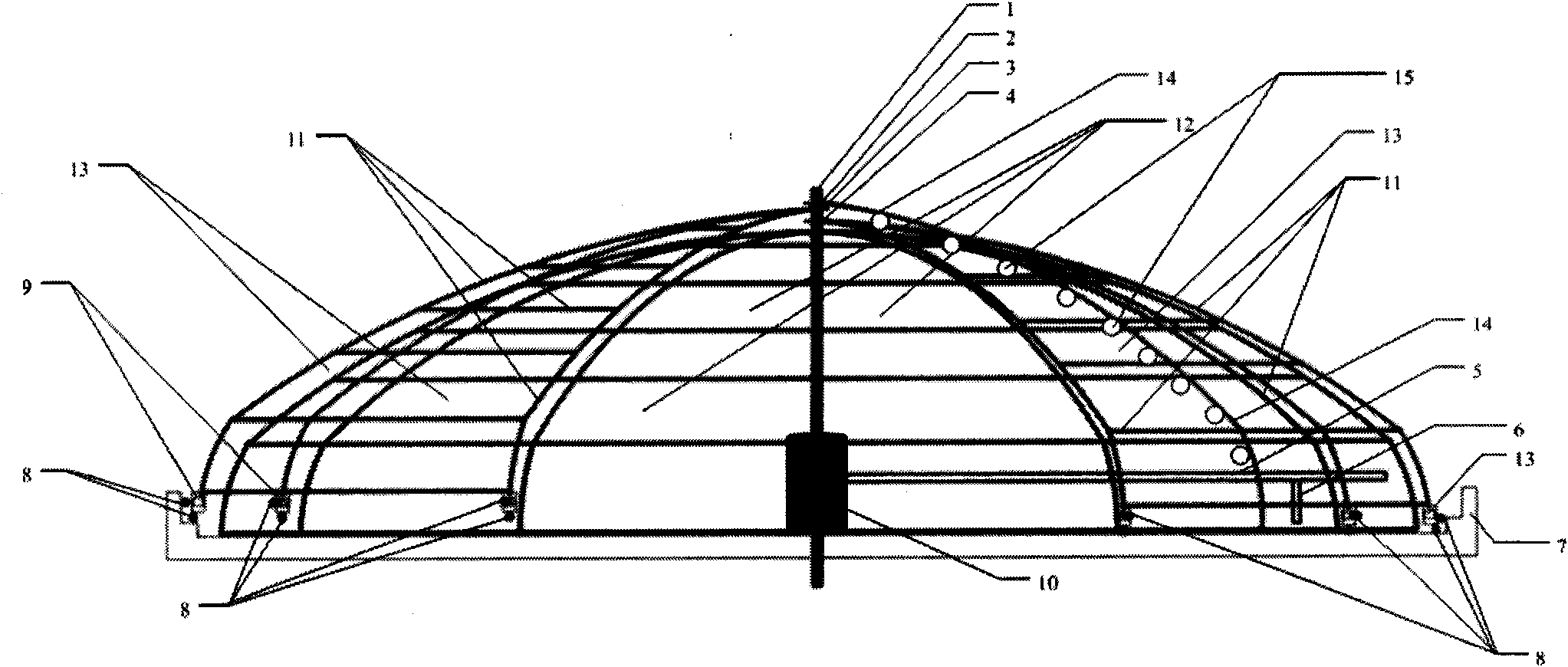

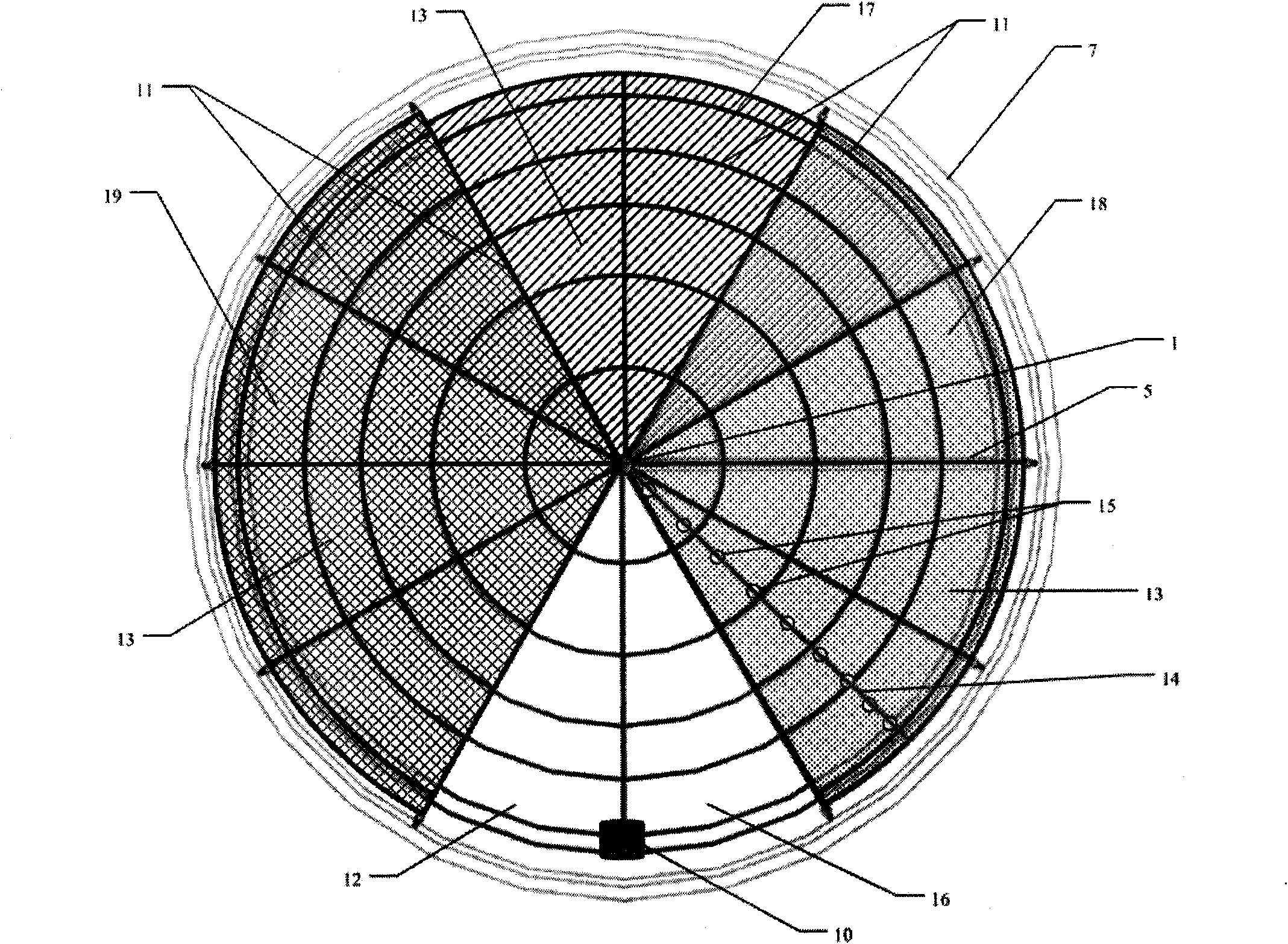

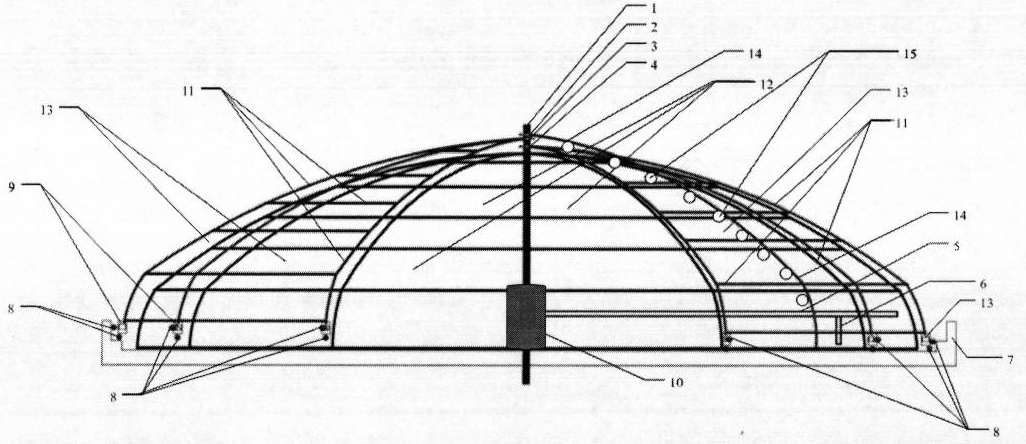

All-weather and full-automatic multi-layer temperature-control circular greenhouse

InactiveCN101906889AIncrease temperatureImprove insulation effectBuilding roofsRoof coveringAutomatic controlInsulation layer

The invention discloses a method for manufacturing an all-weather and full-automatic multi-layer temperature-control circular greenhouse. The greenhouse is characterized by consisting ofcomprising support columns, a light collecting layer, heat insulation layers, a skeleton, a driving device, a rotating device, a moving device, a horizontal working arm, a vertical working arm, layered rails, a snow sweeping arm, a snow sweeping device and the like. The bottom of the multi-layer ceiling is connected with the layered rails on the ground through the moving device, and the automatic control module can freely control the greenhouse to rotate through the moving device according to the time and sunlight intensity. The greenhouse can be sufficiently irradiated by sunlight in daylight, and the multi-layer ceiling is fully insulated at night, so that the temperature in the greenhouse is stable, the heat insulating effect is good and the yield rate of crops is greatly enhanced; the labor cost is reduced, and the service life of field ridge for farmers is prolonged.

Owner:康名彦 +2

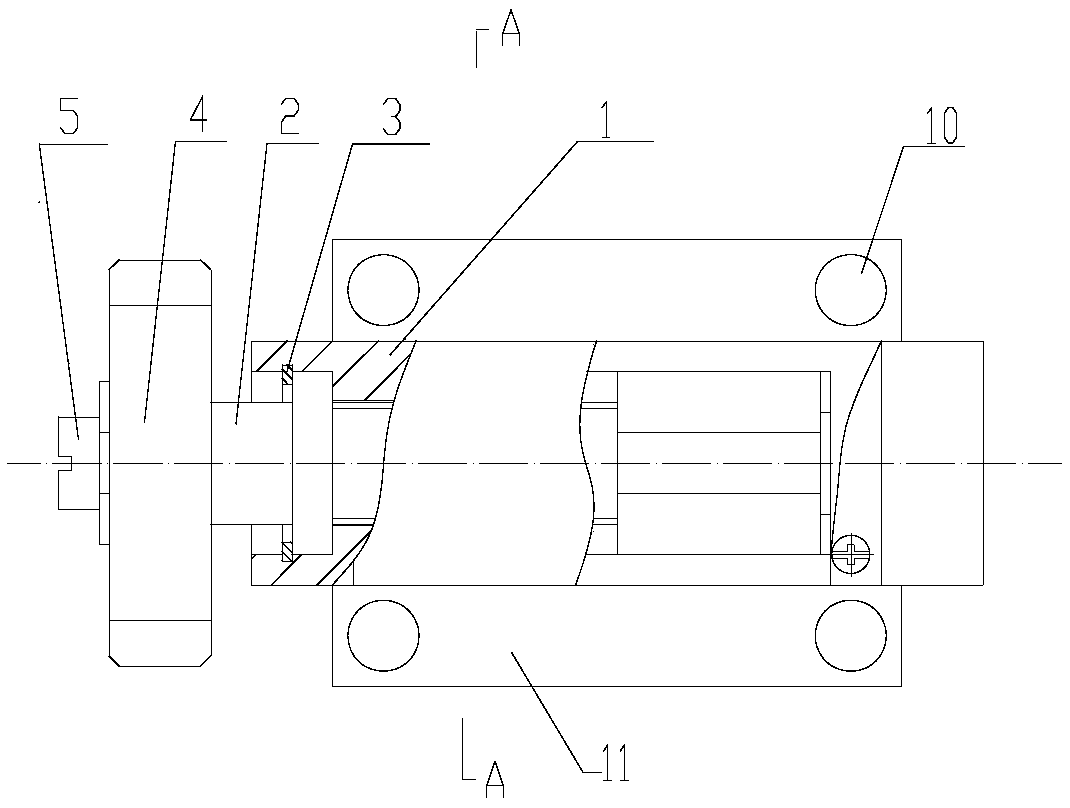

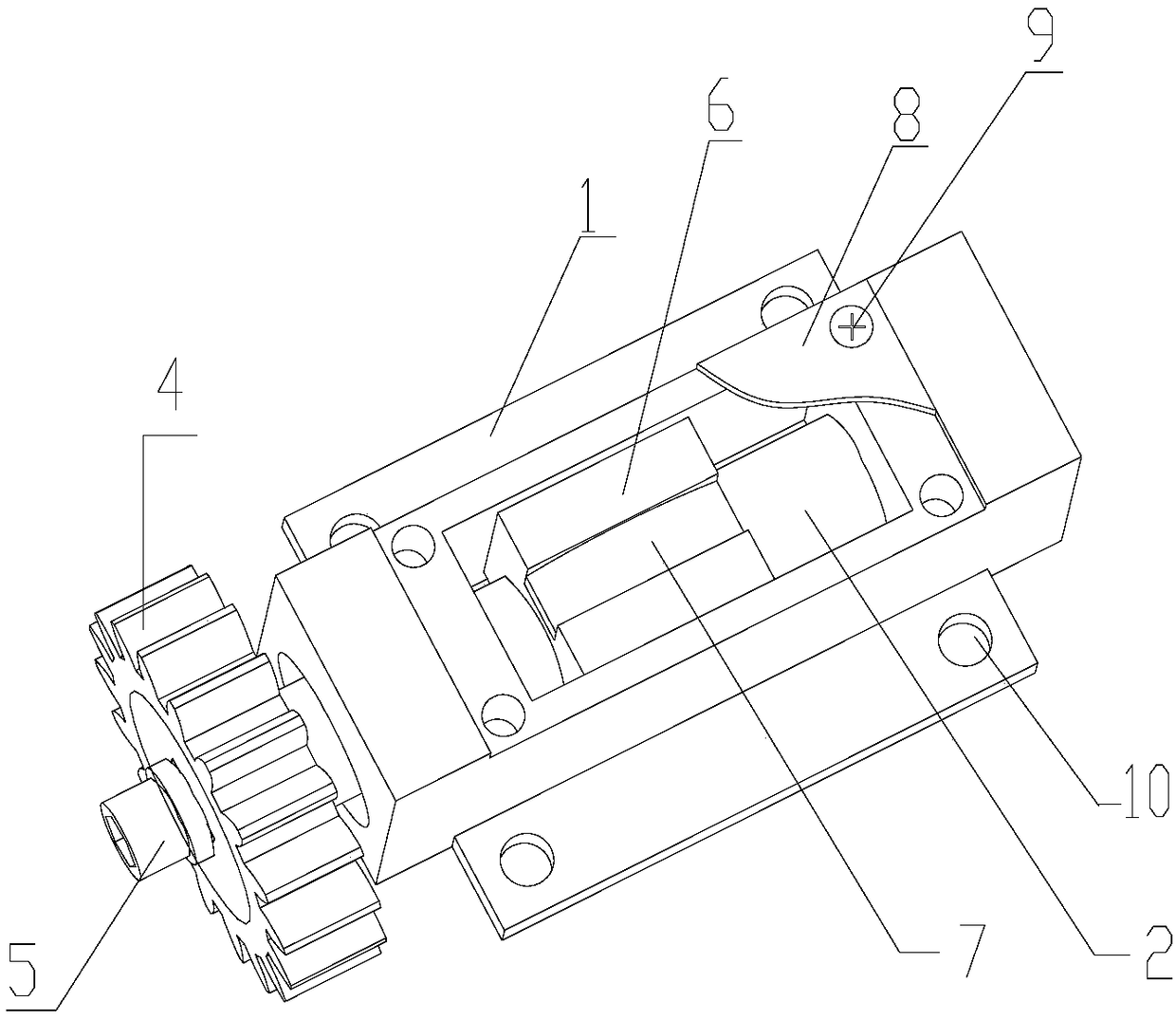

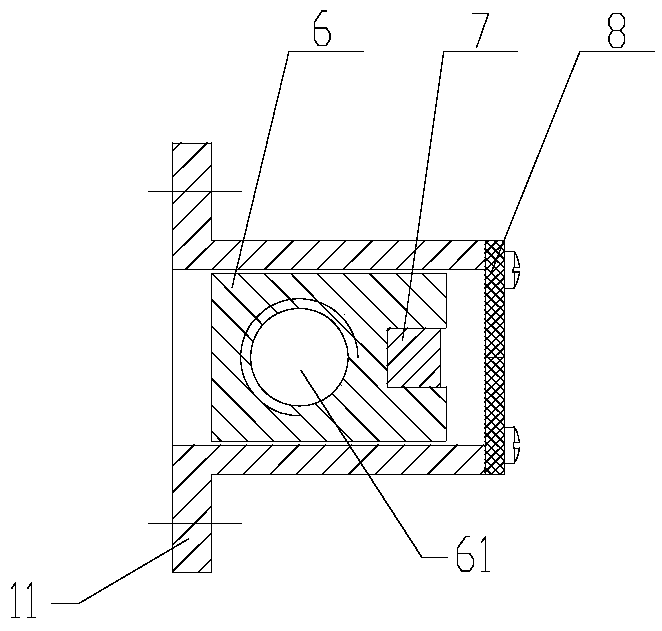

Density determination device for slurry in wet desulfurization absorption tower

InactiveCN103868822AImprove the level of automatic controlPerfect technologySpecific gravity by measuring pressure differencesReal-time dataDifferential pressure

The invention discloses a density determination device for slurry in a wet desulfurization absorption tower. The device comprises a diaphragm type differential pressure transmitter (1) with isometric capillary tubes on flanges at double sides, an intelligent calculation controller (2), a measurement sampling pipeline component (3) and a cleaning discharge pipeline component (4), wherein the differential pressure transmitter (1) continuously monitors a pressure difference value of the gypsum slurry within the fixed height difference in the absorption tower; the intelligent calculation controller (2) calculates the slurry density; the measurement sampling pipeline component (3) is characterized of being inclined upwards and capable of forming an included angle of 30-60 degrees together with the inner wall of the absorption tower, so as to prevent a sampling pipeline from being blocked to interrupt real-time data; the cleaning discharge pipeline component (4) is used for cleaning the sampling pipeline component and a transmitter pressure diaphragm online, so as to ensure the real-time and accurate measurement. By adopting the density determination device related to the invention, the problems of large power consumption, easiness in blockage, easiness in abrasion, the safety and the like existing in a similar device commonly used at present are solved, and the purposes of environment protection, energy conservation and consumption reduction are completely accorded.

