Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Nitrofurantoin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nitrofurantoin is an antibiotic used to treat or prevent certain bladder infections.

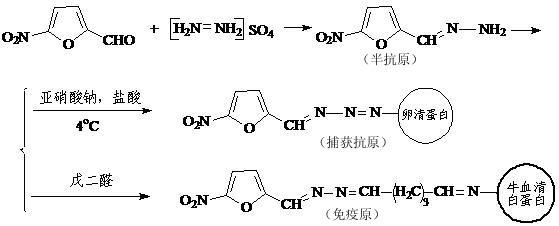

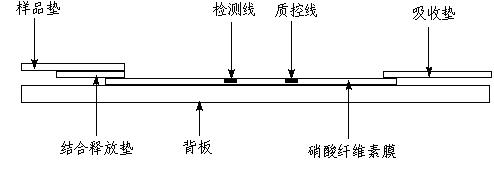

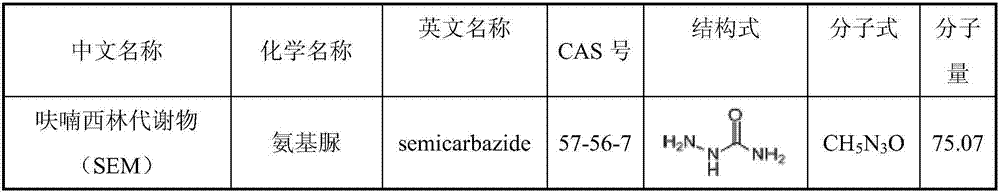

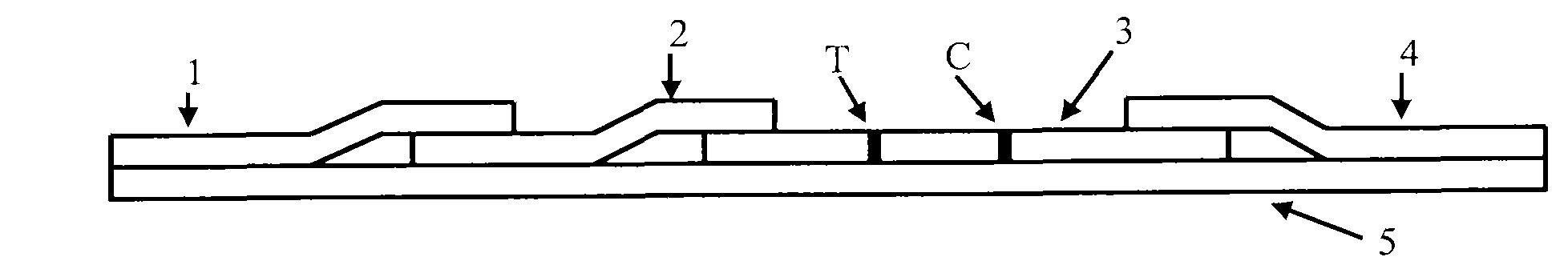

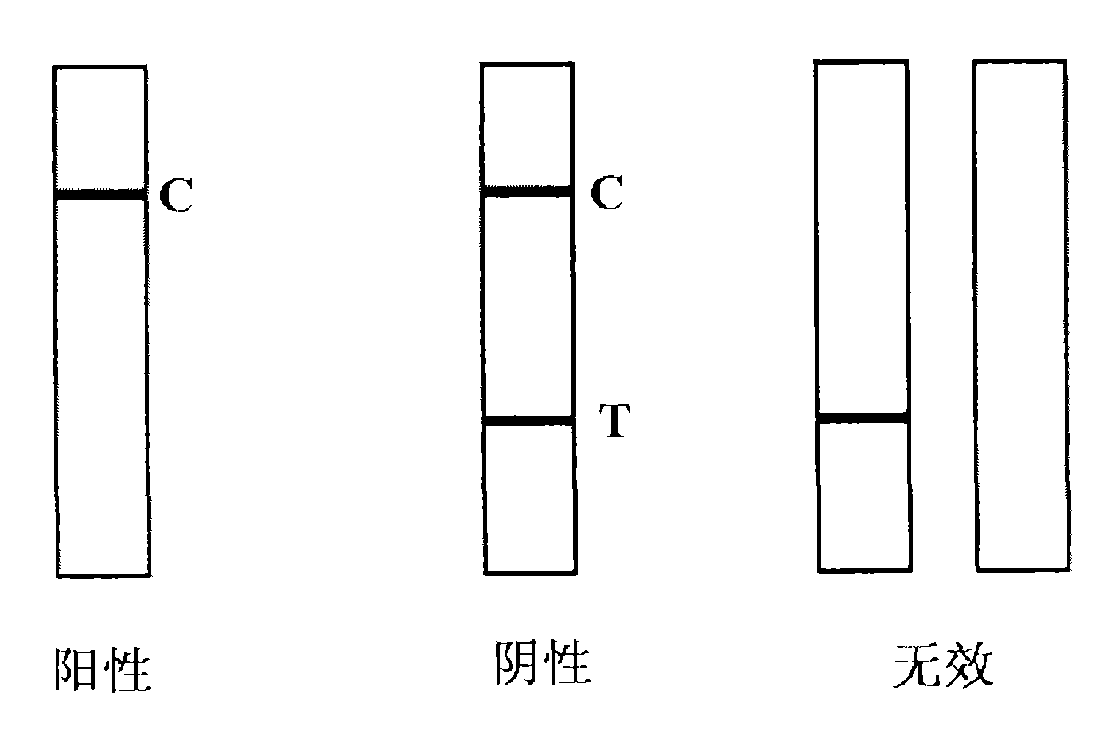

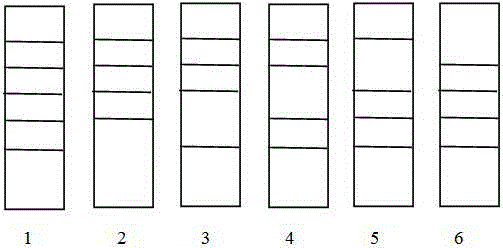

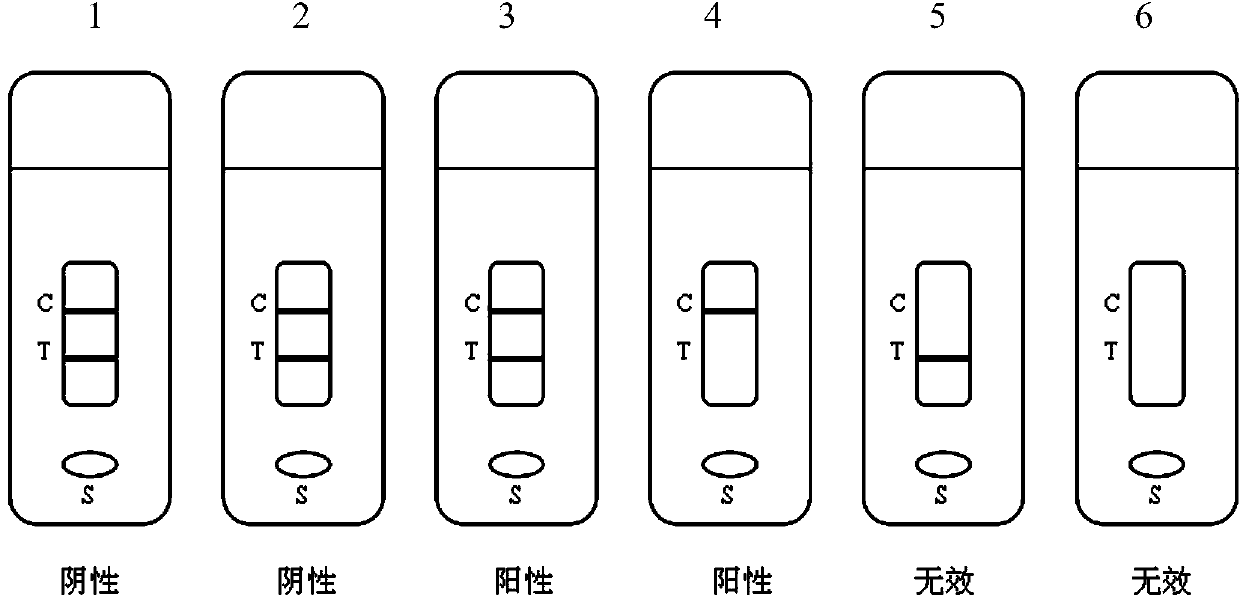

Immune nano gold test strip for quickly detecting four nitrofuran medicaments

The invention relates to an immune nano gold test strip for quickly detecting four nitrofuran medicaments. The immune nano gold test strip is prepared by the following steps of: synthesizing general hapten, immunogen and captured antigen aiming at the four nitrofuran medicaments comprising nitrofurazone, furaltadone, nitrofurantoin and furazolidone by using 5-nitrofurfural as a raw material, immunizing a domestic rabbit serving as an experimental animal to acquire polyclonal IgG antibody, preparing gold labeled antibody by using nano gold and the polyclonal IgG antibody, coating the gold labeled antibody solution on a Glass33 glass cellulose membrane, namely a combined release pad, coating the captured antigen and goat anti-rabbit antibody on a detection line and a quality control line of an AE99 nitrocellulose membrane respectively, sequentially sticking the AE99 nitrocellulose membrane, the combined release pad, namely the Glass33 glass cellulose membrane, an absorption pad Cotton linters 2668 and a sample pad Glass33 on a polyvinyl chloride (PVC) back board, and finally, cutting the back board into 4*50mm test strips. The test strip can simultaneously and quickly detect the four medicaments comprising nitrofurazone, furaltadone, nitrofurantoin and furazolidone in feed; and the cost of the test strip is less than 5 yuan, so the test strip is suitable to be widely applied in feed detection or food animal detection.

