System for continuously preparing N, N'-ethylene bis stearamide through micro-channel and method thereof

A technology of ethylene bisstearamide and microchannels, which is applied in the preparation of carboxylic acid amide, chemical instruments and methods, and the preparation of organic compounds, and can solve the problem of low mass transfer and heat transfer efficiency in reactors and the time required for adding ethylenediamine long time, difficult to guarantee the replacement effect, etc., to save the time of receiving and feeding materials, save the replacement operation, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

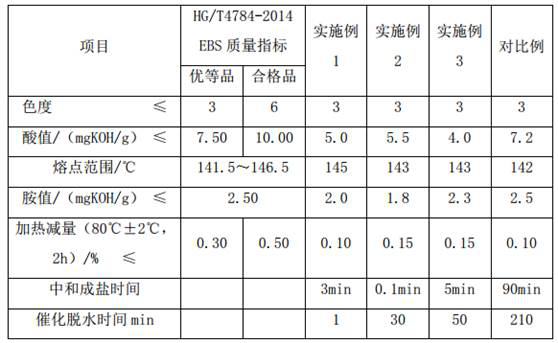

Embodiment 1

[0056] The present invention provides a method for preparing N,N'-ethylene bisstearamide using the above system, which is characterized in that it comprises the following steps,

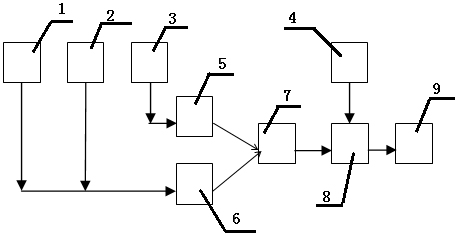

[0057] (a) Replace the whole system with nitrogen, and feed nitrogen into the stearic acid melting tank. The nitrogen passes through the ethylenediamine storage tank 3, the stearic acid delivery metering device 6, the ethylenediamine delivery metering device 5, and the neutralization agent. Salt micro-reaction device 7, catalytic dehydration device 8 and spray granulation device 9, the above-mentioned devices have been replaced with nitrogen until the detection is qualified, and the detection method is to sample and test the nitrogen oxygen content from the feed port of the spray granulation device 9, nitrogen oxygen content Content≤1×10 -6 time is qualified.

[0058] After the nitrogen replacement is qualified, add stearic acid in each stearic acid melting tank, start heating, and melt it, and the ...

Embodiment 2

[0067] The present invention provides a method for preparing N,N'-ethylene bisstearamide using the above system, which is characterized in that it comprises the following steps,

[0068] (a) Replace the whole system with nitrogen, and feed nitrogen into the stearic acid melting tank. The nitrogen passes through the ethylenediamine storage tank 3, the stearic acid delivery metering device 6, the ethylenediamine delivery metering device 5, and the neutralization agent. Salt micro-reaction device 7, catalytic dehydration device 8 and spray granulation device 9, the above-mentioned devices have been replaced with nitrogen until the detection is qualified, and the detection method is to sample and test the nitrogen oxygen content from the feed port of the spray granulation device 9, nitrogen oxygen content Content≤1×10 -6 time is qualified.

[0069] After nitrogen replacement is qualified, add stearic acid in each stearic acid melting tank, start heating, and it is melted, and hea...

Embodiment 3

[0078] The present invention provides a method for preparing N,N'-ethylene bisstearamide using the above system, which is characterized in that it comprises the following steps,

[0079] (a) Replace the whole system with nitrogen, and feed nitrogen into the stearic acid melting tank. The nitrogen passes through the ethylenediamine storage tank 3, the stearic acid delivery metering device 6, the ethylenediamine delivery metering device 5, and the neutralization agent. Salt micro-reaction device 7, catalytic dehydration device 8 and spray granulation device 9, the above-mentioned devices have been replaced with nitrogen until the detection is qualified, and the detection method is to sample and test the nitrogen oxygen content from the feed port of the spray granulation device 9, nitrogen oxygen content Content≤1×10 -6 time is qualified.

[0080] After nitrogen replacement is qualified, add stearic acid in each stearic acid melting tank, start heating, and it is melted, and hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com