Owner:国能朗新明环保科技有限公司

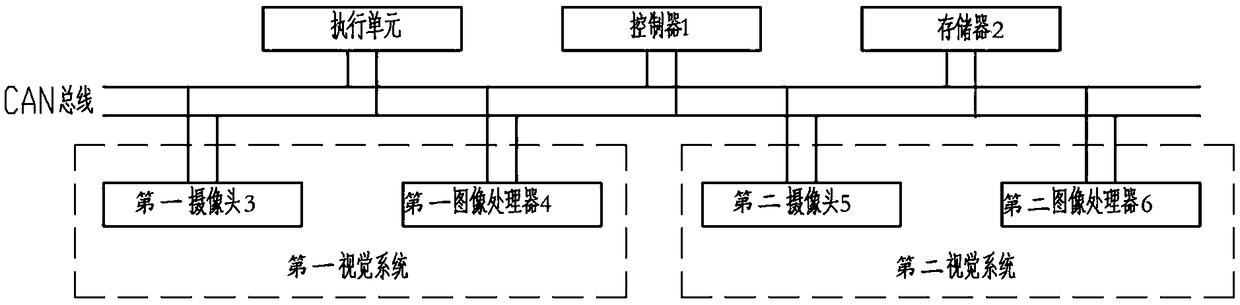

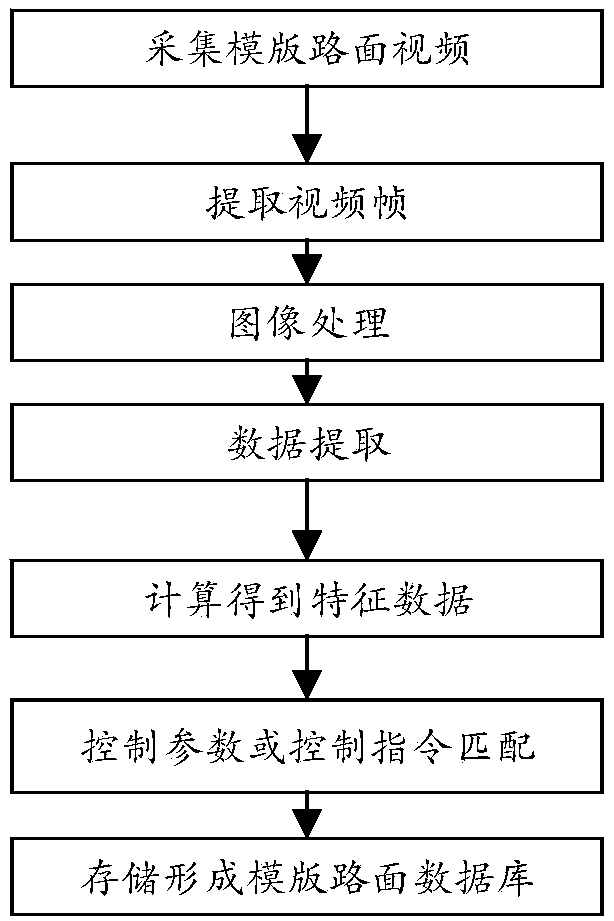

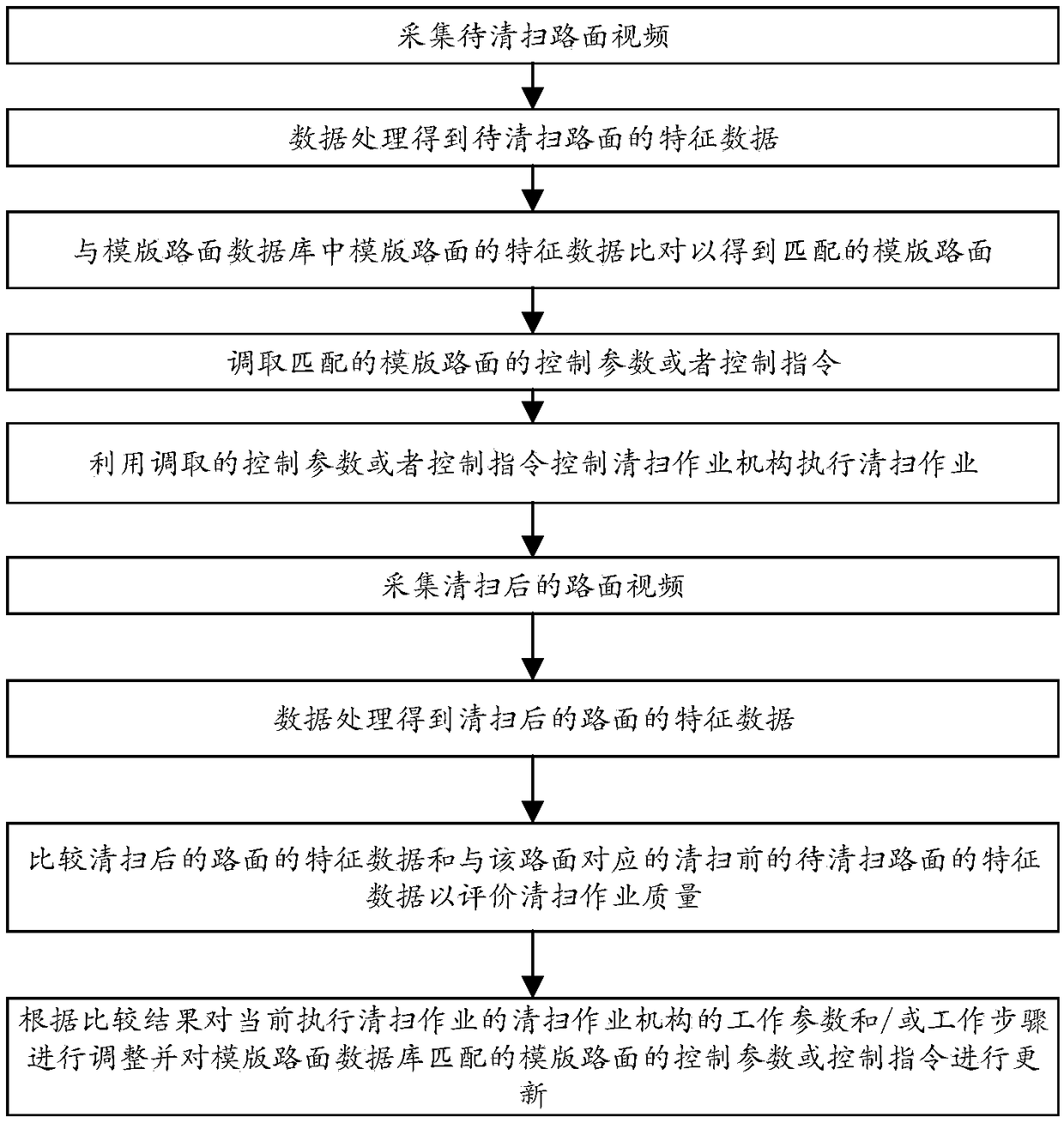

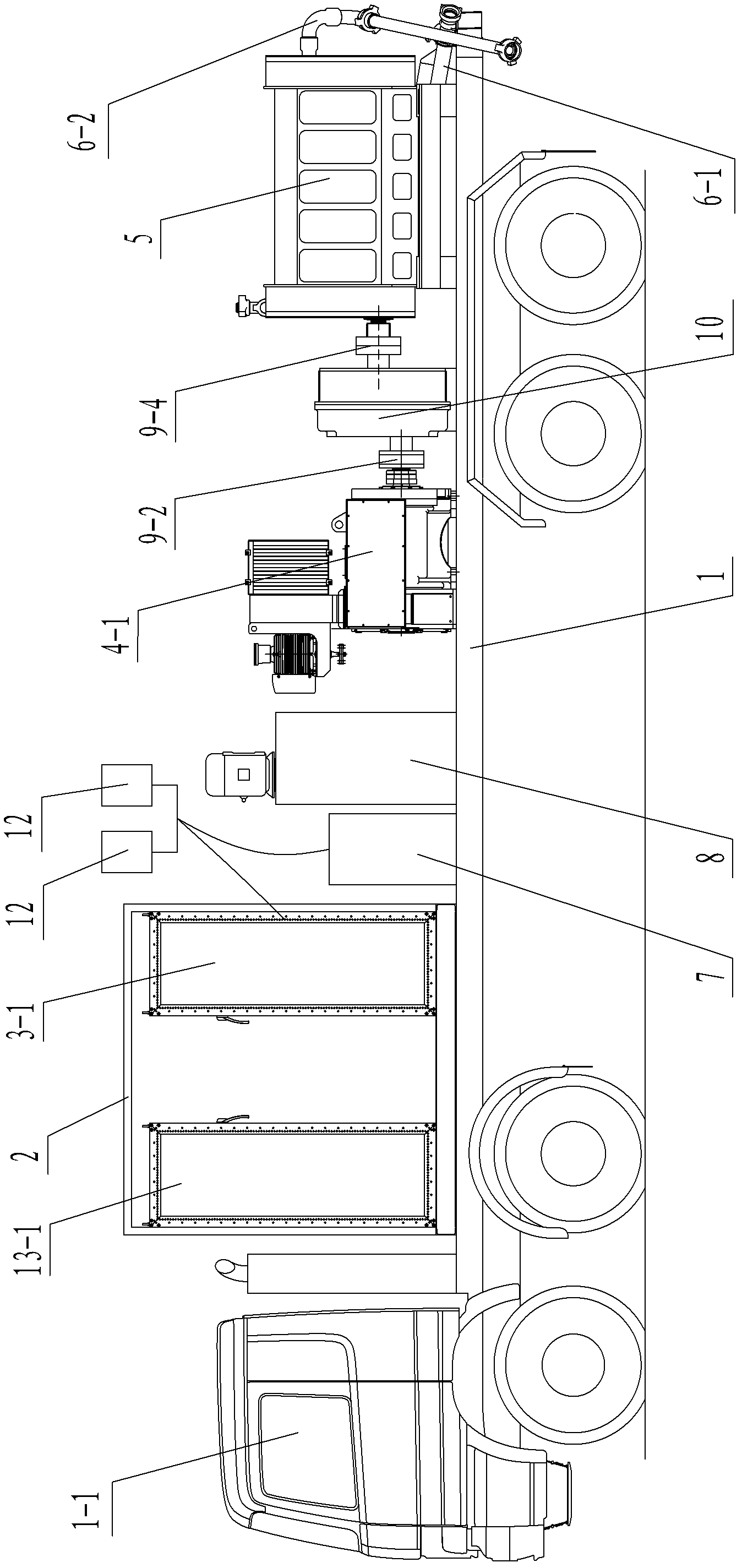

Road operation vehicle operating automatic control method and road operation vehicle

InactiveCN109407606AImprove the level of automatic controlProgramme control in sequence/logic controllersAutomatic controlEngineering

The present invention provides a road operation vehicle operating automatic control method and a road operation vehicle. The method comprises the steps of: obtaining feature data of a road to be operated; comparing feature data of a plurality of template roads in a template road database with the feature data of the road to be operated to determine a matching template road, and transferring a setof control parameters or control commands corresponding to the matching template road in the template road database; and automatically controlling an operation mechanism of the vehicle operation vehicle to regulate the working parameters and / or working steps of the operation mechanism according to the transferred set of the control parameters or control commands. The method is applied to perform automatic selection of the working parameters and / or working steps of the operation mechanism for different road work conditions so as to improve the automatic control level. The present invention further provides a road operation vehicle applying the automatic control method.

Owner:XUZHOU XUGONG ENVIRONMENTAL TECH CO LTD

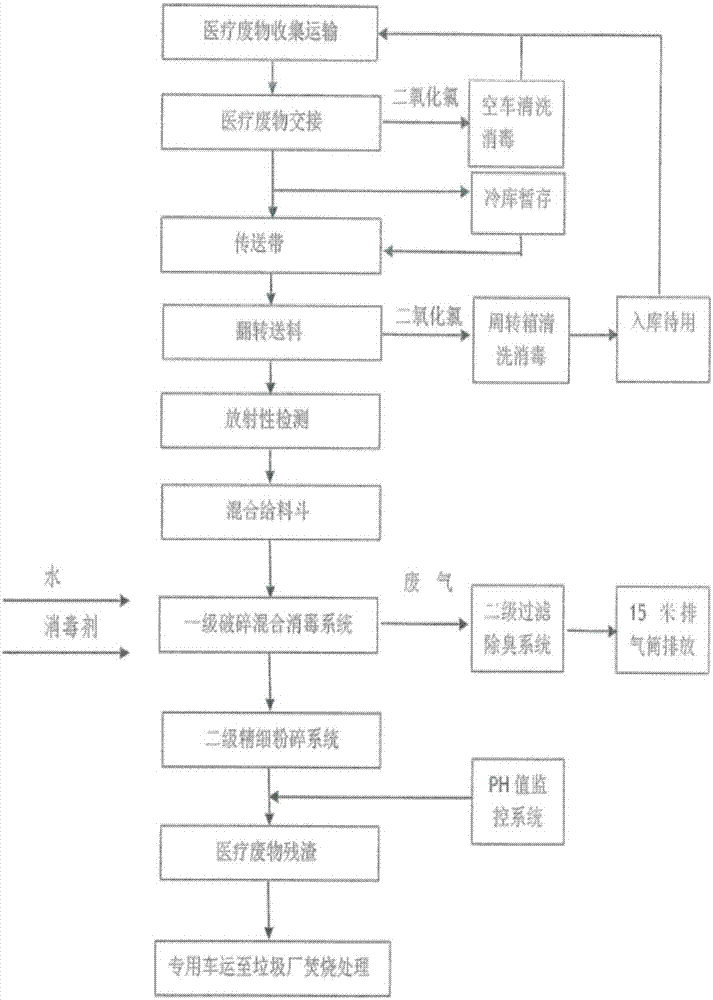

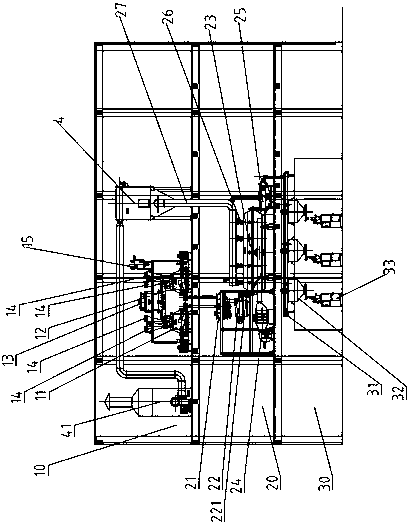

Chemical disinfection harmless treatment technology for medical waste

InactiveCN107497828AWide range of processing adaptationDisinfect and sterilize thoroughlySolid waste disposalMedical waste disposalAutomatic controlMedical waste

The invention belongs to the technical field of waste treatment and provides a chemical disinfection harmless treatment technology for medical waste. The chemical disinfection harmless treatment technology for the medical waste comprises smashing treatment and disinfection treatment of the medical waste and comprises the steps that the medical waste is collected and transported through transportation vehicles, the medical waste conveyed by a conveyer belt is shifted to a lifting frame of an overturning feeding device to be lifted and fed through a circulation box; the medical waste is fed into a mixing feeding hopper through the lifting frame, and meanwhile radioactivity detection is conducted on the medical waste; the medical waste is processed into medical waste residues through fine smashing, and PH value monitoring is conducted when second-grade fine smashing is conducted; and finally, the medical waste residues are transported through dedicated vehicles to a waste plant for incineration treatment. The chemical disinfection harmless treatment technology for the medical waste comprises smashing treatment and disinfection treatment of the medical waste has the advantages of being low in investment, low in operation expense, less in pollutant discharge, high in automatic control level and the like. The chemical disinfection harmless treatment technology for the medical waste is high in automation degree, greatly lowers the treatment cost of the medical waste, solves the medical waste treatment problem of Ningbo City and has good application and popularization value in the industry.

Owner:宁波市北仑环保固废处置有限公司

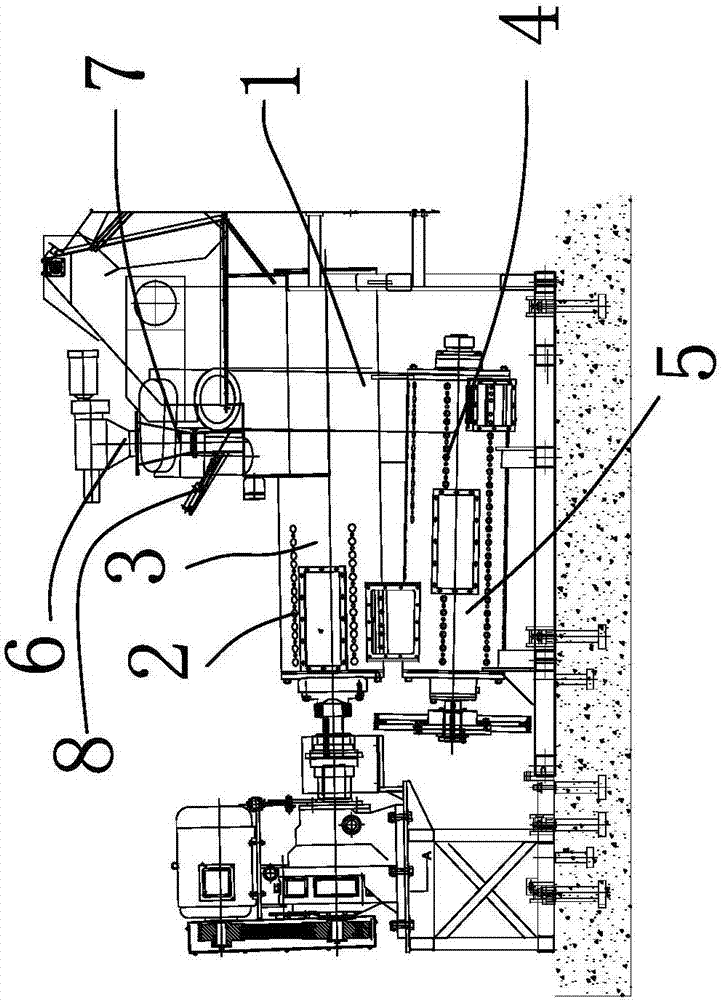

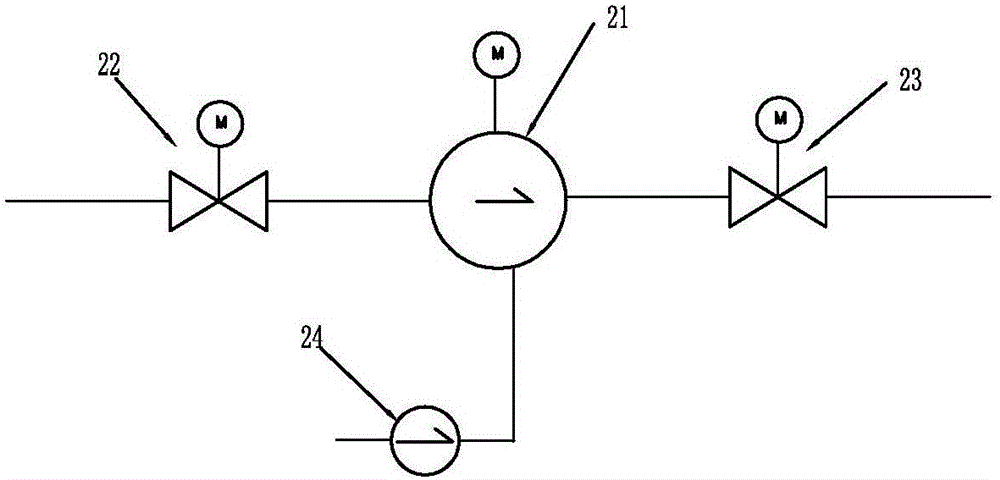

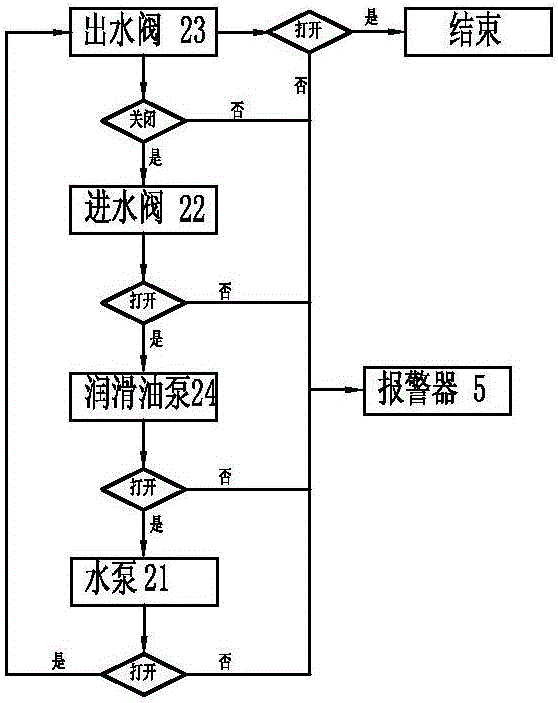

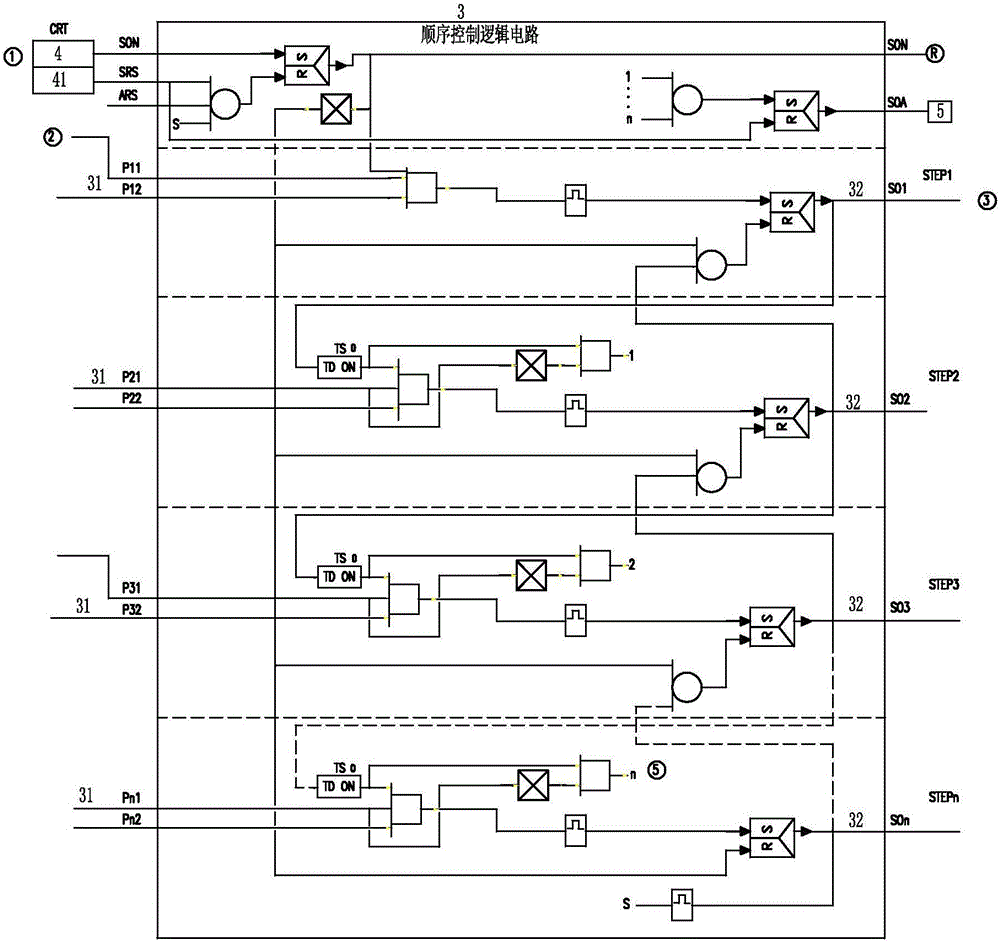

Subunit-level sequence control logic module for nuclear power plant and application method of subunit-level sequence control logic module