Owner:河北省兽药监察所

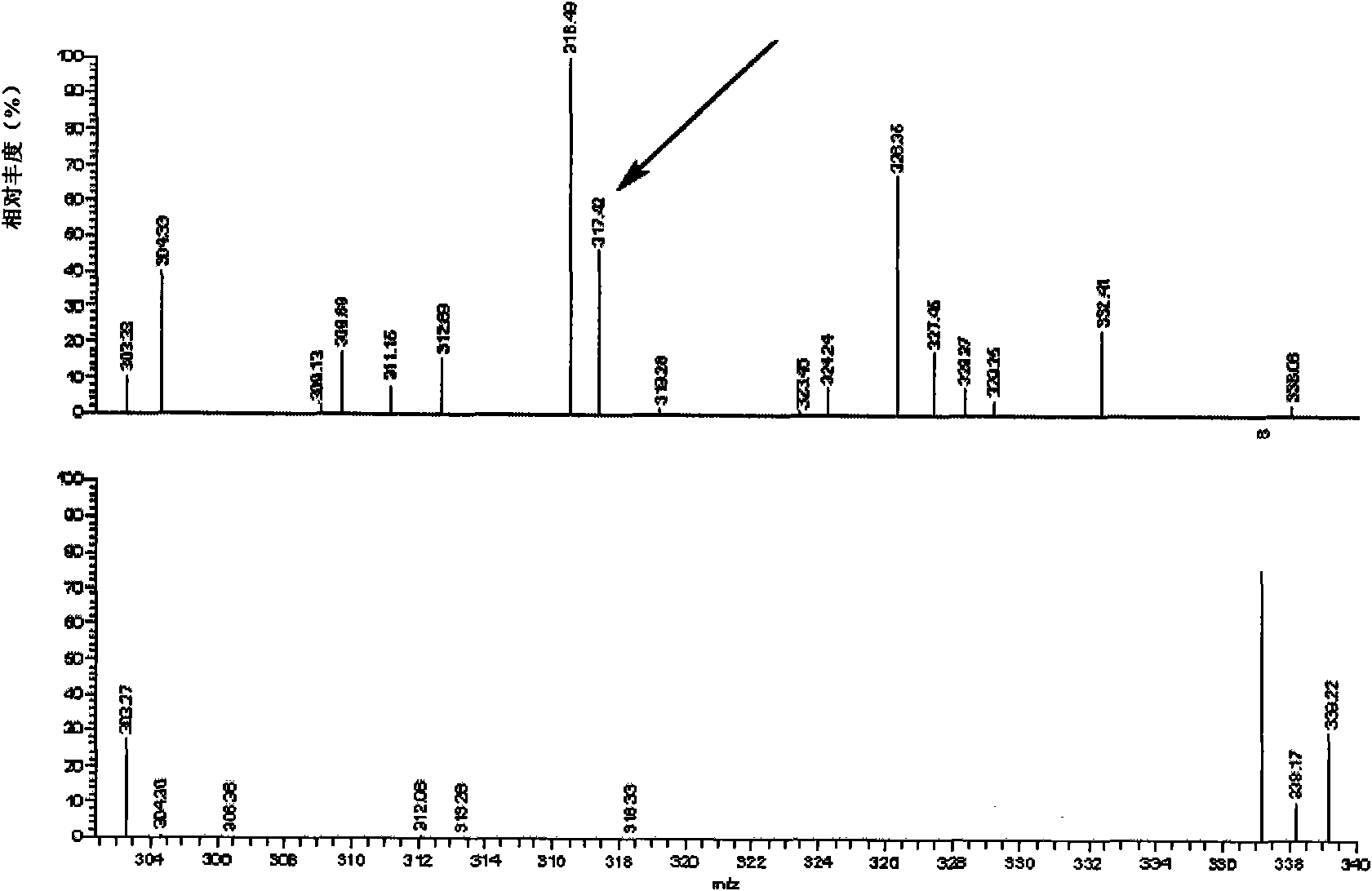

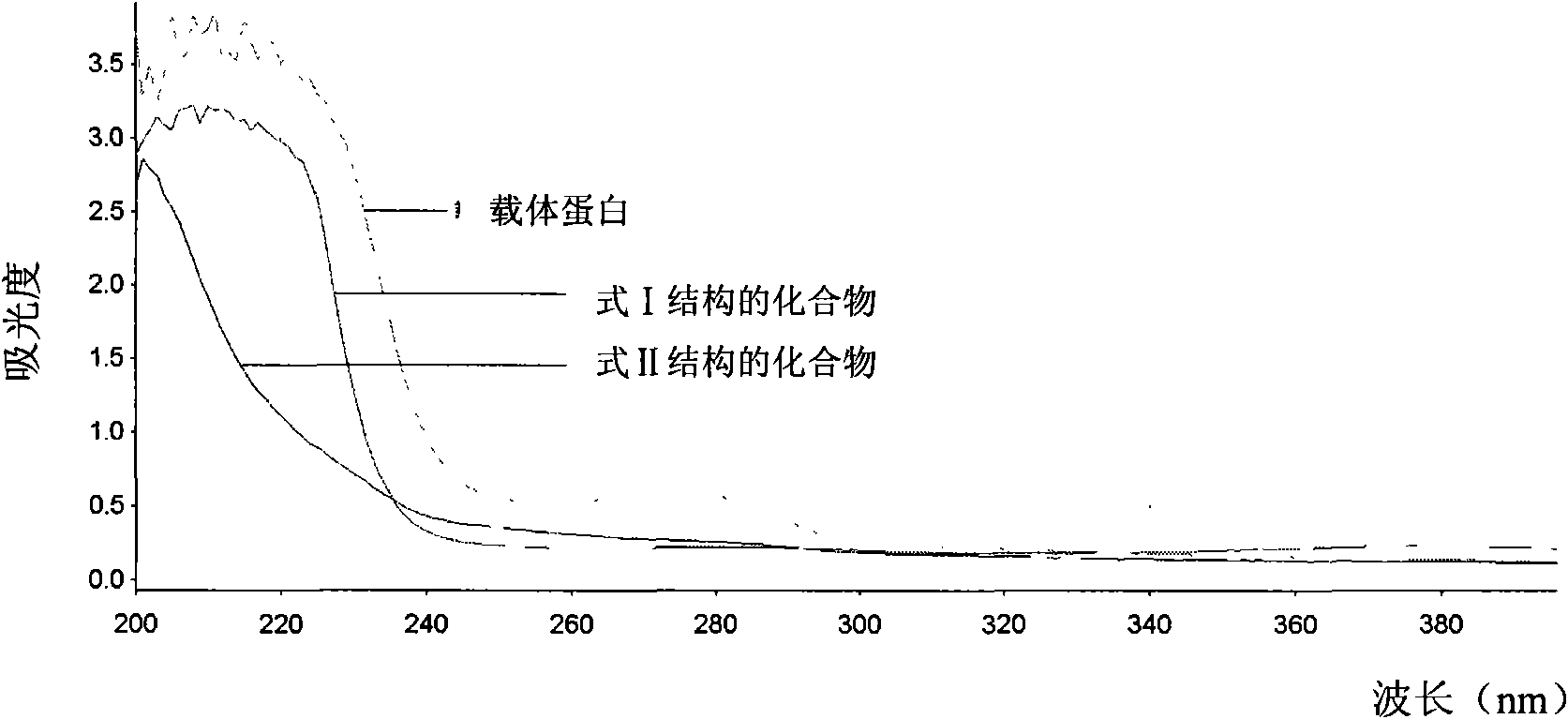

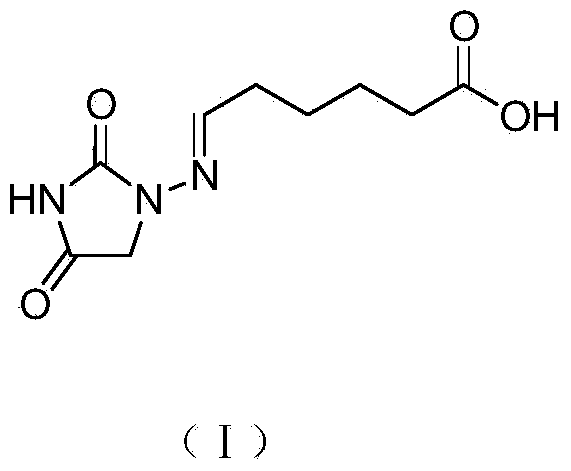

Hapten and antigen of nitrofurans and preparation method and application thereof

InactiveCN101643462AImprove detection efficiencyShorten detection timeOvalbuminSerum albuminNitrofurazoneFuraltadone

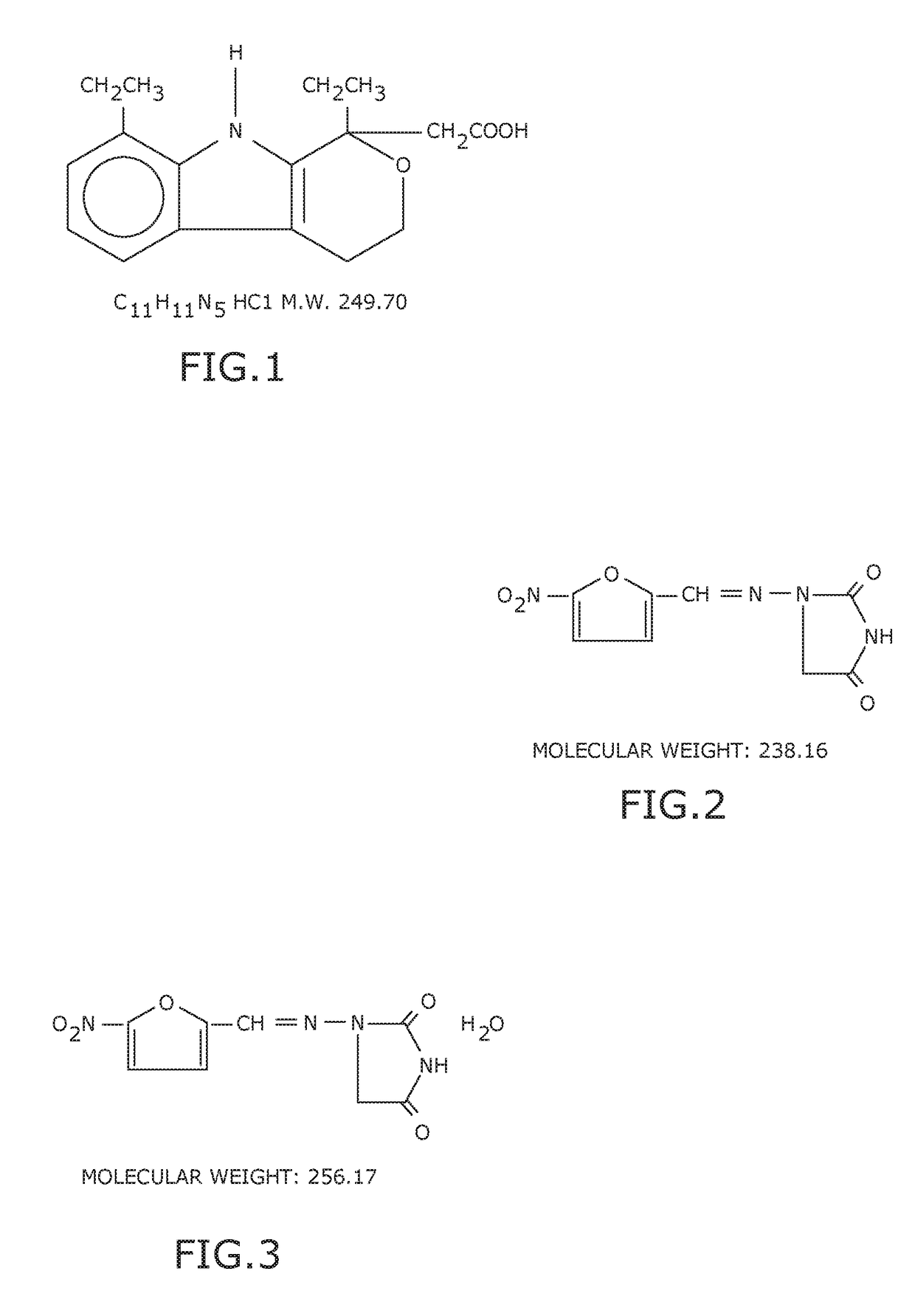

The invention discloses hapten and antigen of nitrofurans and a preparation method and application thereof. The antigen is a nitrofuran compound which is conjugate obtained by conjugating the compoundof formula I structure and carrier protein. As the antigens of the invention have 5-nitrofuran ring structure in common, the antibodies of the nitrofurans can be obtained by taking the antigens as immunogen to immunize animals. The antibodies can simultaneously identify four kinds of nitrofurans (nitrofurazone, furazolidone, furaltadone and nitrofurantion). Therefore, the antigen prepared by theinvention can be used for immunoassay and screening of the nitrofurans, improve the detection efficiency, shorten the detection time and lower the detection cost.

Owner:北京维德维康生物技术有限公司

Selective growth medium for Listeria spp

ActiveUS7960164B2Quick and accurate identificationBacteriaMicrobiological testing/measurementBacteroidesLithium chloride

The invention is a selective growth medium for investigating, isolating, counting and directly identifying pathogenic bacteria of the genus Listeria.The medium promotes the Listeria spp. while simultaneously inhibiting the growth of non-Listeria organisms. The medium does not produce a bacterial biomass contaminated with interfering fluorophores. The medium contains nitrofurantoin, esculin and lithium chloride and lacks acriflavin.

