Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Nickelous Chloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

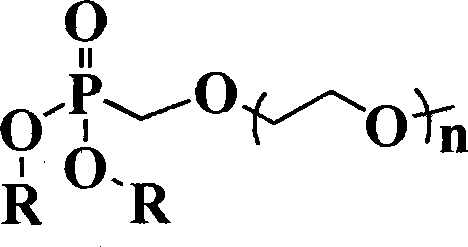

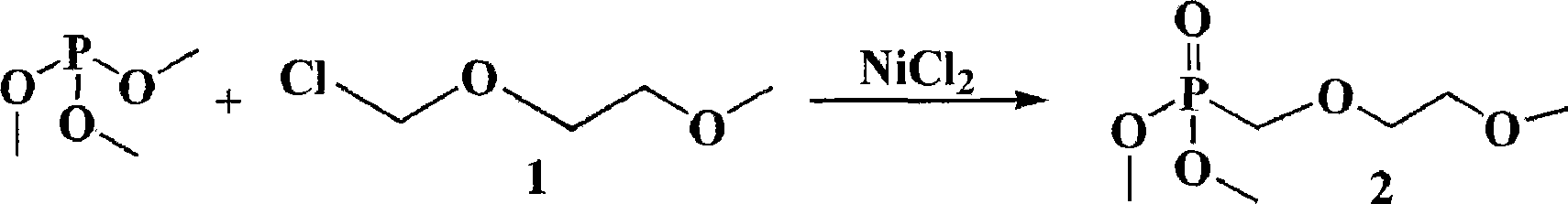

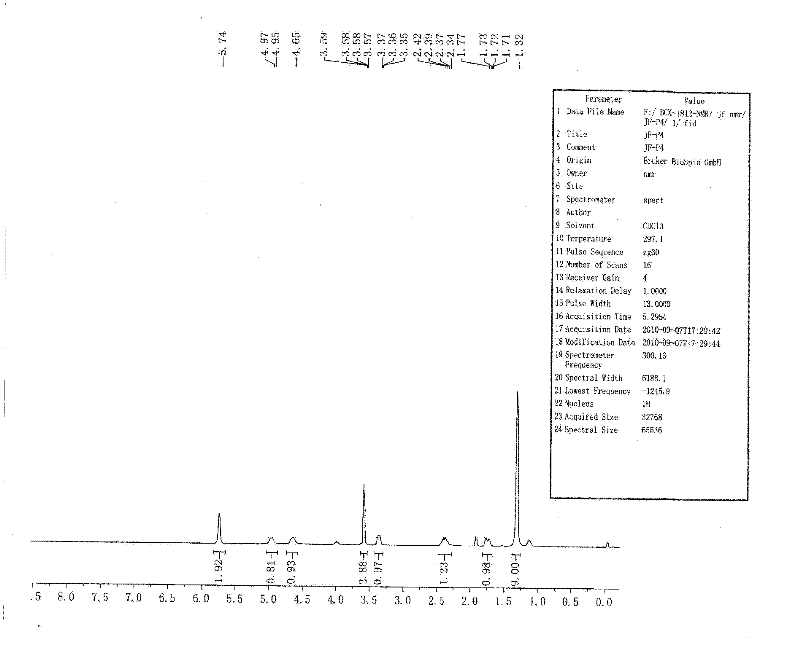

Phosphoester containing ethoxy unit, and preparation and use thereof

InactiveCN101440105AImprove securityImprove flame retardant performanceSecondary cellsPhosphorus organic compoundsOrganic phosphatesElectrochemistry

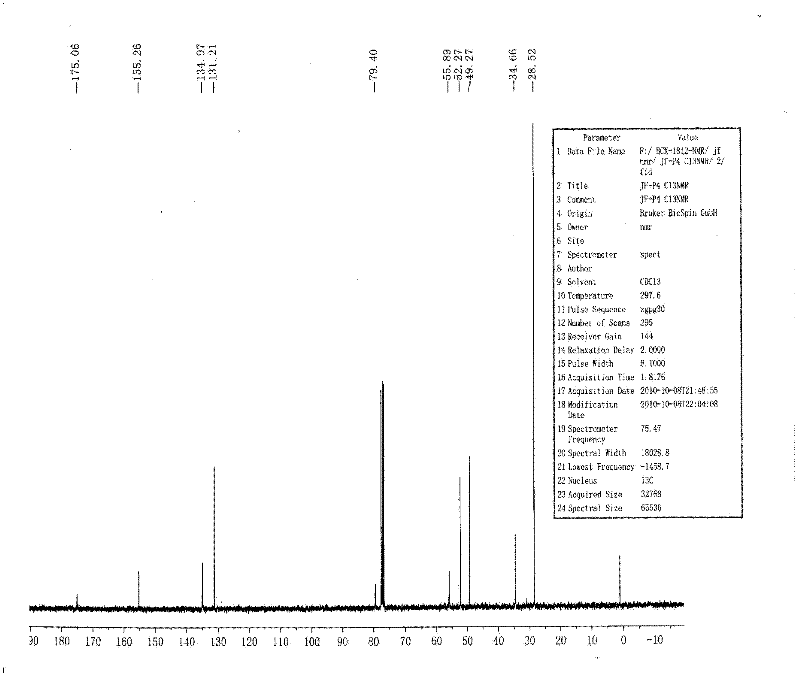

The invention discloses organic phosphates containing an ethyoxyl (CH2CH20) unit, a preparation method and application thereof. The organic phosphates have the following structural general formula: in the formula, n is 1 or 2; R can be CH3 or C2H5 or CF3CH2; and radicals of two R are the same. The preparation method is to heat ethylene glycol monomethyl ether containing chloromethyl or diethylene glycol monomethyl ether containing the chloromethyl and phosphite ester containing an R radical as raw materials by taking absolute nickelous chloride as a catalyst for a sufficient reaction, and distill at reduced pressure so as to obtain the organic phosphate. The organic phosphate prepared by the method has excellent flame retardance, thermal stability and excellent electrochemistry performance, can be used as secondary lithium ion battery high-safety electrolysing solution, and has wide industrial application prospect. The method has the advantages of simple steps, short time, completion in a common laboratory and easy popularization.

Owner:WUHAN UNIV

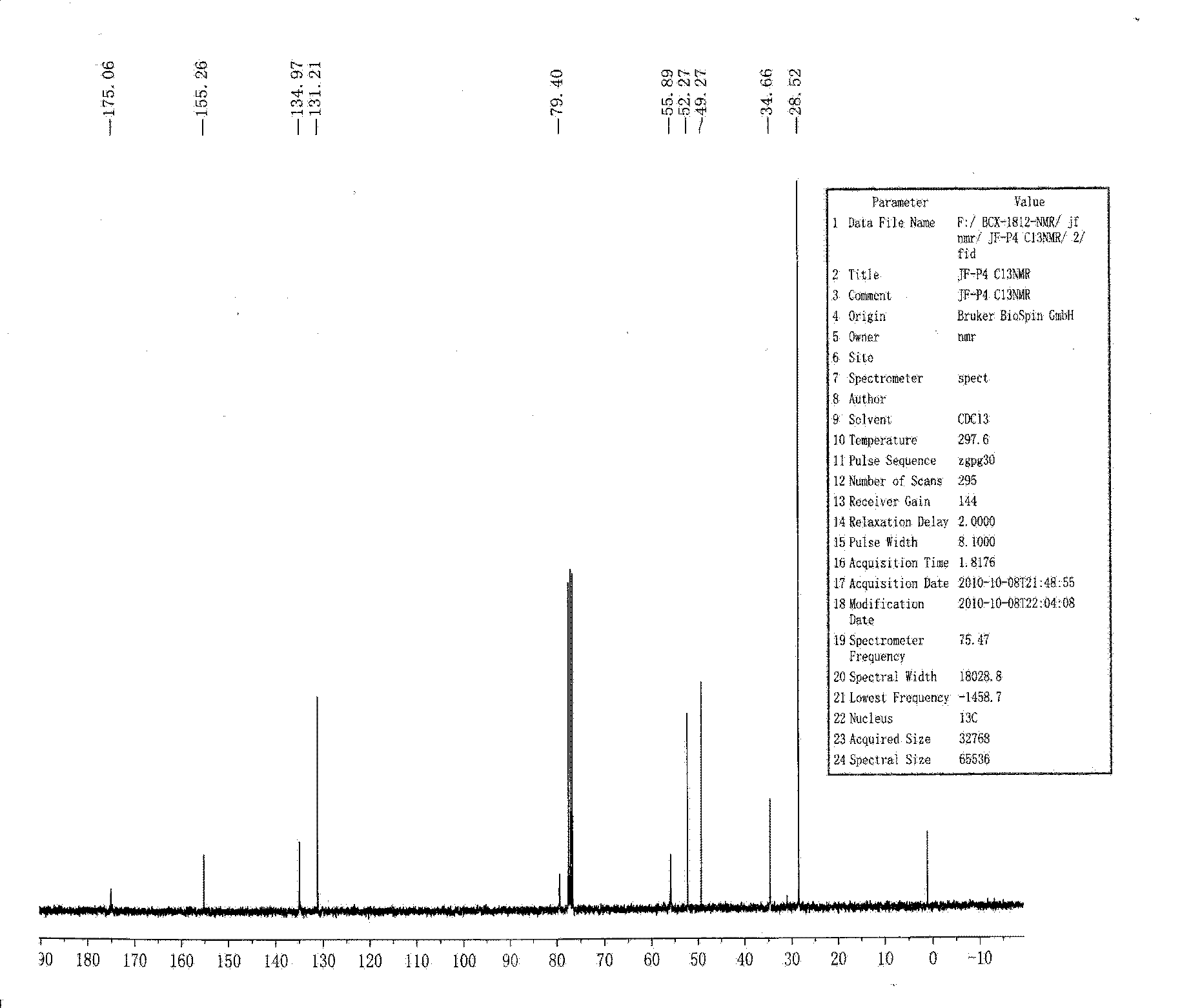

Synthesis method of anti-influenza and avian influenza virus resistant medicine peramivir

InactiveCN102372657AMild reaction conditionsSimple and fast operationOrganic chemistryOrganic compound preparationSynthesis methodsKetone

The invention belongs to the synthesis technical field of organic medicine, and discloses a synthesis method of anti-influenza and avian influenza virus resistant medicine peramivir, which is characterized by adopting (1R, 4S)-2-azabicyclo[2.2.1]hept-5-en-3-one as a raw material and by comprising the following steps: step I: catalyzing, loop-opening and amino protection; step II: 1,3-dipolarcycloaddition; step II: sodium borohydride and nickel chloride hexahydrate reduction and acetylization; and step IV: amino protection removal, and chloroformamidine hydrochloride is adopted as reaction agent to generate guanidyl and hydrolysis methyl ester to prepare peramivir. The sodium borhydride and the nickelous chloride reduction system is used for substituting the expensive platinum dioxide to be used as reducing agent during the hydrogenation reduction process, and the self-produced chloroformamidine hydrochloride is used during the process for feeding the guanidyl reagent, so the cost is reduced, and the operation procedures are simplified. The synthesis method has short reaction routine and moderate reaction condition, is simple and convenient to operate, has low cost, and is suitable for the industrialized production.