InactiveCN105867339AReduce operating intensityAvoid misuseTotal factory controlProgramme total factory controlProcess systemsControl signal

The invention relates to a subunit-level sequence control logic module for a nuclear power plant. The subunit-level sequence control logic module comprises a plurality of auxiliary machines arranged at the subunit level, wherein a plurality of accessory facilities are arranged on the auxiliary machines; a logic control circuit is arranged according to the process system operating sequence of the auxiliary machines and the accessory facilities and is provided with a plurality of signal input ends and a plurality of signal output ends; the auxiliary machines and the accessory facilities are provided with state feedback signal output ends which are electrically connected with the signal input ends, and the signal output ends are connected with control signal input ends of the auxiliary machines and the accessory facilities; the logic circuit judges working states of the auxiliary machines and the accessory facilities on corresponding state feedback loops according to received state feedback signals, and outputs control signals from the signal output ends to control the auxiliary machines and the accessory facilities to start or stop operation according to the process system operating sequence of the auxiliary machines and the accessory facilities, and a subunit-level sequence control logic structure for the nuclear power plant is formed. The subunit-level sequence control logic module for the nuclear power plant has the outstanding beneficial effects of high efficiency, safe and reliable operation, good economic performance and the like.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

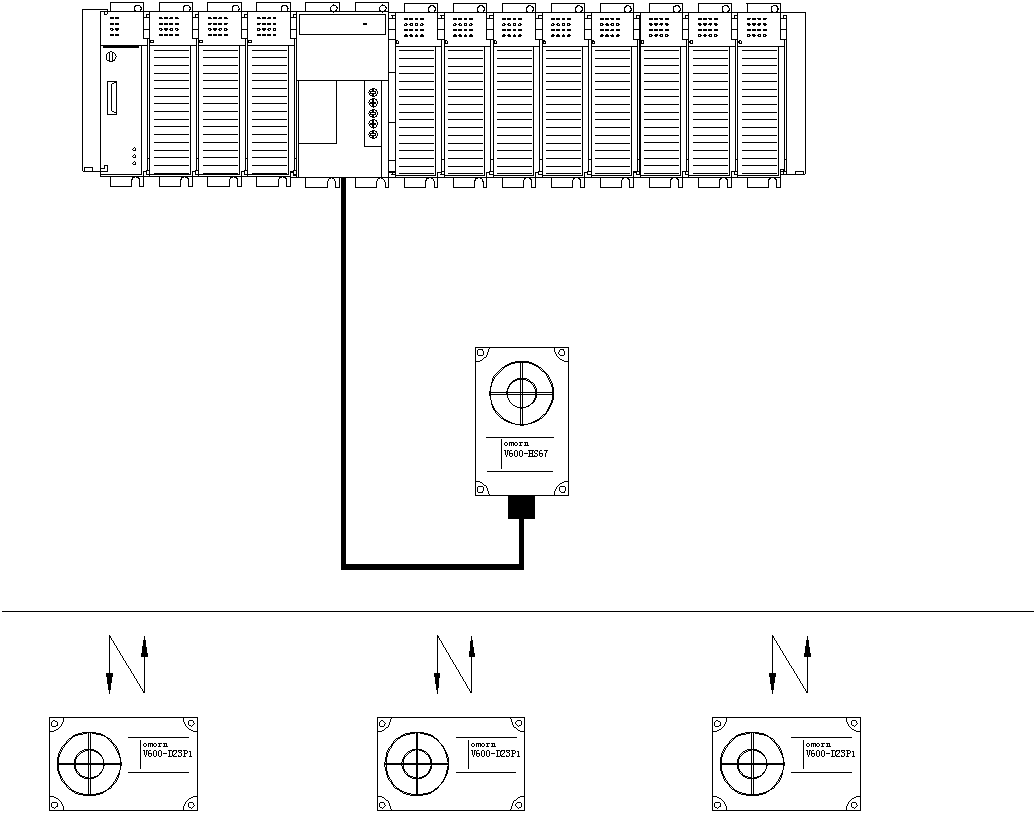

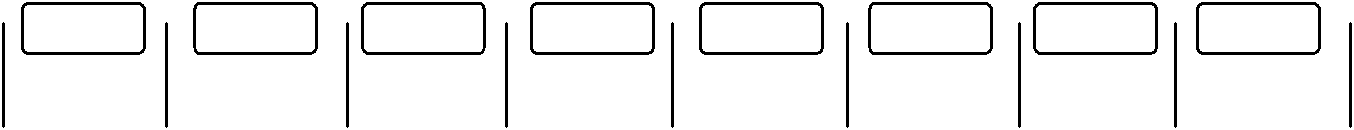

Method for controlling traveling positioning device positioned on gate type scraper material taking machine by applying radio frequency identification technology

InactiveCN102063126AJudging the actual locationEasy to installCo-operative working arrangementsControl using feedbackAutomatic controlDesign cycle

The invention relates to a method for controlling a traveling positioning device positioned on a gate type scraper material taking machine by applying a radio frequency identification technology, which is used for a material taking machine detection industry. The method is characterized in that the actual position of the gate type scraper material taking machine is accurately judged by applying the identification capability of the radio frequency identification technology; the existence of loss of signals is detected through logic judgment; the automation degree of the control of the gate type scraper material taking machine is increased, and the protection grade of the integral machine is enhanced; the contents of different labels are read to obtain different information by detecting the different labels when equipment is moved; a design cycle is shortened, and the automatic control level is enhanced; data passing through an RFID (Radio Frequency Identification Devices) is read through a PLC (Programmable Logic Controller) on an assigned position by matching the traveling positioning device with a traveling coder so as to obtain an actual position value; and the actual position value is written into the traveling coder to achieve the purpose of enhancing the accuracy of a traveling position. The method has easy installation performance, accurately judges the actual position of the gate type scraper material taking machine and enhances the positioning accuracy of the equipment, the generalization of the equipment, the protection grade of the integral equipment and the automatic control level.

Owner:沈阳矿山机械有限公司

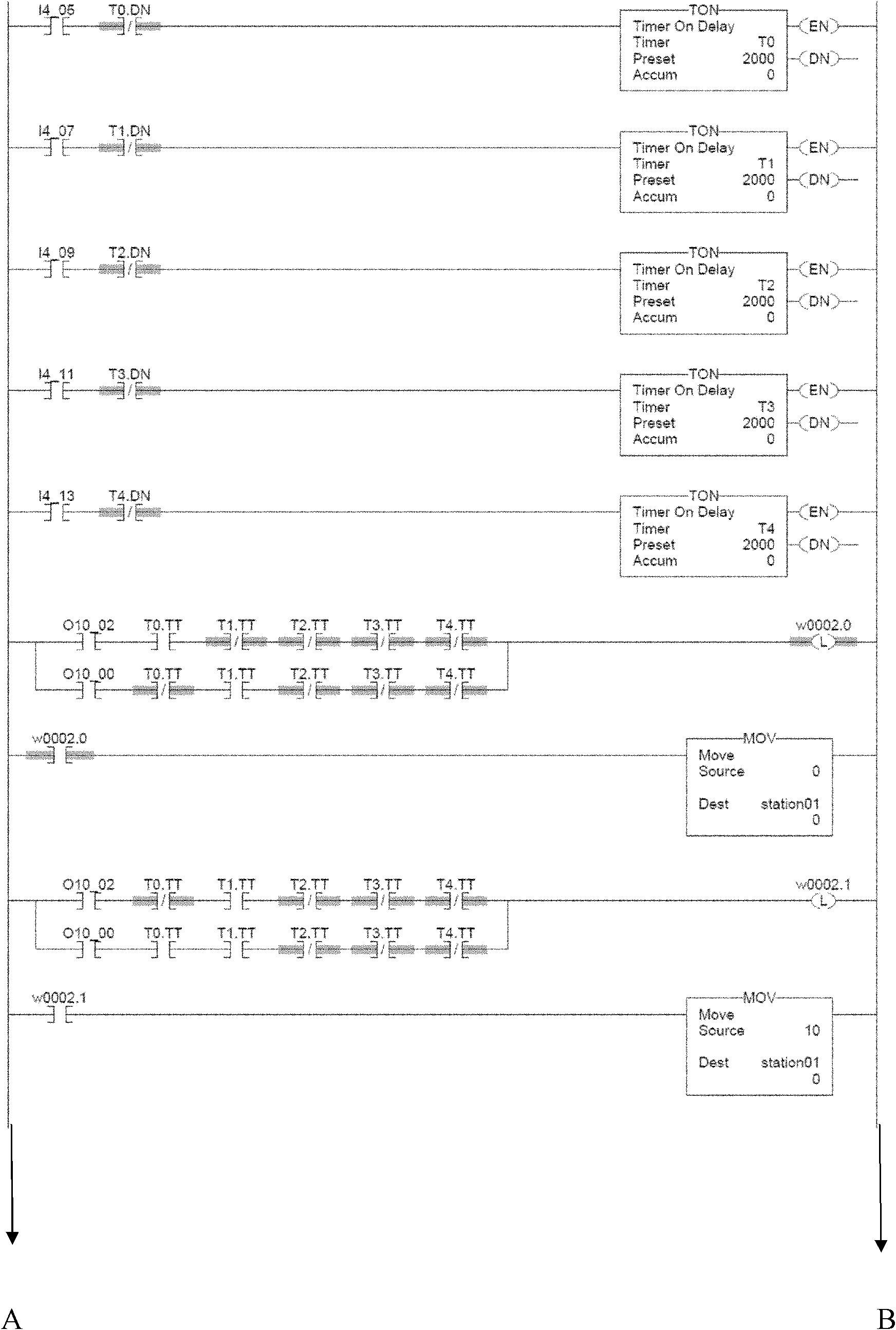

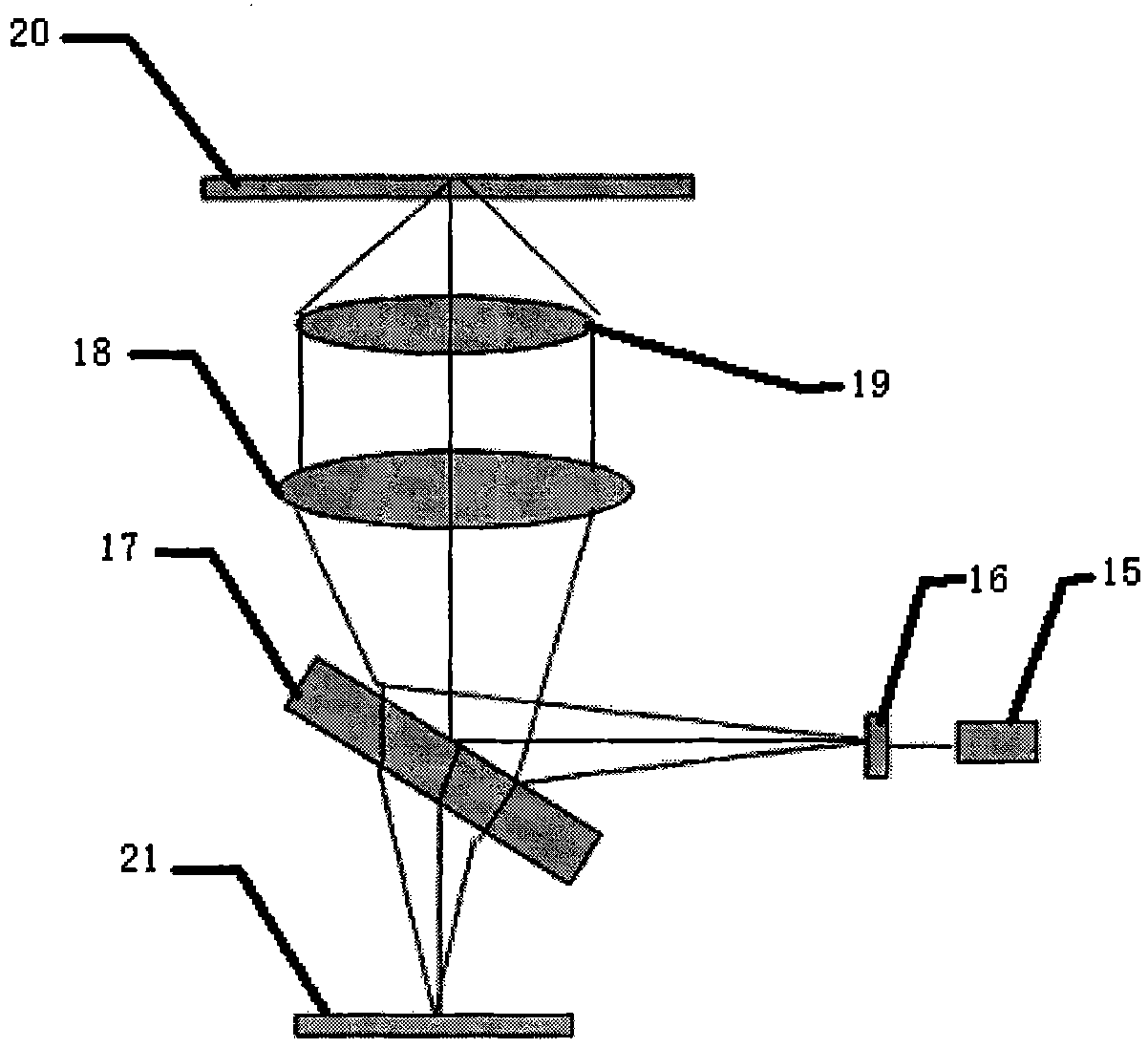

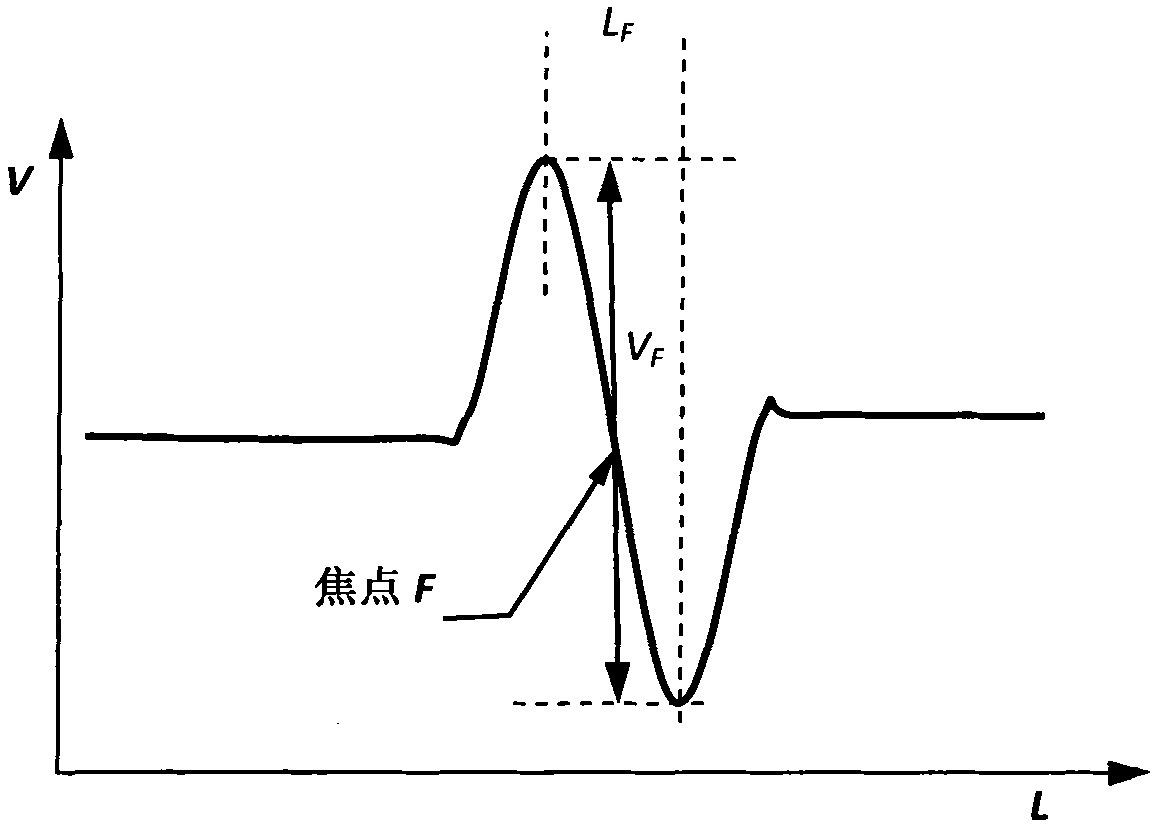

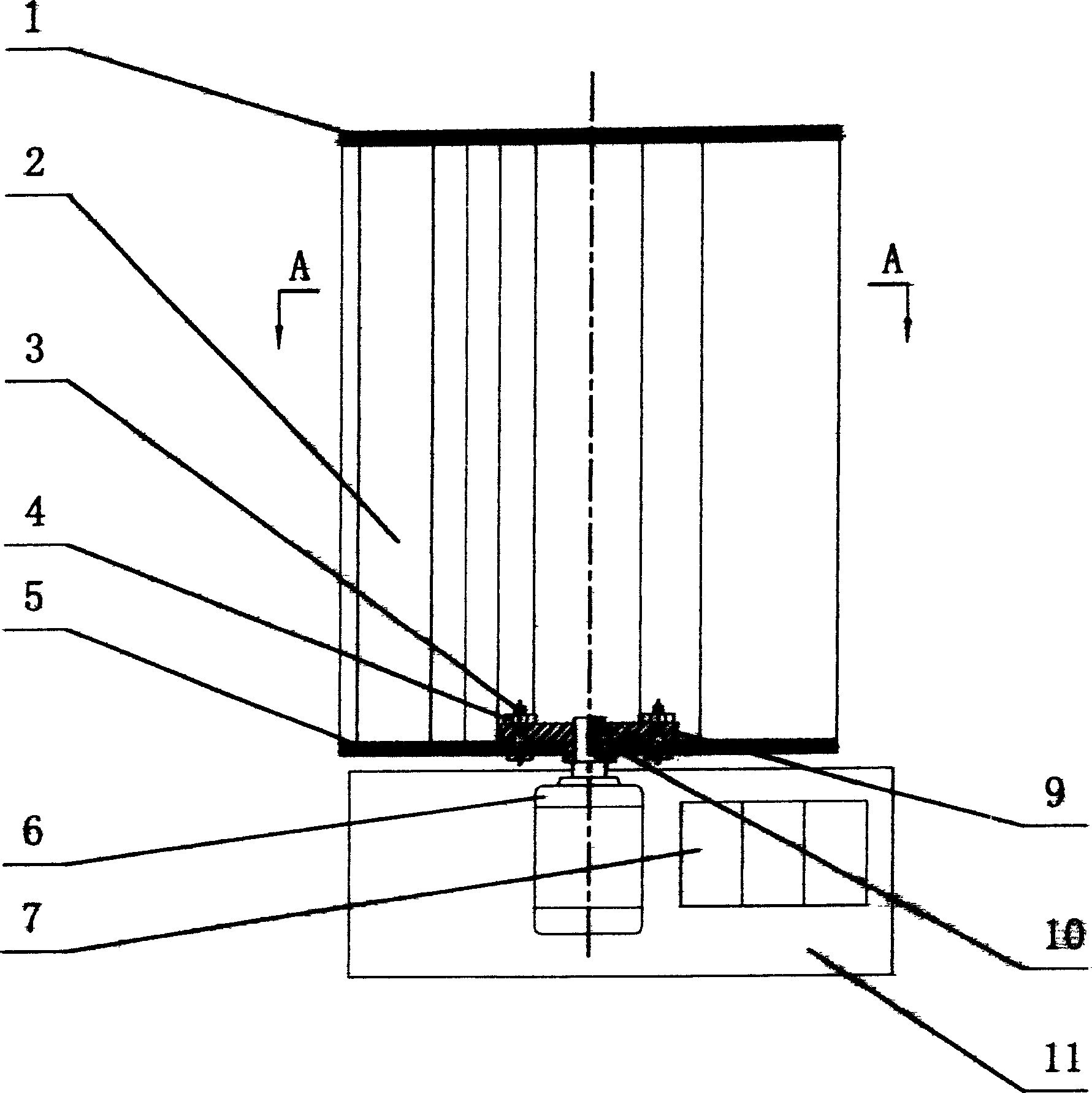

Compound sensor for measuring appearance of nanometer by using holographic laser

ActiveCN102155922ASimple structureLow priceUsing optical meansAutomatic controlMeasurement precision