Owner:PARADIGM DIAGNOSTICS

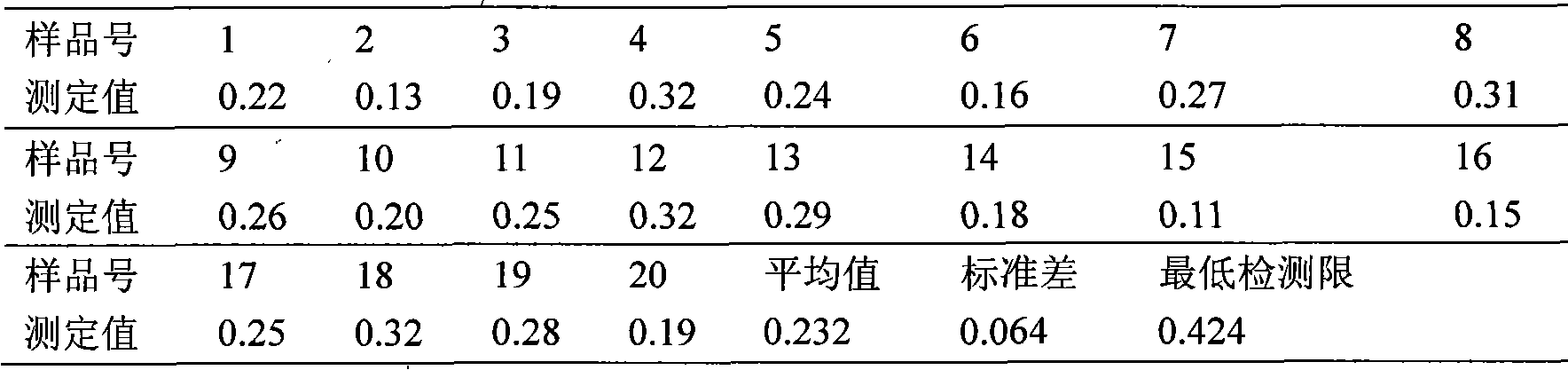

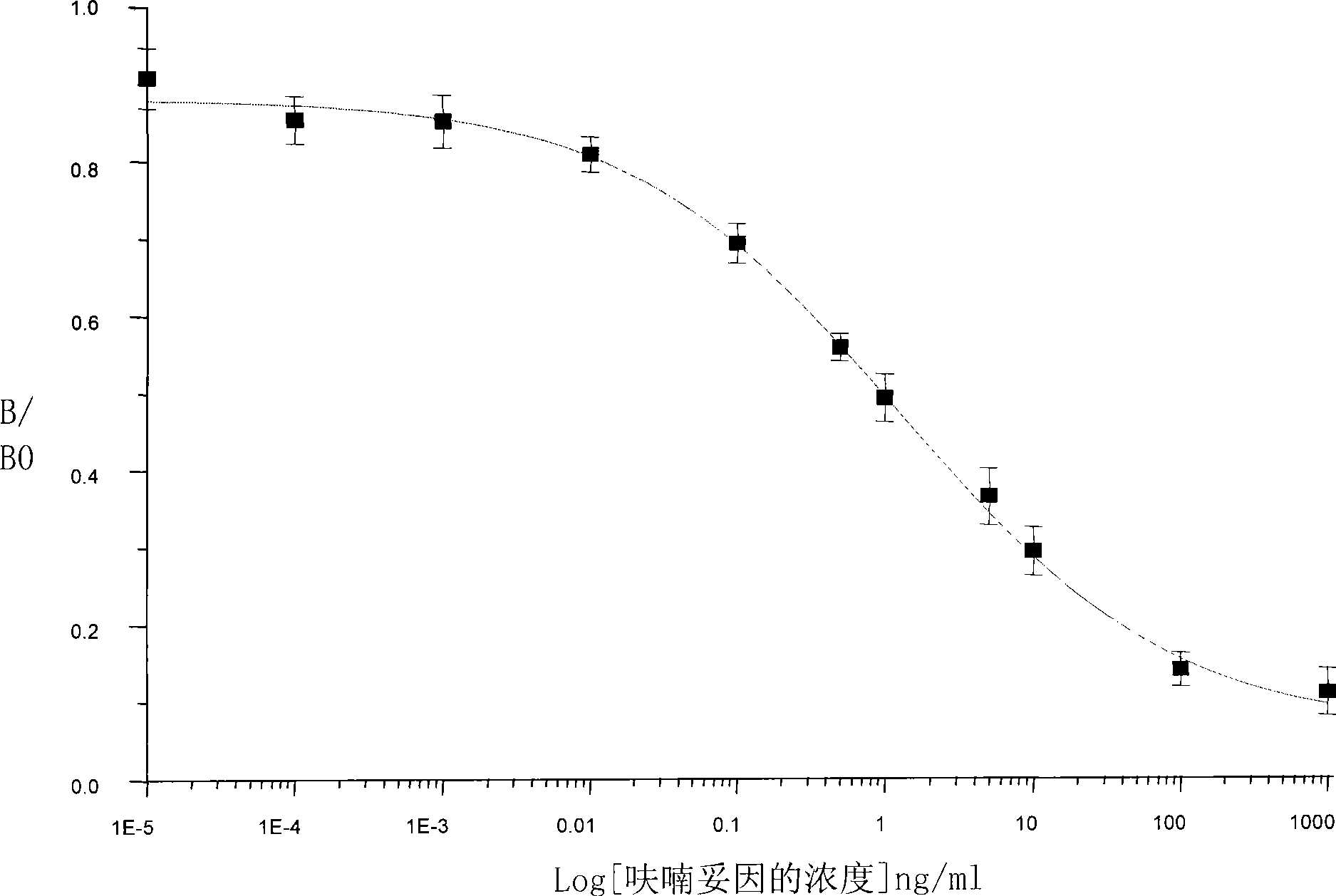

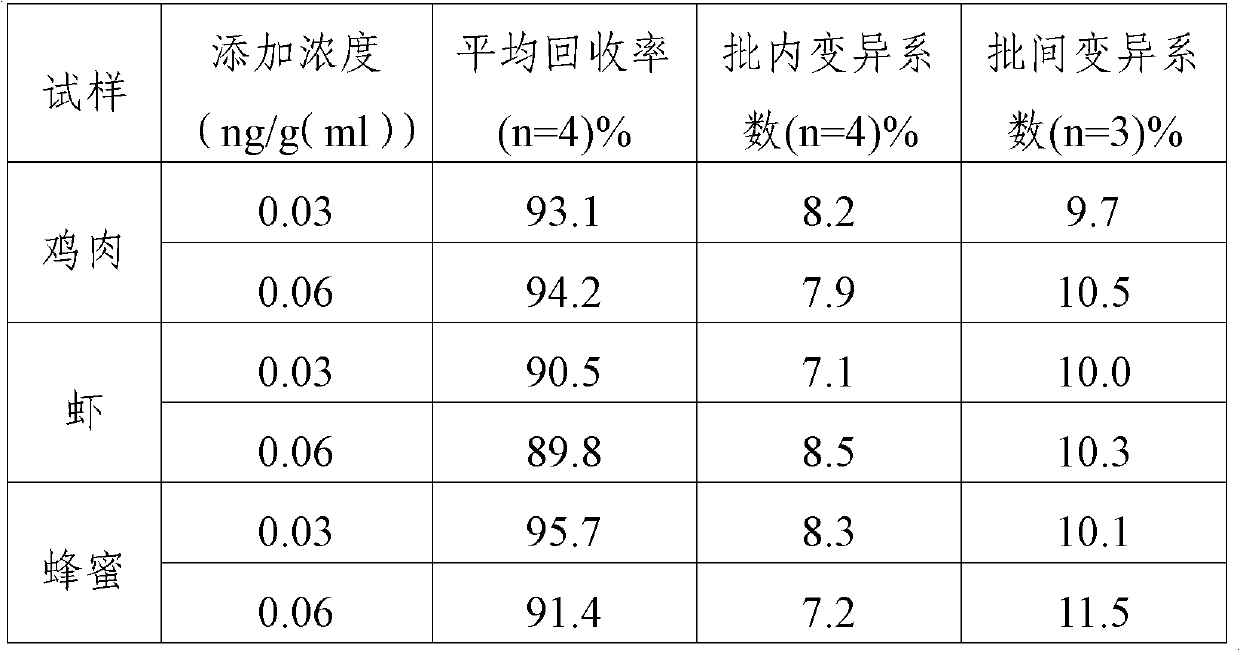

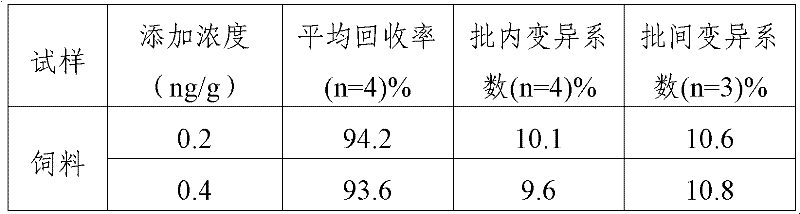

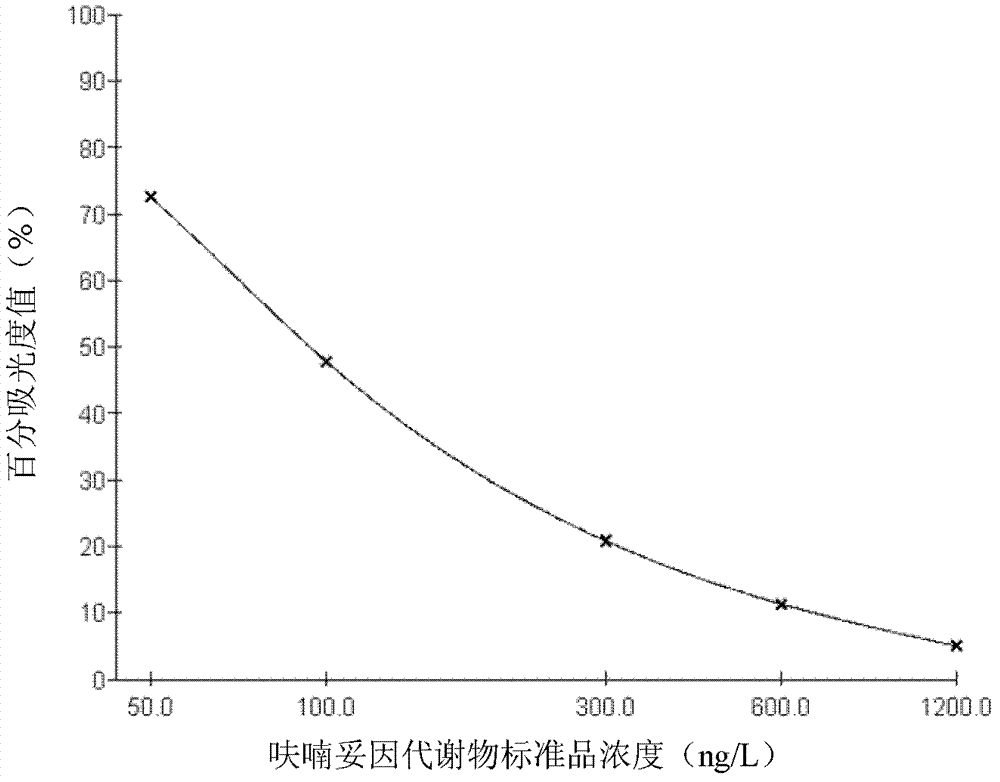

Furantoin metabolite enzyme linked immunosorbent analytical reagent casing and uses thereof

The invention provides a detecting nitrofurantoin metabolite ELISA kit, which contains: an ELISA plate covered by the original coated, enzyme marker, nitrofurantoin metabolite specific antibody or nitrofurantoin metabolite derivative antibody, nitrofurantoin metabolite standard solution or nitrofurantoin metabolite derivative standard solution, the substrate color solution, the termination solution, the condensed washing solution, the condensed complex solution. The invention also provides a method to apply the above ELISA kit detecting nitrofurantoin metabolite, which includes steps: firstly, sample pre-treatment, and then using the kit for testing, and finally analyzing testing results. The invention is to provide the nitrofurantoin metabolite residues in the ELISA kit for detection of animal derived foods, such as chicken, pork, fish, shrimp, milk, honey, egg, and other samples, and the detection method is simple, low cost, high sensitivity, and it can monitor on the scene and suitable for screening large number of samples.

Owner:BEIJING WANGER BIOTECH

Nitrofurantoin residue enzyme-linked immunoassay kit

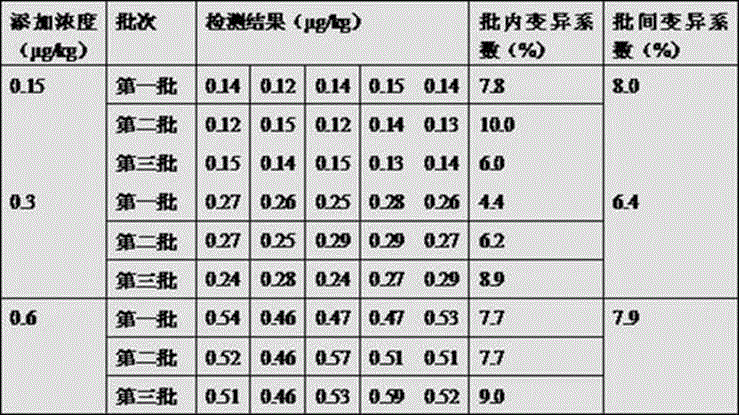

The invention discloses a nitrofurantoin residue enzyme-linked immunoassay kit which comprises a) an ELIAS plate, b) a standard solution, c) an antibody working solution, d) a cleaning solution, e) an enzyme marker, f) a substrate developing solution and g) a stopping solution, wherein the ELIAS plate is coated with nitrofurantoin metabolite AHD or coupling antigen of a derivative of the nitrofurantoin metabolite and a protein; and the standard solution is prepared by o-nitrobenzaldehyde which is dissolved in the dimethyl sulfoxide and then reacts with hydantoin derivative. The invention is mainly provided in a form of working solution, is characterized by convenient use, high specificity, high sensitivity, high precision, high accuracy and the like, and is applied to the detection of nitrofurantoin residues in animal food such as aquatic products and the like.

Owner:FOOD INSPECTION CENT OF CIQ SHENZHEN

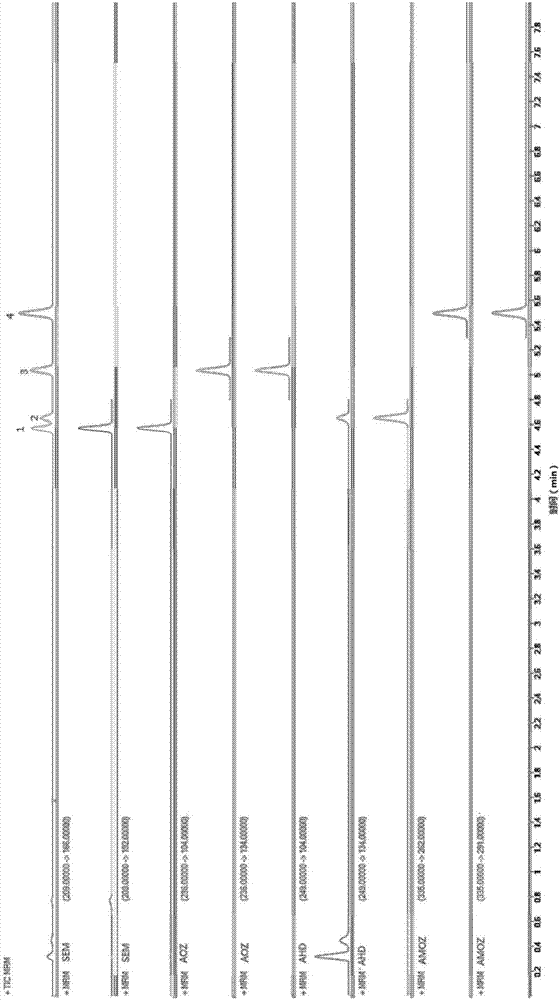

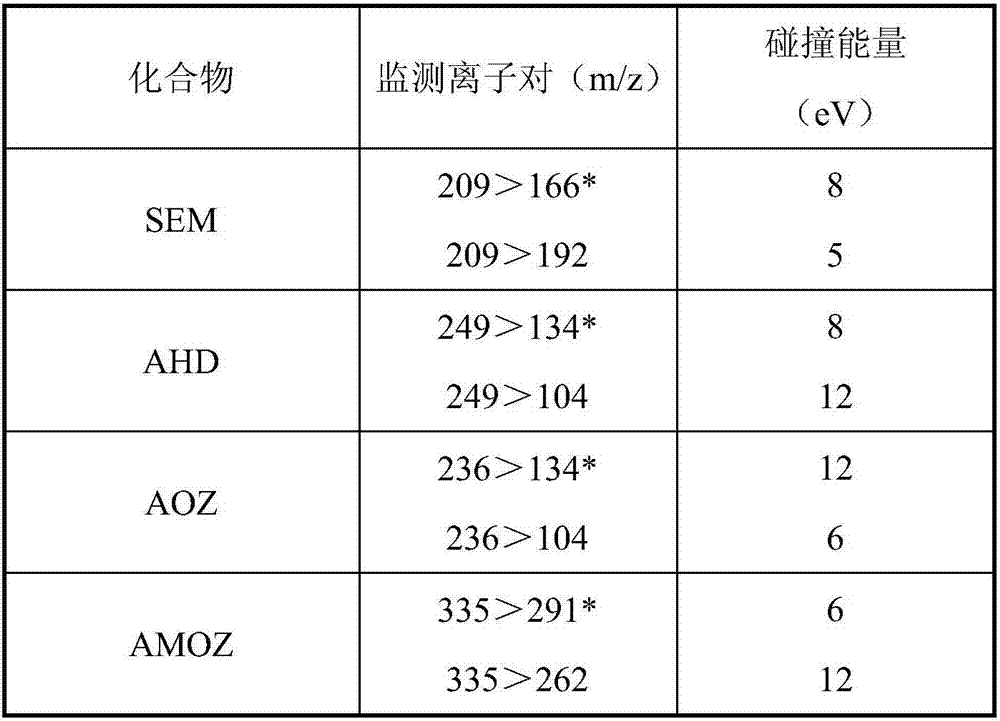

Method for determining residues of metabolites of four nitrofurans drugs in animal glue traditional Chinese medicine

The invention discloses a method for determining residues of metabolites of four nitrofurans drugs in an animal glue traditional Chinese medicine. The method comprises the following steps: preparing to-be-tested sample solution; preparing standard solution; injecting a standard series of working solution into a liquid chromatograph / mass spectrometer, determining appearance positions of the metabolites of the four nitrofurans drugs and qualitative and quantitative determination ion pairs thereof, and making a standard curve equation by taking the abundance of the quantitative ion pairs as a vertical coordinate and taking the concentration as a horizontal ordinate; substituting data obtained by corresponding detection for the to-be-tested sample solution into the standard curve equation forcalculation, so as to obtain the contents of the metabolites of all the nitrofurans drugs in the to-be-tested sample. The metabolites of the four nitrofurans drugs are: a furanzolidon metabolite (AOZ), a furaltadone metabolite (AOMZ), a furacilin metabolite (SEM) and a furadantin metabolite (AHD).

Owner:杭州市食品药品检验研究院

Chemiluminescence ELISA detection kit of furadantin

InactiveCN101393212AEasy to handleThe result is high sensitivityChemiluminescene/bioluminescenceMetaboliteNitrofurantoin

The invention discloses a chemiluminescence enzyme immunoassay detection reagent kit for nitrofurantion, which comprises a kit body, an ELIAS plate arranged in the kit body and a reagent in the kit body, wherein each hole of the ELIAS plate is enveloped with an envelope antigen, and the envelope antigen is produced by coupling a metabolite 1-aminohydantoin (AHD) of the nitrofurantion and carrier protein; and the reagent comprises a polyclonal antibody of the nitrofurantion, a goat anti-rabbit antibody labeled by an ELIAS secondary antibody (horseradish peroxidase), a nitrofurantion series standard solution, a condensed phosphate buffer liquid, a concentrated cleaning solution, and a luminescent solution. The reagent kit has the characteristics of high sensitivity, good repetitiveness, simplicity, convenience, quickness, and accuracy; compared with the prior colorimetric ELISA method, the sensitivity can be improved by one order of magnitude; and the reagent kit is expected to play an important role in residue detection of the nitrofurantion of water for livestock raising, feedstuff, and animal derived food, such as milk samples, animal tissue samples, and urine samples.