Owner:JINAN UNIVERSITY

Nickel-contained materials abstraction and type-reverting production method of nickel salt

InactiveCN101139112AReduce demandRelieve production pressureNickel halidesNickel ammonia complexesNickel saltSulfamic acid

An extraction and transformation method to produce nickel salt with material containing nickel relates to an extraction and transformation technology with nickel salt medium solution in the preparation process of nickel salt products, in particular to the preparation of nickelous chloride and nickel sulfamic acid. The present invention is characterized in that the nickel salt solution after purified is extracted by P204 extracting agent and the main metal nickel is led into an organic phase and then the organic phase is back extracted by various acid solution. The nickel is transferred into outer nickel salt solution and then produced to other nickel salt products after the procedures of depth decontamination, evaporating and crystallization. The present invention can enlarge the material range of nickel salt products, greatly improve working environment and save production cost.

Owner:JINCHUAN GROUP LIMITED

Magnesium and magnesium alloy high corrosion resitance composite cladding and its preparing process

InactiveCN1580325AImprove corrosion resistanceLiquid/solution decomposition chemical coatingSuperimposed coating processVolumetric Mass DensityDodecylsulfonic acid

The inventions are sorts of magnesium, magnesium alloy which is compound plating coat of high anti corrosion, and their preparation technics. Compound plating coat based on the chemical nickel coat, the thickness of which is between 20 and 25 micron. The callow of it is electrolytic zinc plating and nickel alloy, the thickness of which is between 8 and 10 micron. The following is the preparation craftwork: the chemical nickel plating of magnesium alloy adopts the standard B480-88 of American material experimentation association. Plating time is between 1.4 and 2 hours. The coating thickness is between 20 and 25 micron. The content of phosphor in the plating layer is 9-12%; electrolytic zinc plating and nickel alloy: the plating liquid of it and technics conditions are followed: sodium hydroxide 8-15%, zinc oxide 2-5%, nickelous chloride 0.5-3%, ethylamine 2-4%, tiethanolamine 2-4%, nylander reagent 0.5-3%, DE0.2-0.8%, sodium dodecanesulphonate 0.01-0.1%, the overmeasure is water. Curl density is 0.5-5A / dm2. Plating time is 30 minutes. The content of nickel in the plating coat is 13-18%; It adopts black passivation technics of zinc and nickel alloy. The thickness of plating coat of this invention doesn't exceed 35 micron.

Owner:SHANGHAI JIAO TONG UNIV

Composition for repairing surfaces of metallic rubbing pairs and preparation thereof

InactiveCN101412943AReduce repair costsReduce difficultyAdditivesRestorative materialPhysical chemistry

The invention provides a composition for restoring the surface of a metallic rubbing pair and a preparation method thereof, and relates to the composition for restoring the surface of the metallic rubbing pair and the preparation method thereof. The invention solves the problem that the restoring film formed by the prior restoring material has limited thickness which can not reach over 0.5 millimeter and can not effectively control the clearance between the metallic rubbing pair. The composition consists of nickelous chloride powder, aluminum powder, nickel powder, ferric oxide powder, silicon dioxide powder, a powder suspending agent, a surface modifier and mineral lubricating oil. The preparation method is to put the nickelous chloride powder, the aluminum powder, the nickel powder, the ferric oxide powder, the silicon dioxide powder, the powder suspending agent, the surface modifier and the mineral lubricating oil in a high-speed viscolizer to be homogenized for 30 to 40 minutes. The composition for restoring the surface of the metallic rubbing pair and the preparation method thereof realize restoring modification to the surface of the metallic rubbing pair of which a restoration layer reaches 1.5 millimeters, and effectively control the clearance between the metallic rubbing pair.

Owner:三亚圣龙新材料开发有限公司

Technology for preparing Ni shaped charge liner using sulfamic acid nickel electroforming solution

InactiveCN101376997AImprove performanceControl performanceAmmunition projectilesElectroforming processesNickelous ChlorideMaterials science

The invention relates to a technology for preparing a nickel shaped charge liner through a nickel sulfamic acid electroforming method, which belongs to the technical field of electroforming preparation. The key technology is the preparation of electroforming solution; nickel sulfamic acid, nickelous chloride, boric acid, saccharine and deionized water are added into an electroforming bath; and then the stirring speed is regulated, temperature is raised and preserved; sodium dodecyl sulfate, butynediol and deionized water are added into a glass container to be stirred and heated to boil; after the sodium dodecyl sulfate and the butynediol are dissolved, the well mixed solution in the glass container is poured into the electroforming bath; the deionized water is injected to the required volume and then stirred, and the temperature is preserved for 10h to 30h. Follow-up procedures comprise cathode mandrel and electroformed nickel anode pre-treatment, electroforming and cathode demoulding. The technology has the advantages that the technology can prepare the nickel shaped charge liner with stable performance, and can conveniently and effectively control the grain size of the electroformed nickel so as to control the performance of the electroformed nickel.

Owner:UNIV OF SCI & TECH BEIJING

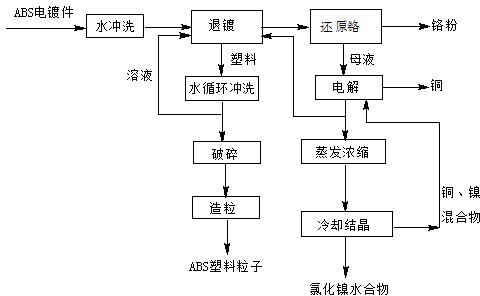

Method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts

InactiveCN102534222AReduce lossMaximize recyclingPlastic recyclingProcess efficiency improvementRecovery methodEvaporation

A method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts belongs to the field of solid waste recovery. The method comprises the steps of crushing, deplating, ABS plastic recovery, chromium reduction, electrolytic reduction of copper, and evaporation and concentration for preparing nickelous chloride. According to the method, the dynamic closed cycle of all working solution is realized, the primary recovery of ABS plastic is achieved, the recovery rate is above 99 percent, both the electrolytic copper and the nickelous chloride reach the national primary standards, the recovery rate of copper is above 97 percent, and the recovery rate of nickelous chloride is above 98 percent. The method is simple to operate, low in energy consumption and environmental-friendly.

Owner:NANCHANG UNIV

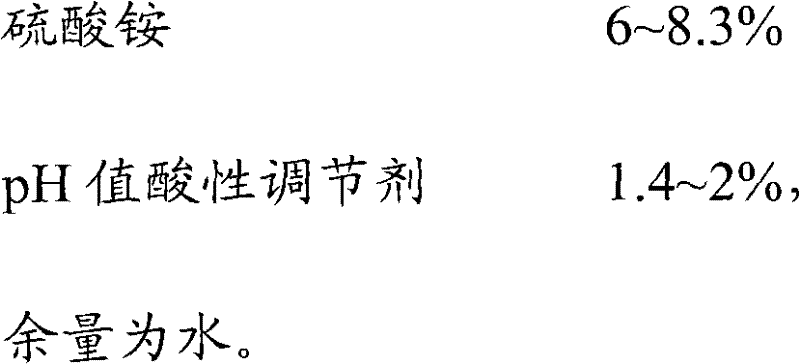

Galvanized chromium-free black passivating agent and preparation method thereof

ActiveCN102418095ANot easy to wearEasy to handleMetallic material coating processesChromium freeMolybdate

The invention relates to a galvanized chromium-free black passivating agent and a preparation method thereof. The galvanized chromium-free black passivating agent comprises the components such as nickelous chloride, molybdate, ammonium sulphate, a pH acid regulator, water and the like. The preparation method comprises the following steps of: operating the black passivating agent at the operation temperature of 20-40DEG C and the pH value of 4.0-5.0 for 0.5-1.5 minutes; preparing materials according to the mass fraction of various components; adding 50-70 percent of water in the raw materials into a stirring device; sequentially feeding other components; finally, adding residual water; and stirring for at least five minutes to obtain a finished product. The galvanized chromium-free black passivating agent has no hexavalent chrome and trivalent chromium, is suitable for black passivation of galvanized parts, can obtain a glossy black effect same as the passivation of the hexavalent chrome and the trivalent chromium and can meet the requirement of products. Before the galvanized chromium-free black passivating agent is dried, workpieces are not easily ground; and the passivated galvanized chromium-free black passivating agent is glossily black without being closed. The galvanized chromium-free black passivating agent has the advantages of strong corrosion resistance, no pollution, easiness in wastewater treatment and simpliness in operation.

