Carburizing method capable of adjusting nitrogen-methanol atmosphere proportion

An adjustable methanol technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the problem of high proportion of chemical consumption in carburizing furnaces, and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

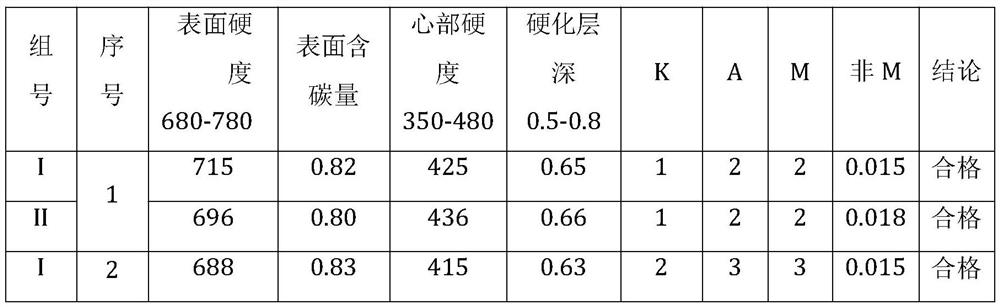

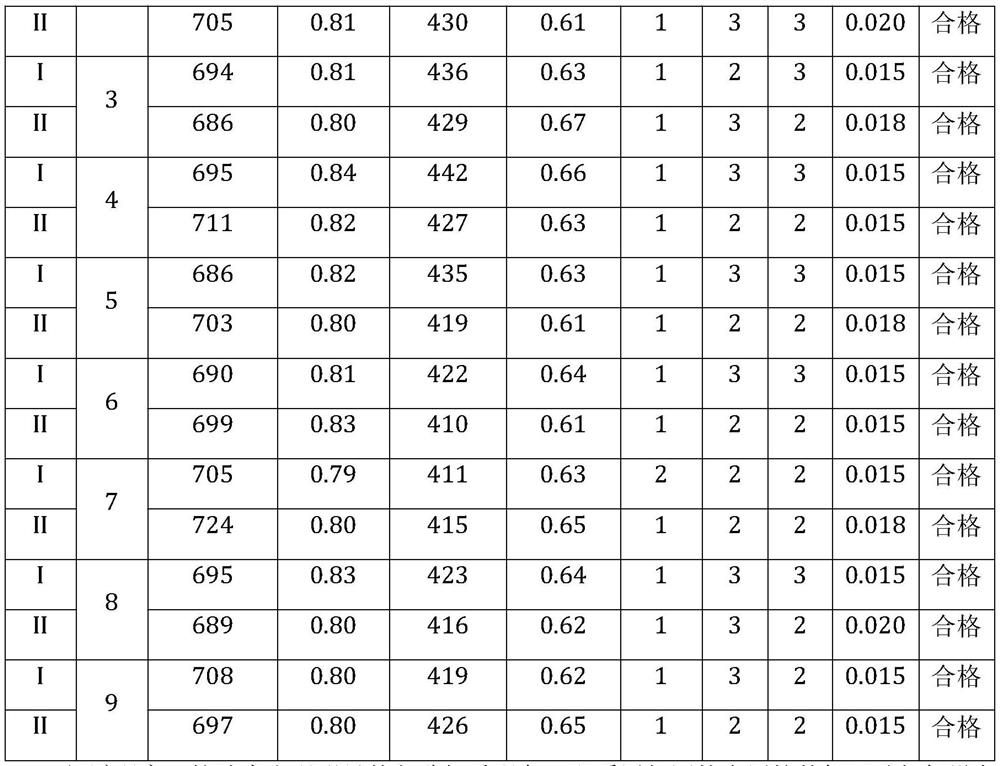

[0015] This embodiment selects the transmission gear as the test part, the part material is 20MnCr5, the depth of the carburized layer is required to be: 550HV1: 0.50-0.80mm, the metallographic structure of the carburized layer is carbide of grade 1-4, and the residual of grade 1-5 Austenite, non-martensite structure ≤0.020mm.

[0016] The carburizing process of this embodiment adopts Aichelin VKES2 / 4 type box-type multi-purpose furnace, uses propane as carburizing and enriching agent, and HOUGHTON quenching oil.

[0017] The specific carburizing method of this embodiment, the existing methanol 4.0L / h, nitrogen 4.5m 3 / h; adjusted to: methanol 4.0L / h, nitrogen 3.4m 3 / h, the CO value of the oxygen probe is corrected from 20% to 23%. After the nitrogen flow rate decreased, the furnace pressure showed a drop from 300pa to 290pa, and the carburizing enriched gas propane did not change. The carbon potential of the whole carburizing process is stable, without increasing fluctuat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com