Owner:SHANDONG UNIV

Selective Growth Medium for Listeria Spp

ActiveUS20080020445A1Quick and accurate identificationBacteriaMicrobiological testing/measurementCell culture mediaNitrofurantoin

Disclosed is a growth medium containing nitrofurantoin. The growth medium is selective for the growth of Listeria spp.

Owner:PARADIGM DIAGNOSTICS

Nitrofurantoin controlled release dosage form

The present invention generally relates to controlled release dosage forms which provide immediate release and sustained release of nitrofurantoin, and processes for their preparation. The controlled release dosage form includes a sustained release portion and an immediate release portion. The sustained release portion includes nitrofurantoin and one or more pH dependent hydrophilic polymers. The immediate release portion includes nitrofurantoin.

Owner:RANBAXY LAB LTD

Nitrofurans drug metabolite assay kit and production method thereof

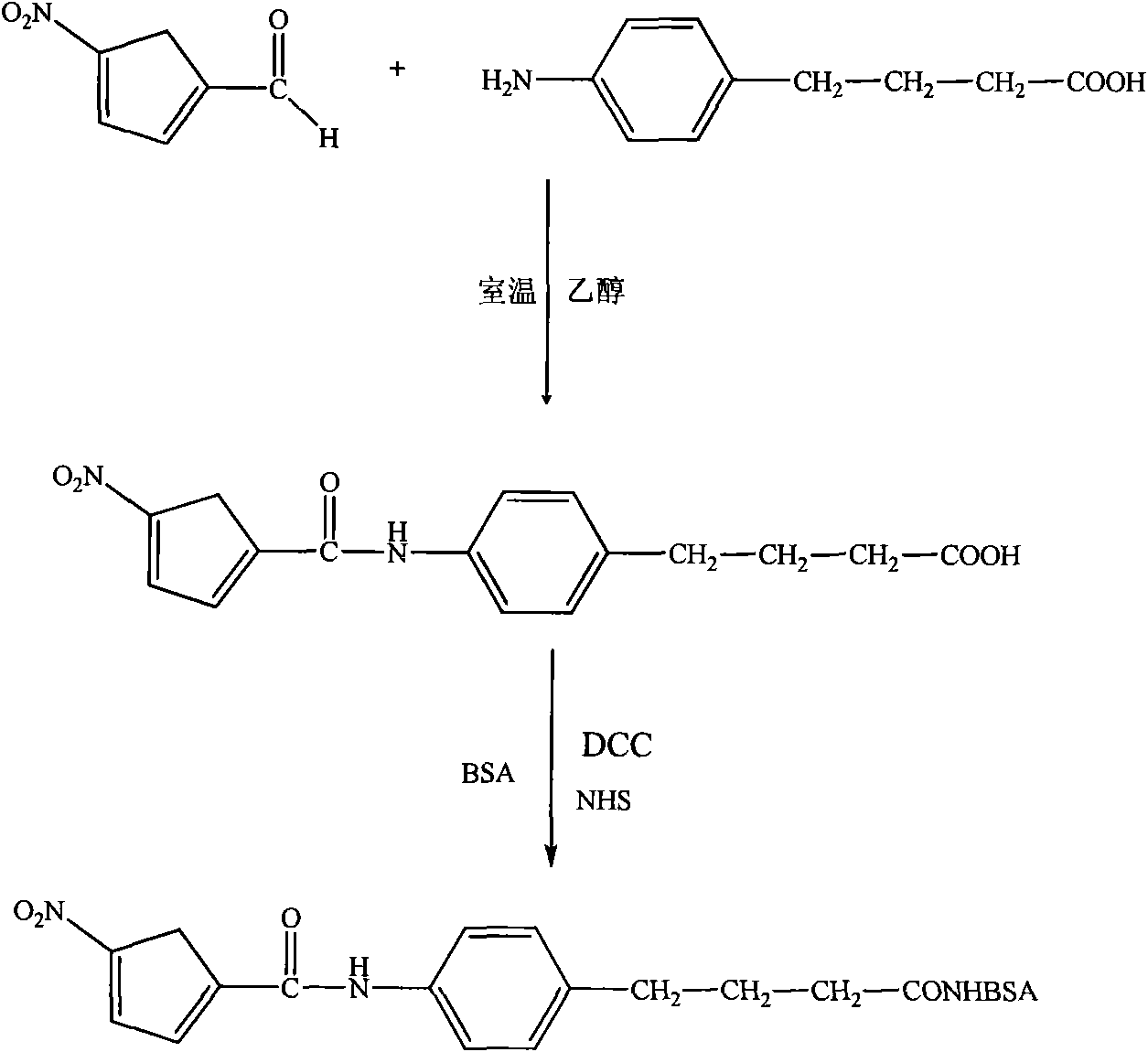

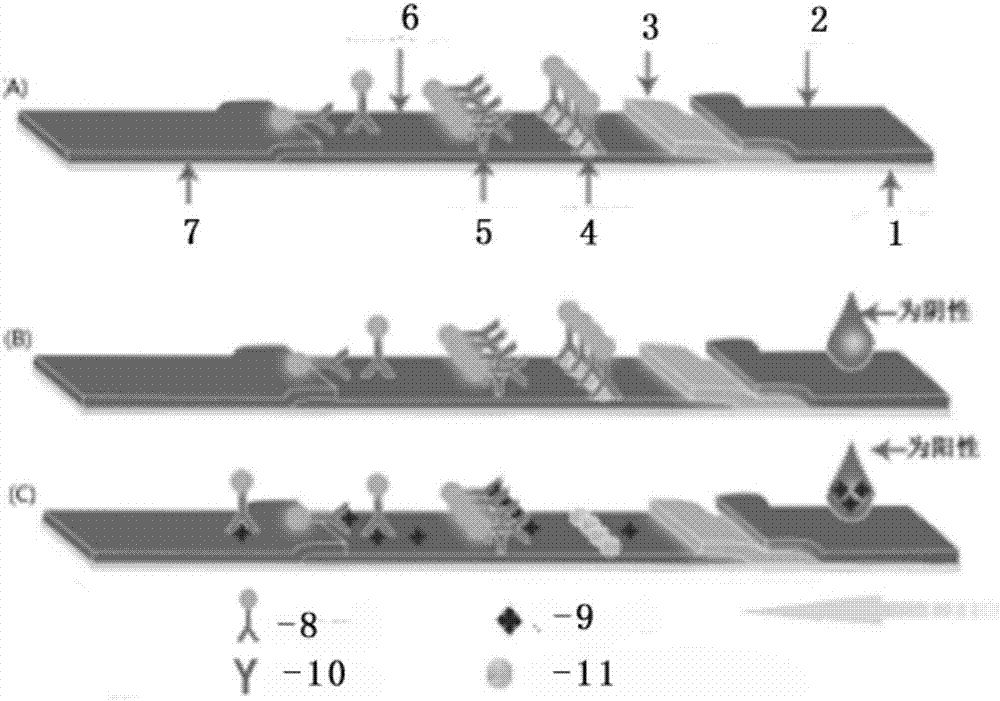

The invention provides a nitrofurans drug metabolite assay kit, which consists of a furazolidone metabolite test paper strip, a furaltadone metabolite test paper strip, a nitrofurazone metabolite test paper strip and a furantoin metabolite test paper strip. Each test paper strip consists of a sample pad, a colloidal gold pad, a nitrocellulose membrane, a sample adsorbing pad and a PVC (polyvinyl chloride) supporting plate, wherein the colloidal gold layer is a nitrofurans drug metabolite monoclonal antibody polyester film marked with colloidal gold, the nitrocellulose membrane is sequentially coated with nitrofurans drug metabolite coupled carrier protein as a test line (a T-line) and goat anti-mouse IgG antibody as a quality control line (a C-line). The nitrofurans drug metabolite assay kit is produced according to the nano colloidal gold technology, antigen-antibody specificity reactions and principles of immunity competitive inhibition reaction, and is used for testing whether samples contain nitrofurans drug metabolites or not.

Owner:宝瑞源生物技术(北京)有限公司

Method for producing cistofuran large particle crystal

The invention relates to a method for producing large-grained nitrofurantoin crystals, and belongs to the field of chemical synthesis. The invention adopts a technical proposal which comprises: placing a crude product of nitrofurantoin formed by the condensation of raw materials of 5-nitrofurfural diacetate and 1-aminohydantoin, and DMF of which the weight is two times of that of the crude product of the nitrofurantion in a retort, heating the mixture to between 85 and 90 DEG C, stirring the mixture, maintaining the temperature for 10 minutes, stirring the mixture, opening a clamping sleeve, cooling the retort by cooling water for 80 to 90 minutes to between 30 and 35 DEG C, stopping stirring, standing the retort for 2.5 to 3 hours to less than 2 DEG C below zero, casting material, and washing the material with 95 percent ethanol to obtain odorless DMF. Nitrofurantoin crystals prepared by the process are larger and the granularity of 95 percent of the products is more than 80 meshes, so the process facilitates filtration and separation and contributes to the reduction of production cost.

Owner:SHANDONG FANGXING SCI & TECH DEV

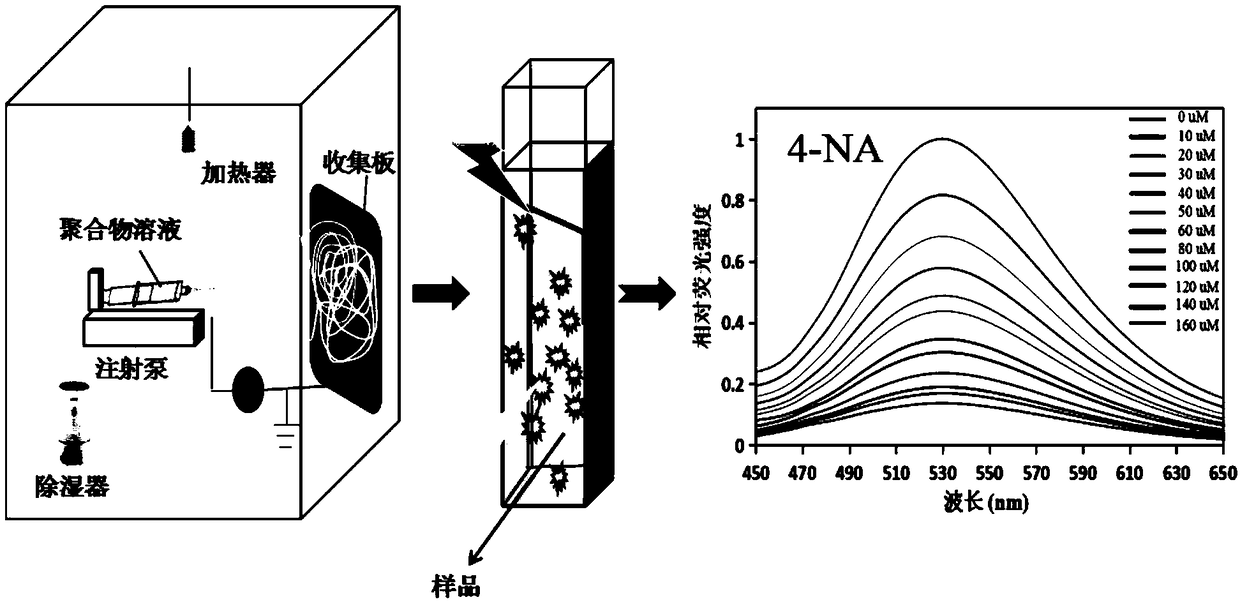

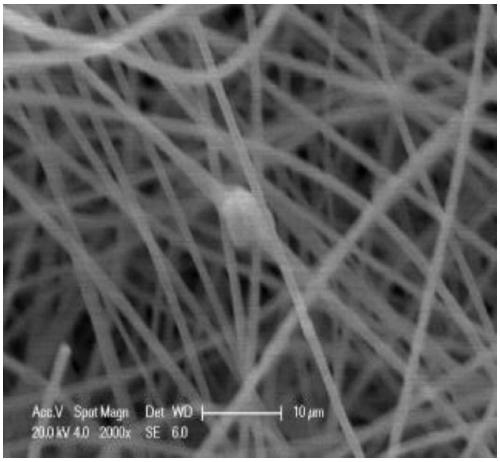

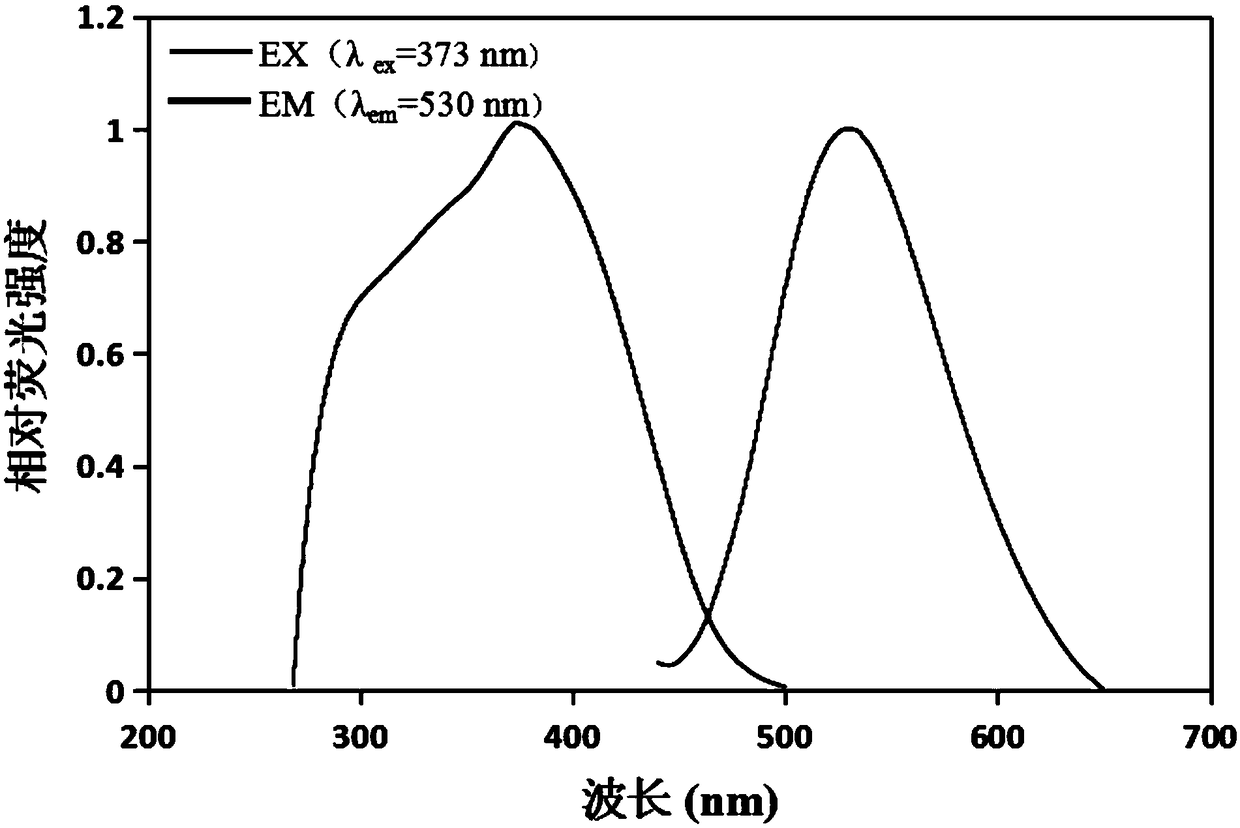

Preparation method and application of fluorescent nanofiber film based on bimetallic organic framework

