Novel ultrafine metal powder preparation equipment

A kind of ultra-fine metal powder, a new technology, applied in the field of equipment for the preparation of new ultra-fine metal powder, to achieve the effect of good fluidity, less consumption, and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

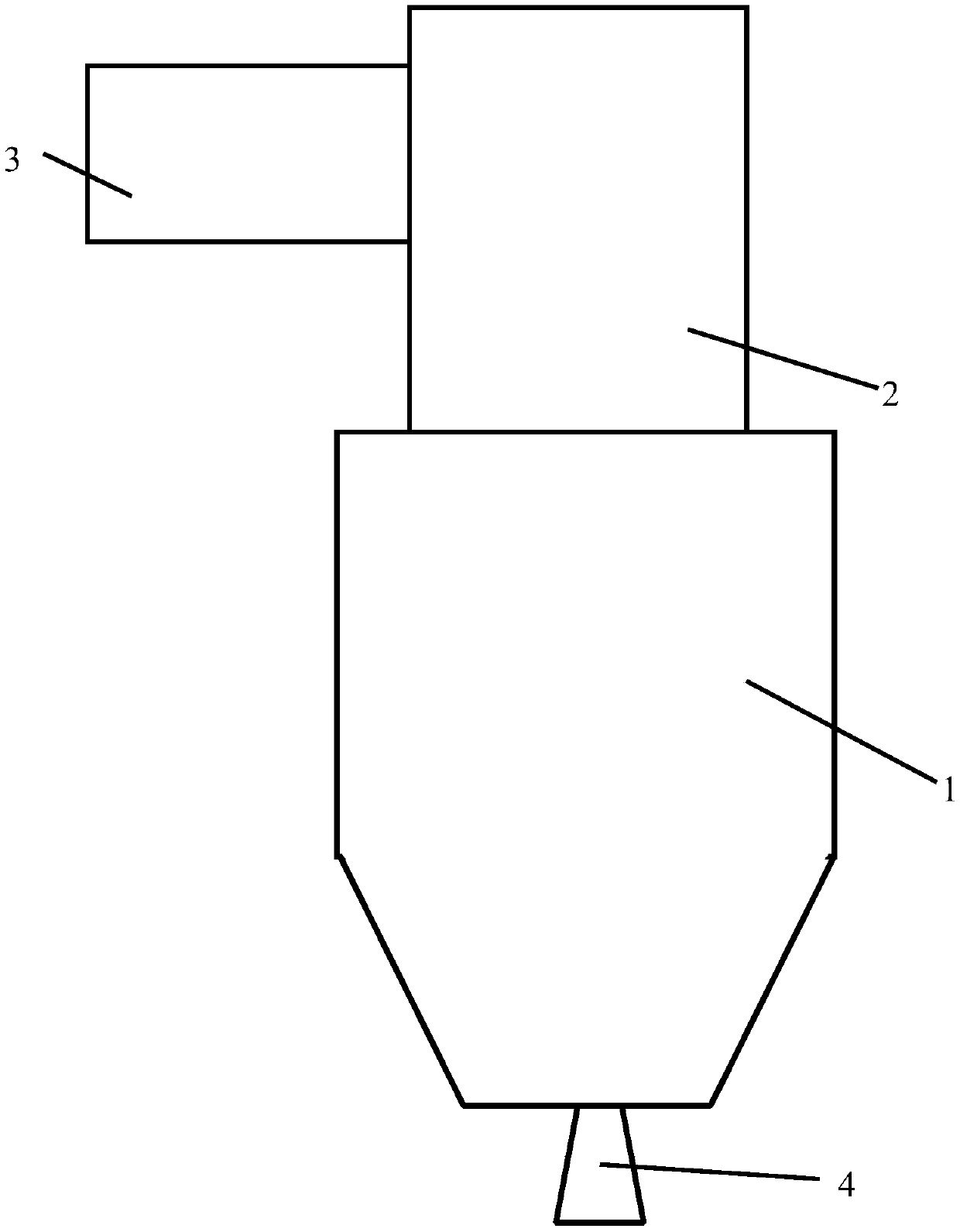

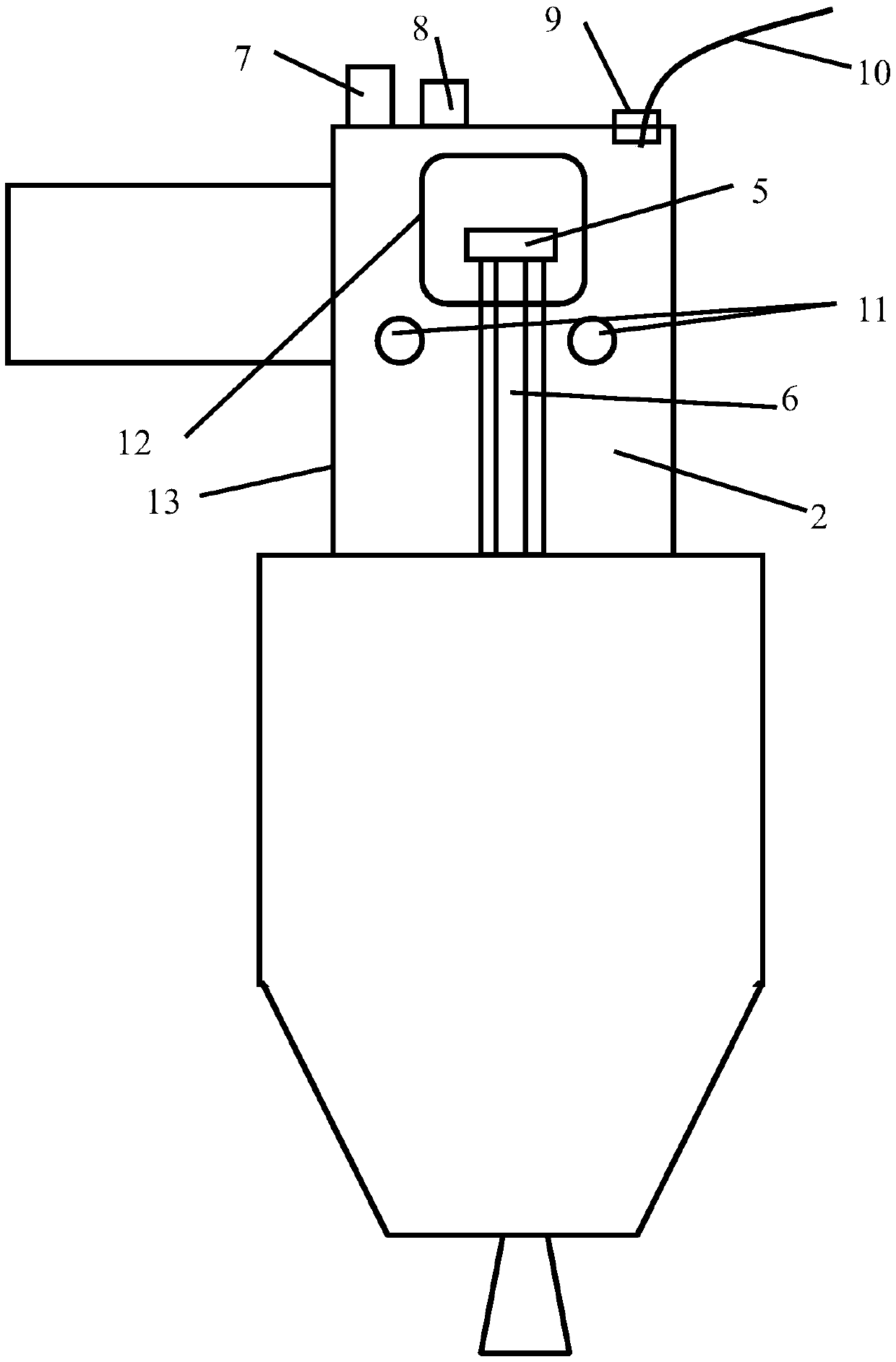

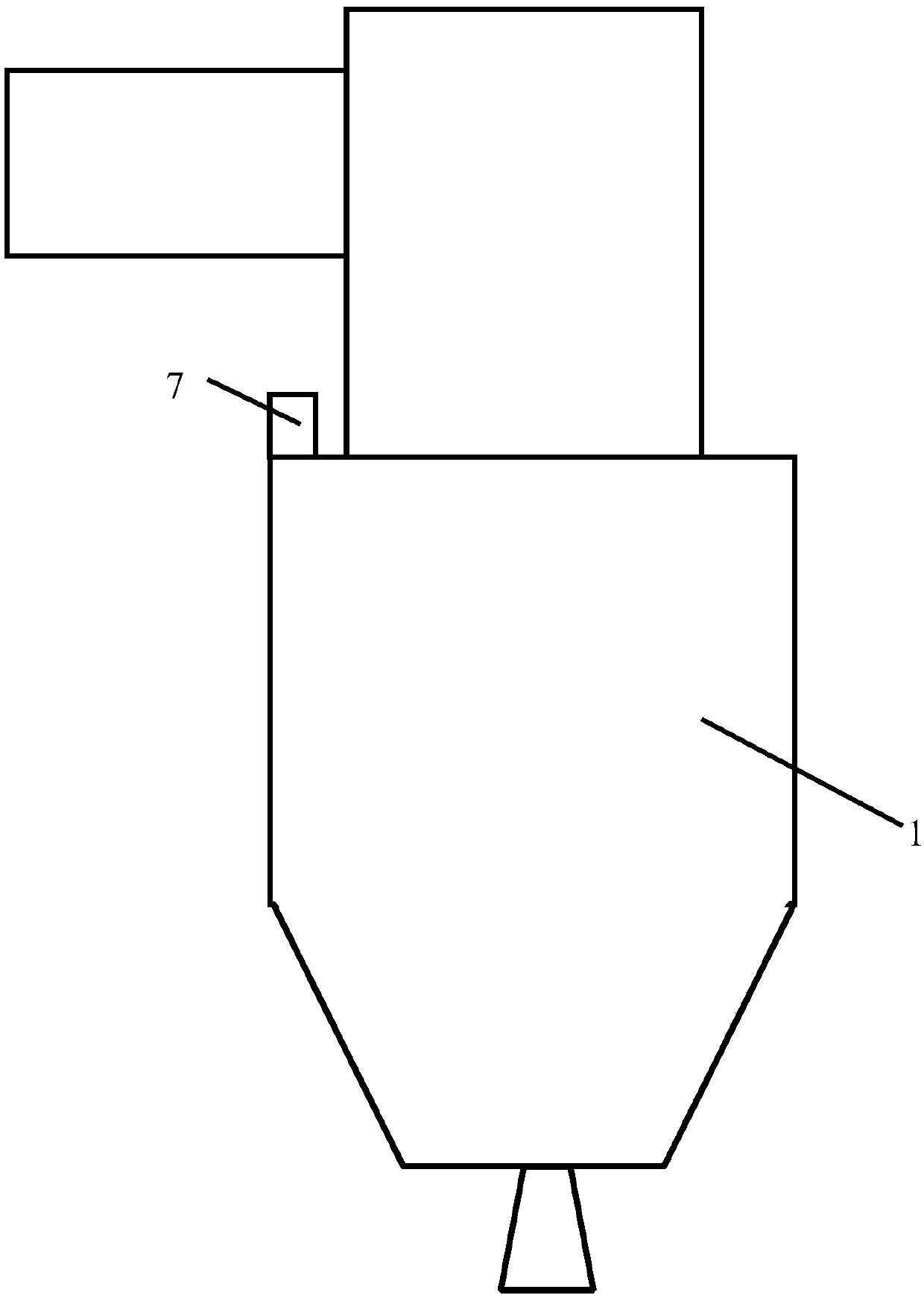

[0019] The present invention is a kind of equipment for the preparation of novel superfine metal powder, the structure is as follows figure 1 As shown, it includes the atomization chamber 1, the top of the atomization chamber 1 is connected with the sealed feeding bin 2, the bottom of the atomization chamber 1 is connected with the powder collection device 3, and the side of the sealed feeding bin 2 is also connected with the feeding transition sealing bin 3, as figure 2 as shown in image 3 As shown, the oxygen content measuring device 7 is installed on the top of the atomization chamber 1, the sealed feeding chamber 2 and the feeding transition sealing chamber 3, and the pressure sensor 8 is also installed on the top of the sealing feeding chamber 2 and the feeding transition sealing chamber 3.

[0020] The sealed feeding bin 2 includes a feeding system 5, the feeding system 5 is externally covered with a sealing cover 13, the sealing cover 13 is connected with the atomizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com