Owner:DONGGUAN DONGHUI TRADE

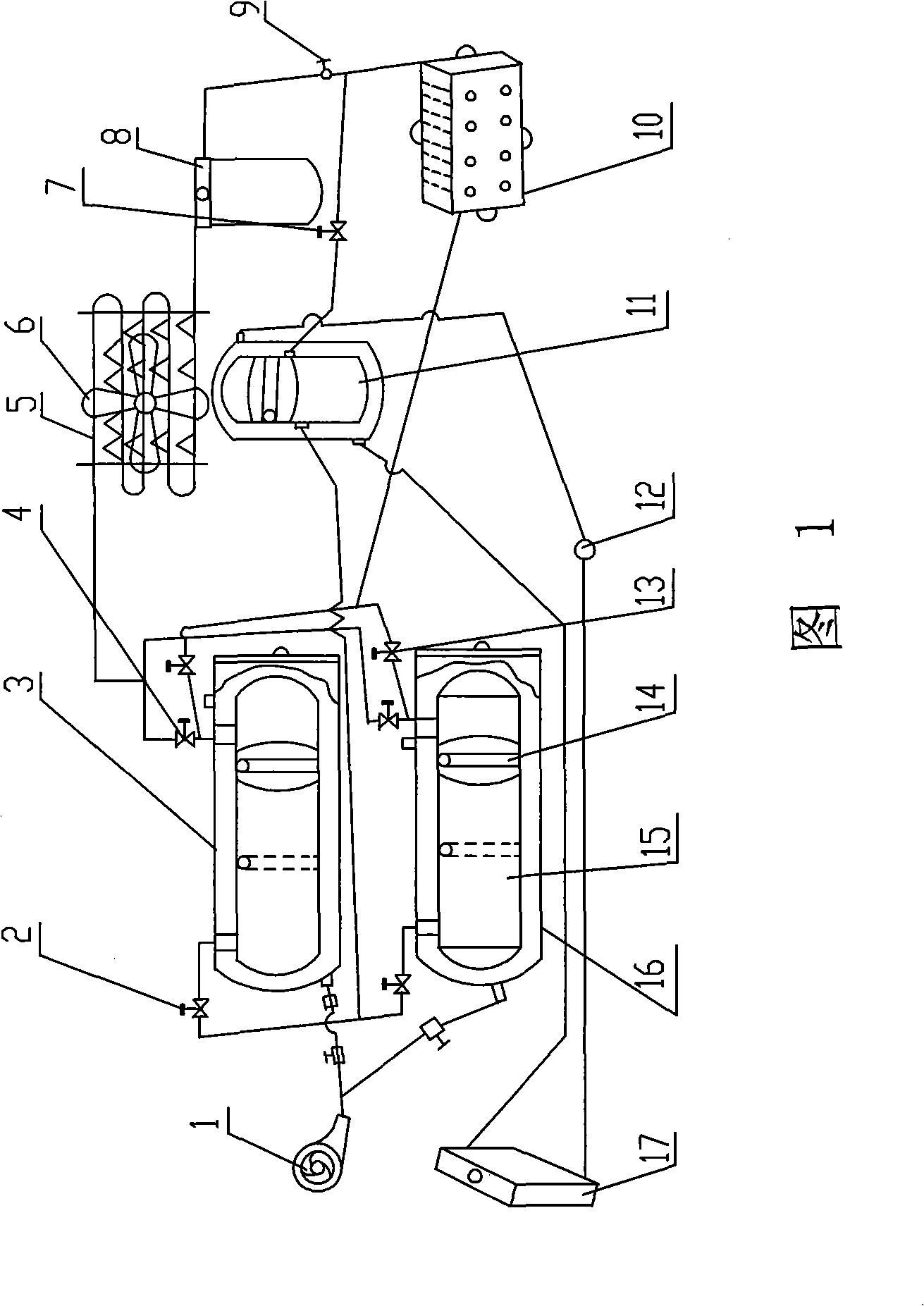

Adsorption refrigerating device adopting liquid-storing cartridge heater

InactiveCN101285626AHigh adsorption rateSimple structureEnergy efficient heating/coolingClimate change adaptationFiberThermal energy

The invention belongs to the freezer technical field, in particular to an adsorption freezer adopting a liquid receiving cartridge heater. The adsorption freezer comprises a high-pressure valve, two adsorption barrels, a liquid receiving cartridge heater, a high-pressure output valve, a condenser, a liquid receiving bottle, a throttling valve, a multiple-pipe evaporator, a liquid inlet valve, a hot water tank and a fan, wherein, the adsorption barrel consists of an outer adsorption barrel, an adsorption agent container, a heating pipe and an adsorption agent arranged inside the adsorption agent container; liquid ammonia is stored inside the liquid receiving heating barrel container; the adsorption agent is composite adsorption agent which is made of a plurality of compositions of the following: lime chloride, strontium chloride, manganese chloride, nickelous chloride, active carbon fibers, silica gel, graphite powder, graphite lath, active carbon and alumina; the method for producing the composite adsorption agent is as follows: the compositions, the graphite lath and a slim tube with a hole are placed inside the adsorption agent container and are pressurized to form. The adsorption freezer adopts the chemical adsorption theory to combine the heat energy of external heating and the heat energy of the chemical adsorption heat and to high-temperature heat and cool, thereby saving energy and protecting the environment.

Owner:金继伟

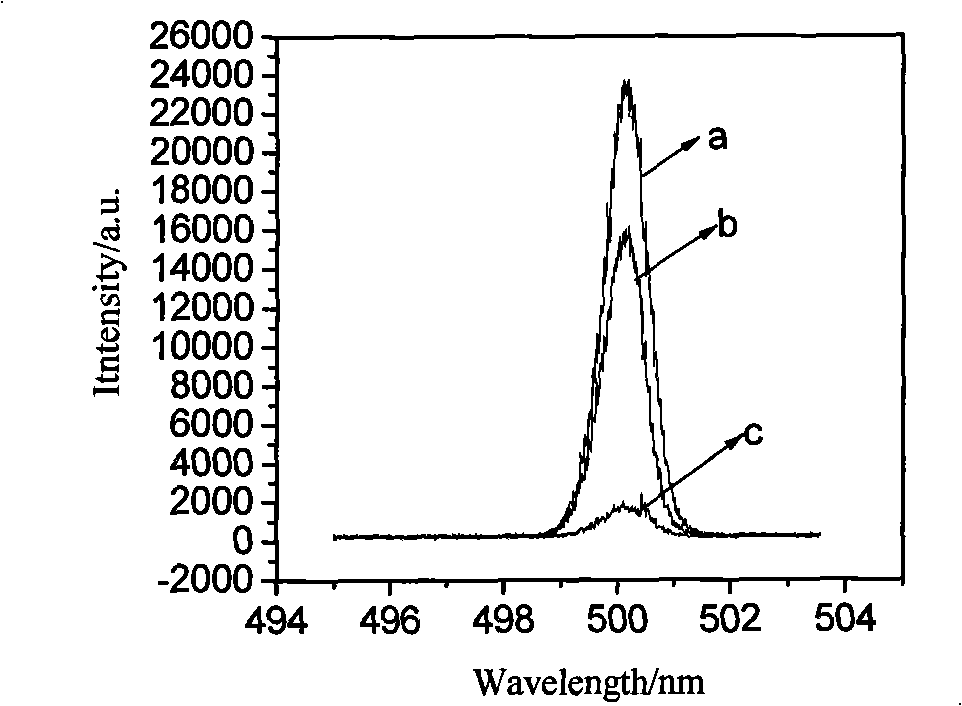

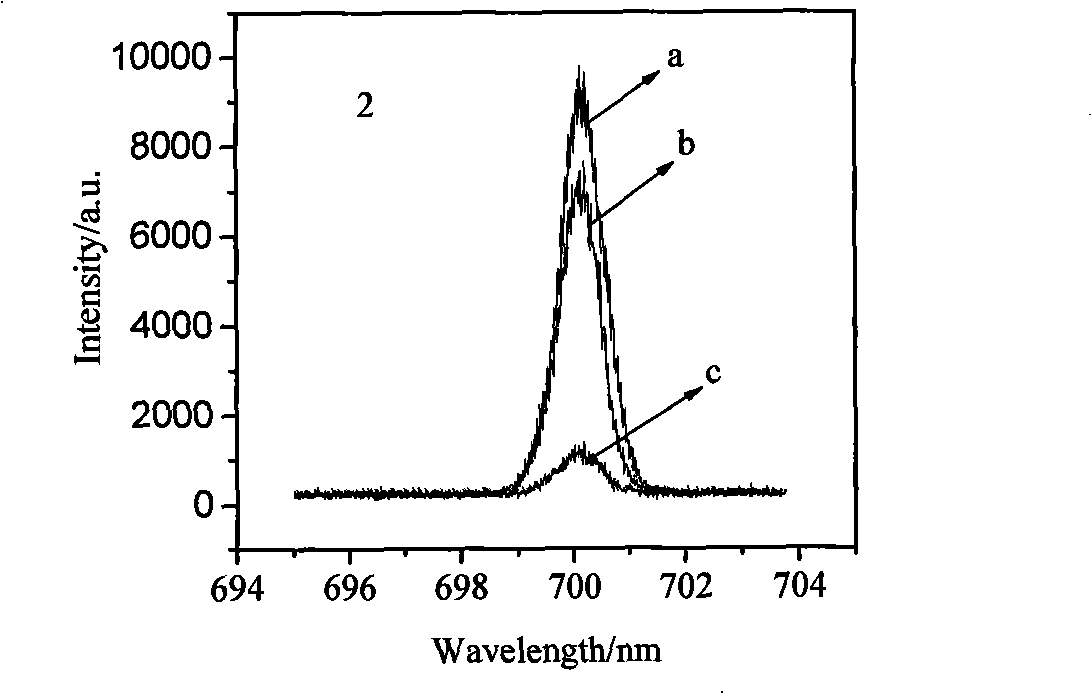

Galvano-chemistry preparation method for electrochromic magnesium-nickel alloy film