ActiveCN109385751ANo pollution in the processHigh sensitivityFilament/thread formingMonocomponent synthetic polymer artificial filamentNitrofurazoneFluorescence

The invention discloses a preparation method and application of a fluorescent nanofiber film based on a bimetallic organic framework. The fluorescent nanofiber film is prepared by taking the bimetallic organic framework and a PMMA polymer as raw materials and utilizing an electrostatic spinning technology. The purpose of detection is achieved through the quenching amount of the fluorescent signalof the fluorescent nanofiber film. The fluorescent nanofiber film has the unique advantages of high sensitivity, good selectivity, short response time and the like when used for detecting nitro-explosive { (4-NA (p-nitroaniline), TNP (picric acid) } and antibiotic { (NFT nitrofurantoin, NFZ nitrofurazone) } in water.

Owner:WUHAN UNIV

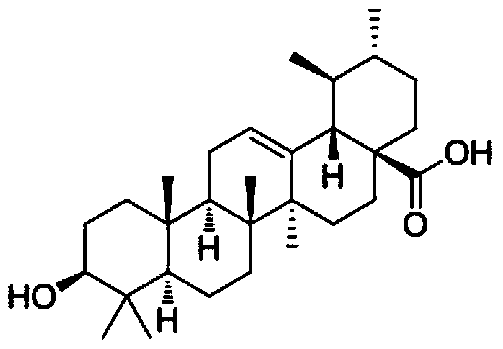

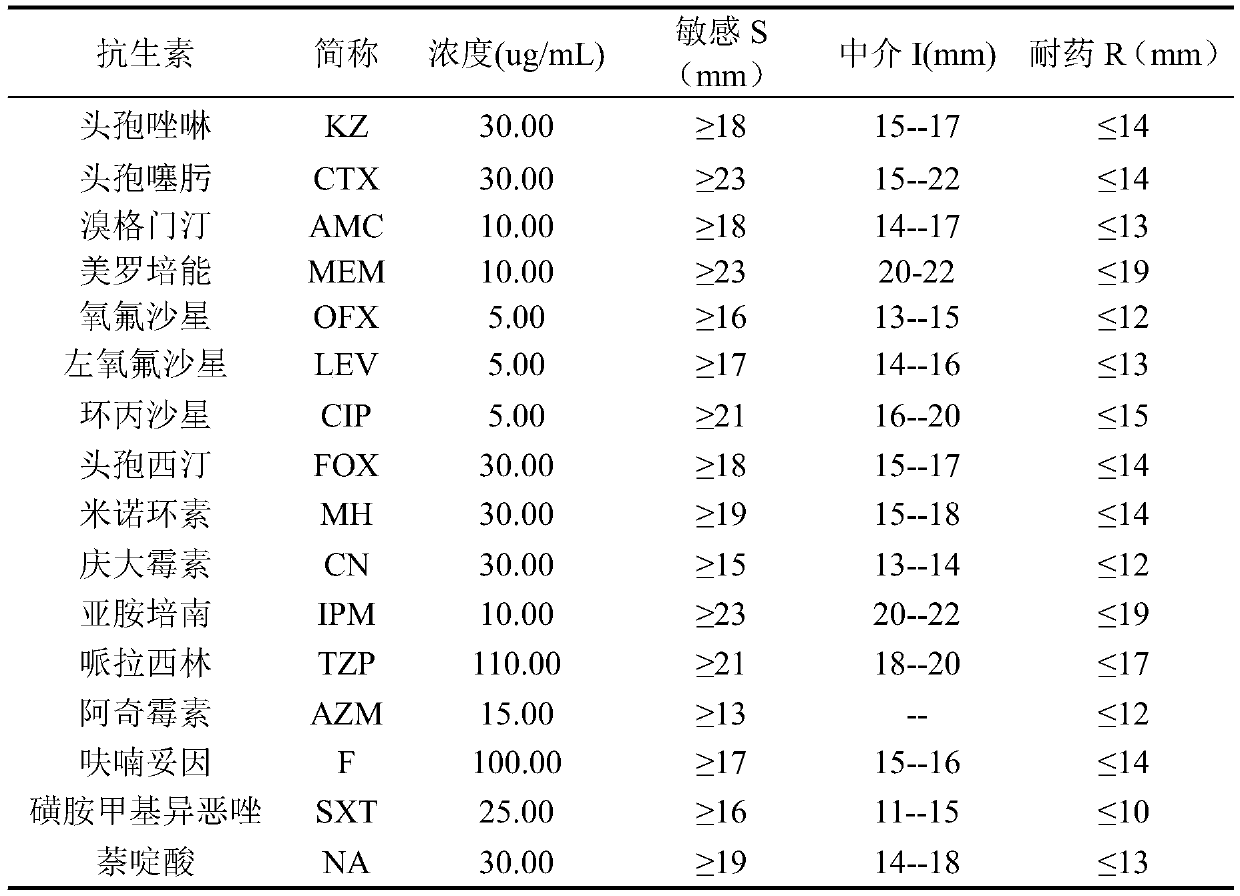

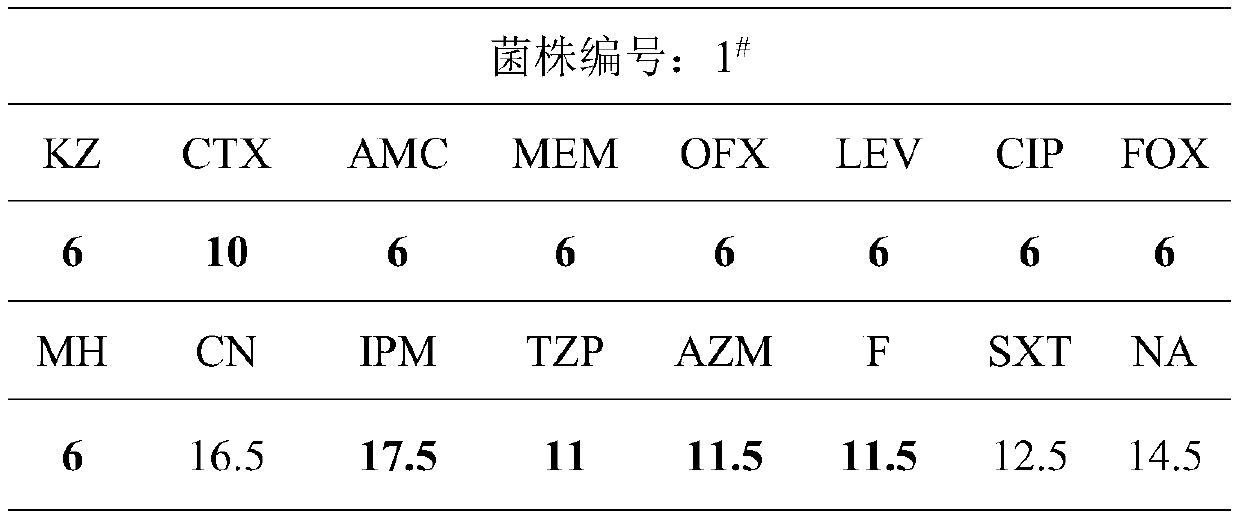

Application of ursolic acid in inhibiting growth of multi-drug-resistance enterobacter cloacae

InactiveCN110279701AMitigate or resolve drug-resistant infectionsReduce fatality rateAntibacterial agentsOrganic active ingredientsInfections problemsCase fatality rate

The invention discloses application of ursolic acid in inhibiting growth of multi-drug-resistance enterobacter cloacae. According to a good in-vitro killing function of ursolic acid upon anthropogenic multi-drug-resistance enterobacter cloacae which resists to cefazolin, cefotaxime, aupmentn, meropenem, ofloxacin, levofloxacin, ciprofloxacin, cefoxitin, minocycline, imipenem, piperacillin, azithromycin and macrodantin, growth of multi-drug-resistance enterobacter cloacae can be inhibited, the lowest sterilization concentration is 0.6mg / mL, and the lowest antibacterial concentration is 0.3mg / mL. The invention discloses an inhibition function of the ursolic acid upon the multi-drug-resistance enterobacter cloacae, and the ursolic acid is capable of effectively alleviating or solving the drug-resistance infection problem of the multi-drug-resistance enterobacter cloacae and reducing the case fatality rate, provides new ideas for inhibiting anthropogenic multi-drug-resistance enterobacter cloacae, and has great practical significances.

Owner:SHAANXI UNIV OF SCI & TECH

Cistofuran synthesis and purification method

InactiveCN101450941AReduce contentMeet the requirements of version 29Organic chemistryChemical synthesisPurification methods

The invention discloses a method for synthesizing and refining nitrofurantoin and belongs to the field of chemical synthesis. The invention adopts a technical proposal that: hydrochloric acid and water are placed in a retort, heated to be between 65 and 70 DEG C, added with 5-nitrofurfural diacetate and kept at between 75 and 80 DEG C for hydrolyzation; after the 5-nitrofurfural diacetate is completely hydrolyzed, aminohydantoin preheated to be between 60 and 65 DEG C is pressed into a condensation tank, heated to be between 90 and 92 DEG C and kept at the temperature for 50 to 60 minutes; a valve on the bottom of the tank is opened to discharge materials to a filter tank; the materials are washed with running water till the pH value reaches 6.5 to 7.5; the materials are dried by spinning and discharged; and the obtained nitrofurantoin and DMF are placed into the retort according to a ratio (by weight) of 1:2 and heated to be between 85 DEG C and 90 DEG C and thus the nitrofurantoin is obtained. The method reduces the content of nitrofural in the nitrofurantoin to less than 0.01 percent, reduces the content of 5-nitrofurfural diacetate in the nitrofural to less than 1.0 percent and meets the requirements of special users.

