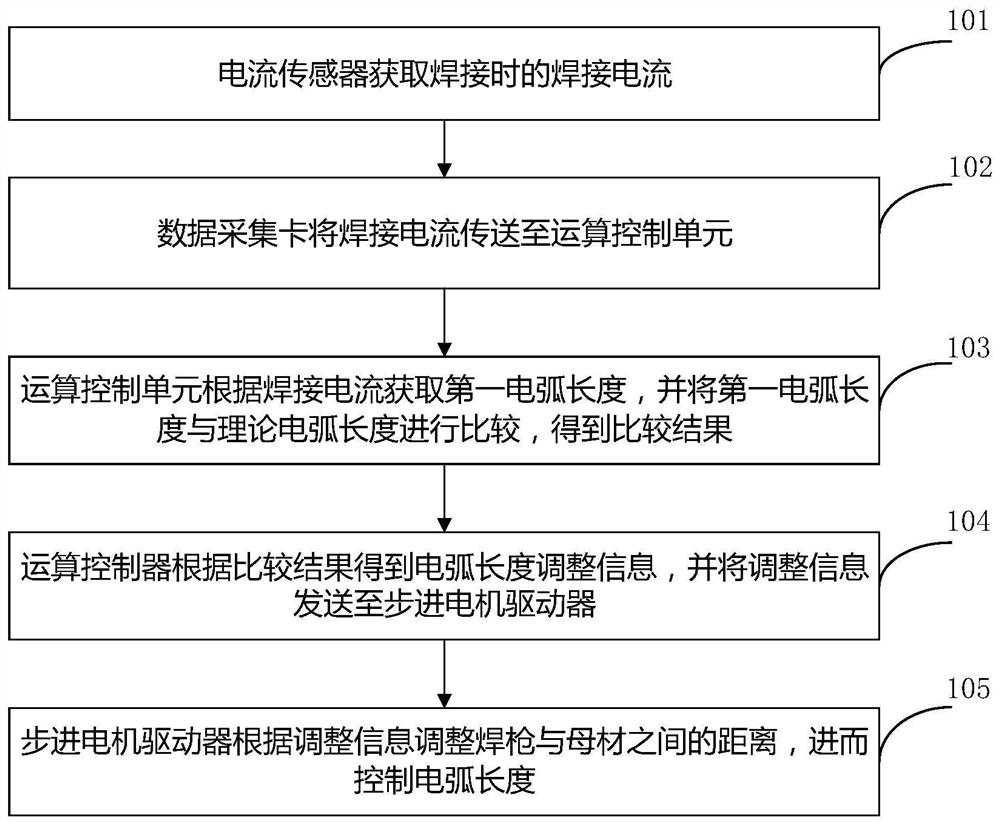

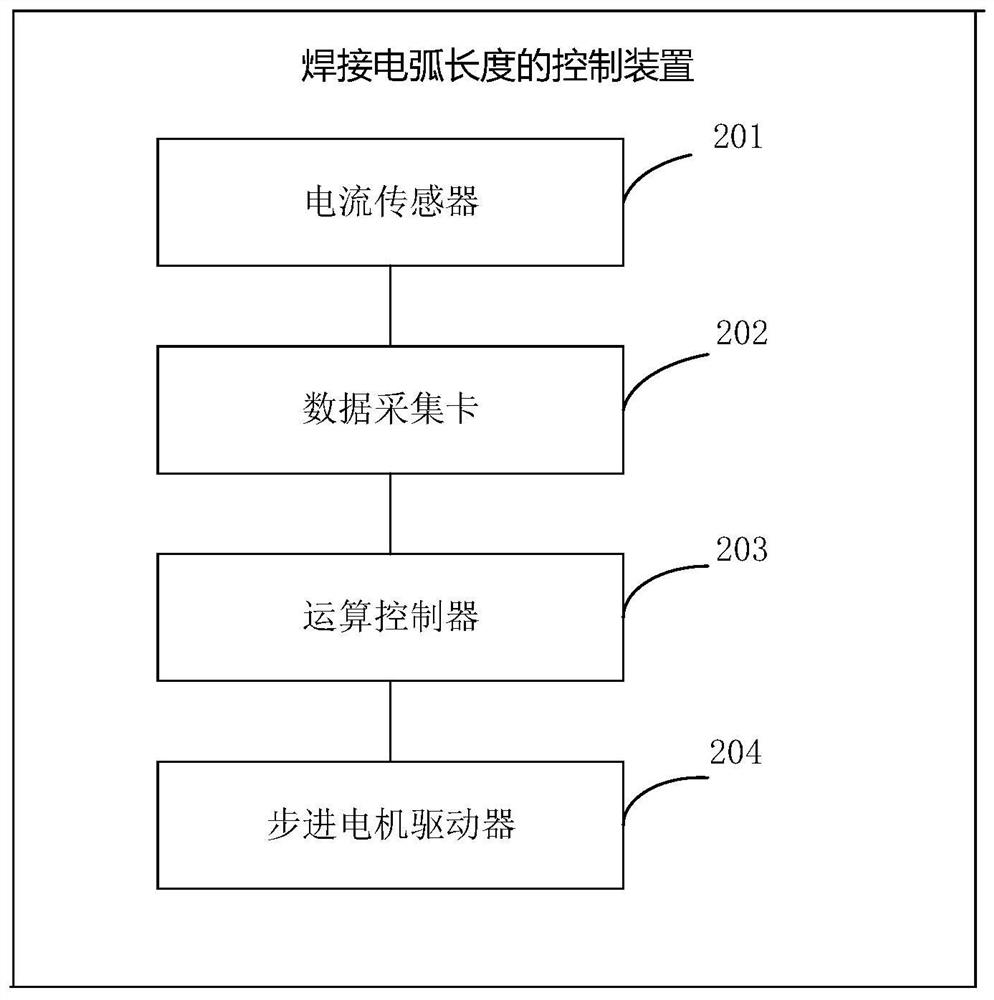

Control method and device for welding electric-arc length

A technology of arc length and control method, which is applied in the direction of electrode support devices, welding equipment, welding accessories, etc., can solve the problems of easy wear of mechanical probes, poor welding effect, and difficult to guarantee the accuracy of arc length control, so as to avoid human intervention in welding Process, low cost, and the effect of improving the level of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Unless otherwise defined, all technical terms used in the embodiments of the present invention have the same meanings as commonly understood by those skilled in the art.

[0046] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0047] During the gas shielded welding construction process, it is necessary to adjust the arc length according to the welding process requirements to achieve different welding effects and ensure welding quality. Traditional manual welding relies on manual observation of the arc and manual adjustment of the arc length. The accuracy of manual adjustment is difficult to guarantee, and the labor intensity is high. In order to realize automatic control, contact follow-up tracking technology has appeared. The mechanical probe is in contact with the base material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com