The invention discloses a compound sensor for measuring appearance of nanometer by using holographic laser, and belongs to the technical field of nanometer appearance measurement. The compound sensor comprises a holographic laser reading head 1, a holographic laser reading head 2, an optical module, a microscopy optical lens, a measurement sample, an electric measurement system, a camcorder (CCD) and a monitoring system, wherein the optical module used for filtering, aligning and splitting lights comprises an optical lens set 1, an optical lens set 2, an adjusting lens 1, an adjusting lens 2, an adjusting lens 3, a splitting lens 1 and a splitting lens 2. The compound sensor has a simple structure and key parts are low in cost. A holographic laser element is taken as the core, and the design structure for the sensor is proposed; by combining improvement on measurement range and maintenance of measurement precision, the sensor can be effectively matched with the measurement system to improve automatic control level for measurement of the system. Moreover, the sensor with video monitoring function can meet the requirements of several fields.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

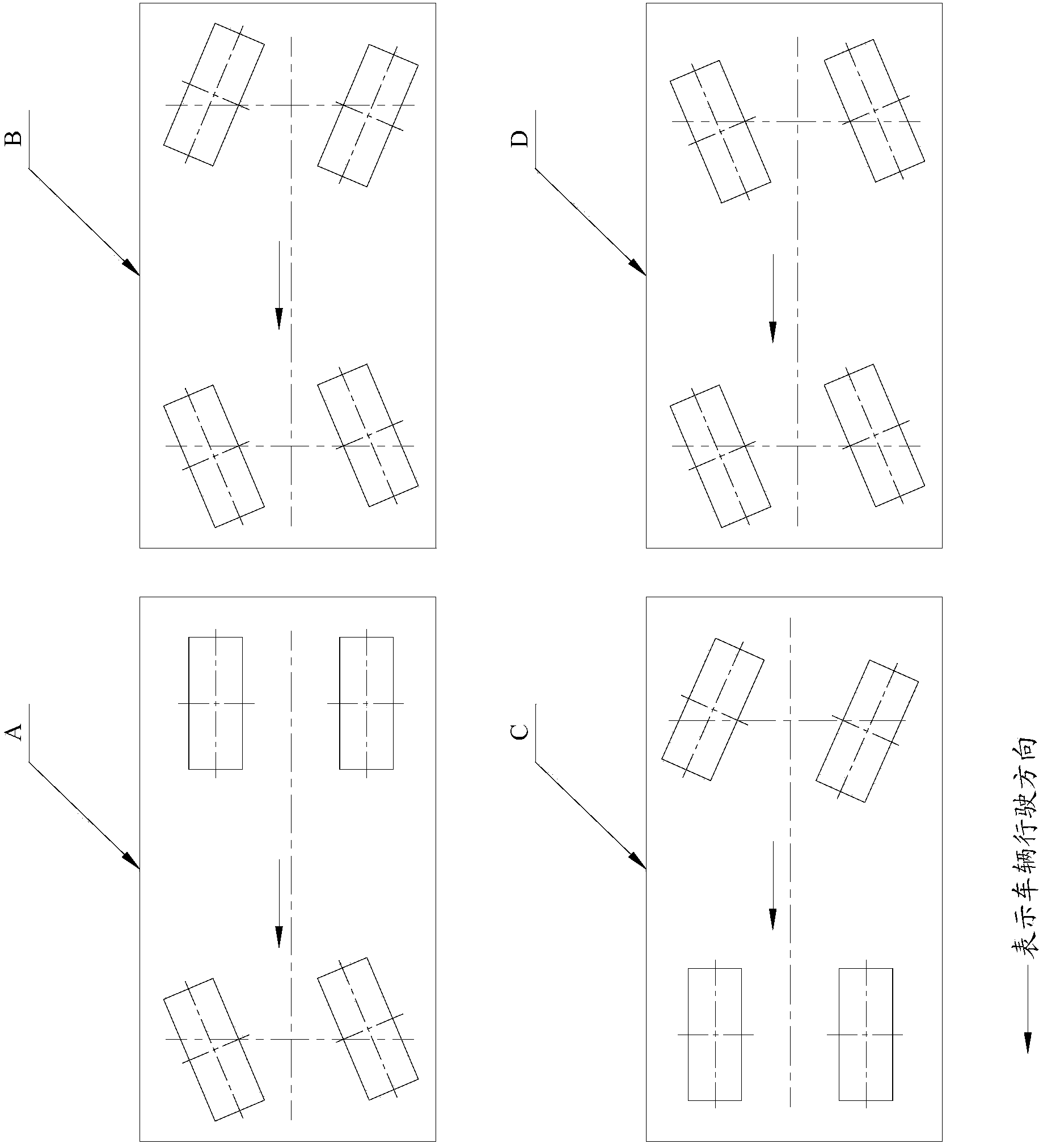

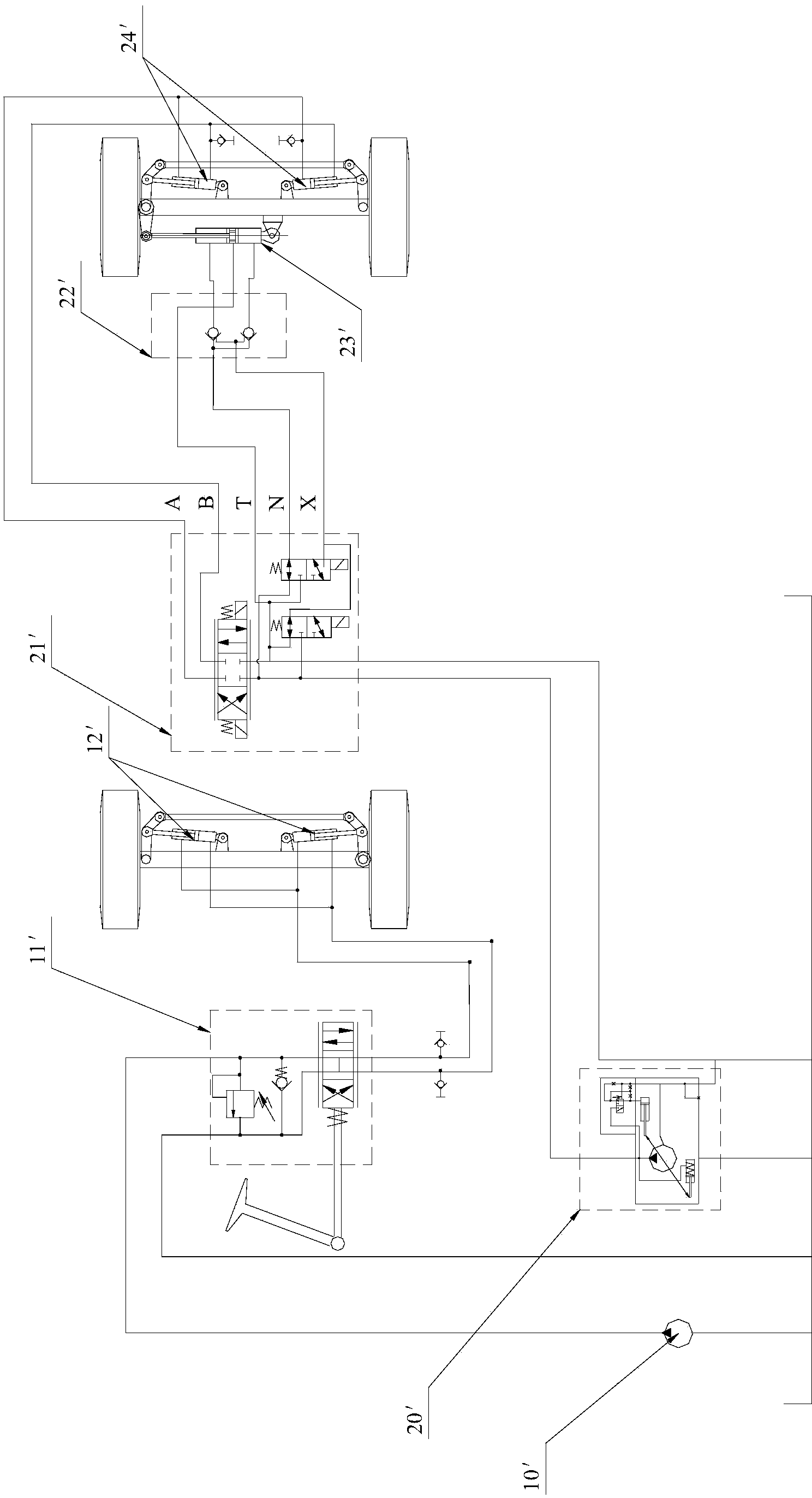

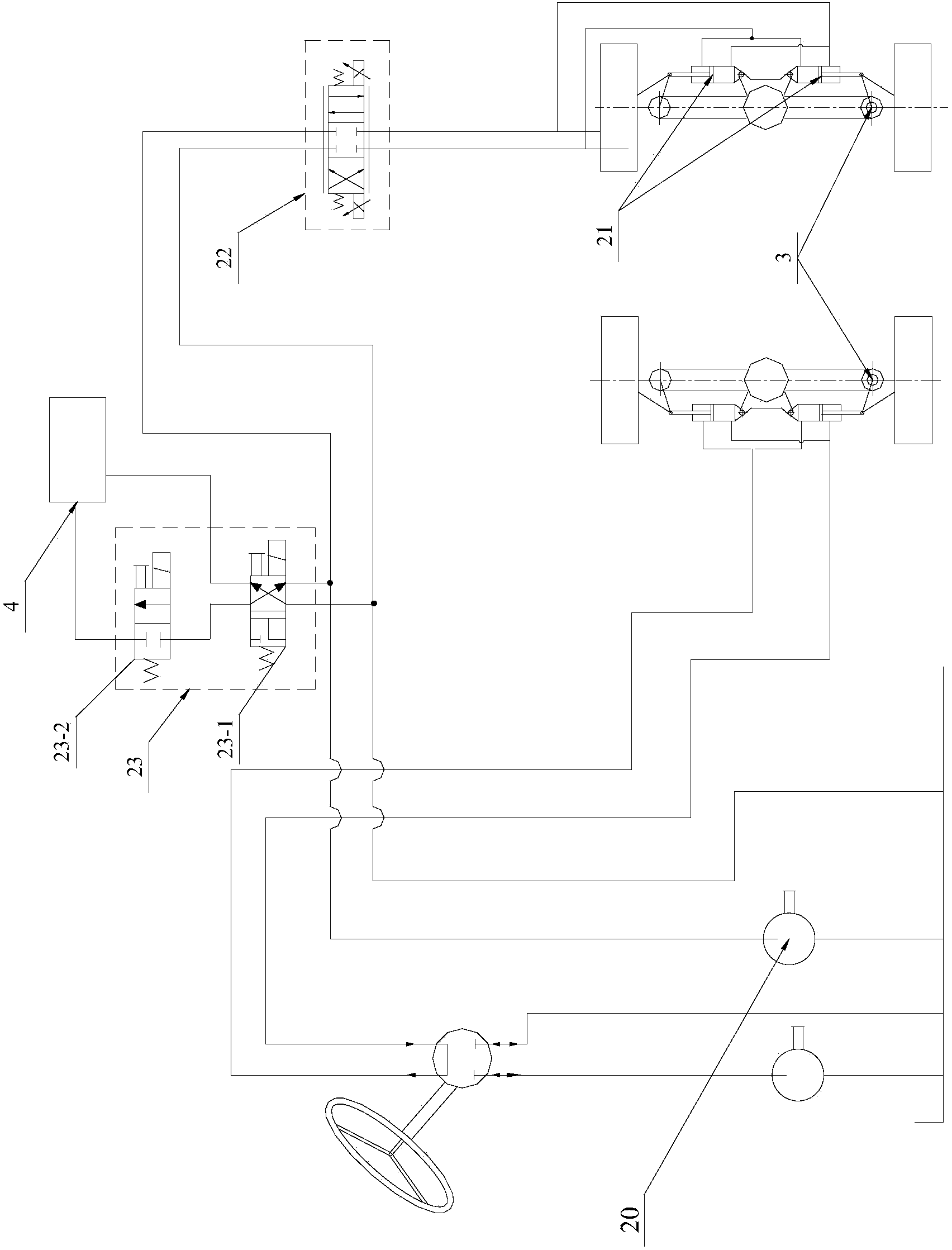

Wheel type crane and steering hydraulic control system thereof

ActiveCN103407488AImprove the level of automatic controlImprove work efficiencySteering linkagesFluid steeringHydraulic pumpControl valves

The invention discloses a steering hydraulic control system. The steering hydraulic control system comprises a front-group wheel steering hydraulic control system and a back-group wheel steering hydraulic control system, wherein the back-group wheel steering hydraulic control system comprises a constant delivery pump, a steering oil cylinder and a first control valve and a second control valve which are arranged between a hydraulic pump and a system return oil way in parallel; the first control valve is used for controlling oil supply of the steering oil cylinder; the second control valve is used for controlling pressure buildup and unloading of the oil way of the steering oil cylinder according to the working condition of the first control valve. The constant delivery pump is taken as a power source, the steering oil cylinder drives back-group wheels to steer by controlling the first control valve and the second valve; and moreover, a locking oil cylinder and a control unit of the locking oil cylinder are further omitted. Obviously, compared with the prior art, the steering hydraulic control system has the advantages that the manufacturing cost and volume are obviously reduced, so that the integral manufacturing costs of the steering hydraulic control system is reduced, and the application range of the steering hydraulic control system is widened. On the basis of the advantages of the steering hydraulic control system, the invention further discloses a wheel type crane comprising the steering hydraulic control system.

Owner:XUZHOU HEAVY MASCH CO LTD

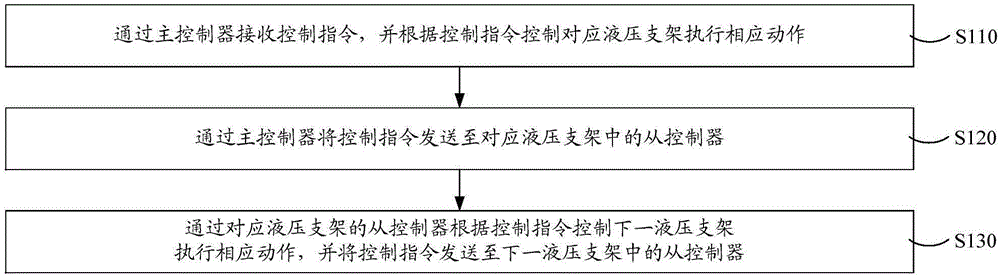

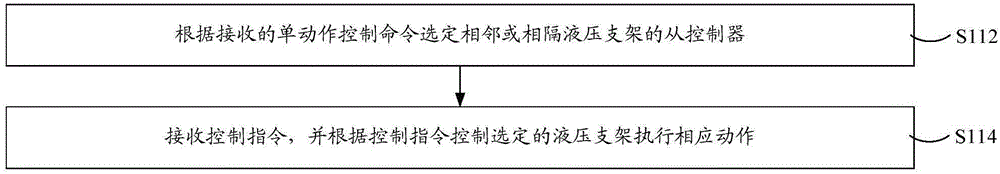

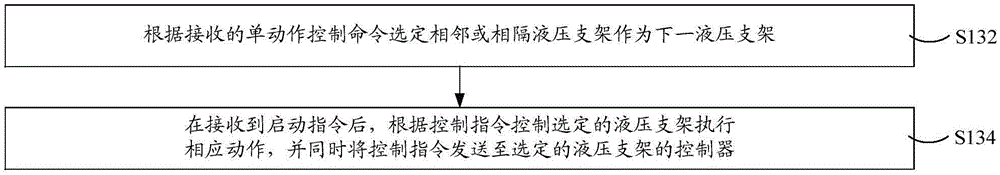

Hydraulic support control method and system

ActiveCN105019929AImprove the level of automatic controlReduce labor intensityMine roof supportsAutomatic controlMaster controller

The invention relates to a hydraulic support control method and system. A master controller receives a control instruction and controls a corresponding hydraulic support according to the control instruction to execute corresponding movements; the master controller sends the control instruction to a slave controller in the corresponding hydraulic support. The corresponding hydraulic support controls a next hydraulic support according to the control instruction to execute corresponding movements and sends the control instruction to a slave controller in the next hydraulic support, related hydraulic supports are controlled according to the steps, and then the control instruction is sent to a slave controller of the next hydraulic support till the related hydraulic supports all complete corresponding movements. The master controller controls the corresponding hydraulic support to execute corresponding movements and sends the control instruction to the slave controller of the corresponding hydraulic support, then the slave controller can repeatedly execute all the single movements executed by the master controller, and then the work efficiency and the automatic hydraulic support control level are improved.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