Owner:SHANDONG FANGXING SCI & TECH DEV

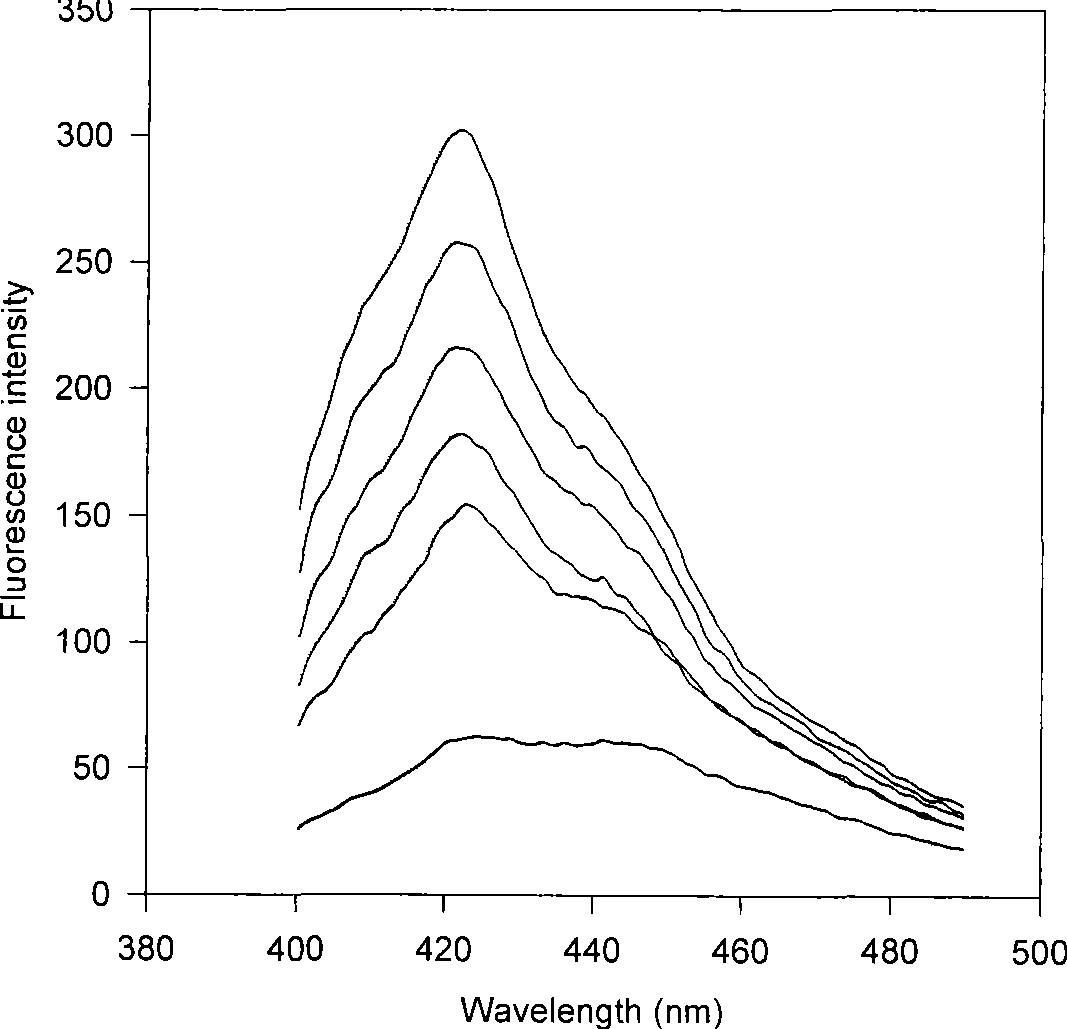

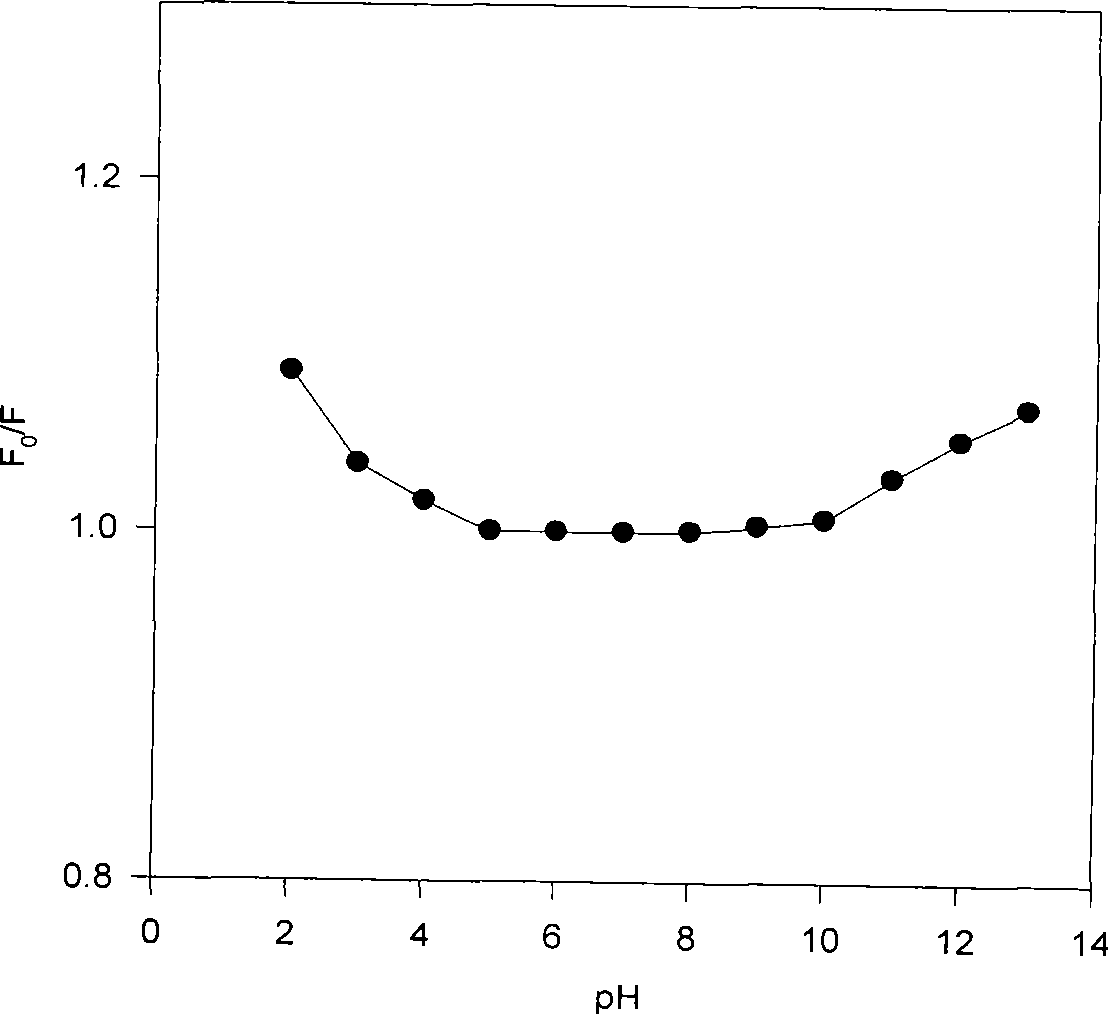

Fluorescent chemical sensor for furadantin detection

InactiveCN101430282ASimple structureImprove stabilityFluorescence/phosphorescence(Hydroxyethyl)methacrylateFluorescence

The invention discloses a fluorescence chemical sensor for detecting nitrofurantoin. 0.1-0.2ml of sensing film solution is coated on a polyfluortetraethylene board and is covered by a silylanized glass slide, and the fluorescence chemical sensor is manufactured after being polymerized by ultraviolet light and dried in room temperature, wherein, the sensing film solution is prepared by a method as follows: 15mg of methacrylate amide pyrene is solved in 0.2ml of N, N-dimethyl formamide; and 200mg of acrylamide, 0.4ml of hydroxyethyl methacrylate, 0.15ml of cross linker, 0.2ml of trolamine and 0.3ml of photosencitizer are added sequentially. The sensor has simple structure, good stability, the short responding time and the large extend of fluorescence and can be applied to the in-situ real-time detection of the nitrofurantoin, and the sensor has the high sensitivity, good selectivity and very wide application prospect.

Owner:焦广旭 +6

Magnetic granule chemiluminescence kit for detecting nitrofurantoin metabolite and application of magnetic granule chemiluminescence kit

The invention relates to a magnetic granule chemiluminescence kit for detecting nitrofurantoin metabolite, which comprises the following reagents: a luminous marker, a fluorescein marker, a standard substance, a quality control substance and a separation reagent. The luminous marker is nitrofurantoin metabolite hapten marked by an isoluminol luminous marker; the fluorescein marker is a nitrofurantoin metabolite monoclonal antibody marked by fluorescein or a fluorescein derivative; and the separation reagent is paramagnetic nano micro-beads enveloped in an anti-goat FITC (fluorescein isothiocyanate) monoclonal antibody. The invention further relates to a method adopting the kit to detecting the nitrofurantoin metabolite in animal derived food; and the method has higher sensitivity, specificity and detecting speed for nitrofurantoin metabolite.

Owner:BEIJING KWINBON BIOTECH

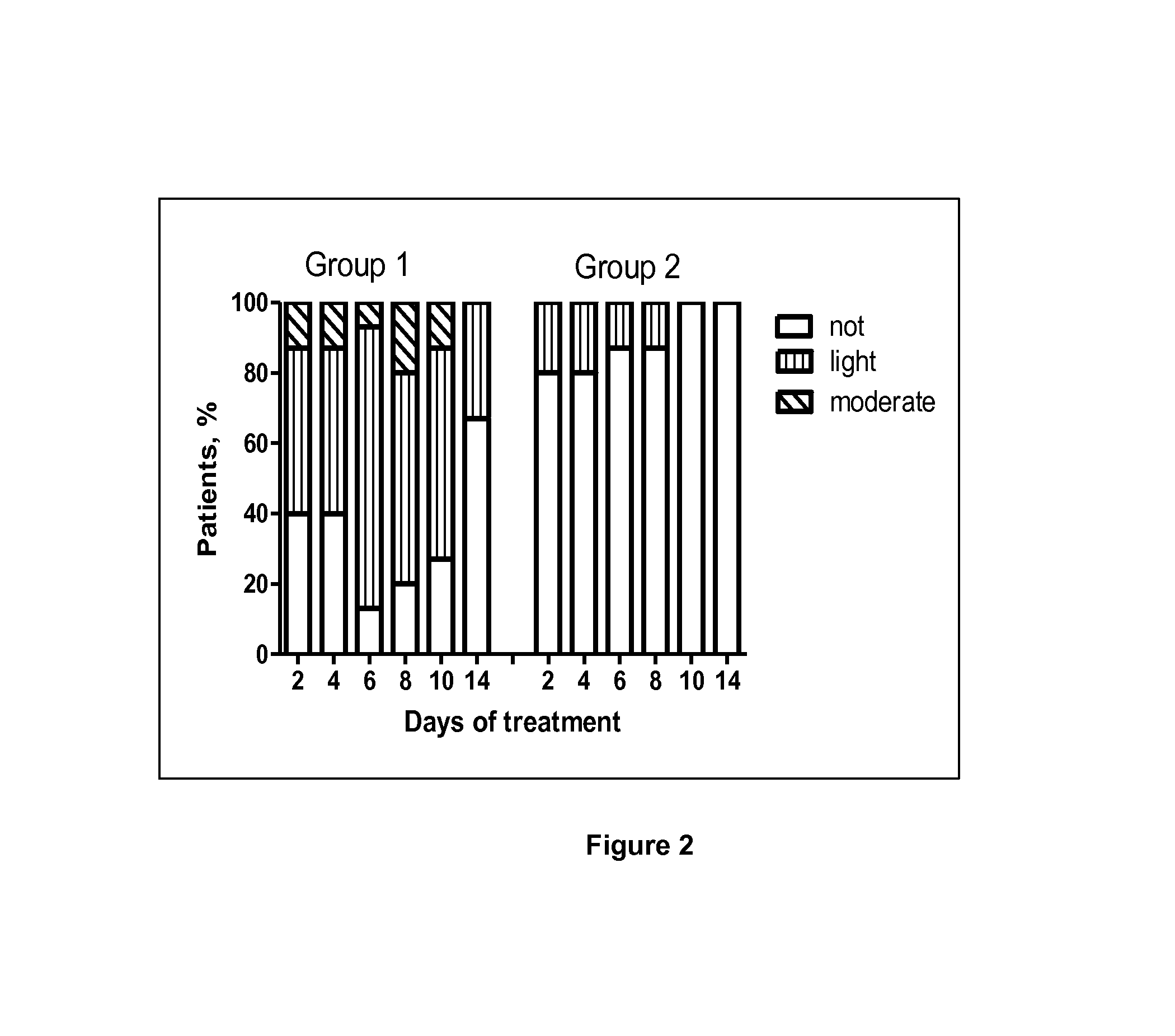

Use of a standardised dry extract of leaves of buddleja globosa hope, bg-126, for the treatment and prevention of gastrointestinal disorders caused by treatment with nitrofurantoin and other antimicrobials

The invention relates to the use of a composition comprising extract of Buddleja globosa Hope and pharmacologically accepted excipients for the preparation of a phyto-pharmaceutical agent, a drug or a nutraceutical for the prevention of gastrointestinal disorders, particularly those associated with treatment with nitrofurantoin or gastric disorders produced by ulcers, gastric diseases or damage to the gastrointestinal tract. The aforementioned disorders can correspond to abdominal pain, dyspepsia, nausea, vomiting, diarrhea, constipation, inflammation and cephalalgia resulting from treatment with nitrofurantoin and other antimicrobials. In addition, the extract and the compositions thereof can be used to enhance the antibacterial action of nitrofurantoin, particularly against Escherichia coli.

Owner:GONZALEZ LAURA XIMENA POLANCO

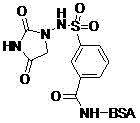

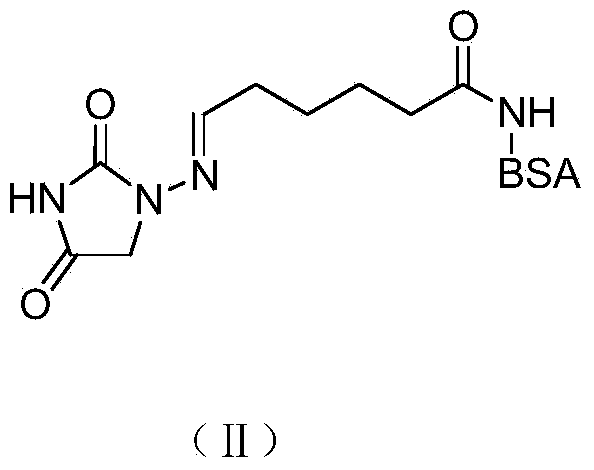

Preparation methods of nitrofurantoin hapten and nitrofurantoin antigen, and applications of nitrofurantoin hapten and nitrofurantoin antigen in chemiluminescence immunoassay kit

InactiveCN105601730AHigh yieldThe preparation method is simple and feasibleOvalbuminSerum albuminMetaboliteMonoclonal antibody

The present invention discloses a nitrofurantoin metabolite hapten, a corresponding artificial antigen, a monoclonal antibody, and preparation methods and applications of the nitrofurantoin metabolite hapten, the corresponding artificial antigen and the monoclonal antibody. According to the present invention, the nitrofurantoin metabolite hapten and a carrier protein are linked to obtain a nitrofurantoin metabolite antigen, and the nitrofurantoin metabolite antigen can be used for preparation of nitrofurantoin metabolite specific antibody; the preparation method has characteristics of simpleness, feasibility, low cost, and high hapten yield; and the nitrofurantoin metabolite artificial antigen and the nitrofurantoin metabolite specific antibody can be used for preparation of a chemiluminescent enzyme-linked immunosorbent assay kit for detecting nitrofurantoin metabolite residue, and has advantages of simpleness, rapidness, high sample treatment capacity, high sensitivity, strong specificity, and the like.

Owner:北京维德维康生物技术有限公司

Magnetic particle chemiluminescence kit for detecting nitrofurantion and application thereof

InactiveCN102539414ANo crossHigh sensitivityChemiluminescene/bioluminescenceFluoresceinMonoclonal antibody

The invention relates to a magnetic particle chemiluminescence kit for detecting nitrofurantion. The kit comprises the following reagents: a luminescent label, a fluorescent label, a standard product, a quality control product and a separating reagent. The luminescent label is of a nitrofurantion hapten labeled by an isoluminol luminescent label, the fluorescent label is of a nitrofurantion monoclonal antibody labeled by fluorescein or derivatives thereof, and the separating reagent is of paramagnetic nano micro-beads coated with a goat anti-FITC (fluorescein isothiocyanate) monoclonal antibody. The invention further relates to a method for detecting the nitrofurantion in feed by adopting the kit, and the method has the advantages of higher sensitivity in detection of the nitrofurantion, higher specificity and faster detection speed.

Owner:BEIJING KWINBON BIOTECH

Pharmaceutical composition and method for the treatment of urinary tract infections

A pharmaceutical composition and method for the treatment of urinary tract infections based on a combination of nitrofurantoin and an analgesic.

Owner:SWEAZY JILL +1

Combination comprising zidovudine and an antimicrobial compound

PendingCN112218633AAntibacterial agentsHeterocyclic compound active ingredientsCefalexinPharmaceutical medicine

The invention provides a combination comprising zidovudine or a pharmaceutically acceptable derivative thereof and an antimicrobial compound selected from nitrofurantoin, mecillinam, fosfomycin, cephalexin and faropenem, or a pharmaceutically acceptable derivative or prodrug thereof. These combinations are particularly useful for the treatment of microbial infections.

