Control method of boiler water level and its control system

A water level control and boiler technology, which is applied in the control of water supply, preheating, steam generation, etc., can solve problems such as the control effect is difficult to meet the requirements, the dynamic characteristic curve is asymmetric, and the mathematical model cannot be obtained, and achieves considerable economic benefits. The effect of maintaining workload and improving the level of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings.

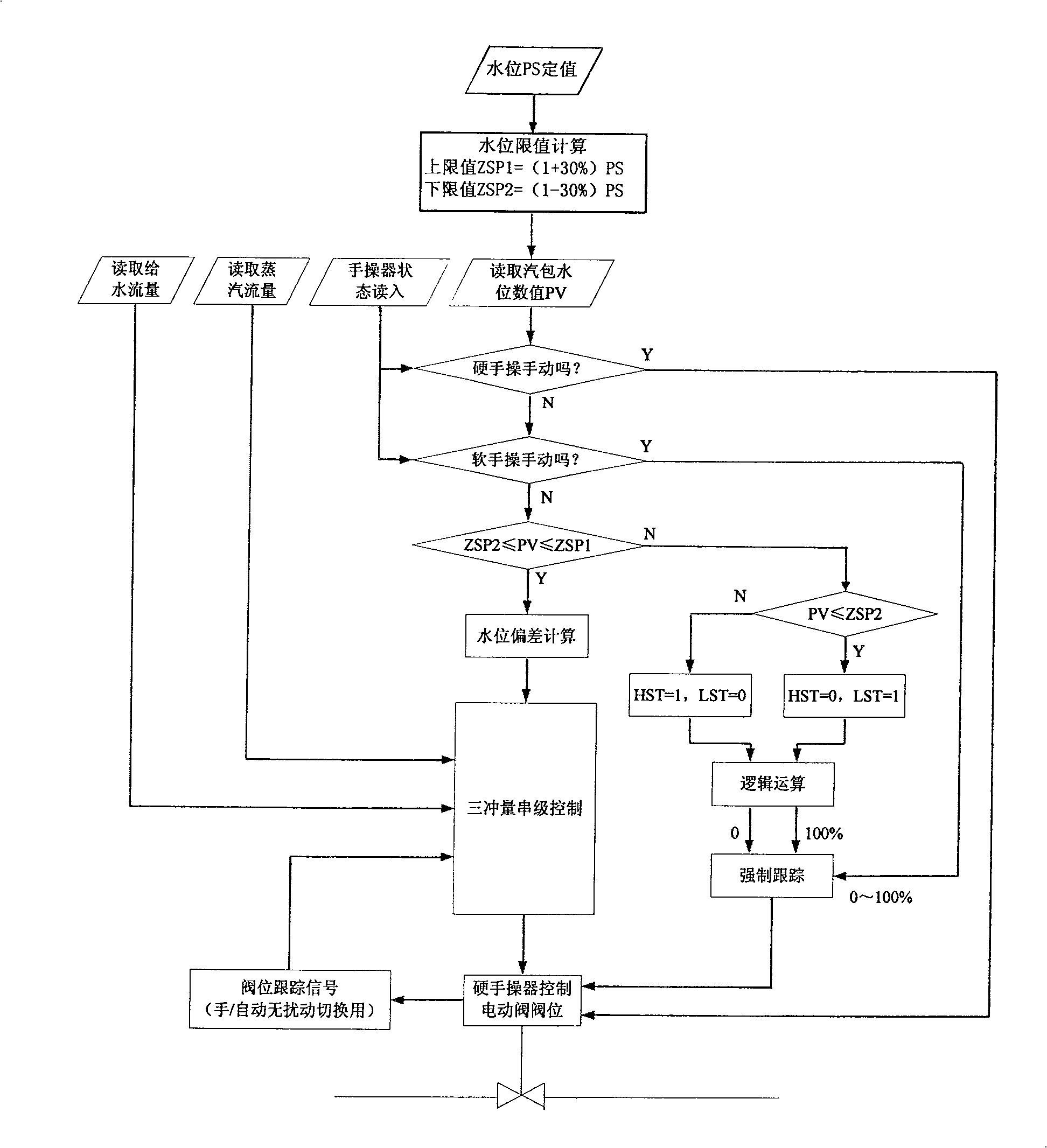

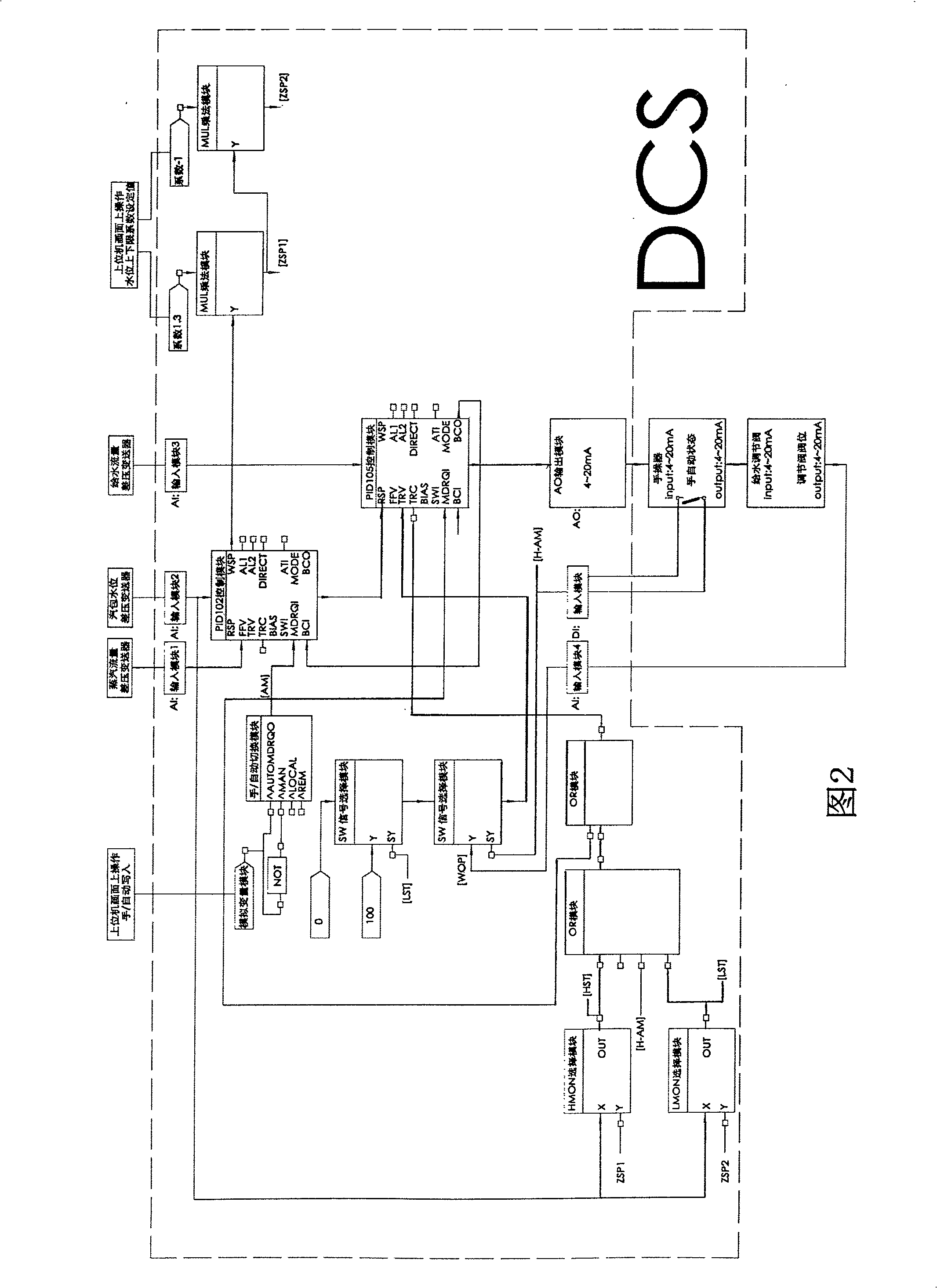

[0025] Such as figure 1 The boiler water level control method shown in the present invention is based on the three-impulse cascade control principle consisting of drum water level, steam flow, and feedwater flow to control the valve position of the feedwater regulating valve to adjust the water level; at the same time, the control system also receives the upper and lower limits of the drum water level. The signal compared with the water level tracking value directly controls the full-close and full-open of the feedwater regulating valve. The control steps are as follows:

[0026] (a) Set the drum water level value PS for the control system as the system control benchmark;

[0027] (b) Based on PS, set the upper limit ZSP1 of the drum water level and the lower limit ZSP2 of the drum water level. The setting range between the upper and lower limits can be adjusted according to specific ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com