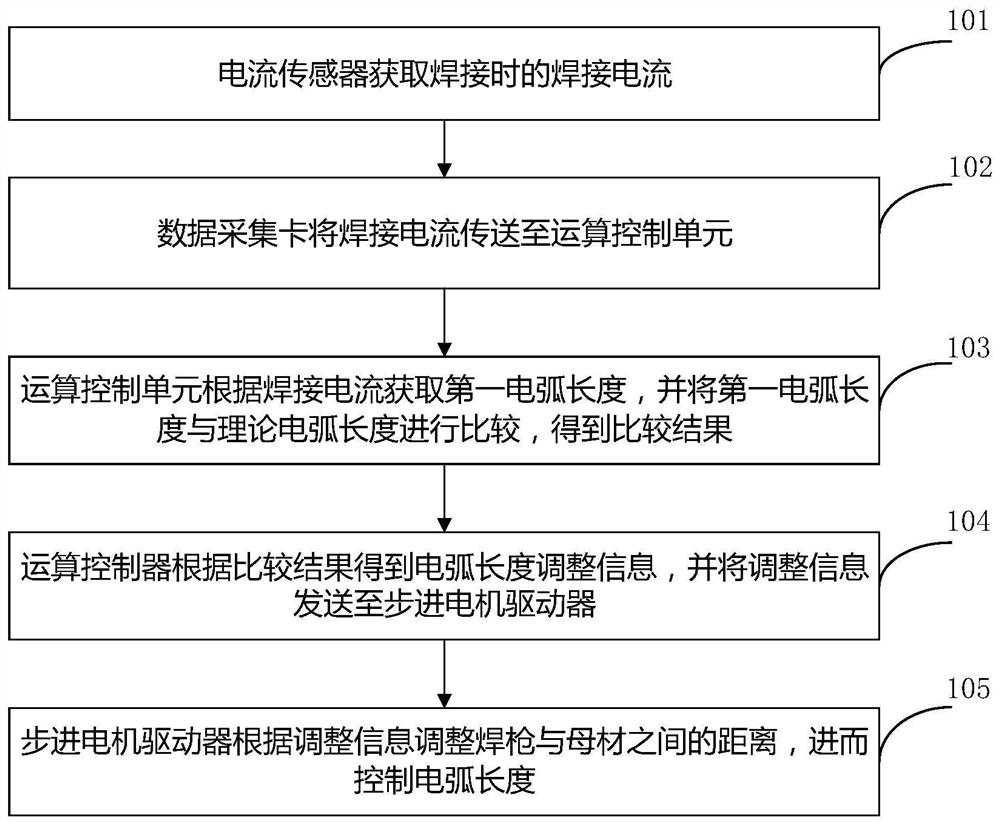

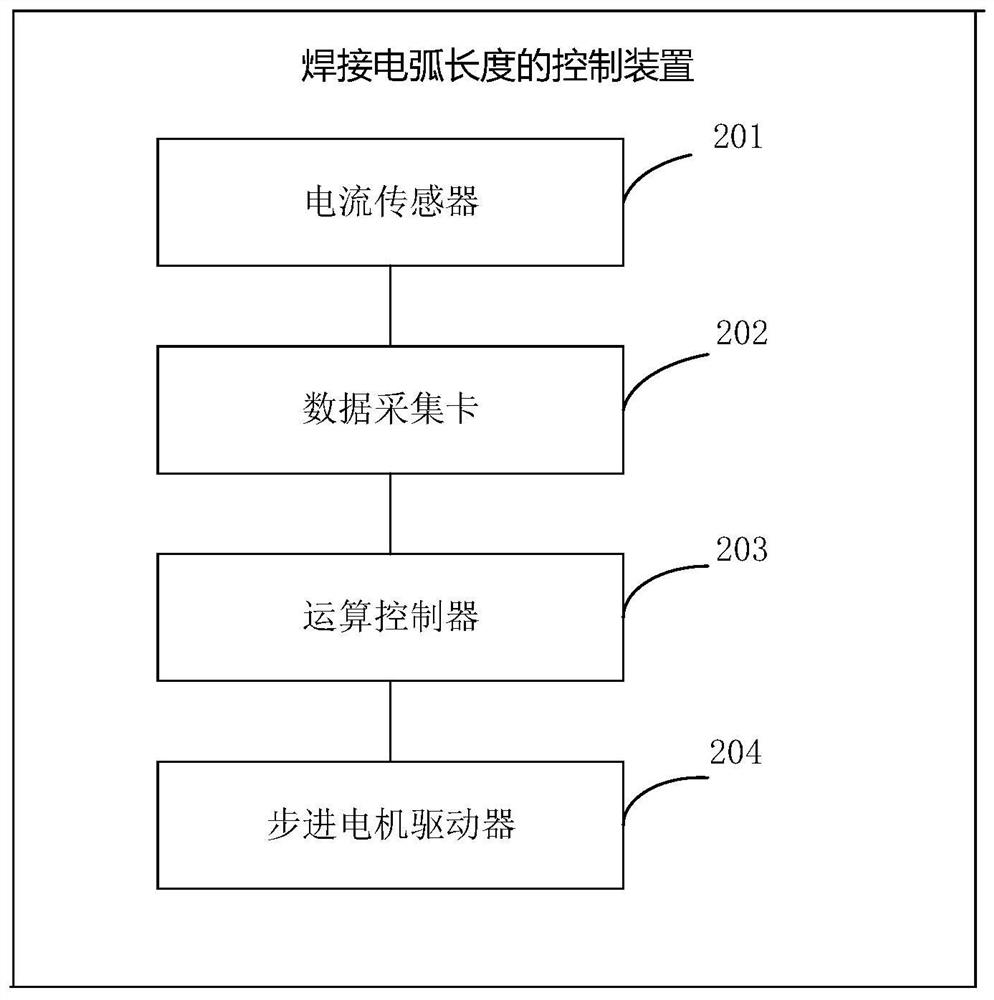

Control method and device for welding electric-arc length

PendingCN112894080ASolve the inaccuracy of automatic controlFix stability issuesElectrode supporting devicesWelding accessoriesCurrent transducerAutomatic control

The invention discloses a control device and device for welding electric-arc length, and belongs to the technical field of welding. The method comprises the following steps: obtaining welding current during welding by a current sensor; transmitting the welding current to a calculating controller through a data acquisition card; obtaining a first electric-arc length according to the welding current by the calculating controller, and comparing the first electric-arc length with a theoretical electric-arc length to obtain compared results; obtaining electric-arc length adjusting information according to the compared results by the calculating controller, and sending the adjusting information to a step motor driver; and adjusting a distance between a welding gun and a mother material by the step motor driver according to the adjusting information to control the electric-arc length. The control method solves the problems that gas-protective welding arc length automatic control is inaccurate, unstable and the like, so that control on welding process parameters is quicker and more accurate.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

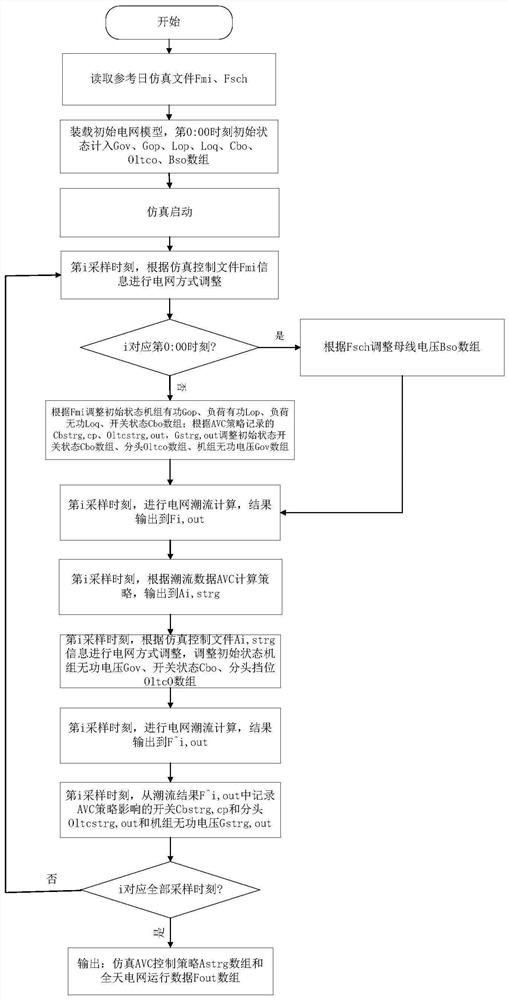

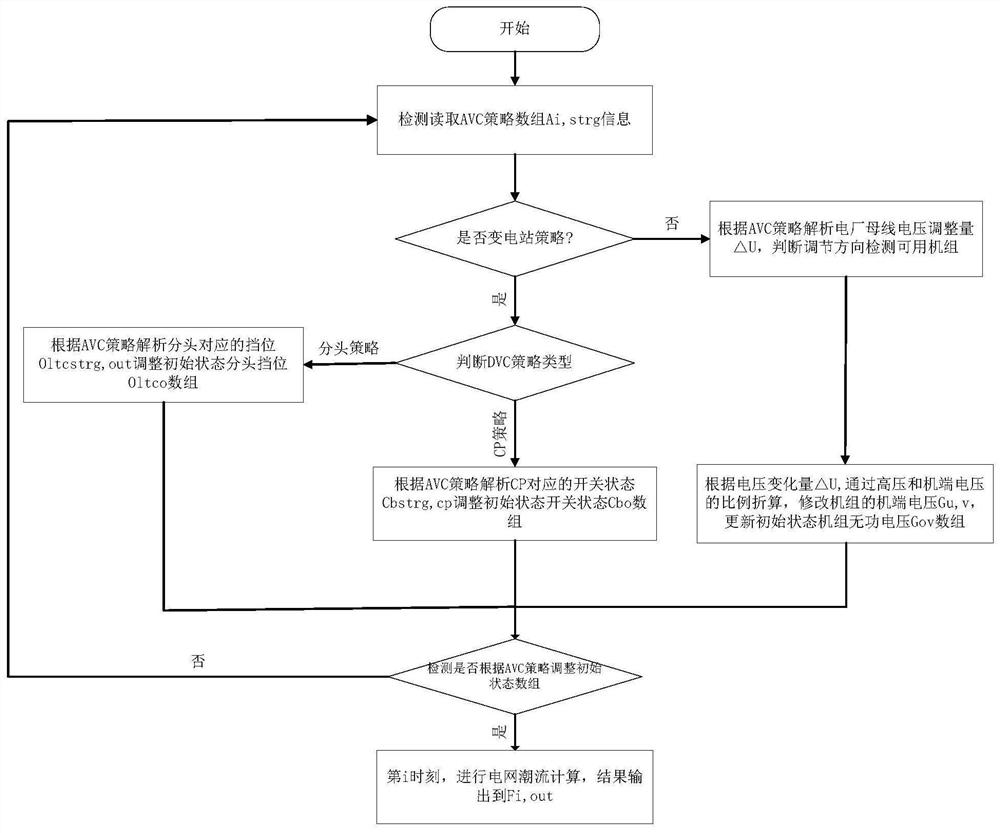

Power grid automatic voltage control simulation method based on continuous power flow simulation

ActiveCN112865108ASolving Voltage Control ProblemsImprove the level of automatic controlAc network voltage adjustmentAc networks with different sources same frequencyAutomatic controlLoop control

The invention belongs to the technical field of power grid dispatching, and particularly relates to a power grid automatic voltage control simulation method based on continuous power flow simulation. According to the method, a model and data of real-time operation of a power grid are utilized, closed-loop control of power grid data and an AVC strategy is formed through simulation load flow calculation from the perspective of the whole system, suggestions and guidance are given to an optimal reactive voltage adjustment scheme of the power grid through simulation data analysis, and real-time optimization control of the voltage is carried out in a continuous closed loop mode by taking voltage safety and high quality as constraints and taking system operation economy as a target. By continuously and cyclically executing the method, automatic control simulation of the reactive voltage of the power grid under various typical daily section conditions is realized, common reference and basis are provided for setting automatic voltage control parameters of the power grid under various load states, an automatic control strategy of the reactive voltage is optimized, and the automatic control level of the reactive voltage is improved.

Owner:XINZHOU POWER SUPPLY COMPANY STATE GRID SHANXI ELECTRIC POWER

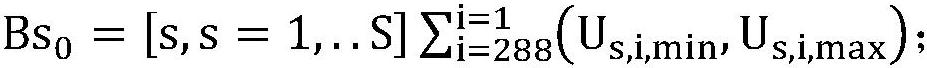

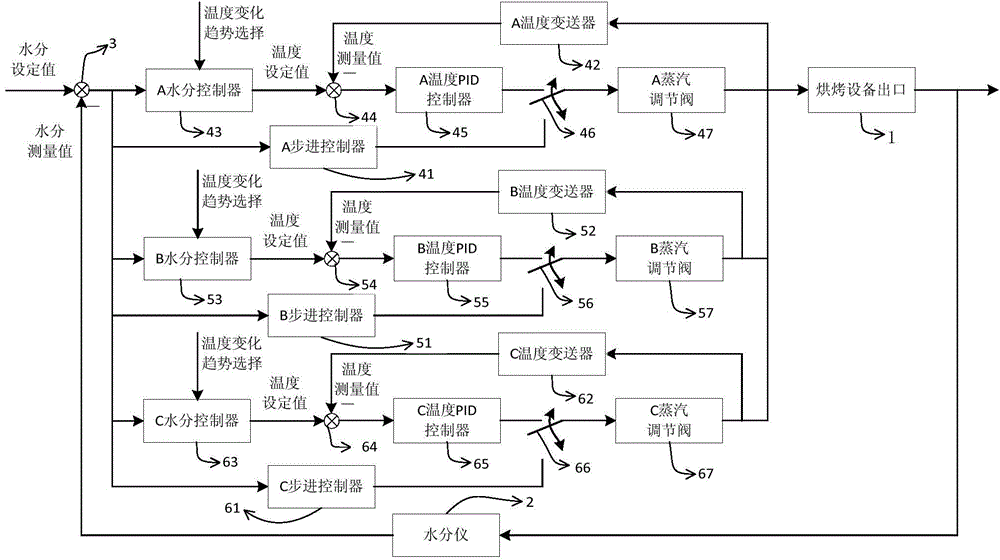

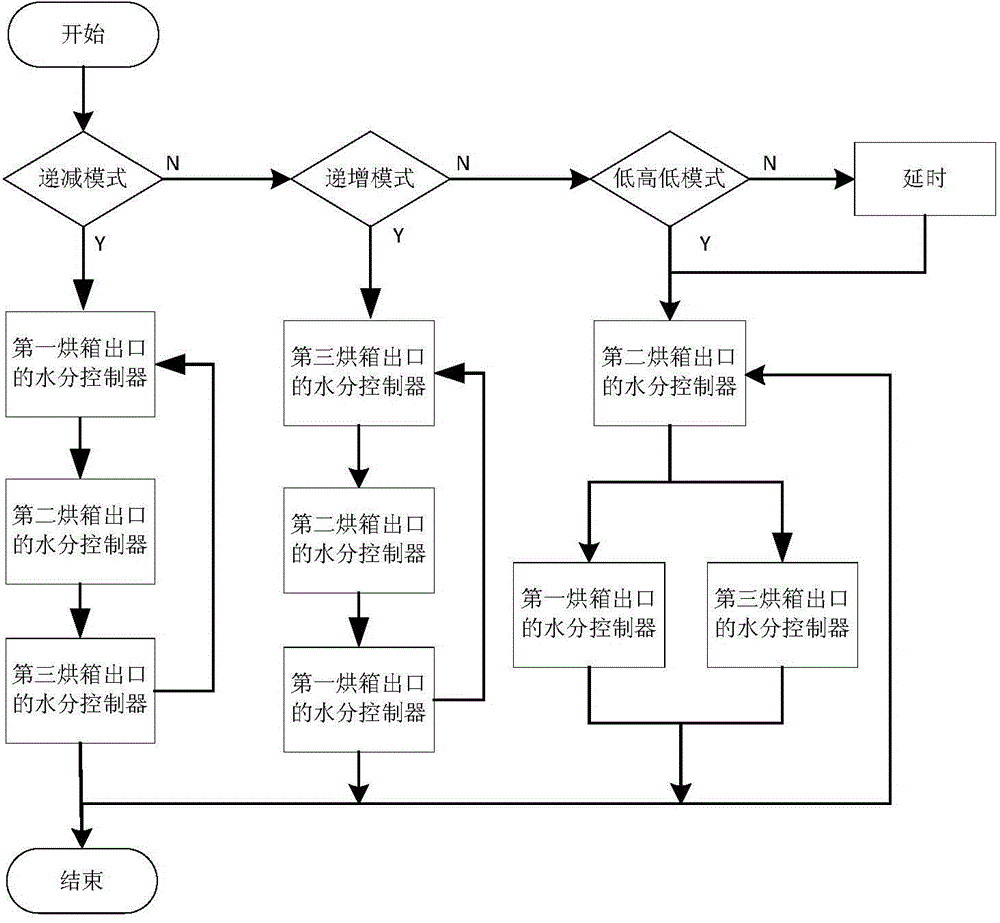

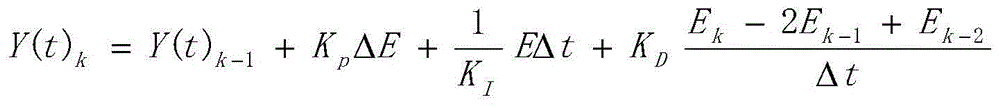

Working method and moisture control system of multi-mode slice baking device

ActiveCN104522872AOvercoming pure hysteresisReduce nonlinear effectsTobacco preparationTobacco treatmentProduction lineAutomatic control