InactiveCN101270491AControl light transmissionControl reflexSupporting electrolyteN dimethylformamide

The invention relates to an electrochemistry preparation method for an electrochromism magnesium-nickel alloy film. Firstly, an organic solvent N,N-dimethylformamide is dried for 48 hours by an activated 4 molecular sieve, then is decompressed and distilled to remove the impurities; then the main salt dehydrate and nickelous chloride as well as the lithium perchlorate supporting electrolyte are respectively dried for four hours under the vacuum with the temperature of 150 DEG C and then placed in an vacuum drying box for spare; then the nicks and the oil stains on the surface of a copper sheet are removed; the main salt and the organic solvent N,N-dimethylformamide used for supporting electrolyte are prepared into liquid with the concentration of 0.2mol / L of the dehydrate, the concentration of 0.2mol / L of the lithium perchlorate and the concentration of 0.02mol / L of the nickelous chloride; argon is pumped into the liquid so as to expel the oxygen dissolved in the N,N-dimethylformamide; finally the magnesium-nickel alloy film is obtained by carrying out electrochemistry deposition under the constant temperature and constant potential condition by a three-electrode system. The method is simple, needs no complex post treatment working procedures like heat treatment and can effectively control the light transmittance and the reflectivity of the film.

Owner:OCEAN UNIV OF CHINA

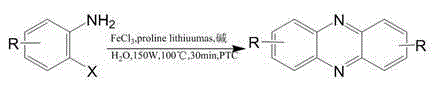

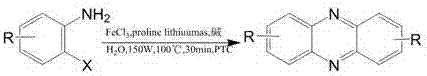

Method for catalytically synthesizing phenazine compounds in water phase under microwave radiation

The invention discloses a method for catalytically synthesizing phenazine compounds in a water phase under microwave radiation, which comprises the following steps: adding a catalytic amount of catalyst ferric chloride or nickelous chloride, a cocatalyst lithium proline, a substrate substituted 2-haloaniline, a phase-transfer catalyst 4-butyl ammonium chloride, 4-butyl ammonium bisulfate or 4-butyl ammonium bromide, an inorganic alkali or organic alkali and water into a reaction vessel, putting into a microwave reaction instrument, reacting at certain temperature under certain power for some time, concentrating under reduced pressure, and purifying the product by column chromatography. The method for preparing phenazine compounds is friendly to the environment, simple to operate and high in efficiency. Compared with the prior art, the method has the advantages of obviously higher reaction speed than conventional heating, mild reaction conditions, high yield, high safety, low cost and environment friendliness, and is simple to operate.

Owner:FUJIAN MEDICAL UNIV

Method for repairing metal frictional or worn surface and special mixing powder used thereby

InactiveCN101412175AImprove restoration qualityImprove applicabilityRepair materialMagnesium stearate

The invention discloses a method for restoring the frictional surface and the wearing surface of metal and mixed powder specially used in the method and relates to a restoring method and mixed powder used in the method. The method solves the problems that the prior restoring method has slow restoring speed, unobvious restoring effect and the prior restoring material has no compositions which have the functions of cleaning and activating the metal surface. The method comprises the following steps: A mixed powder which has the functions of cleaning and activating the frictional surface and the wearing surface of the metal is prepared; B mixed power which has the functions of restoring and introducing a material, reacting, releasing heat and increasing heat energy is prepared; the A mixed powder is added into lube of the frictional surface and the wearing surface of the metal; and the B mixed powder is added into lube of the frictional surface and the wearing surface of the metal. The A mixed powder consists of nickel-clad diamond powder, nickelous chloride powder and magnesium stearate. The B mixed power consists of enstatite powder, calcium carbonate powder, rose aurora powder, nickel-clad aluminum powder, nickel iron alloy powder, yttria powder and magnesium stearate. The method and the mixed powder used in the method can achieve the aim of rapidly restoring the micro-disadvantages of the frictional surface and the macro-wearing disadvantages of the wearing surface of the metal.

Owner:三亚圣龙新材料开发有限公司

Method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts

InactiveCN102534222BReduce lossMaximize recyclingPlastic recyclingProcess efficiency improvementAcrylonitrileEvaporation

A method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts belongs to the field of solid waste recovery. The method comprises the steps of crushing, deplating, ABS plastic recovery, chromium reduction, electrolytic reduction of copper, and evaporation and concentration for preparing nickelous chloride. According to the method, the dynamic closed cycle of all working solution is realized, the primary recovery of ABS plastic is achieved, the recovery rate is above 99 percent, both the electrolytic copper and the nickelous chloride reach the national primary standards, the recovery rate of copper is above 97 percent, and the recovery rate of nickelous chloride is above 98 percent. The method is simple to operate, low in energy consumption and environmental-friendly.

Owner:NANCHANG UNIV

Method of preparing tin-copper-nickel-cobalt alloy cathode material by two-step plating

The present invention relates to a process for preparing tin-cuprum-cobalt-nickel alloy material materials by utilizing two-step electric plating. Said process consists of two steps of electric plating courses such as modification layer electric plating and activation layer electric plating, wherein said modification layer plating solution consists of nickelous chloride of 50-280g, cobalt chloride of 10-180g, boracic acid of 1-50g and distilled water of 800-900mL, with a temperature of 20-75 DEG C and an electric plating time for 0.2-30 minutes; the activation layer plating solution consists of sodium stannate of 5-60g, sodium hydrate of 5-60g, sodium acetate of 5-50g and distilled water of 800-900mL, with a temperature of 40-80 DEG C and an electric plating time of 0.2-50 minutes. Said two steps of electric plating are carried out at any electric current density of the siding-to-siding block of 0.1-1.5 A / dm2. The raw material in accordance with the present invention has a lower cost and a wide source, with a simple preparing process and few time consumption. Said electrode material possesses excellent discharging performances and charging-discharging cycling stability, with its first discharge capacity being higher than 400mAh activity material, exhibits excellent circulation performances, can have application in lithium ion battery, lithium battery, polymer lithium ion battery, especially thin film-type power cell.

