On-line measurement system and method for backflow oxygen content of diffused gas at top of coking tank

A technology for measuring system and gas oxygen content, which is applied in measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of potential safety hazards, exhaust gas discharge, etc., and achieve the effects of improving operating rate, reducing emissions, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

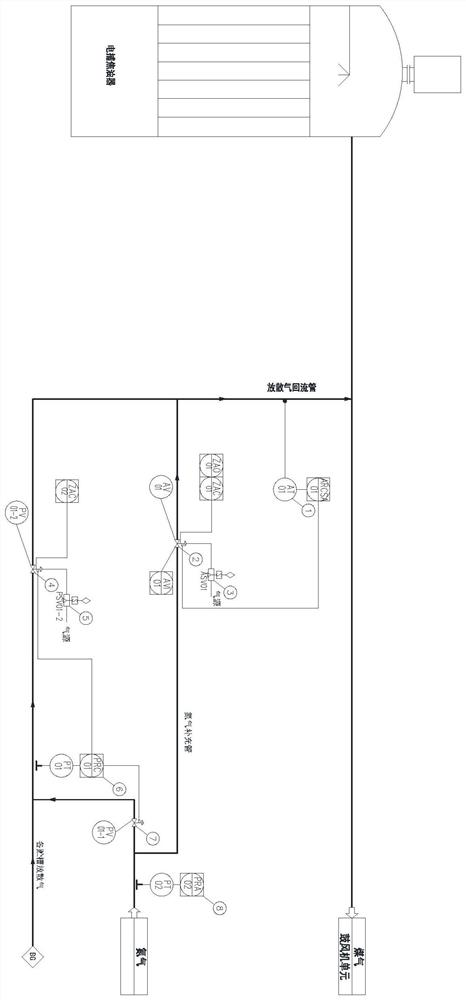

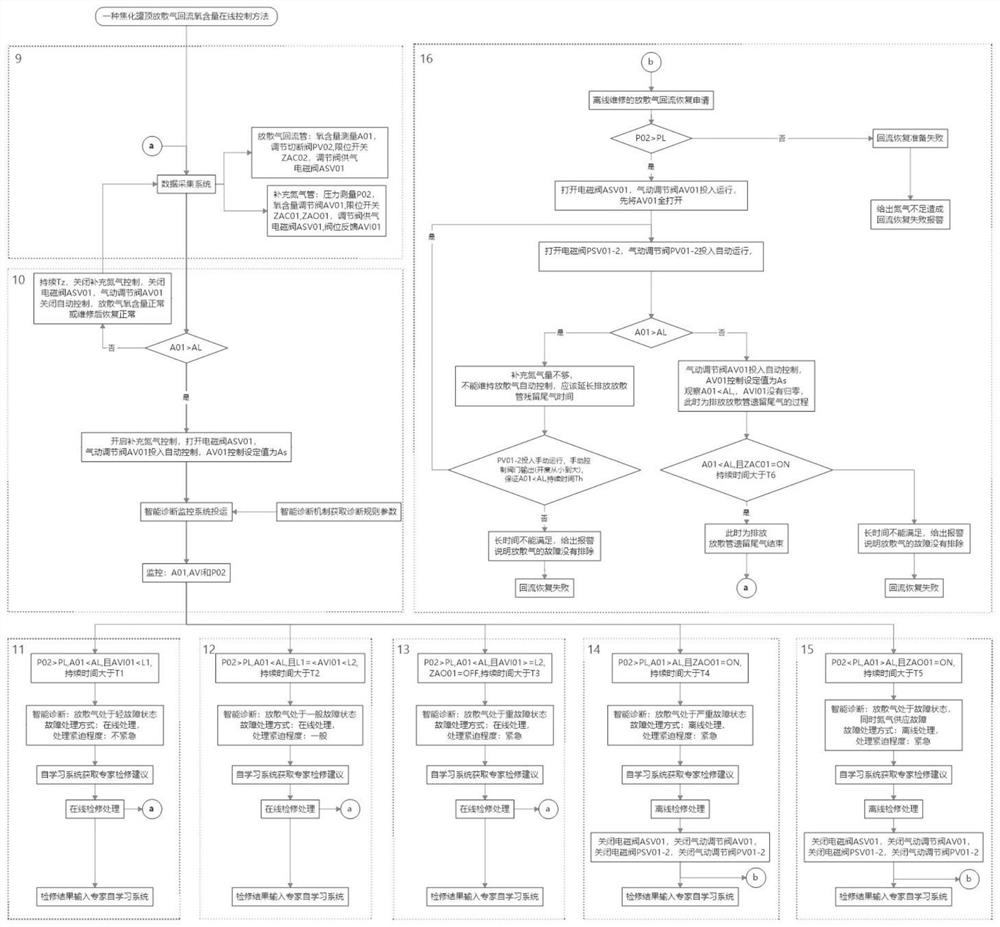

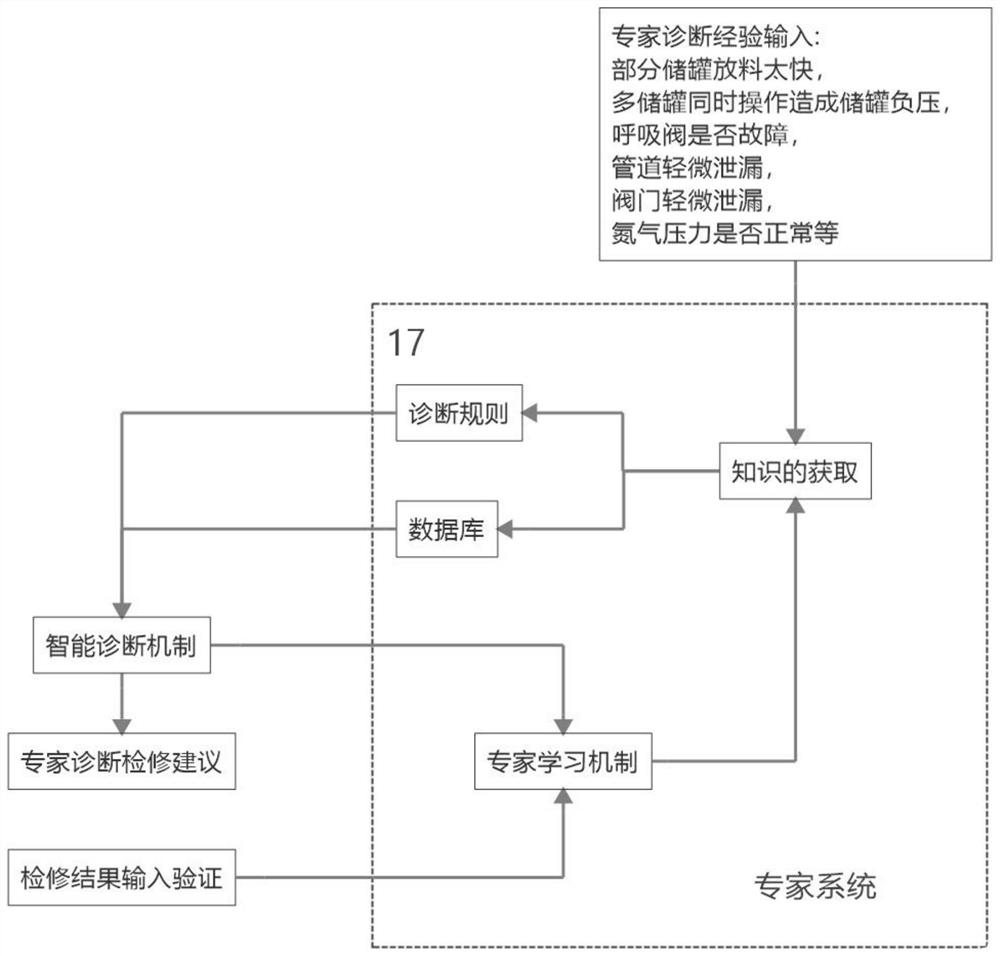

[0064] Such as figure 1 As shown, an on-line measurement system for the oxygen content of the blow-off gas backflow on the top of the coking tank includes the blow-off gas pipeline oxygen content measuring instrument AT01 (1) arranged on the blow-off gas return pipe. It also includes a nitrogen supplement pipe and a nitrogen supplement pipeline regulating valve AV01(2) arranged on the nitrogen supplement pipe; the inlet of the nitrogen supplement pipe is connected to the nitrogen main pipe, and the outlet is connected to the front end of the oxygen content measuring instrument AT01(1) of the vent gas pipeline. on the pipeline. The nitrogen main pipe is also provided with a nitrogen main pipe pressure measuring instrument PT02 (8). The nitrogen supplement pipeline regulating valve AV01(2) is also provided with an air source contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com