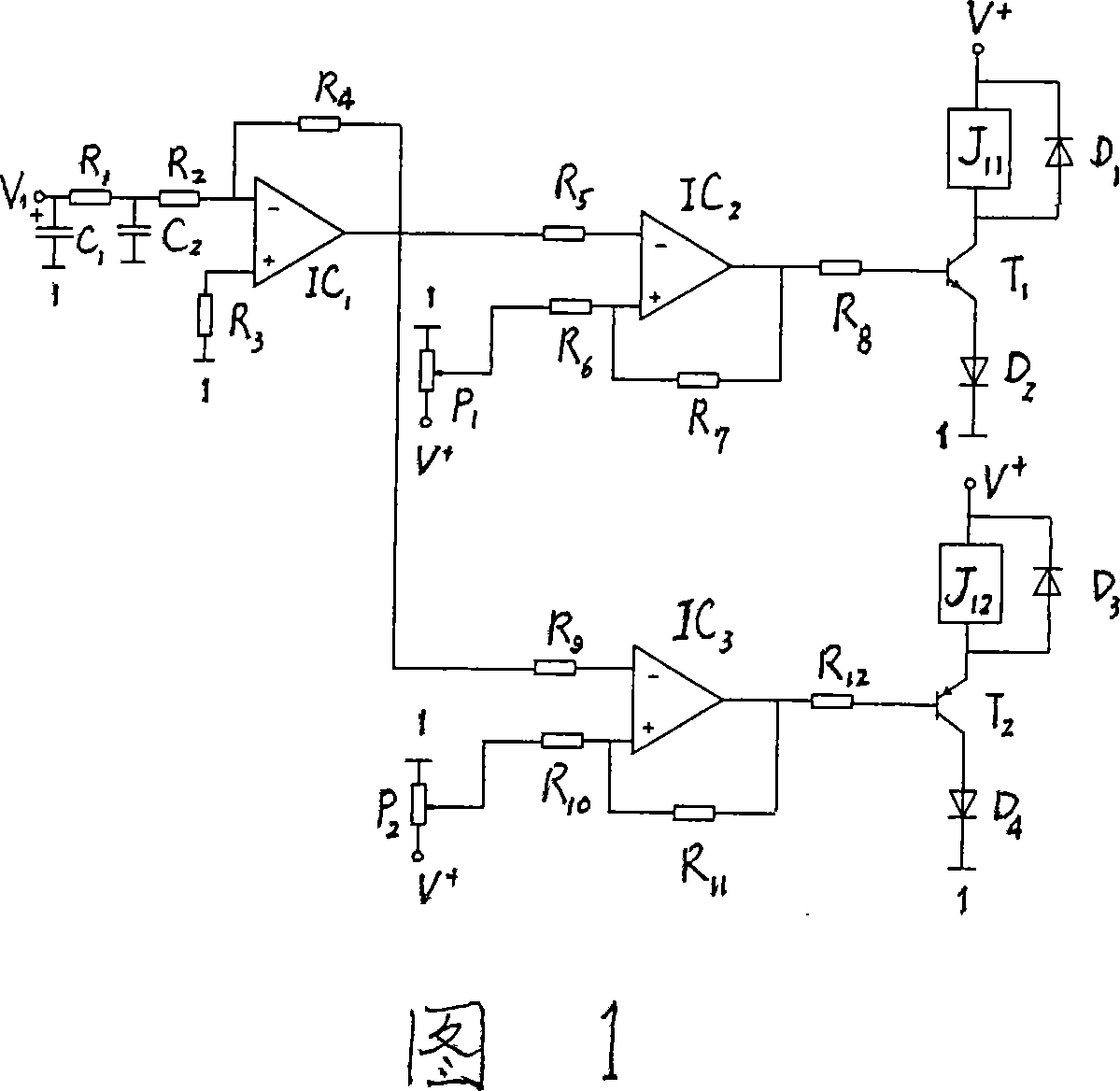

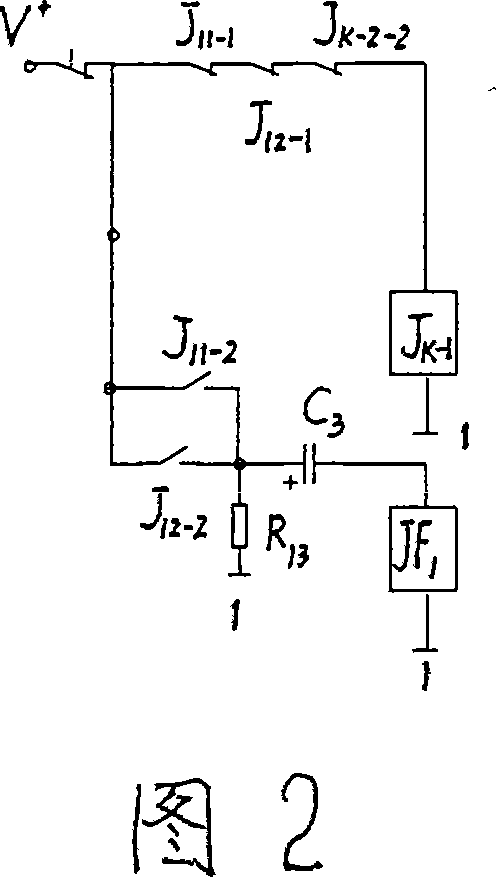

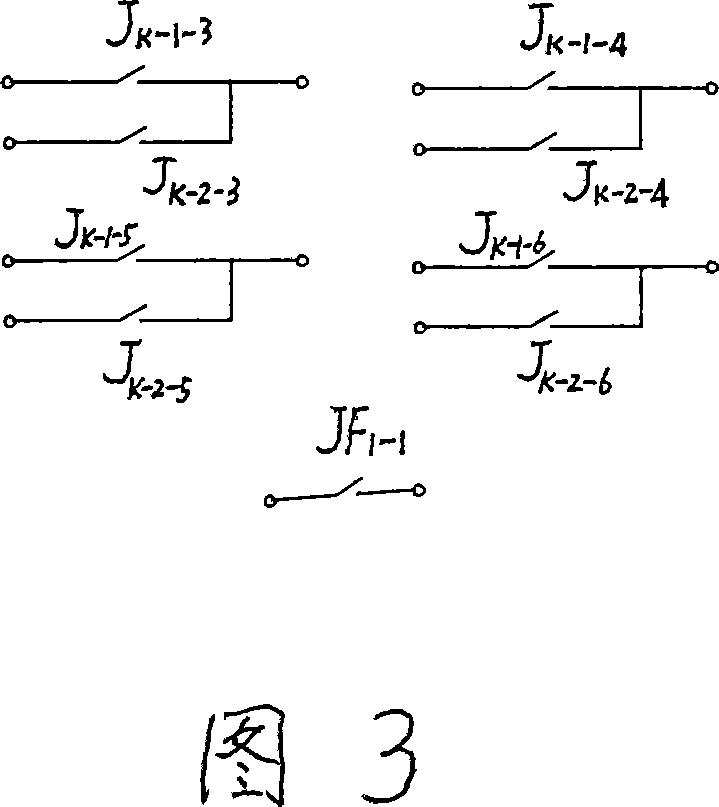

The invention provides a working method and a moisture control system of a multi-mode slice baking device. The moisture control system of the multi-mode slice baking device comprises a baking device outlet and a moisture instrument for measuring slices at the baking device outlet; the moisture instrument is connected with a moisture difference circuit, and the output end of the moisture difference circuit is at least connected with a control branch circuit A, a control branch circuit B and a control branch circuit C in parallel; the automatic control level of related technological parameters, such as moisture, of the slices at the baking device outlet can be improved through the control branch circuit A, the control branch circuit B and the control branch circuit C; produced products are stable and controllable in quality; and meanwhile multiple products can be easily produced on the same production line. According to the working method of the multi-mode slice baking device, the multi-mode slice baking device comprises the moisture control system; the progressive decrease mode, the progressive increase mode and the low-high-low mode can be achieved; different technological requirements are accordingly met; and the quality requirements of the different products are met.

Owner:SHANGHAI TOBACCO GRP CO LTD +1

Industrial control computer redundancy protection device

InactiveCN101059684ARaise the level of automatic control of computer industrySimple structureSafety arrangmentsAutomatic controlManufacturing engineering

The invention provides an industry control computer abundant protector belonging to industry control technical field, which is an abundant automatic electric protector of computer system, composed of electric protective circuits with real-time online detection automatic switch interaction, arranged between abundant computers, which comprises a work abnormal real-time online detect circuit, an automatic switch protect circuit, and relative automatic switch circuits as start, abundant, return or the like. The invention can build computer active / backup automatic abundant protect system for resolving the stable industry control problem of computer, to realize stable and reliable industry control, to improve the automatic control level of computer industry, with simple structure, reasonable design, reliable technique, stable operation, high practicality, and wide application.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Intelligent optimization and adjustment system and method for combustion system of hedging wall/arch combustion boiler

PendingCN111981470AEasy to adjustAdd online monitoring systemFuel supply regulationDesign optimisation/simulationCombustion systemAutomatic control

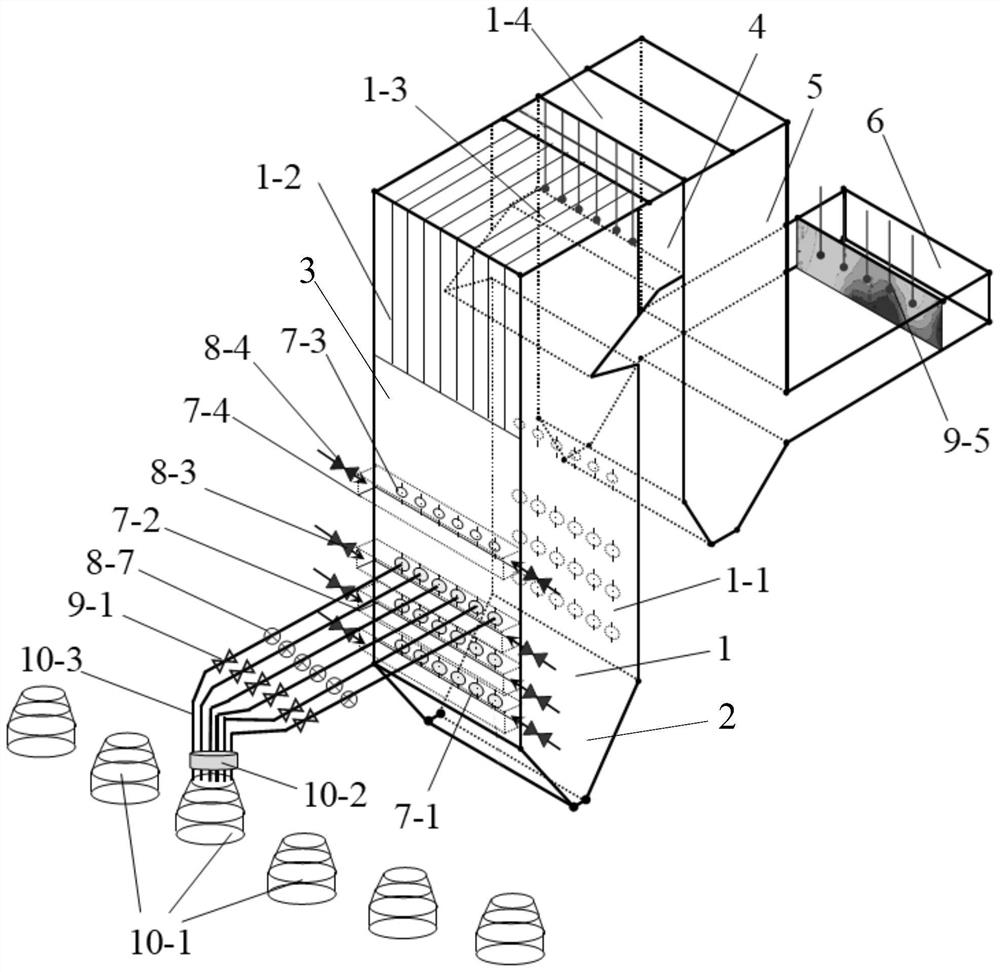

The invention relates to an intelligent optimization and adjustment system for a combustion system of a hedging wall / arch combustion boiler. The intelligent optimization and adjustment system comprises an online adjustment control system and an online monitoring system; the online adjustment control system comprises a primary total air volume online adjustment system, a secondary total air volumeonline adjustment system, a same-layer over fire air volume online adjustment device, a single combustor powder volume online adjustment system and a single over fire air volume online adjustment system; and the online monitoring system comprises a primary air powder pipe air volume and powder volume online monitoring system, a high-temperature heated surface same-screen tube bundle temperature rising monitoring system and an economizer outlet flue gas composition distribution monitoring system. The intelligent optimization and adjustment system has the beneficial effects that the online adjustment control system and the online monitoring system of two kinds of boiler combustion systems are added, some existing manual adjustment modes are changed into electric or pneumatic adjustment modes, new monitoring means is added in a furnace, and the automatic control level of combustion systems of coal-fired power station boilers is improved.

Owner:ZHEJIANG ZHENENG TECHN RES INST +2

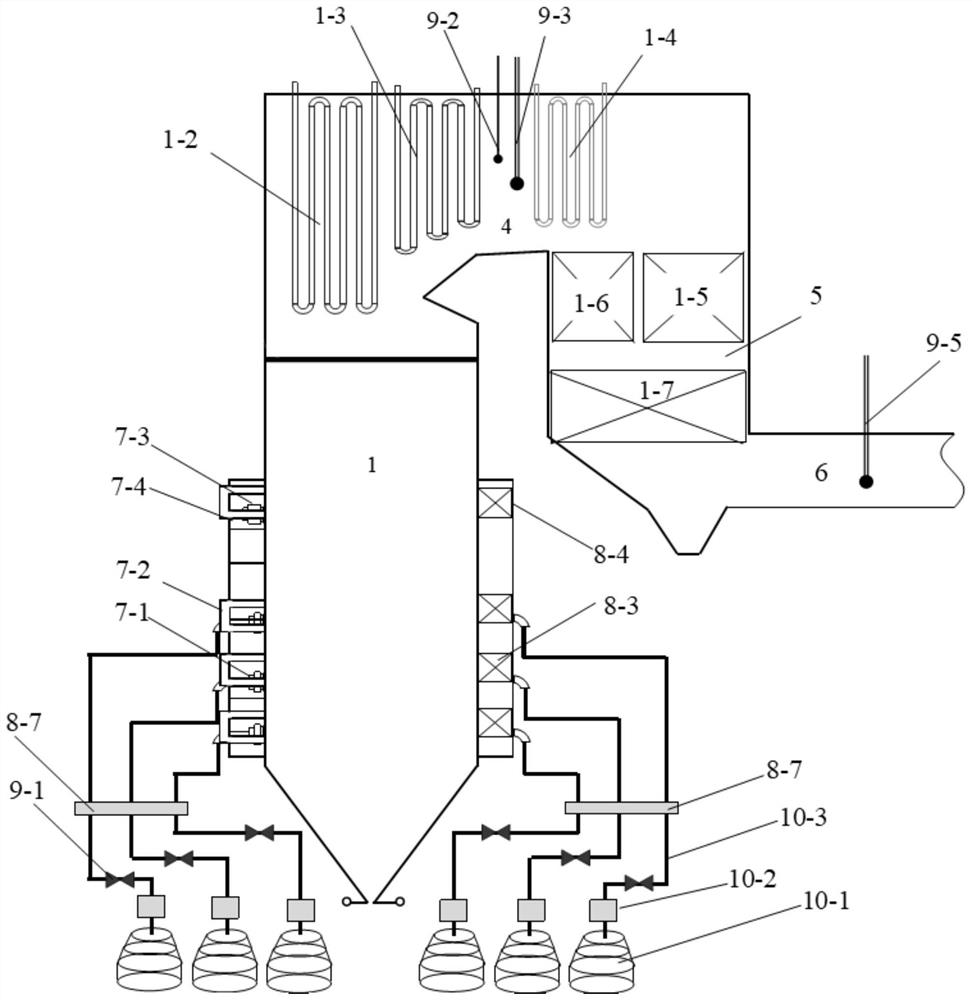

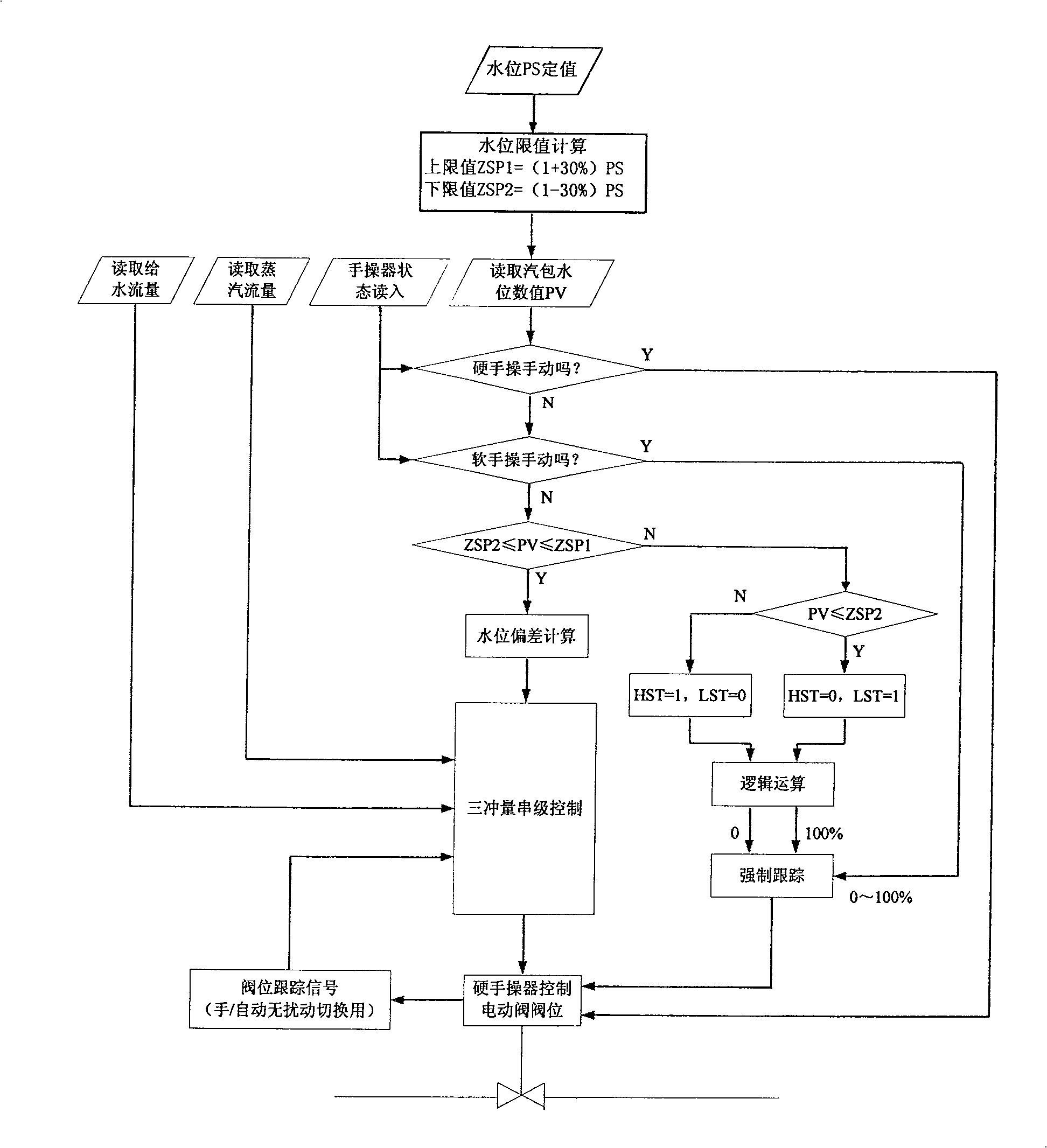

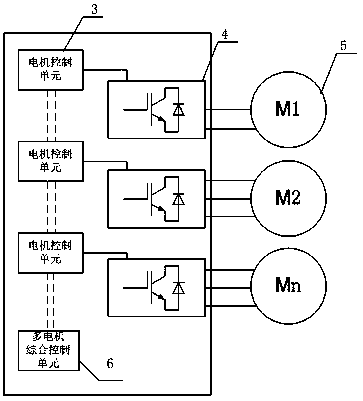

Control method of boiler water level and its control system

InactiveCN100535513CGuaranteed safe operationReduce maintenance workloadWater feed controlLimit valueElectric control

A boiler water level control method and its control system, based on the principle of three-impulse cascade control, controls the valve position of the feed water regulating valve; the control system can also compare the upper and lower limit values of the water level from the steam drum with the water level tracking value respectively The signal directly controls the full closing and full opening of the water supply regulating valve. The boiler water level control system working in the above method is composed of three-impulse transmitters for steam drum water level, steam flow rate and feed water flow rate, controller, upper computer, hand operator and electric water feed regulating valve. , The selection module and the comparison module are used to calculate the upper limit value and the lower limit value of the water level, set the limit valve position, and judge the state of the water level exceeding the limit. The system responds quickly and has a high level of automation, reducing labor intensity and ensuring safe operation of the boiler.

Owner:SHANGHAI HONGJIAN AUTOMATION EQUIP

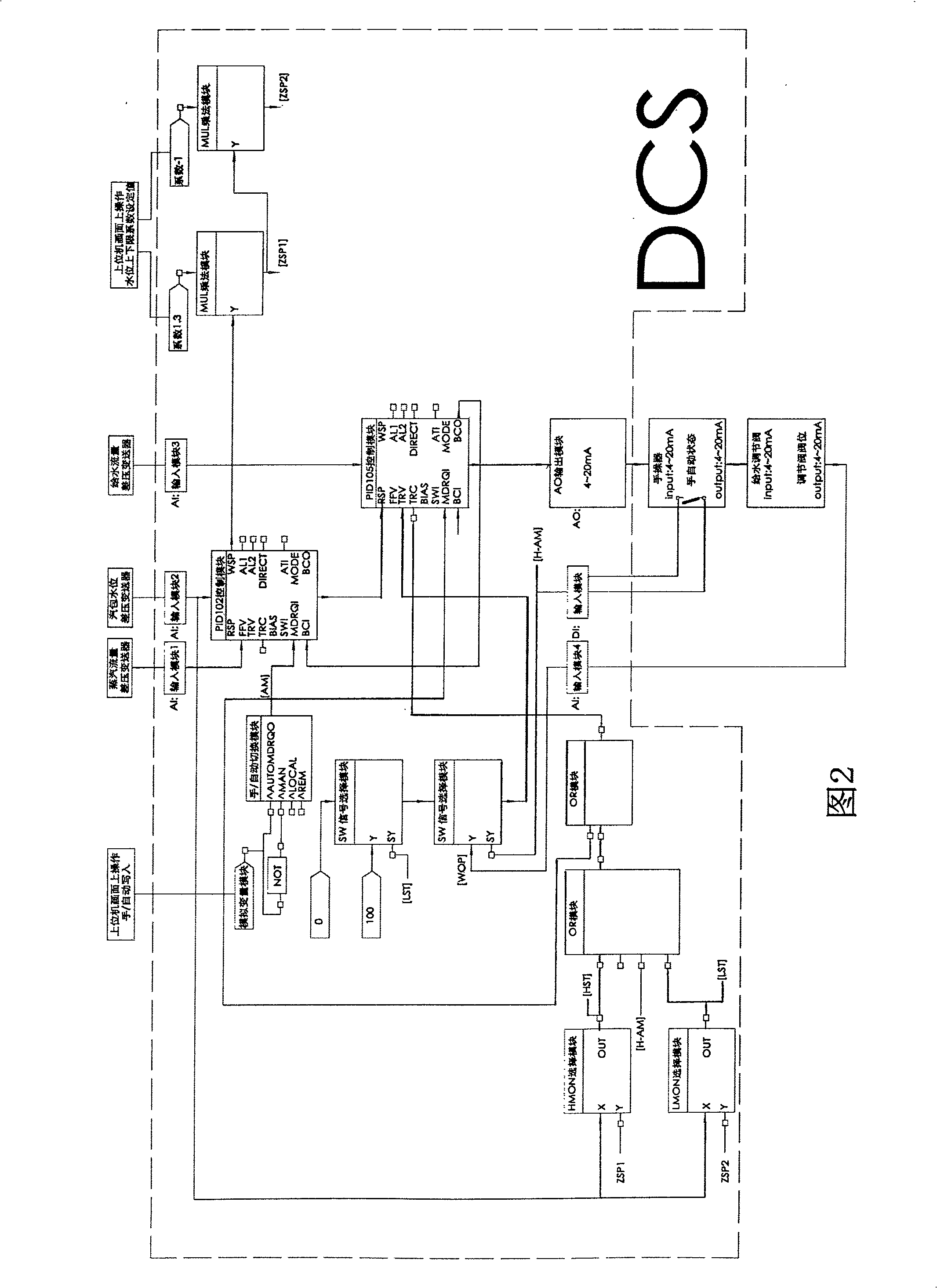

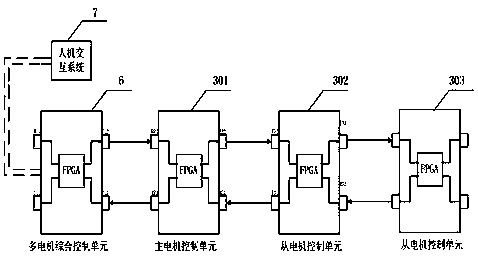

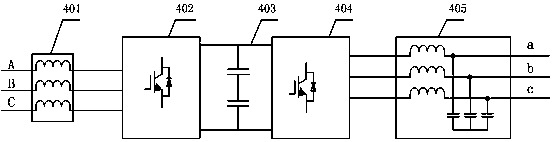

Multi-motor cluster system driving control device, method and system

PendingCN110943652ARealize variable frequency drive controlImprove the level of automatic controlElectronic commutation motor controlVector control systemsAutomatic controlControl engineering

The invention discloses a multi-motor cluster system driving control device, method and system. The multi-motor cluster system driving control device comprises a multi-motor comprehensive control unit, a plurality of motor control units and variable frequency drivers corresponding to the motor control units, wherein in the plurality of motor control units, one motor control unit is set as a main motor control unit, and the rest motor control units are set as slave motor control units; wherein the multi-motor comprehensive control unit is connected with the plurality of motor control units in series through two groups of optical fibers, the plurality of motor control units are connected with the variable-frequency driver, and the variable-frequency driver outputs signals to the motors. Themulti-motor group system is managed in a unified mode through the multi-motor comprehensive control unit, and the automatic control level of the multi-motor group system is improved.