Owner:FUJIAN NORMAL UNIV

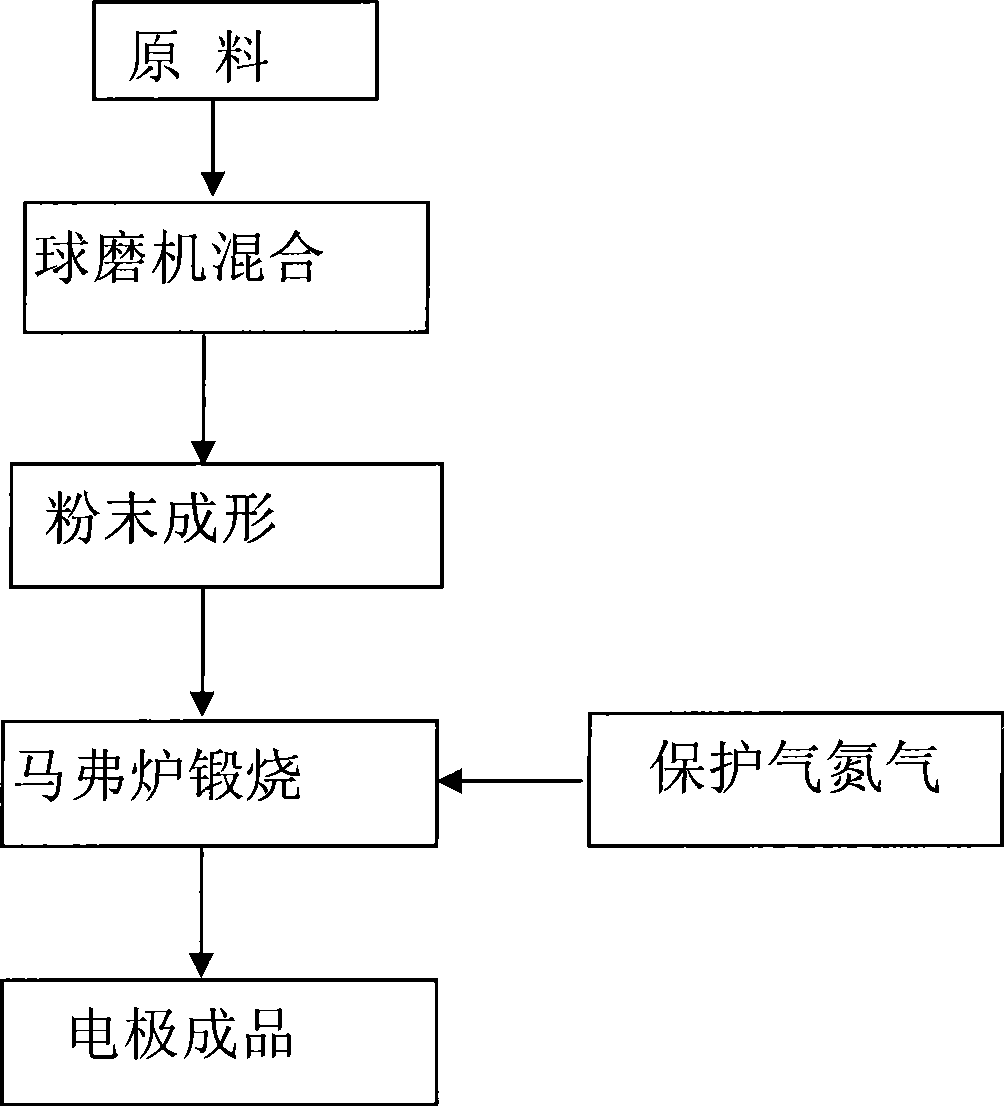

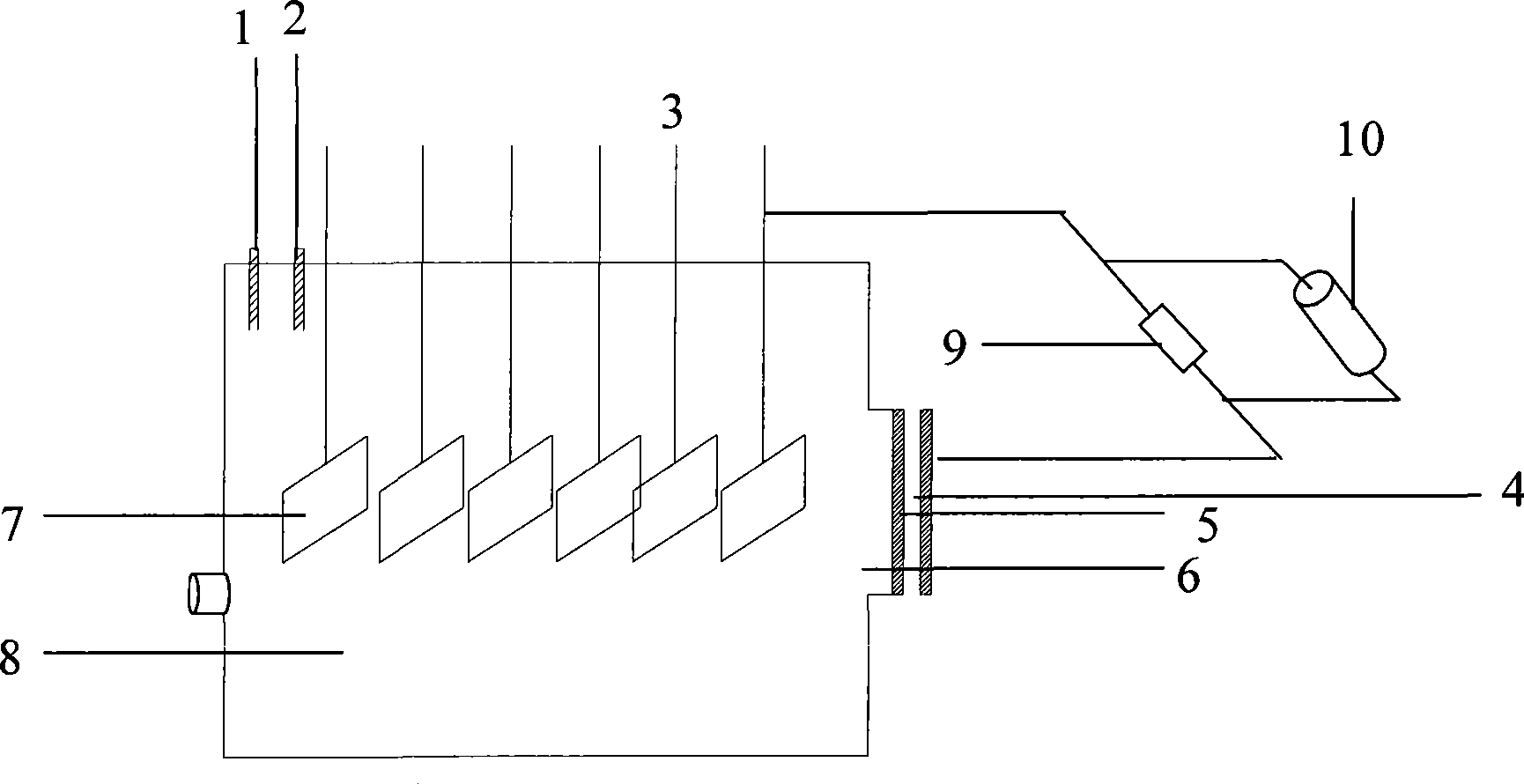

Iron ion circulating electrode and preparation method thereof

The invention provides an iron ion circulating electrode which contains ferric sulfate, graphite powder, kaolin and nickelous chloride and has a porous structure. The invention also provides a method for preparing the iron ion circulating electrode, which comprises the steps: the graphite powder, the ferric sulfate, the kaolin, the nickelous chloride and pore creating material are mixed together for ball milling, and then the mixture processed by ball milling is pressed for forming under the pressure intensity of 10-30kgf / cm<2>; after that, the formed mixture is calcined for 8-15 hours at the temperature of 1000-1200 DEG C in shielding gas atmosphere. Compared with the existing iron ion circulating electrode, the iron ion circulating electrode (especially prepared by the method of the invention) can be taken as the cathode of a microbiological fuel cell, so as to remarkably improve the output power density of the microbiological fuel cell.

Owner:BYD CO LTD

Method of removing iron from nickel chloride leachate

A method to remove iron in nickelous chloride lixivium relates to a method to remove impurities from chlorination medium, in particular to a method to remove iron in nickelous chloride lixivium, which is characterized in that: the chlorination lixivium is heated to 85-95 DEG C, chlorine is pumped into the chlorination lixivium, oxidation-reduction potential is controlled to be 650-750mv, Fe2+ in the chlorination lixivium is oxidized into Fe3+, pH value of the solution is adjusted to 3.0-4.0 by nickel carbonate, then the nickel carbonate is stopped to added and Fe(OH)3 is generated, the reaction lasts for 2-4 hours and the nickelous chloride solution containing less than 0.006g / l iron is obtained after the separation of solid and liquid. The method of the invention realizes that the complete degree of iron removal is not affected by the iron concentration of the chlorination solution and meets the requirements of deep purifying iron in nickelous chloride solution.

Owner:JINCHUAN GROUP LIMITED

Multilayer nickel-iron alloy composite coating process

The invention discloses a multi-layer Ni-Fe alloy complexly smearing-plating technique. It includes: make degreasing and rust cleaning on metal surface; make the mixing solution (A) of nickelous chloride, natrium acetate, nickel sulfate, ferrous sulphate and ferrous chloridize; make saturated solution (B) by using amido-sulfonic nickel, nickelous chloride and boric acid; first smear A, then smear B to make the thickness reaches the requirement, and then mix A and B to make mixing solution (C) which is evenly smeared on the coat surface.