Owner:HELPERBY THERAPEUTICS LTD

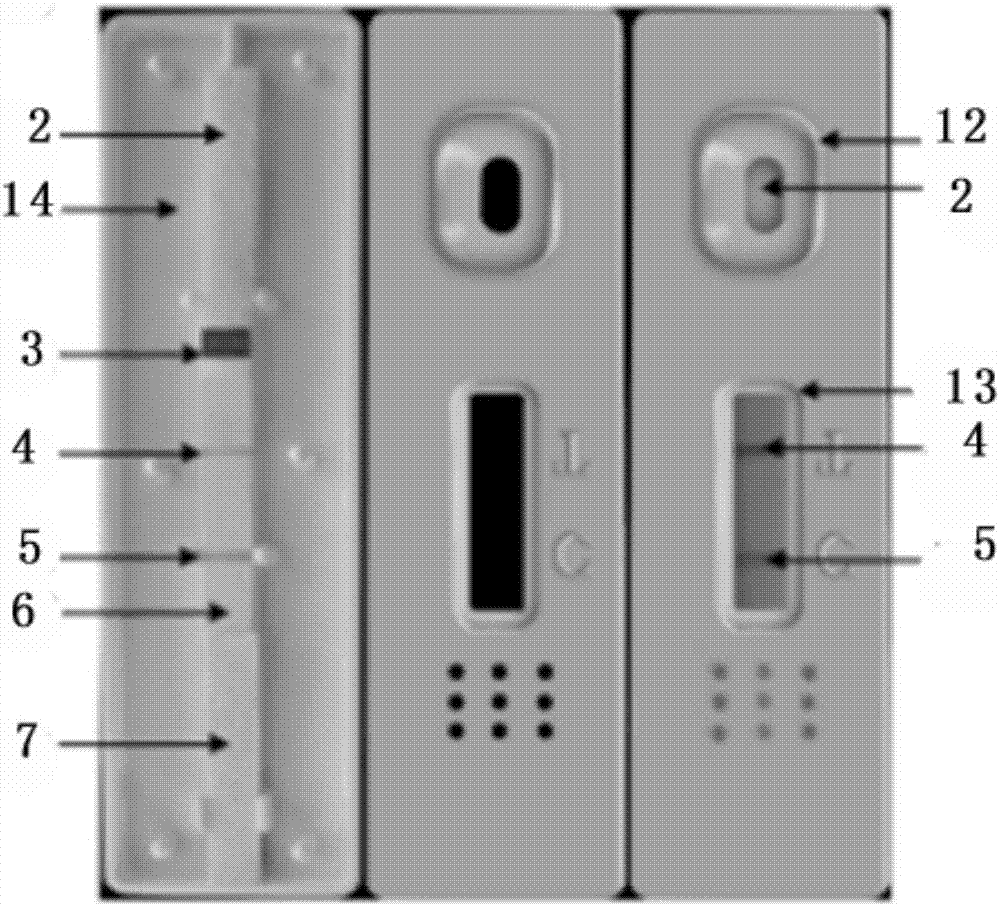

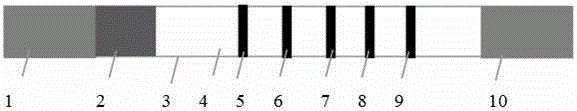

Quantum dot immunochromatographic test strip for detecting nitrofurantoin metabolite, preparation method and application thereof

The invention provides a quantum dot immunochromatographic test strip for detecting a nitrofurantoin metabolite. The test strip is formed by sequentially sticking a sample pad, a microporous fiber membrane, a reaction membrane and an absorbent pad onto a supporting plate, wherein a nitrofurantoin metabolite-specific antibody-quantum dot probe is arranged on the microporous fiber membrane. A detection method using the quantum dot fluorescent immunochromatographic test strip has the advantages of high sensitivity, strong specificity, low cost, simple operation, short detection time, applicability for various units, simple storage, long shelf life, qualitative and quantitative detection and the like; through use of a nitrofurantoin metabolite-specific monoclonal antibody with highly specificity, the reliability of a detection result is ensured; the method for detecting the nitrofurantoin metabolite by using the test strip is simple, convenient, rapid and accurate.

Owner:CHONGQING NORMAL UNIVERSITY

Cistofuran metabolite detection reagent kit

The invention relates to a nitrofurantoin metabolite detection kit for detecting nitrofurantoin metabolites, which comprises an enzyme-linked plate which is coated with nitrofurantoin metabolite derivant antigen and an enzyme label nitrofurantoin metabolite specific antibody or an enzyme-linked plate which is coated with nitrofurantoin metabolite derivant specific antibody and an enzyme label nitrofurantoin metabolite antigen, wherein the nitrofurantoin metabolite derivant antigen is got through coupling nitrofurantoin metabolite derivant hapten and carrier protein through adopting an active ester method. The invention has the advantages of excellent property in the aspects of accuracy, sensitivity, specificity and other aspects.

Owner:深圳市绿诗源生物技术有限公司

Selective enrichment media and uses thereof

ActiveUS9518283B1Preventing undesirable false positive responseBacteriaMicrobiological testing/measurementEscherichia coliSulfur drug

Selective enrichment media and methods for selectively growing and detecting Salmonella spp. and / or Shiga toxin-producing E. coli. The media may comprise a carbon and nitrogen source, an inorganic salt, a fermentable sugar, one or more selective agents, and an efflux pump inhibitor. Various selective agents include sulfa drugs, surfactants, aminocoumarins, cycloheximide, supravital stains, ascorbic acid, bromobenzoic acid, myricetin, nitrofurantoin, rifamycins, polyketides, and oxazolidinones. Various efflux pump inhibitors include arylpiperazines, such as 1-(1-naphthylmethyl)piperazine, and quinoline derivatives, such as 4-chloroquinoline. Methods of selectively growing and detecting Salmonella and / or Shiga toxin-producing E. coli are provided.