Owner:CHAJNA MAJNING DRAJVS EHND AUTOMEHJSHN KO

High-speed bar yield improvement method

InactiveCN110180890AIncrease water pressureUniform heating temperatureTemperature control deviceMetal rolling arrangementsTemperature controlHeating furnace

The invention relates to the technical field of high-speed bar yield improvement, and discloses a high-speed bar yield improvement method. The method comprises the following steps that (1) the yield is improved by controlling a heating zone with the heating temperature controlled at 1,000-1,400 DEG C to be preserved for 4-7 hours, the start heating temperature in a heating furnace is 1,100 DEG C,and the temperature in the heating furnace is controlled higher than or equal to 850 DEG C after the heating is finished; a heating system is strictly executed, and the heating efficiency is improved,so that the billet heating temperature is promoted to be uniform, black marks do not appear, the oxidation burning loss is reduced, the furnace condition is kept normal, the maintenance difficulty ofthe bottom of the heating furnace is reduced, and the production is guaranteed to be smooth. According to the method, less finished scale is generated due to good guide groove air nozzles of water tanks, good water nozzle gaps, correct maintenance and water pressure increase of the water tanks, the yield of high-speed bars is integrally improved from multiple aspects, therefore, it is convenientfor an enterprise to implement the method effectively and efficiently, the implementation efficiency and the yield of the high-speed bars are improved, and the method is convenient to apply.

Owner:成渝钒钛科技有限公司

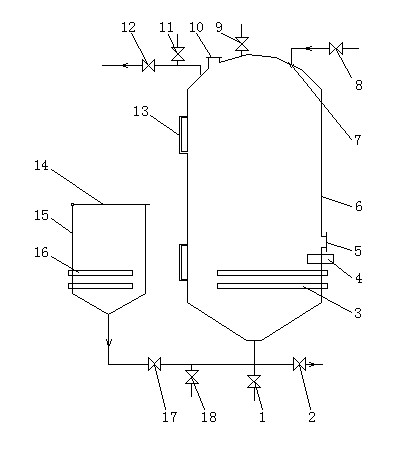

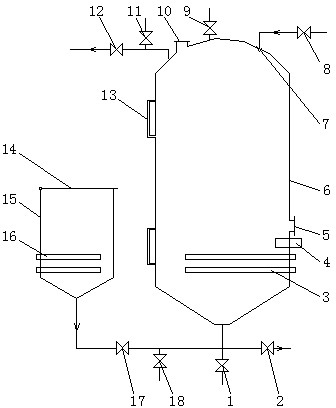

Oil purifier reaction kettle capable of automatically adding filter aid

InactiveCN102688733AHigh speedNo pollution in the processChemical/physical/physico-chemical processesFeed devicesVertical tubeAutomatic control

The invention relates to an oil purifier reaction kettle capable of automatically adding filter aid, belonging to a filtering device for an oil purifier. The oil purifier reaction kettle capable of automatically adding the filter aid is characterized in that a tank body of the reaction kettle is a sealed tank body; the top of the tank body of the reaction kettle is provided with an oil inlet valve, an air valve and a vacuum valve; the side wall of the tank body of the reaction kettle is provided with a liquid level control switch, an access hole and a liquid level meter; a reaction kettle heater is arranged at the lower part in the tank body of the reaction kettle; the bottom of the tank body of the reaction kettle is provided with a vertical pipe; the lower end of the vertical pipe is connected with a slag discharge valve; the vertical pipe is also connected with an oil outlet valve and a feeding valve; the feeding valve is connected with the lower part of a feed box body by a pipeline; and the feed box body is provided with a feed box cover. The oil purifier reaction kettle capable of automatically adding the filter aid is rapid in speed of automatic adding the filter aid and free from pollution, thus greatly lightening the labor intensity of workers, reducing the potential safety hazard, improving the automatic control level of the oil purifier reaction kettle, and having popularization value.

Owner:豆远奎

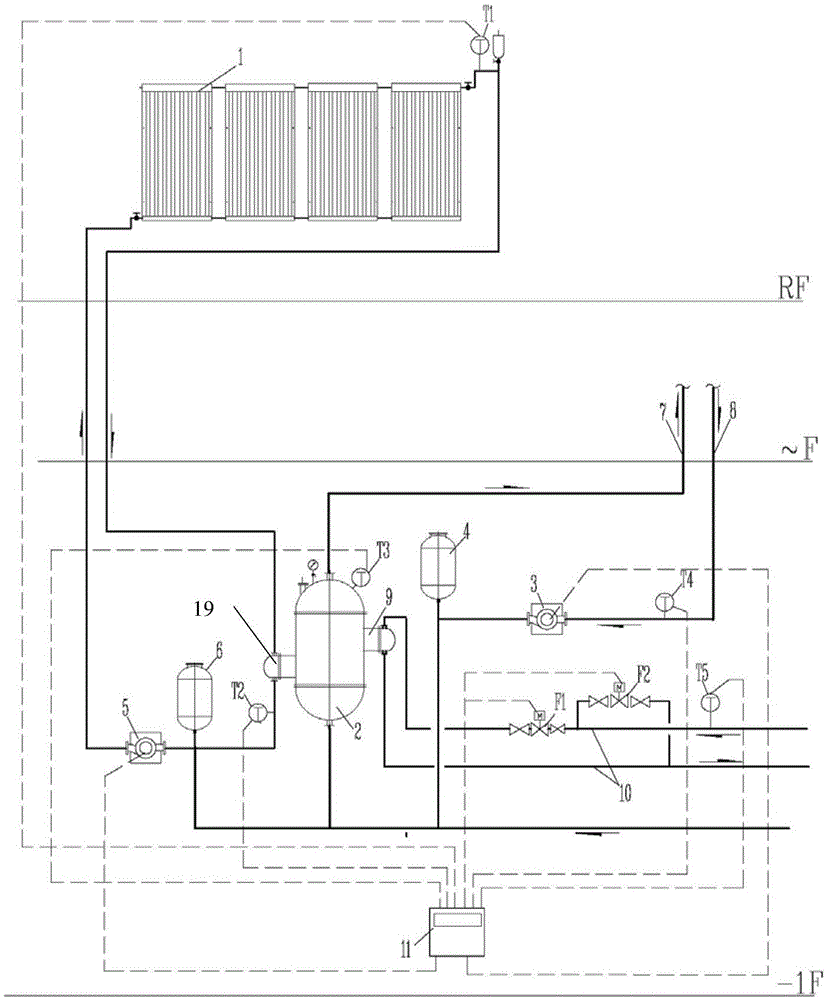

Centralized and indirect solar water heating system adopting non-electric auxiliary heat source

InactiveCN105546836AImprove the level of automatic controlLess investmentSolar heating energySolar heat collector controllersExpansion tankSolar water heating system

The invention discloses a centralized and indirect solar water heating system adopting a non-electric auxiliary heat source. The centralized and indirect solar water heating system comprises a centralized solar hot water supply system and a non-electric auxiliary heat source system, wherein the centralized solar hot water supply system comprises a solar heat collector plate group, a heat collecting system circulating water pump, a displacement heat exchanger, a heat collecting system expansion tank, a hot-water system circulating water pump and a hot-water system expansion tank; the displacement heat exchanger is a double-coil displacement heat exchanger. The heat-collecting medium water of the centralized solar hot water supply system is introduced to a group of coil, and the hot water of the non-electric auxiliary heat source system is introduced to the other group of coil. The hot water of the non-electric auxiliary heat source system takes a heat hump, a boiler room or municipal hot water as a heat source, so that the defect that the area is insufficient when the solar water heating system of a huge building or a building group is provided with the heat collector is overcome, or the operating cost of auxiliary heating is reduced when sunlight is lacked; the relevant national energy conservation policy is met, and the supply quality and the assurance rate of the solar water heating system are increased.

Owner:POWERCHINA BEIJING ENG

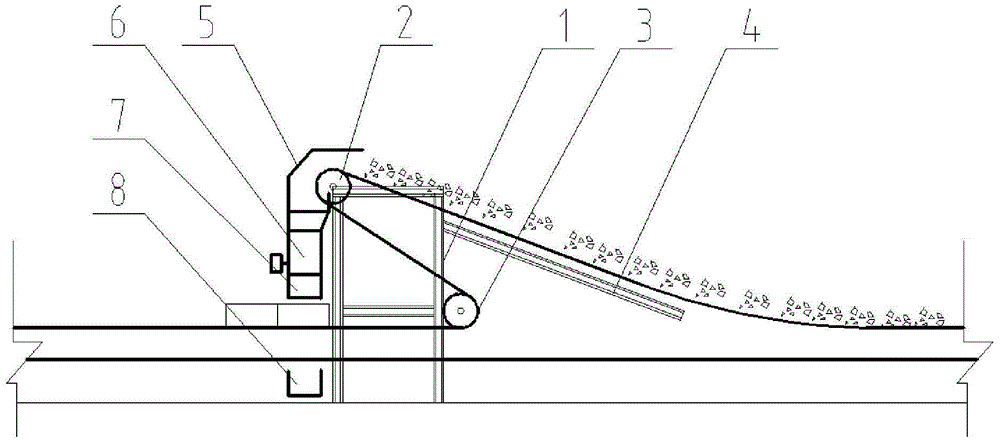

Rubber belt conveyor capable of realizing multi-point unloading and use method thereof

InactiveCN106315189ARealize automatic unloadingAchieve continuous operationConveyorsConveyor partsAutomatic controlEngineering

The invention relates to a rubber belt conveyor capable of realizing multi-point unloading and a use method thereof, and belongs to the fields of metallurgical production and mine production. The rubber belt conveyor is provided with a novel unloading device, wherein the novel unloading device is divided into two parts, that is, a support and an unloading chute; two turnabout drums, that is, a front-end turnabout drum and a rear-end turnabout drum, are arranged on the support, the front-end turnabout drum is located on the upper part of the front end of the support, the rear-end turnabout drum is located on the lower part of the rear end of the support, a rubber belt of the rubber belt conveyor is arranged on the front-end turnabout drum in a winding manner at first, and then is arranged on the rear-end turnabout drum in a winding manner to form a reciprocating winding structure; and an oblique beam is fixed on the support, and is arranged slantwise from the front to rear, and a horizontal section of the rubber belt is upwards slantwise along the oblique beam. According to the rubber belt conveyor disclosed by the invention, the novel unloading device is used as multi-point unloading equipment, and unloading at different unloading points is realized through remote adjustment for the position of an electric triple damper. Thus, the number of operating personnel is reduced, an automatic control level is increased, and continuous running and continuous unloading of the rubber belt conveyor can be realized.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

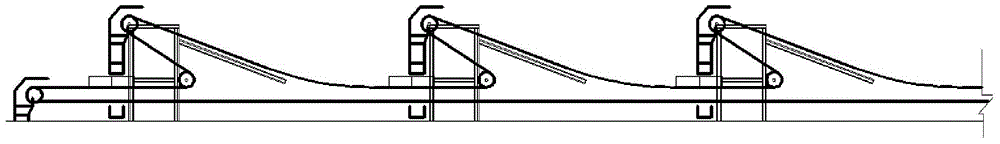

Disturbance wind speed wind generator system and vertical axis micro wind mill thereof

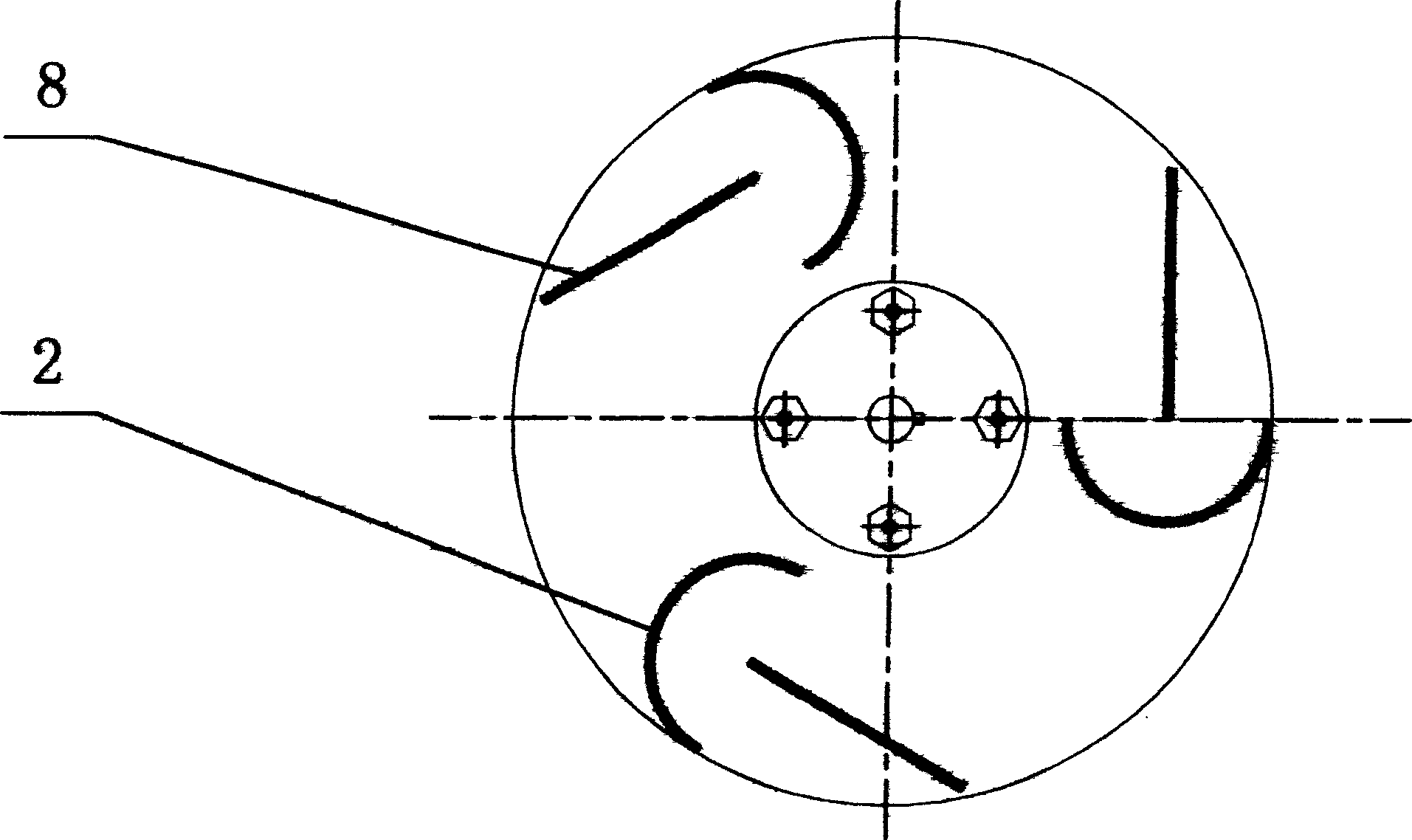

InactiveCN1594874ASimple structureHigh reservesWind energy with electric storageEnergy storageElectricitySEMI-CIRCLE

The present invention relates to a disturbance wind speed wind generator system which can generate electricity by using disturbance wind speed and a wind mill thereof. It is characterized in that the wind generator system includes a mobile disturbance wind source and the track of the mobile wind source, the side surface of the track of the wind source is mounted with a wind mill and a generator with a certain space, the electricity energy generated by the generator will be transmitted to corresponding electric appliances after the energy storage transformation. The wind mill is composed of an upper end plate 1, a lower end plate 5, plural vanes 2 disposed uniformly between the upper end plate and the lower end plate 5, an output shaft 10 fixed at the center of the lower end plate 5 and a base 11, wherein the section of the vane 2 is semi-circle shape, one end of the vane 2 is fixed to the inner side of the upper end plate 1, the another end of the vane 2 is fixed to the inner side of the lower end plate 5, the output shaft 10 passes through the base 11 and is connected to the corresponding rotation device on the base 11, the central axis of each semi-circle shaped vane 2 is disposed with a wind guiding board 8.