Owner:王旭东 +2

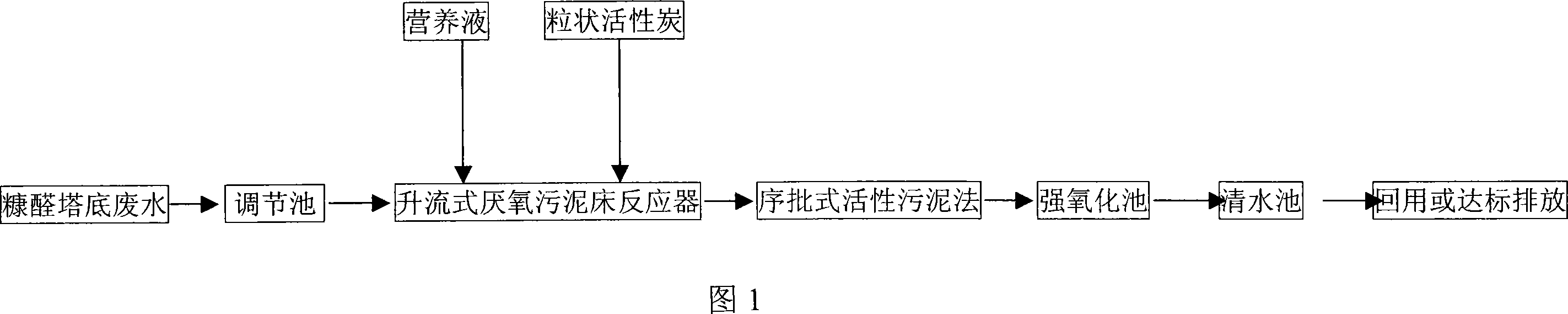

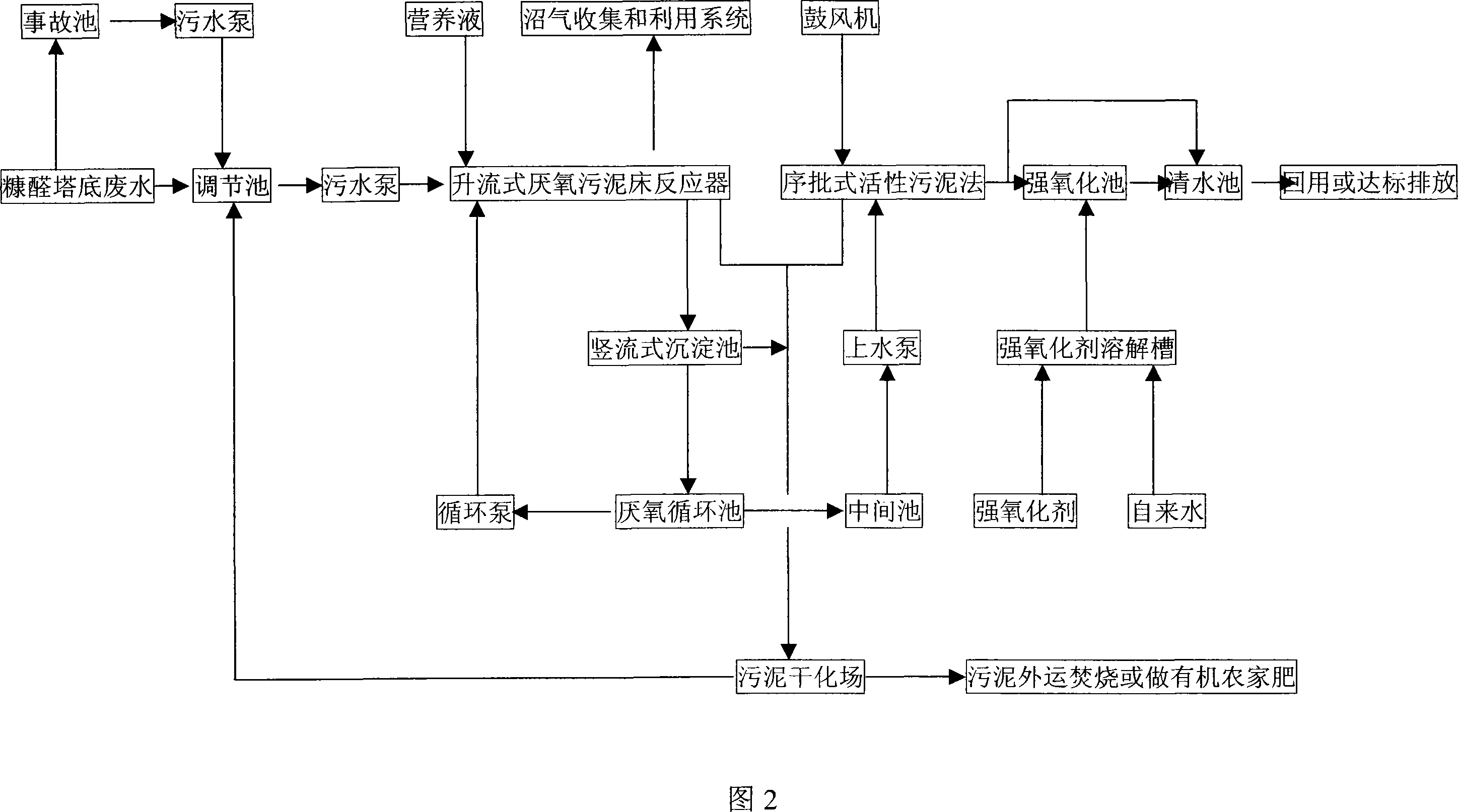

Neutralization-free furfural waste-water biochemical treatment process

InactiveCN101070218AReduce processing costsImprove decomposition abilityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeVitamin B12

This invention relates to a neutralization-free furfural wastewater biochemical treatment craft. First furfural wastewater enter balancing tank, then enter upwash type anaerobic sludge bed reactor by the exaltation of slush pump, add furfural wastewater nutrient solution and granular activated carbon to the pool of upwash type anaerobic sludge bed reactor; then the water after disposing of upwash type anaerobic sludge bed reactor enter vertical sedimentation tank, then influx intermediate pool; water in the intermediate pool according to sequencing batch type activated sludge process enter pool by the exaltation of sequencing batch type activated sludge process influent pump; the water from pool of sequencing batch type activated sludge process enter clean water basin, then reclaimed or discharged. The described nutrient solution according to weight is mixture of urea 80.47%, trisodium phosphate 13.44%, white ash 3.17%, iron power 0.56%, ferrous sulfate 0.56%, magnesium sulfate 0.43%, cobaltous chloride 0.097%, nickelous chloride 0.073%, zinc chloride 0.48%, cupric sulfate 0.24%, vitamin B5 0.24% and vitamin B12 0.24% and water.

Owner:张动科

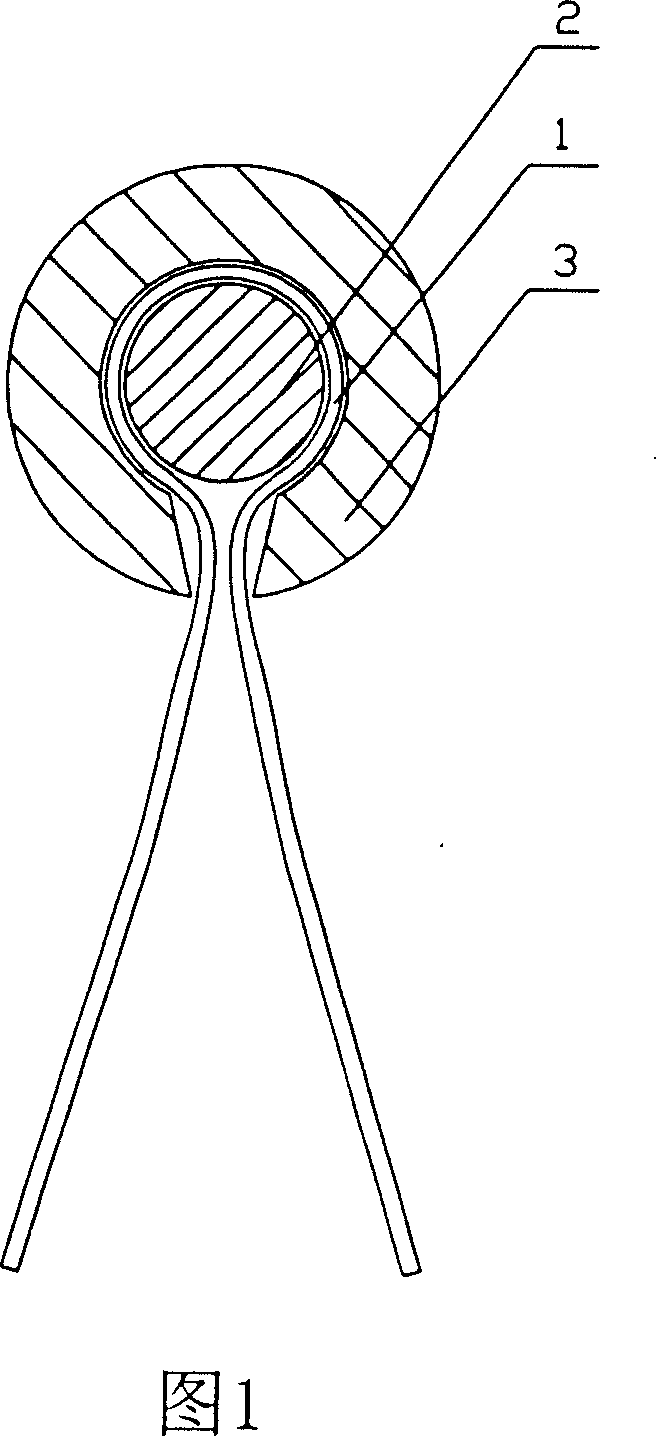

Refrigerant composition and its packaging device

The inventions are sorts of magnesium, magnesium alloy which is compound plating coat of high anti corrosion, and their preparation technics. They belong to domain of surface treatment of non-ferrous metal. Compound plating coat based on the chemical nickel coat, the thickness of which is between 20 and 25 micron. The callow of it is electrolytic zinc plating and nickel alloy, the thickness of which is between 8 and 10 micron. The following is the preparation craftwork; the chemical nickel plating of magnesium alloy adopts the standard B480-88 of American material experimentation association. Plating time is between 1.4 and 2 hours. The coating thickness if between 20 and 25 micron. The content of phosphor in the plating layer is 9-12%; electrolytic zinc plating and nickel alloy: the plating liquid of it and technics conditions are followed: sodium hydroxide 8-15%, zinc oxice 2-5%, nickelous chloride 0.5-3%, ethylamine 2-4%; tiethanolamine 2-4%, nylander reagent 0.5-3%, DE0.2-0.8%, sodium dodecanesulphonate 0.01-0.1%, the overmeasure is water. Curl density is 0.5-5A / dm2. Plating time is 30 minutes.

Owner:吴成翰 +2

Cathode shielding preparation method for super-thick open-hole foam iron-nickel filter material

InactiveCN106757206AImprove permeabilityImprove filtration efficiencyMembrane filtersFiltration separationAlloyIron(II) chloride

The invention discloses a cathode shielding preparation method for a super-thick open-hole foam iron-nickel filter material. According to the method, a foam through-hole sponge is coated with conductive graphite glue or subjected to chemical nickel-plating to serve as an electroplating cathode, a pure iron plate or an alloy plate with a certain proportion of iron and nickel is adopted as an anode, and the cathode, the anode and a cathode shielding plate are put into an electroplating solution with ferrous chloride as main salt or ferrous chloride and nickelous chloride as main salt for electroplating; a semi-finished product is subjected to heat treatment under the reducing atmosphere / inert gas shielding; and the finished product is cut according to the technical requirements. Compared with the prior art, by means of the method, the good deep plating and even-plating are achieved, and the super-thick open-hole foam iron-nickel filter material which is good in permeability, high in filtering efficiency and low in cost is formed, the content of impurities is reduced by over 20%, detection is conducted according to an HJ / T762-2001 test method, the removal rate generated when the method is applied to foam iron-nickel lampblack ranges from 85% to 94%, the wind speed is 1.2 m / s, the pressure loss is less than 20 pa, the economic benefits are increased remarkably, and the method has the great market popularization value.

Owner:CHANGDE LYRUN MATERIAL

Method of removing copper from nickel chloride leachate

InactiveCN101125686ATo achieve the purpose of copper removalSolve pollutionNickel halidesSlagFiltration

A method to remove copper in nickelous chloride lixivium relates to a method to remove impurities from chlorination medium, in particular to a method to remove copper in nickelous chloride lixivium with nickel ore concentrate, which is characterized in that the chlorination lixivium is heated to 80-95 DEG C, nickel ore concentrate and lixiviated slag are added into the chlorination lixivium according to volume ratio of 5:1, oxidation-reduction potential is controlled to be below -50mv, the reaction lasts for 1-2h and the nickelous chloride lixivium containing less than 1 g / l copper is obtained after pressure filtration and separation of slag and solution. The method of the invention realizes the purpose of removing copper from nickelous chloride lixivium, produces solution that meets the requirements of deep copper removal process and solves the problems of effect of harmful gases on the environment and the health of workers.

