Refrigerant composition and its packaging device

A refrigerant and separation device technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of high price and increased refrigerant cost, and achieve the effects of easy portability, reduced production costs, and scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] A kind of refrigerant involved in the present invention is characterized in that: described refrigerant is made of ammonium bisulfate, ammonium nitrate, sodium sulfite and sodium sulfate decahydrate, i.e. Na 2 SO 4 10H 2 O is formulated, and its weight ratio is 35-45 parts by weight of ammonium bisulfate, 45-55 parts by weight of ammonium nitrate, 25-35 parts by weight of sodium sulfite, sodium sulfate decahydrate, namely Na 2 SO 4 10H 2 O, 90-100 parts by weight.

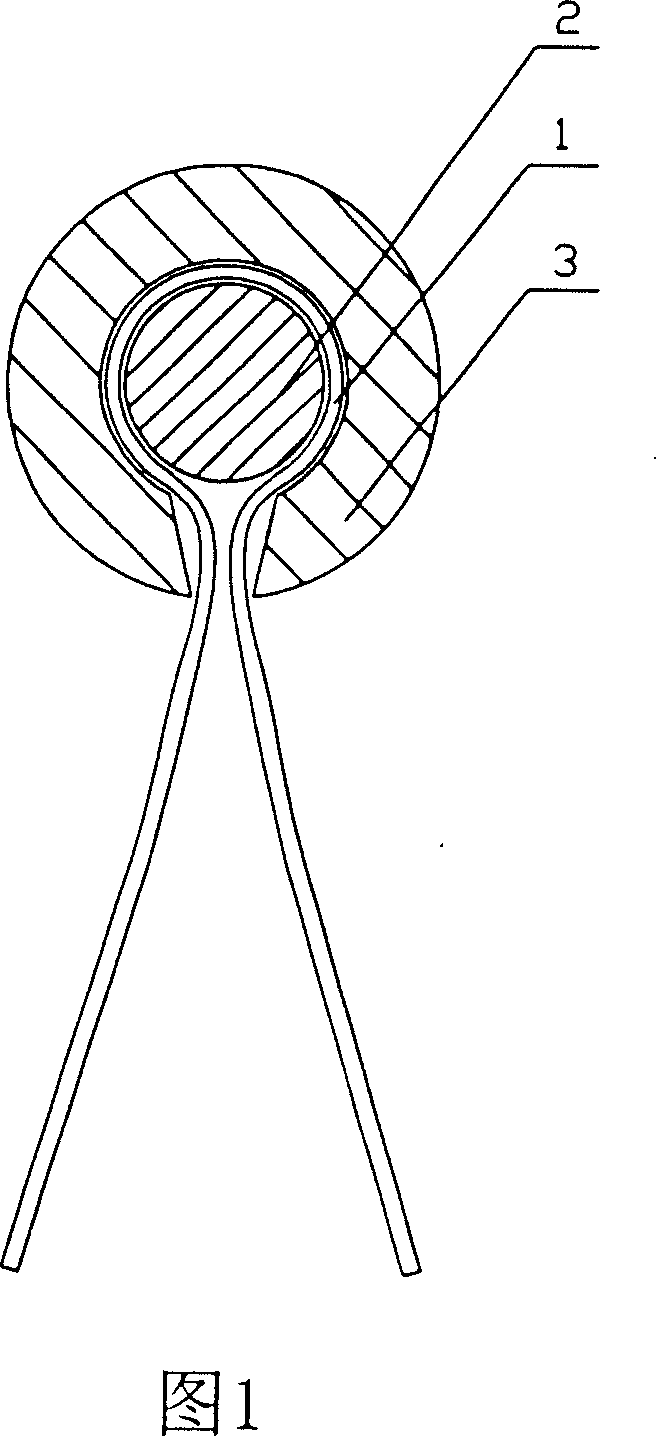

[0009] The preparation steps of the refrigerant are as follows: after weighing each component of the refrigerant according to the weight ratio, sodium sulfate is placed on one side of a portable packaging device provided with a separator, and ammonium bisulfate, sodium sulfite, nitric acid The ammonium is placed on the other side of the portable packaging device provided with a partition device, and the partition device of the packaging device is opened during use to allow the components of the refrigera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com