Owner:PARADIGM DIAGNOSTICS

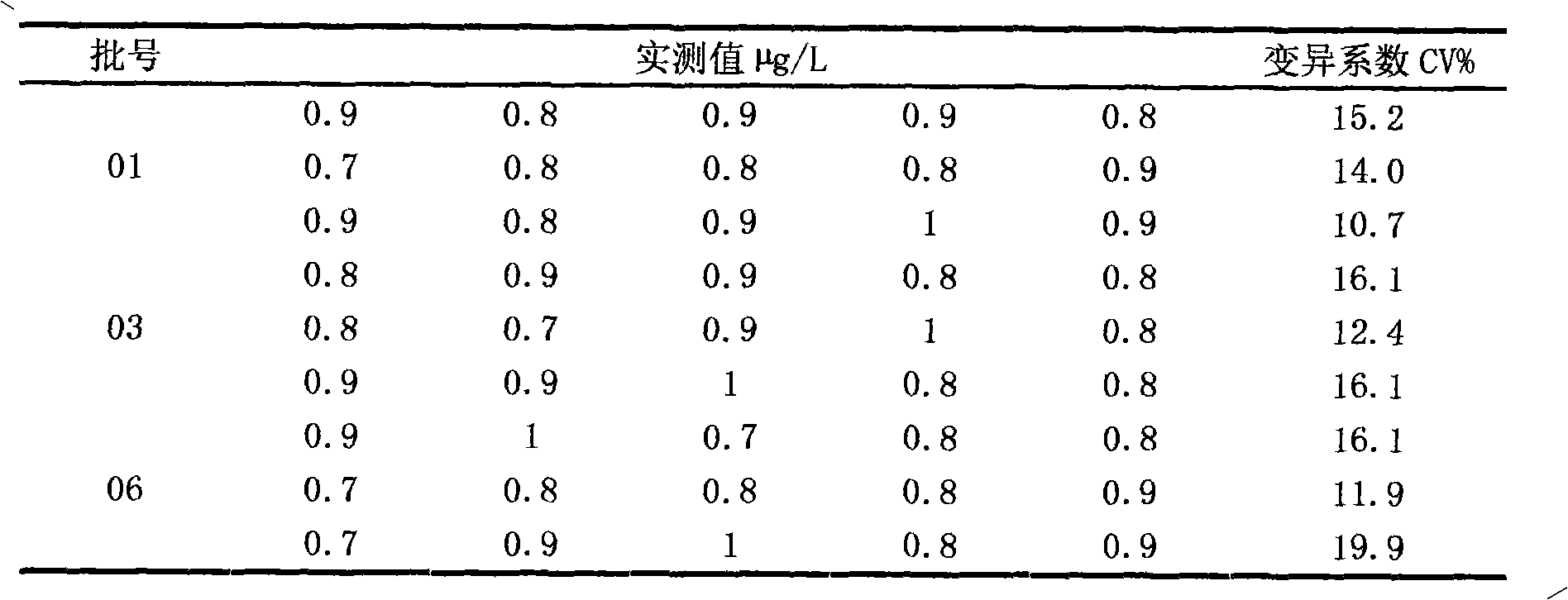

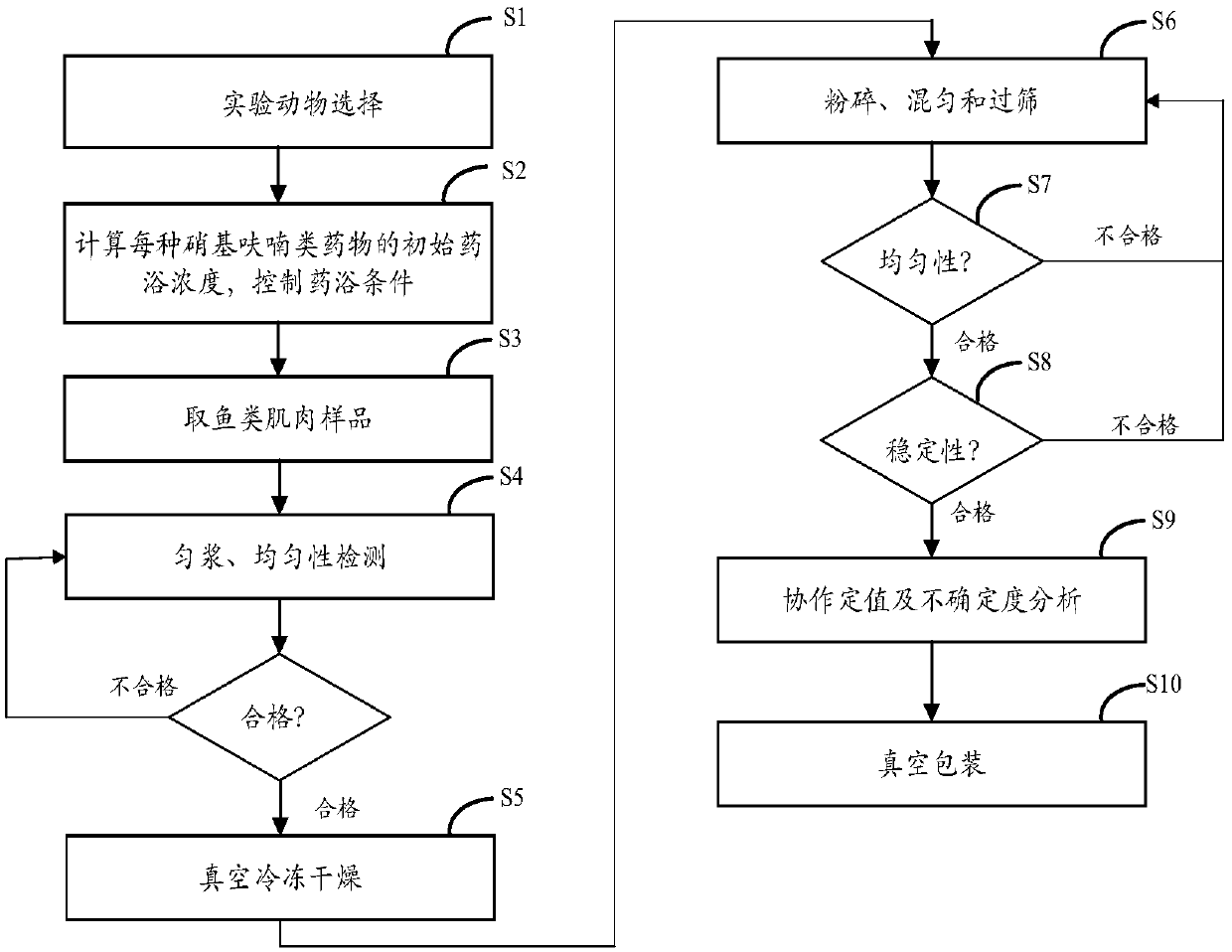

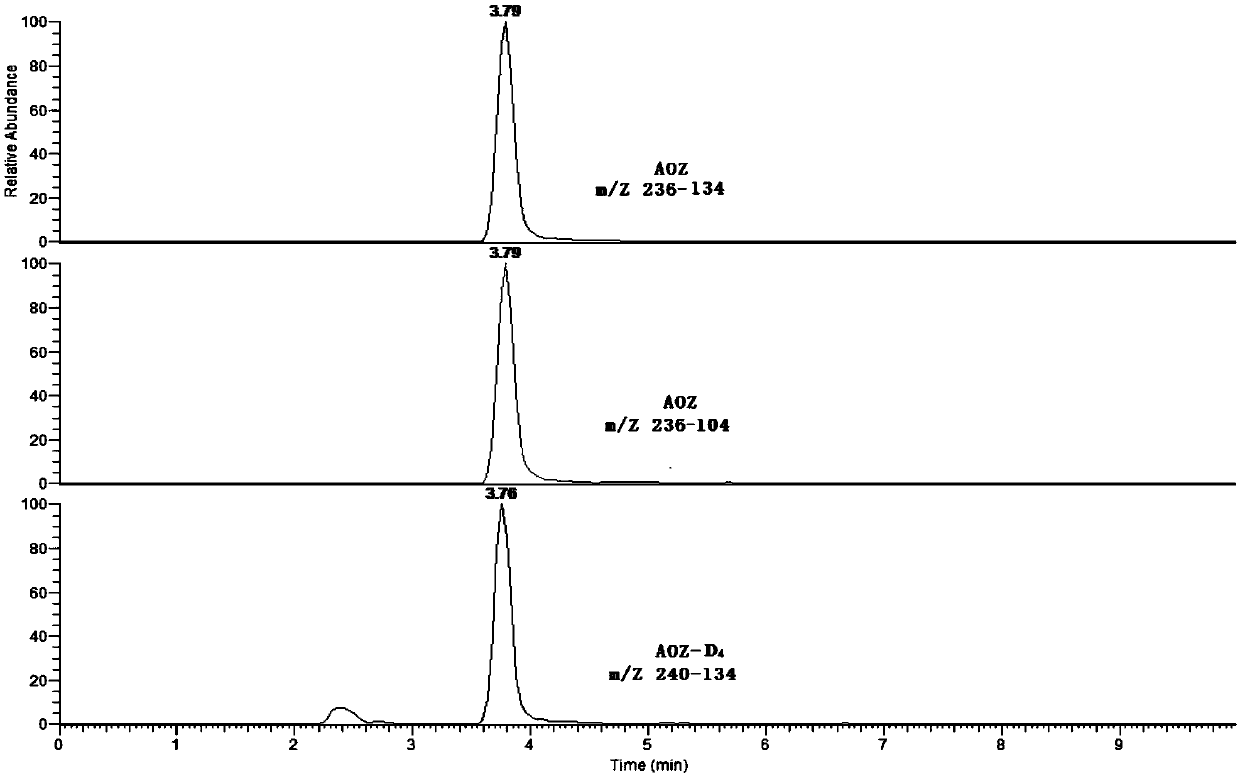

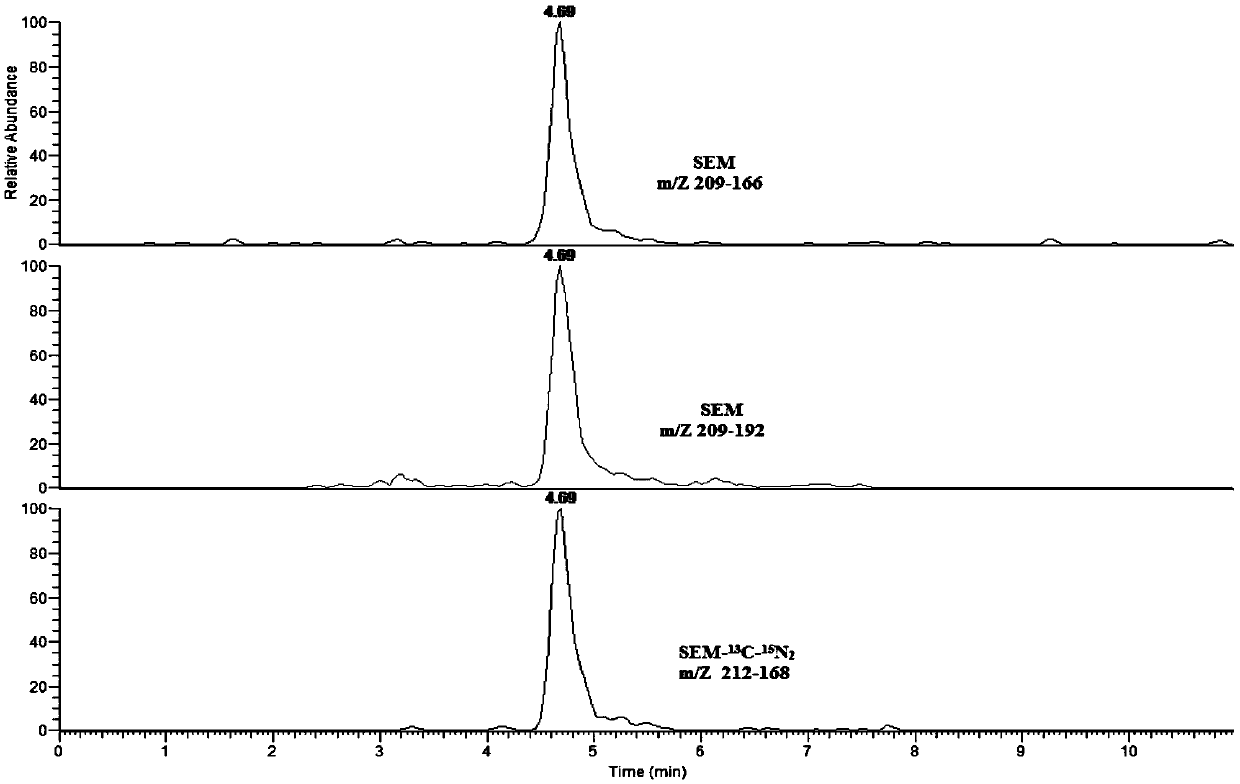

Preparation method of quality control sample of nitrofuran metabolite residues in fish muscle

The invention discloses a preparation method of a quality control sample of nitrofuran metabolite residues in fish muscle. The preparation method comprises the following steps: selecting negative living fish which meets pre-set specification and size and is not fed by a nitrofuran medicine; carrying out medicine bath treatment under pre-set conditions, wherein a water body of a medicine bath tankcontains four types of nitrofuran drugs including a furazolidone crude drug, a furaltadone crude drug, a furacilin crude drug and a furantoin crude drug; fishing out a positive sample subjected to themedicine bath treatment and killing the fish and taking back muscle to obtain a fish muscle sample; adding a vitamin C solution and uniformly stirring to obtain minced fish; after pre-cooling the minced fish, putting into a freezing drying machine and carrying out freezing drying to obtain a freeze-dried sample; carrying out crushing, blending and sieving treatment on the freeze-dried sample to obtain the quality control sample containing nitrofuran metabolite residues with a target content level. By adopting the scheme, the quality control sample contains four types of nitrofuran metabolitesand can meet the requirements of actual inspection better.

Owner:CHINESE ACAD OF FISHERY SCI

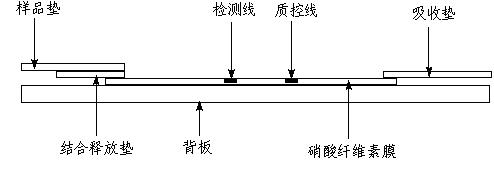

Monoclonal antibody of furantoin residue marker aminohydantoin, and preparation method and application thereof

InactiveCN103288961AThe synthesis process is simpleHigh synthesis efficiencyMicroorganism based processesTissue cultureElisa kitBenzaldehyde

The invention discloses a monoclonal antibody of furantoin residue marker aminohydantoin, and a preparation method and application thereof. The monoclonal antibody is secreted by a hybridoma cell AHD / 3D4 of which the collection number is CCTCC NO:C201151. The preparation method comprises the following steps: A, coupling hapten CPAHD and bovine serum albumin to obtain immunogen; B, coupling hapten CPAHD and ovalbumin to obtain coating antigen; C, preparing the monoclonal antibody from the immunogen in the step A, wherein the monoclonal antibody is secreted by a hybridoma cell strain AHD / 3D4 of which the collection number is CCTCC NO:C201151; D, coating a solid-phase carrier with the coating antigen in the step B; E, treating a sample to be detected with acid, adding benzaldehyde, performing ultrasonic derivation, extracting with ethyl acetate, taking nitrogen gas at the ethyl acetate layer, performing blow-drying, purify n-hexane, and redissolving a sample diluent to obtain a substance to be detected; and F, performing ELISA (enzyme-linked immunosorbent assay) detection on the substance to be detected. The invention also discloses application of a kit in furantoin residue detection of animal edible tissues. The method is convenient, quick, sensitive and accurate, and can be used for developing an ELISA kit capable of detecting 1-aminohydantoin residue in animal edible tissues.

Owner:HUAZHONG AGRI UNIV

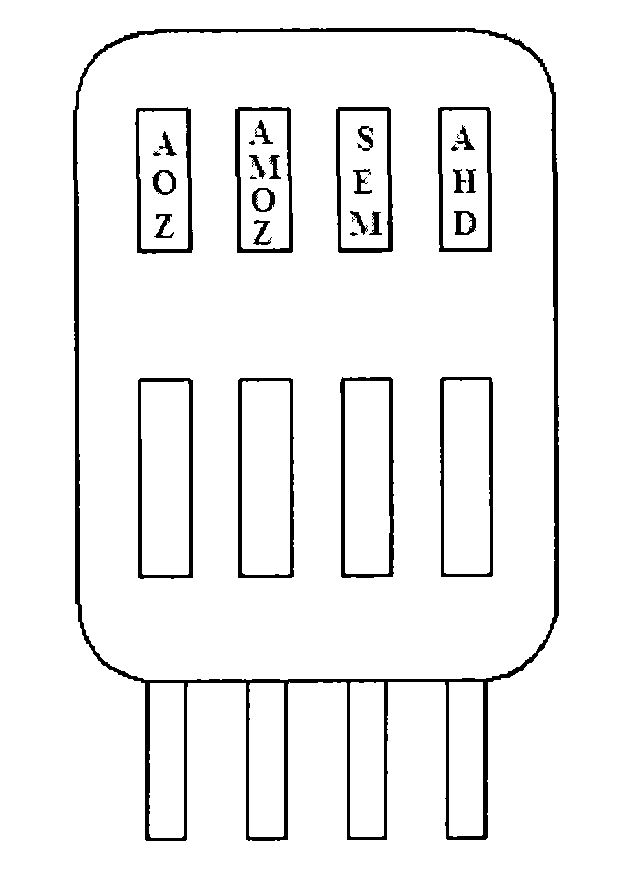

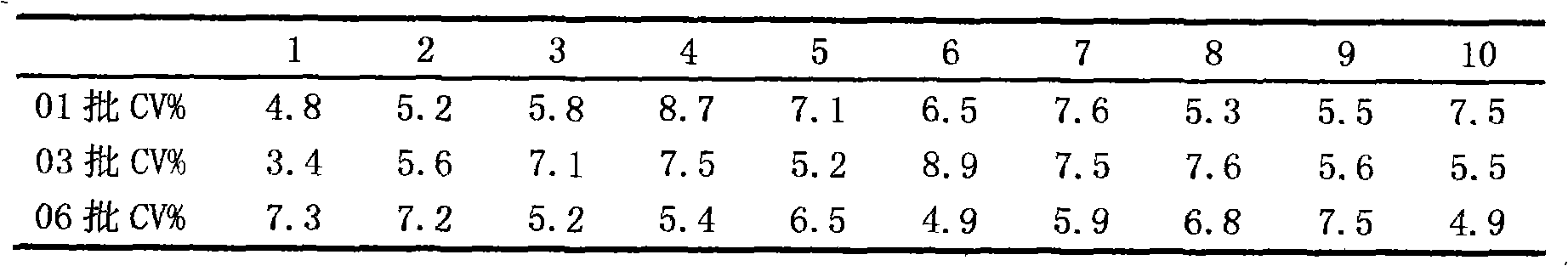

Colloidal gold test strip for detecting four kinds of nitrofuran metabolites and preparation method thereof

InactiveCN106248976AImprove detection efficiencyShorten detection timeBiological testingMetaboliteFuraltadone

The invention relates to a colloidal gold test strip for detecting four kinds of nitrofuran metabolites and a preparation method thereof. The four kinds of nitrofuran comprise: furazolidone (AOZ), furaltadone (AMOZ), nitrofurantoin (AHD), and furacilin (SEM). The invention aims at providing the colloidal gold test strip for simultaneously detecting residues of four kinds of nitrofuran metabolites with fast and accurate characteristics and simple operation and the preparation method thereof. The aspects are improved, such as a method for marking four kinds of antibodies with colloidal gold, lineation on a nitrocellulose membrane (NC membrane), and treatment fluid for a combination pad; results show that the test strip has the advantages of high integration, high specificity, good repeatability, low cost, and the like. The operation is simple, the result is accurate, the method can be used for producing the test strip for combined detection of four kinds of nitrofuran metabolites, and the method has a certain guidance effect for producing test strips for combined detection.

Owner:北京艾旗斯德科技有限公司 +1

Hybridoma cell strain for secreting anti 1-amino-hydantoin monoclonal antibody and application of hybridoma cell strain

The invention discloses a hybridoma cell strain for secreting an anti 1-amino-hydantoin monoclonal antibody and application of the hybridoma cell strain, and belongs to the technical field of biologics. The hybridoma cell strain is named a hybridoma cell strain 2G9A3-35H11, and the preservation number is CCTCC NO: C2015141. According to the hybridoma cell strain, a conjugate formed by AHD-CP (1-Aminohydantoin Hydrochloride-4-Carboxyphenyl Oxime) and bovine serum albumin is adopted as antigen to immunize BALB / c mice, spleen cells obtained after immunization are fused with rejuvenated SP2 / 0 myeloma cells, cell culture is performed with a culture medium without antibiotics, and thus the hybridoma cell strain is prepared through multiple times of screening and cloning; in in-vitro culture, the hybridoma cell strain can secrete a great number of specific antibodies of an anti-AHD derivatization product, and thus the hybridoma cell strain can be applied to rapid and accurate immunodetection and immunoassay on macrodantin metabolin.

Owner:HANGZHOU ACAD OF AGRI SCI

Nitrofurantoin metabolite hapten as well as preparation method and application thereof

The invention discloses a nitrofurantoin metabolite hapten. The nitrofurantoin metabolite hapten is characterized in that the molecular structural formula is shown in formula (1) in the description). The invention further provides a synthetic method of the nitrofurantoin metabolite hapten and an application of the nitrofurantoin metabolite hapten used as a raw material of antigen systems in animal immunization. An antibody prepared from the nitrofurantoin metabolite hapten disclosed by the invention is used in an ELISA (enzyme-linked immuno sorbent assay) method for detecting nitrofurantoin metabolites, the use is convenient, and the detection cost is low; and the detection method is efficient, accurate and fast, can be used for simultaneously detecting large-batch samples and is suitable for on-site supervision of residual nitrofurantoin metabolites in animal-origin foods and screening of the large-batch samples.

Owner:BEIJING KWINBON BIOTECH

Preparation of immunizing antigen and envelope antigen for detecting nitrofurantoin metabolites

InactiveCN104215765APreserve the skeletal structureImproving immunogenicityTesting foodMetaboliteThiol

The invention discloses preparation of immunizing antigens and envelope antigens for detecting nitrofurantoin metabolites. The preparation method is characterized by comprising the following steps: by adopting an active thiol ester method, coupling a nitrofurantoin metabolite hapten with a carrier protein, and preparing nitrofurantoin metabolite immunizing antigens and envelope antigens, wherein the nitrofurantoin metabolite hapten is prepared by introducing a nitrofurantoin metabolite into a spacer through an acetal method. According to the optimized coupling technical route, the structure is optimized, and the antibody quality is improved, so that high-sensitivity and high-specificity immunizing antigens and envelope antigens for nitrofurantoin metabolite immune colloidal gold rapid detection are further increased.

Owner:佛山市质量计量监督检测中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com