Owner:JINCHUAN GROUP LIMITED

Preparation method of top-grade pure nickelous chloride

InactiveCN104108756AMeet the needs of high-end technologyThe process steps are simpleNickel halidesFiltrationReaction temperature

Owner:TIANJIN CHEM REAGENT RES INST

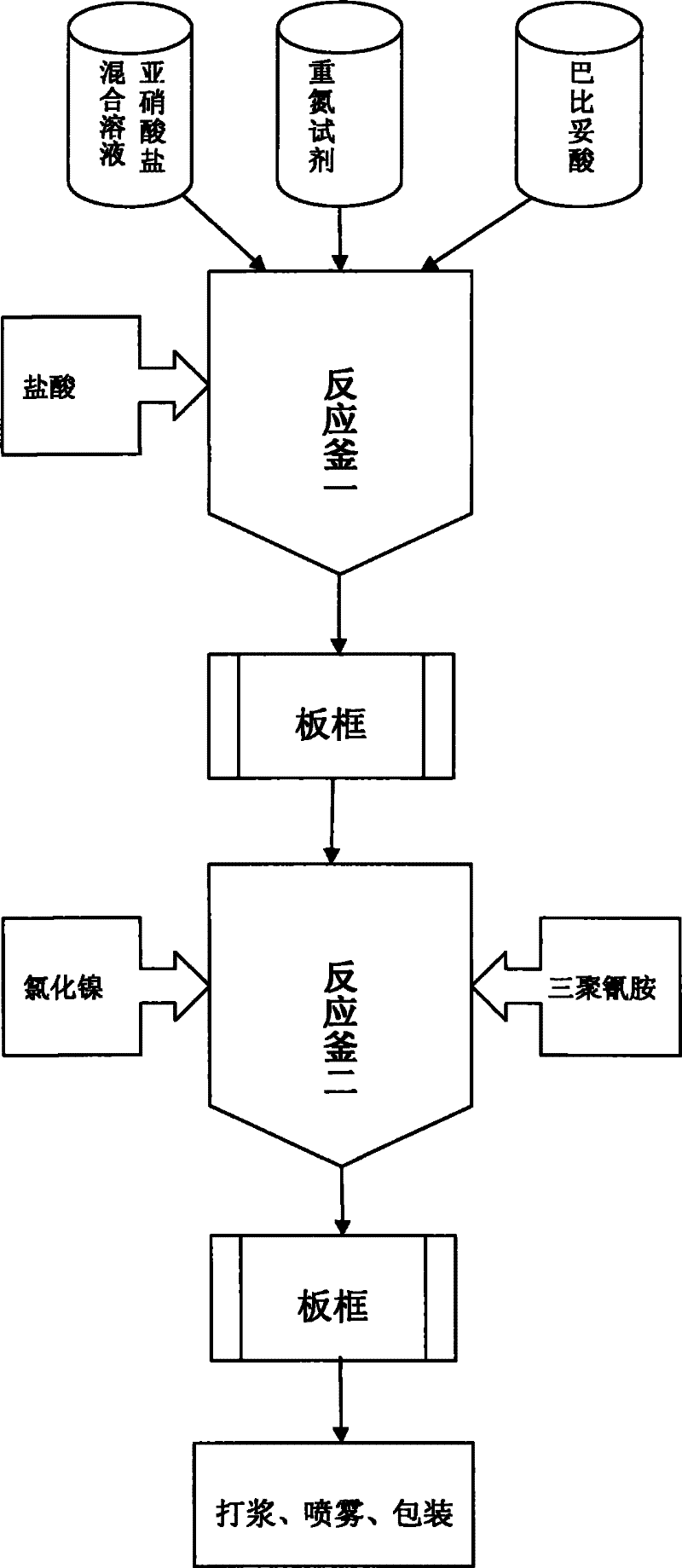

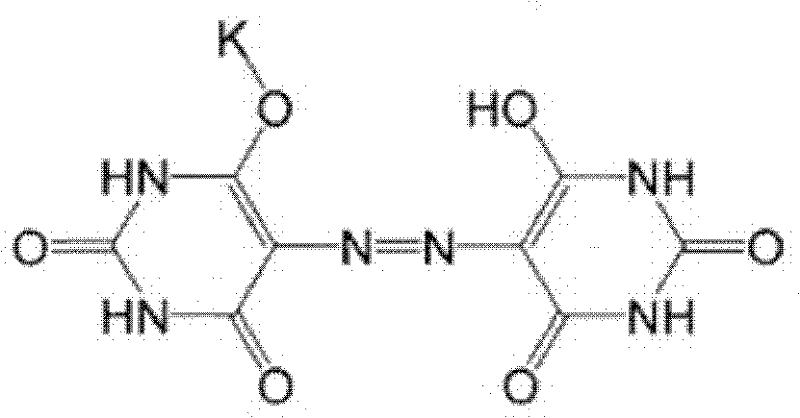

Method for preparing pigment yellow 150 with salt mixture of kalium azoic barbiturate and natrium azoic barbiturate

The invention provides a method for preparing pigment yellow 150 with a salt mixture of kalium azoic barbiturate and natrium azoic barbiturate. The invention aims at providing the method for preparingnickel azoic barbiturate complex dye, namely, the pigment yellow 150. The method comprises the following steps: 1. aminoguanidine carbonate is used for preparing the salt mixture of the kalium azoicbarbiturate and the natrium azoic barbiturate; and 2. p toluene sulfonyl hydrazine is used for preparing the salt mixture of the kalium azoic barbiturate and the natrium azoic barbiturate so as to prepare the nickel azoic barbiturate complex dye. The invention is characterized in that the pigment yellow 150 is again prepared by the orange red powdered salt mixture of the kalium azoic barbiturate and the natrium azoic barbiturate with the following steps: adding in distilled water, stirring, heating up, slowly adding nickelous chloride solution, adding melamine, stirring, adjusting the pH valueof the system with potassium hydroxide solution; washing by means of suction filtration, drying and obtaining finished products. The nickel azoic barbiturate complex dye has good transparency, liquidity and color intensity, and is suitable for the fields such as printing ink, color filter, etc.

Owner:XIANGTAN JIALI TECH

Refrigerant composition and its packaging device

Owner:吴成翰 +2

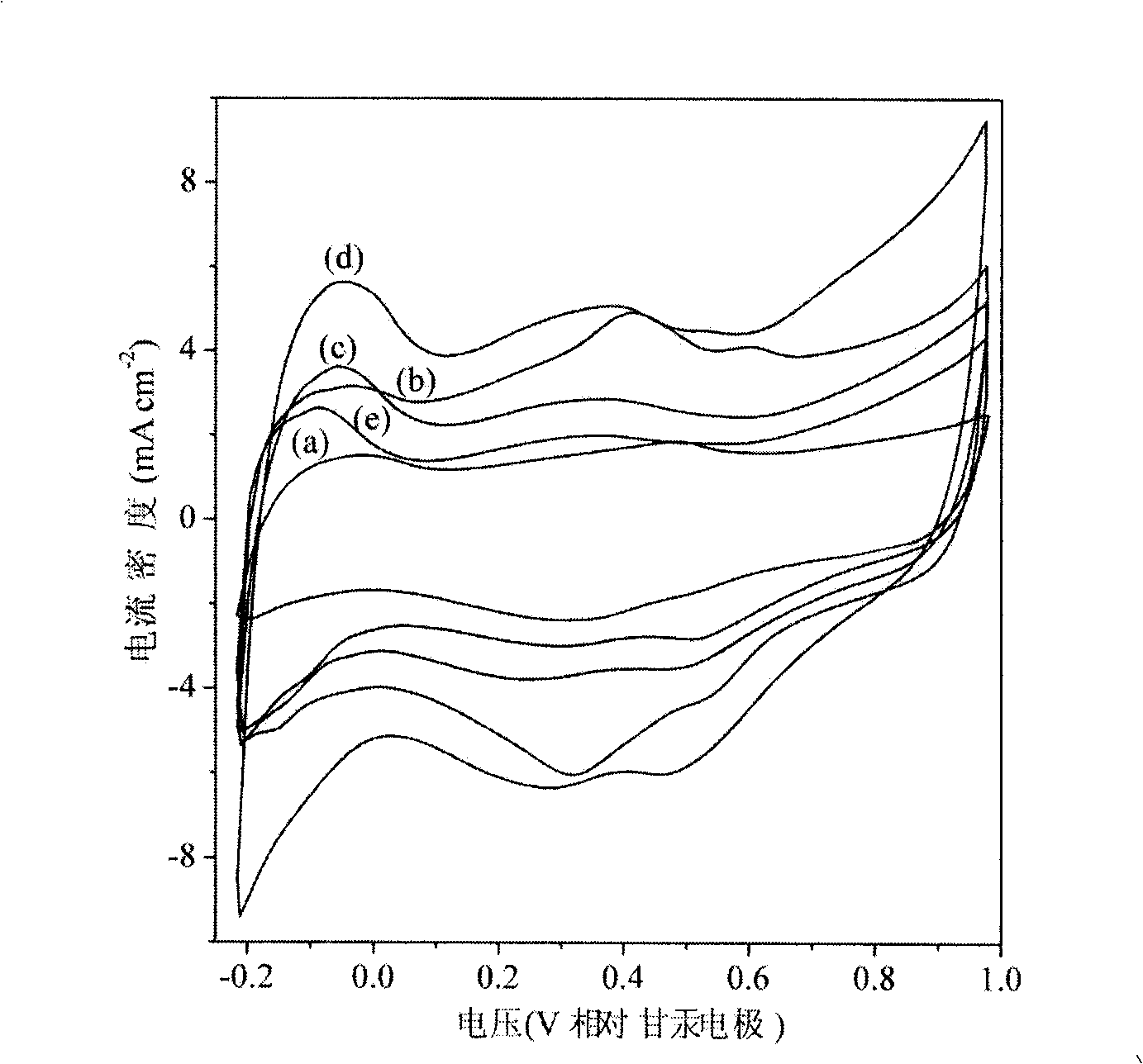

Preparation method of nickel molybdenum sulfide/foamed nickel electrode material

PendingCN114446676AEvenly dispersedSimple preparation processElectrolytic inorganic material coatingHybrid capacitor electrodesNickel saltNickel electrode

The invention discloses a preparation method of a nickel molybdenum sulfide / foamed nickel electrode material, which comprises the following steps: taking foamed nickel as a working electrode, taking nickel salt as an electrolyte, and carrying out constant-potential anode electrodeposition to obtain nickel hydroxide / foamed nickel; mixing with molybdate and an organic sulfur source, and carrying out hydrothermal reaction to prepare a nickel molybdenum sulfide / foamed nickel electrode material; the nickel salt is one or two of nickelous nitrate, nickelous chloride, nickelous bromide, nickelous sulfate and nickelous acetate; the molybdate is one of sodium molybdate, potassium molybdate and ammonium molybdate; the organic sulfur source is one or two of thioformamide, thioacetamide, thiopropanamide, thiobutyramide and thiobutyramide; the organic sulfur source is one or two of thiobutyramide, thioacetamide, thiopropanamide, thiobutyramide and thiobutyramide; the material has good electrochemical performance and has a good application prospect in the field of supercapacitors.

