Online measuring and controlling system for combustion condition of steel rolling heating furnace

A combustion state, heating furnace technology, applied in the direction of heat treatment furnace, heat treatment process control, furnace, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

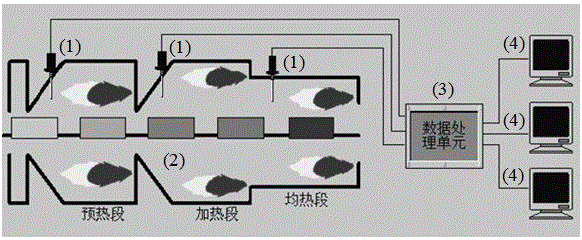

[0024] see figure 1 , the online measurement and control method for the combustion state of the steel rolling heating furnace is characterized in that it comprises the following steps:

[0025] 1) Install the oxygen analyzer (1) on the top of the preheating section, heating section and soaking section of the heating furnace (2).

[0026] 2) Use the oxygen analyzer (1) in step 1) to measure the oxygen content of the combustion atmosphere in the preheating section, heating section and soaking section of the heating furnace (2) online, and convert the measurement information through the data processing unit (3) and then sent to the programmable logic controller (4).

[0027] 3) Compare and analyze the measured value of the oxygen content of the combustion atmosphere in different sections described in step 2) and the set value, and adjust the air excess coefficient of the corresponding section online through the programmable logic controller (4) to realize heating Precise contro...

Embodiment 2

[0029] This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0030] The online measurement and control method for the combustion status of a steel rolling heating furnace is characterized in that:

[0031] The oxygen analyzer (1) in step 1) uses COMTEC6000 in-line oxygen analyzer, which has a high temperature resistant protective sleeve, and can accurately and reliably collect and collect combustion in real time at temperatures above 1200°C and below 1800°C Oxygen content data in the atmosphere. The oxygen analyzer (1) described in step 1) is installed on the top of the preheating section, heating section and soaking section of the heating furnace (2), the detection probe is located at the outlet of the combustion gas, and the height should avoid the billet to prevent the billet from moving and colliding damage the probe.

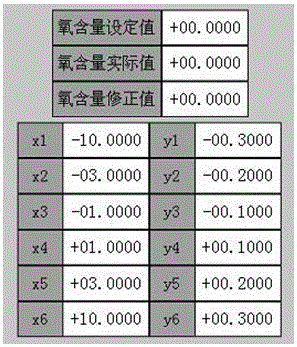

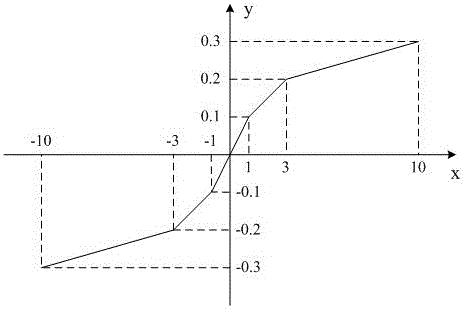

[0032] The data processing unit (3) in step 2) is an analog / digital conversion module commonly used in any in...

Embodiment 3

[0037] Such as figure 1 As shown, the online measurement and control method for the combustion status of the steel rolling heating furnace uses equipment including an oxygen analyzer (1), a heating furnace (2), a data processing unit (3) and a programmable logic controller (4).

[0038] During the moving process of the steel slab being heated to an elevated temperature, it passes through the preheating section, the heating section and the soaking section of the heating furnace (2) successively, while the flow direction of the combustion gas is opposite to it. This patent is an online measurement and control method for the combustion status of a steel rolling heating furnace. A COMTEC6000 in-line oxygen analyzer (1) is installed at the outlet of the combustion gas in the three sections of the preheating section, the heating section and the soaking section, and the online measurement furnace Oxygen content in the combustion atmosphere of different sections in the heating furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com