Owner:MIANYANG ZHONGTIAN SCI & TECH

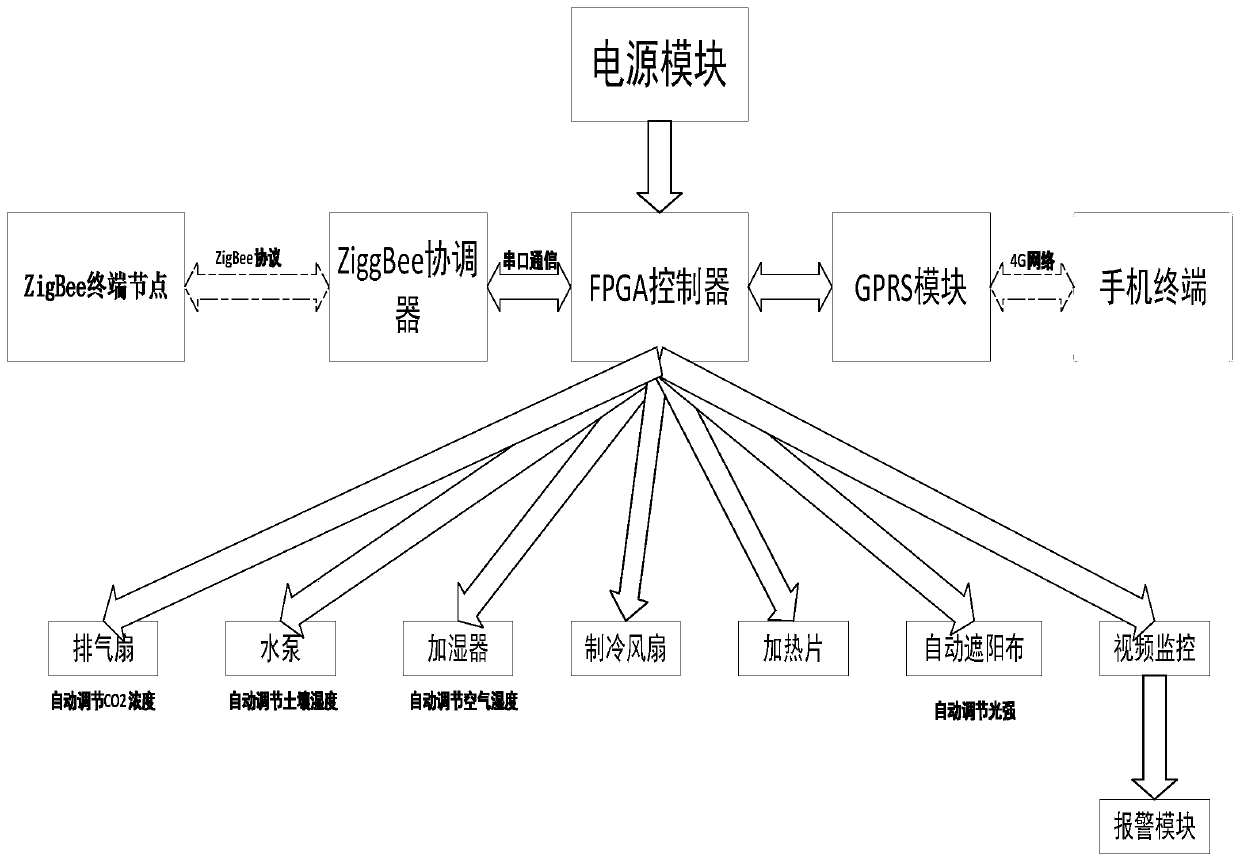

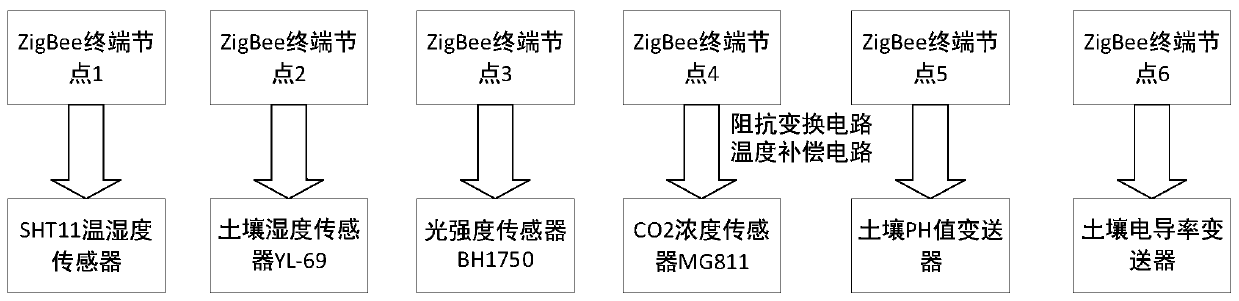

Greenhouse plant growth environment adjusting system based on ZigBee

InactiveCN110149990AReduce power consumptionImprove parallel processing capabilitiesProgramme controlMeasurement devicesVideo monitoringTime information

The invention discloses a greenhouse plant growth environment adjusting system based on ZigBee. The system comprises a short-distance ZigBee networking communication module, a power management module,an FPGA controller, a GPRS module, a mobile phone terminal, a temperature and humidity sensor, a soil humidity sensor, an illumination intensity sensor, a CO2 concentration sensor, a soil pH value transmitter and a soil conductivity sensor, wherein the short-distance ZigBee networking communication module consists of a ZigBee terminal node module and a ZigBee coordinator; the FPGA controller is connected with the ZigBee coordinator and the GPRS module; the GPRS module is connected with the mobile phone terminal network, and the output end of the FPGA controller is sequentially connected withan exhaust fan, a water pump, a humidifier, a refrigeration fan, a heating sheet, an automatic sunshade cloth and a video monitoring module; and the ZigBee terminal node is connected with the temperature and humidity sensor, the soil humidity sensor, the illumination intensity sensor, the CO2 concentration sensor, the soil pH value transmitter and the soil conductivity transmitter. The system enables farmers to acquire real-time information of plant growth environment without going to a scene and automatically adjust.

Owner:EAST CHINA NORMAL UNIV

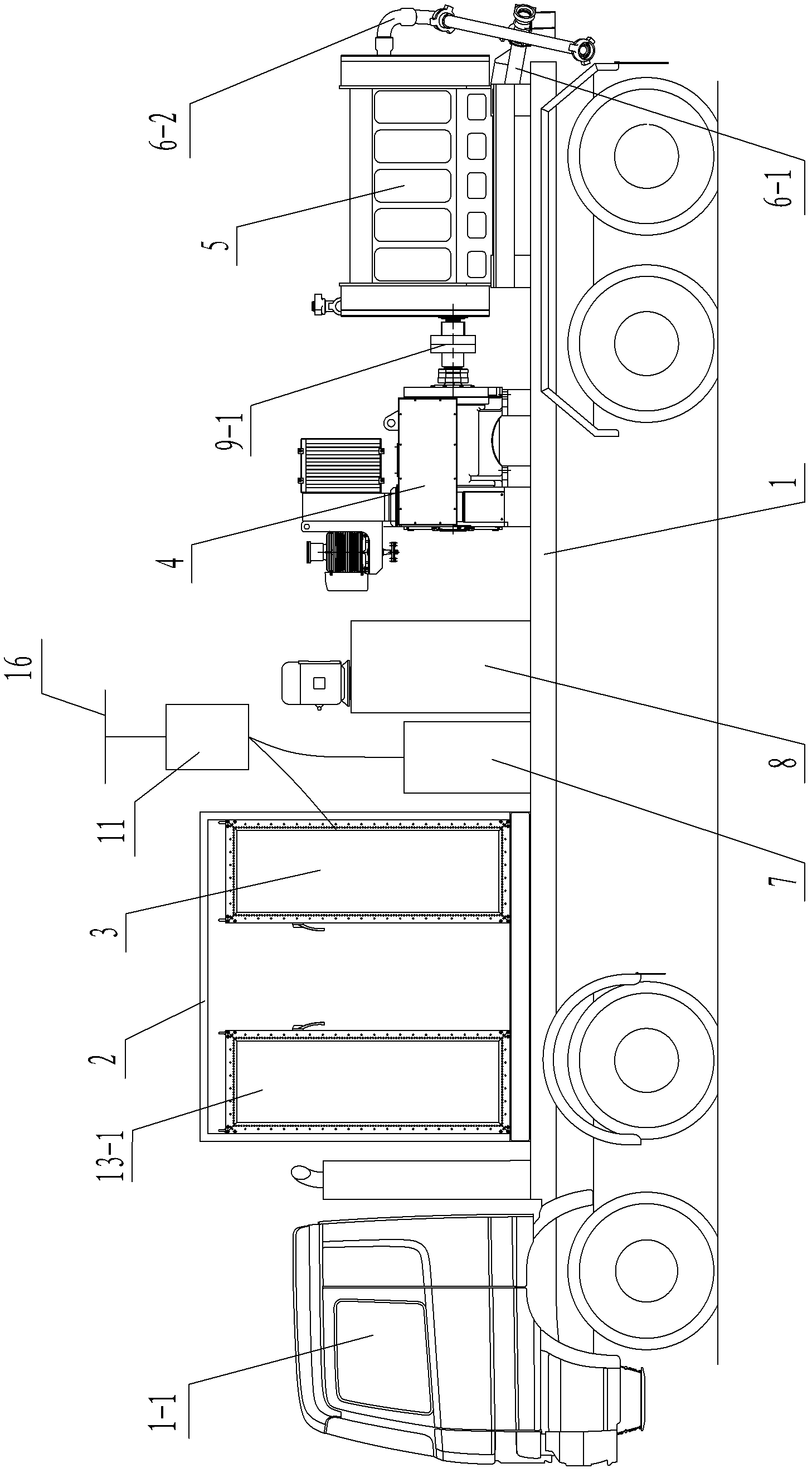

Electrically-driven fracturing pump truck

The invention discloses an electrically-driven fracturing pump truck, which comprises a truck chassis with a cab. A lubricating and cooling system, a fracturing pump, a suction manifold, an exhaust manifold, an electrically-driven system and a control system, the suction manifold and the exhaust manifold are connected with the fracturing pump, the electrically-driven system comprises a motor and a motor-driven device, the motor is used for driving the fracturing pump to run, the control system comprises a main power control system and an auxiliary power control system, the main power control system is used for controlling the motor-driven device, the auxiliary power control system is used for controlling the lubricating and cooling system, and the motor-driven device, the main power control system and the auxiliary power control system are powered by an external power source. The electrically-driven fracturing pump truck is simple in structure, reasonable in design, convenient in matching, low in manufacture cost, high in work efficiency and reliability, convenient in energy supply, fine in emission reducing effect, easy in maintenance, capable of overcoming defects and shortcomings of high fuel consumption, difficulty in matching of an engine and a torque converter and the like of a fracturing pump truck in the prior art, and convenient in popularization and use.

Owner:XIAN BANGPU IND AUTOMATION

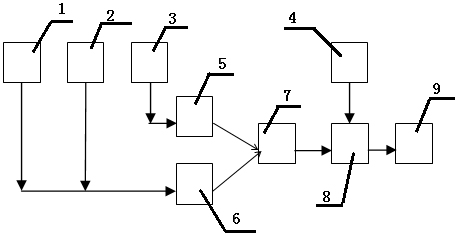

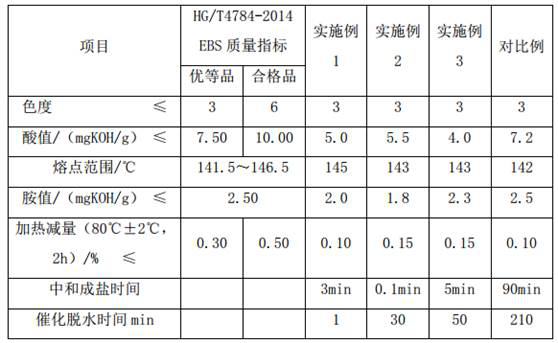

System for continuously preparing N, N'-ethylene bis stearamide through micro-channel and method thereof

ActiveCN111704556AHigh mass and heat transfer efficiencyImprove securityOrganic compound preparationCarboxylic acid amides preparationPtru catalystPhysical chemistry

The invention relates to a system for continuously preparing N, N'-ethylene bis stearamide. The system comprises a stearic acid melting tank, ethylenediamine storage tank, the stearic acid conveying and metering device and the ethylenediamine conveying and metering device are respectively connected with the stearic acid melting tank and the ethylenediamine storage tank; the neutralization and salification micro-reaction device is connected with the stearic acid conveying and metering device and the ethylenediamine conveying and metering device, and is sequentially connected with a catalytic dehydration device and a spray granulation device; and a catalytic dehydration device is connected with a catalyst antioxidant storage tank. The invention further provides a method for preparing N, N'-ethylene bis stearamide, continuous production of N, N'-ethylene bis stearamide is achieved through the micro-channel continuous reaction system with efficient mass and heat transfer performance, the automatic control level is high, the safety is high, the production cost is low, the product purity is high, and the quality is stable.

Owner:石家庄华复化工科技有限公司

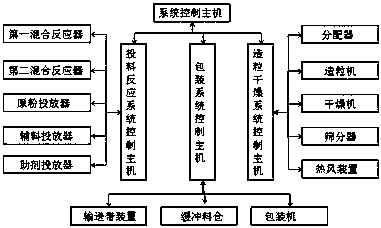

Production system and preparation method of glyphosate ammonium soluble granule

PendingCN108094423AFunctionalHigh degree of mechanizationBiocideGroup 5/15 element organic compoundsAutomatic controlGlyphosate

The invention discloses a production system and a preparation method of a glyphosate ammonium soluble granule. The production system includes a feeding reaction system, a granulation drying system anda packaging system that are arranged from top to bottom in order at one or more layers. The preparation method can directly use glyphosate raw powder as the raw material, and the preparation processhas high automatic control level. The production system provided by the invention integrates automatic metering feeding, mixing reaction, granulation and size stabilization, granule drying and detection, screening, automatic packing, dust removal, tail gas treatment and other functions, has powerful comprehensive functions and high mechanization degree, greatly improves the production efficiency and production quality of the product, saves manpower and time, and can adapt to the mass production demand.

Owner:JIANGYIN PHARMA MACHINERY

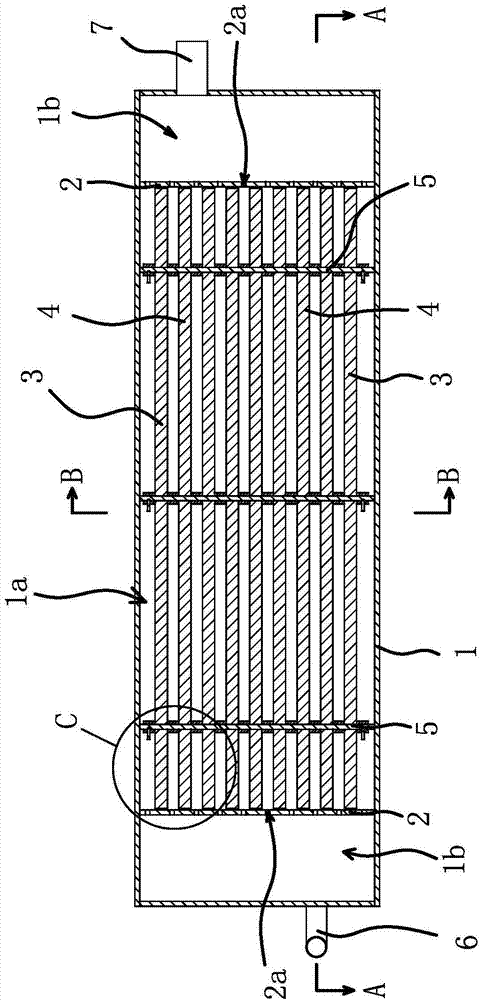

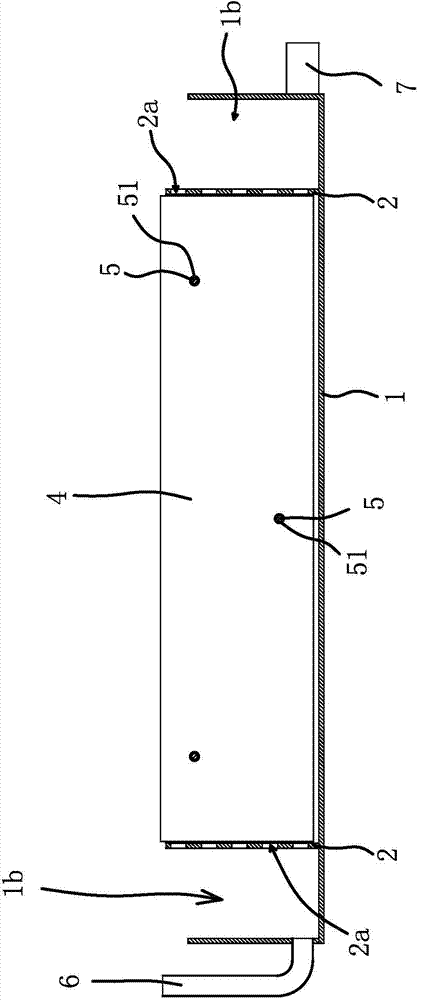

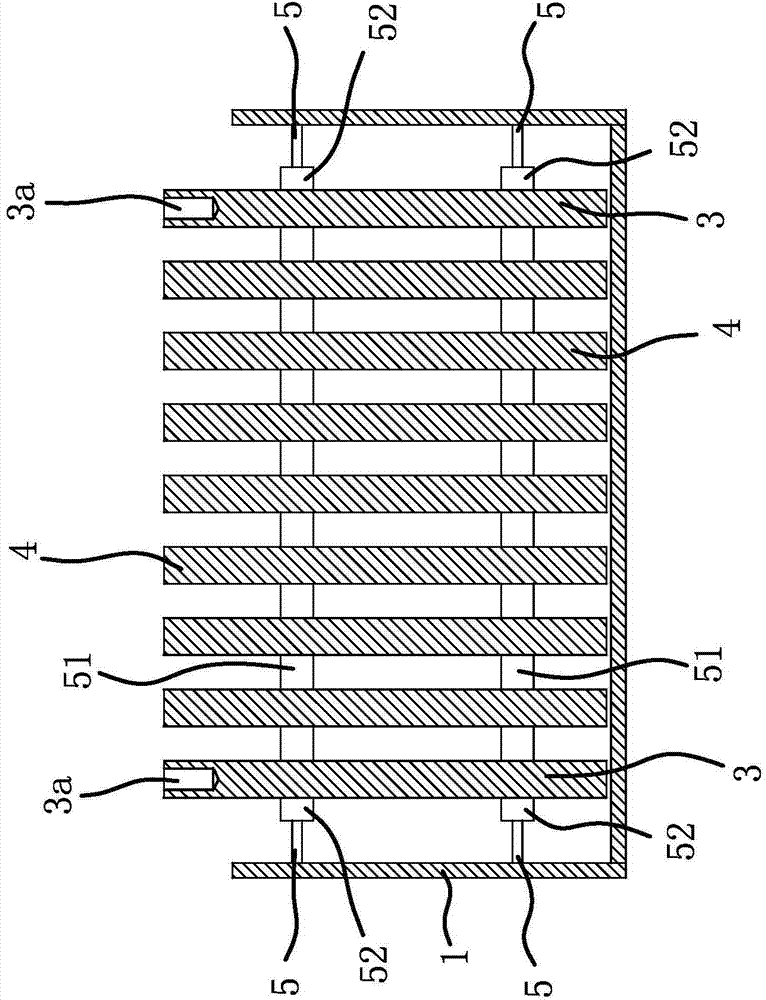

Electrochemical reactor for preparing oligosaccharide from marine biology functional sugars and preparation method

ActiveCN104233365AMaximize efficiencyImprove efficiencyElectrolysis componentsElectrolytic organic productionElectrochemical responseElectrolysis

The invention provides an electrochemical reactor for preparing oligosaccharide from marine biology functional sugars and a preparation method and belongs to the electrolysis field. The technical problem that the oligosaccharide cannot be prepared from the marine biology functional sugars through an electrochemical reaction in the prior art is solved. The electrochemical reactor comprises a reaction tank which comprises an empty chamber; two separating plates are fixed in the reaction tank; the empty chamber is divided into three chambers through the two separating plates; the three chambers comprise a reaction chamber and two flow chambers which are located on the bilateral sides of the reaction chamber respectively; each separating plate is provided with a circulation hole which is communicated with the reaction chamber and the corresponding flow chamber; a polar plate is arranged in the reaction chamber. According to the electrochemical reactor, the integration is easy to control and optimize. The preparation method for preparing the oligosaccharide from the marine biology functional sugars comprises step A, feeding; step B, reaction; step C, discharging; step D, separation and collection. According to the preparation method, the oligosaccharide can be extracted from the marine biology functional sugars.

Owner:ZHEJIANG CHENGXIN PHARMA & CHEM EQUIP

Oilfield electric water injection tool stroke sensor

PendingCN109184637ASimple structureEasy installationFluid removalAutomatic controlMechanical engineering

The invention relates to an oilfield electric water injection tool stroke sensor and belongs to the technical field of the stroke control and valve position feedback control of a water distribution valve in an oilfield water injection tool. The oilfield electric water injection tool stroke sensor is characterized in that the sensor comprises a sensor body which is a shell with a rectangular structure, an upper end surface of the sensor body is provided with a window, a screw driving device is arranged in the sensor body, a screw of the screw driving device extends out of the sensor body, the screw extending out of the sensor body is provided with a driven gear which engages with a driving gear on an oilfield electric water injection tool. An upper end surface of the sensor body is providedwith a stroke sensor circuit board which is connected to a power supply through a wire. The oilfield electric water injection tool stroke sensor has the advantages of simple structure and easy installation, the sensor is used with the oilfield electric water injection tool to accurately provide the stroke control and valve position feedback control of the water distribution valve in the oilfieldwater injection tool, and the automatic control level and precision of the working of the oilfield electric water injection tool are improved.

Owner:SHENZHEN JIAYUNTONG ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com