Owner:CHINA JILIANG UNIV

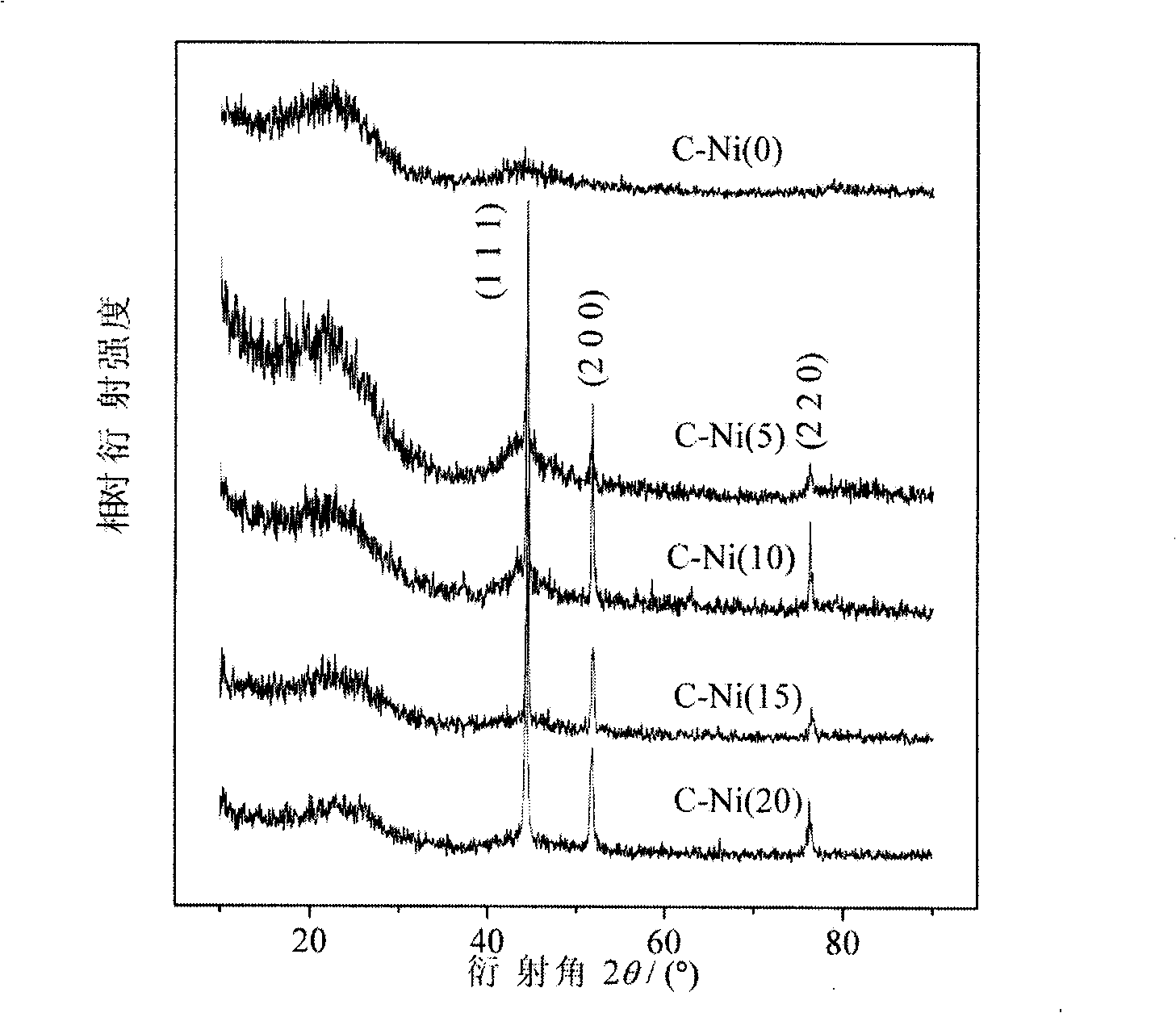

Nickelous chloride assisted synthesis method of fuel cell catalyst carrier ordered mesoporous carbon

InactiveCN101491777BPrevent collapseImprove conductivityCatalyst carriersCell electrodesPtru catalystNickelous Chloride

The invention relates to a method for the nickel chloride-aided synthesis of fuel cell catalyst carrier ordered mesoporous carbon, which belongs to a preparation process of a direct methanol fuel cell catalyst. The method can produce carbon-carried Pt catalyst with excellent performance by adopting in-situ carbon thermal reduction technique and a unique binary metal loading method and is applicable to oxyhydrogen proton exchange membrane fuel cells and direct methanol fuel cells. The method produces a binary electrocatalyst by using a metal chloride as an additive, synthesizing the ordered mesoporous carbon with a modified soft template self-assembly method, forming a metal nanocrystal through carbon thermal reduction, and loading Pt nano particles with a microwave heating glycol reduction method. The catalyst has excellent electrocatalysis performance and substantially increases the catalytic activity and utilization rate of Pt, thereby having enormous application prospect.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A method for catalytically synthesizing phenazine compounds under microwave irradiation in aqueous phase

ActiveCN105085420BSimple and fast operationHigh yieldOrganic chemistryEnvironmental resistancePhenothiazine

The invention discloses a method for catalytically synthesizing phenazine compounds in a water phase under microwave radiation, which comprises the following steps: adding a catalytic amount of catalyst ferric chloride or nickelous chloride, a cocatalyst lithium proline, a substrate substituted 2-haloaniline, a phase-transfer catalyst 4-butyl ammonium chloride, 4-butyl ammonium bisulfate or 4-butyl ammonium bromide, an inorganic alkali or organic alkali and water into a reaction vessel, putting into a microwave reaction instrument, reacting at certain temperature under certain power for some time, concentrating under reduced pressure, and purifying the product by column chromatography. The method for preparing phenazine compounds is friendly to the environment, simple to operate and high in efficiency. Compared with the prior art, the method has the advantages of obviously higher reaction speed than conventional heating, mild reaction conditions, high yield, high safety, low cost and environment friendliness, and is simple to operate.

Owner:FUJIAN MEDICAL UNIV

Thin belt continuous casting crystal roller surface electroplating method and electroplate liquid thereof

ActiveCN100577889CEfficient adjustment of heat transfer coefficientAvoid damageCycles per minuteVolumetric Mass Density

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE

Synthesis method of anti-influenza and avian influenza virus resistant medicine peramivir

InactiveCN102372657BMild reaction conditionsSimple and fast operationOrganic chemistryOrganic compound preparationSynthesis methodsKetone

The invention belongs to the synthesis technical field of organic medicine, and discloses a synthesis method of anti-influenza and avian influenza virus resistant medicine peramivir, which is characterized by adopting (1R, 4S)-2-azabicyclo[2.2.1]hept-5-en-3-one as a raw material and by comprising the following steps: step I: catalyzing, loop-opening and amino protection; step II: 1,3-dipolarcycloaddition; step II: sodium borohydride and nickel chloride hexahydrate reduction and acetylization; and step IV: amino protection removal, and chloroformamidine hydrochloride is adopted as reaction agent to generate guanidyl and hydrolysis methyl ester to prepare peramivir. The sodium borhydride and the nickelous chloride reduction system is used for substituting the expensive platinum dioxide to be used as reducing agent during the hydrogenation reduction process, and the self-produced chloroformamidine hydrochloride is used during the process for feeding the guanidyl reagent, so the cost is reduced, and the operation procedures are simplified. The synthesis method has short reaction routine and moderate reaction condition, is simple and convenient to operate, has low cost, and is suitable for the industrialized production.

Owner:JINAN UNIVERSITY

A kind of method using benzimidazole ionic liquid to prepare sartan biphenyl

ActiveCN104326938BEasy to removeSolve solubilityCarboxylic acid nitrile preparationOrganic compound preparationPolyethylene glycolLosartan

The invention provides application of a polyethyleneglycol-functionalized benzimidazole ionic liquid disclosed as Formula (I) in preparing 2-cyano-4'-methylbiphenyl and a method for preparing 2-cyano-4'-methylbiphenyl by using the polyethyleneglycol-functionalized benzimidazole ionic liquid. The method comprises the following step: by using nickelous chloride as a catalyst and the polyethyleneglycol-functionalized benzimidazole ionic liquid as an accelerator, carrying out coupling reaction on ortho-halo cyanophenyl and 4-methylphenylboronic acid in a pure water solvent to obtain the 2-cyano-4'-methylbiphenyl. The method has the advantages of low cost and environmental protection, and is convenient for purification and suitable for industrial production.

Owner:陕西煤业化工技术开发中心有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com