Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

112results about How to "Maximize recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for reclaiming rare noble metals from waste circuit board

ActiveCN102181644AHigh recovery rateEasy to operateProcess efficiency improvementPrinted circuit boardElectrostatic separation

The invention provides a method for reclaiming rare noble metals from a waste circuit board. The method comprises the following steps of: crushing, performing electrostatic separation, calcining, performing acid leaching, and extracting silver, gold, platinum and palladium respectively. The method can realize maximization of valuable metal resource recycle, can reclaim various rare noble metals respectively, and is high in recovery rate, simple in operation of the reclaiming process, low in energy consumption and environment-friendly.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

Intelligent classification dustbin

ActiveCN106275949AImprove classificationEasy to recycle laterWaste collection and transferRefuse receptaclesRotary valveEngineering

The invention relates to an intelligent classification dustbin. The intelligent classification dustbin is characterized by comprising a base, a rotating driving mechanism, a center shaft, a rotary table, a classification bin and a bin lid unit, the base and the bottom of the center shaft are fixedly installed, the rotating driving mechanism comprises a driving plate and a driving motor, the driving plate is rotatably installed at the bottom of the center shaft, the rotary table which is located above the driving plate is rotatably installed on the center shaft, the rotary table is connected with the driving plate through a connecting column, the classification bin is installed on the rotary table and comprises multiple bin bodies, the bin lid unit is installed on the upper portion of the center shaft, the bin lid unit comprises a support, a bin lid covering the classification bin and an intelligent starting control panel located on the bin lid, the support is horizontally fixed on the top of the center shaft, the bin lid is installed on the support, and the bin lid is provided with an inlet opening capable of being opened and closed automatically. According to the intelligent classification dustbin, the structural design is scientific and reasonable, garbage can be subjected to detailed classification and recycled, maximized recycling of the garbage can be achieved, bacterial infection can be avoided, and odor dispersion is prevented.

Owner:TIANJIN LIGHT IND VOCATION TECHN COLLEGE

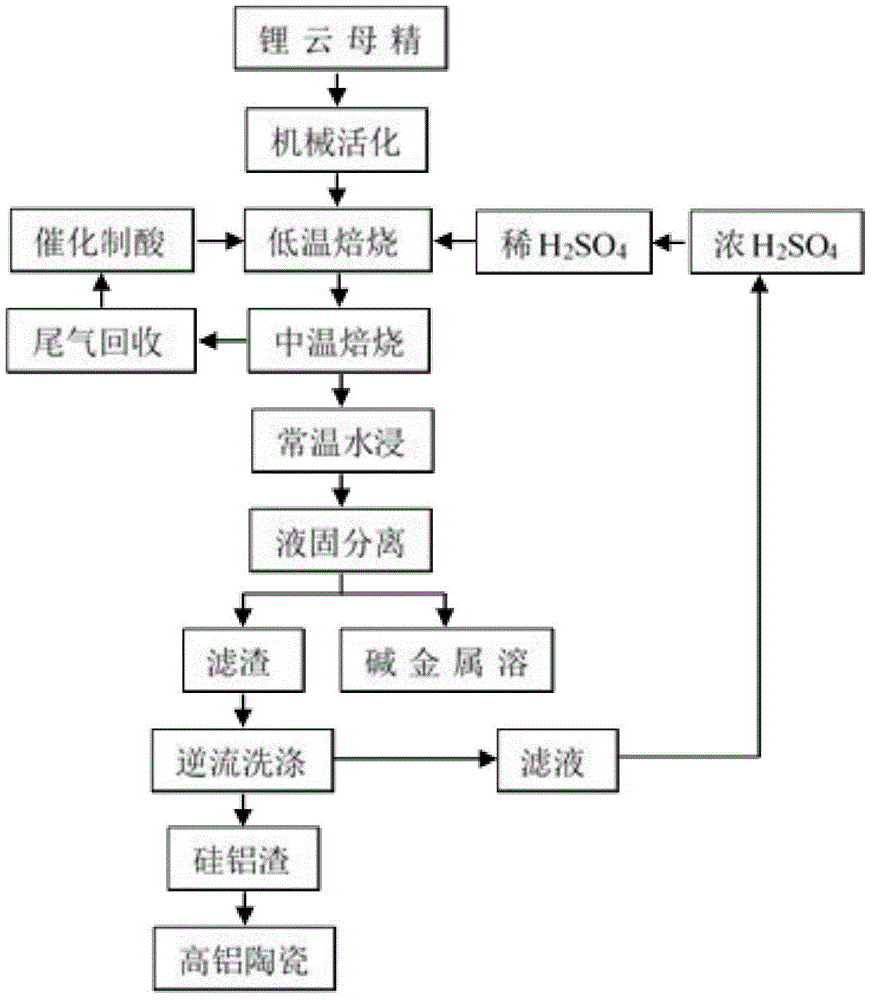

Method for extraction of lithium and removal of aluminum by vitriolization of lepidolite

ActiveCN104876250AEfficient extractionAchieve recyclingLithium carbonates/bicarbonatesAluminium oxides/hydroxidesSlagDecomposition

The invention discloses a method for extraction of lithium and removal of aluminum by vitriolization of lepidolite. The method includes a technical process: 1) mechanical activation of lepidolite; 2) low-temperature vitriolization for extraction of valuable metallic elements; 3) medium-temperature sintering; 4) tail gas recovery; 5) normal-temperature water immersion for extraction of alkali metal sulphates. Alkali metal elements and high-content aluminum in lepidolite are dissolved out and gradually heated until decomposition of aluminum salts, and calcination exhaust is recovered for acid production to realize maximized recycling of leaching agents. Calcination clinkers are subjected to water immersion for extraction of sulfate with the alkali metal elements, and high alkali metal extraction efficiency, technical simplicity, small material flow volume, low energy consumption, maximization in recycling of the leaching agents and the like are realized, so that social benefits of lepidolite are increased. After extraction of the alkali metals, high-aluminum slag can be used for preparation of ceramics, glass, environment-friendly cement, building blocks and the like to realize zero emission of exhaust gas, sewage and waste residues in treatment of lepidolite, and all procedures are in mutual synergy to jointly realize economical and efficient utilization of lepidolite.

Owner:JIANGXI HZONE LITHIUM TECH

Structure for oil-gas separation of engine bearing chamber and axial ventilation of multiple bearing chambers

ActiveCN106837553AClean oil and gas environmentEfficient separationShaftsTurbine/propulsion lubricationAviationPressure balance

The invention relates to a structure for oil-gas separation of an engine bearing chamber and axial ventilation of multiple bearing chambers. An oil-gas separation component assembled on a high-speed rotating shaft is arranged in the bearing chamber, and the peripheral surface of he oil-gas separation component is provided with main oil throw-off hole, an auxiliary throw-off hole and a plurality of oil breaking grooves formed in a circumferential direction; a vent pipe base is arranged in the high-speed rotating shaft and communicated with the oil-gas separation component in a downstream bearing chamber through a vent line, so as to achieve bearing chamber axial ventilation of multiple bearing chambers. By using the structure, the axial ventilation among different bearing chambers can be effectively achieved, the chamber pressure balance of high-speed rotating bearing chambers of an engine and a ground gas turbine engine can be achieved more efficiently, the proportion of oil mist in gas flow during air ventilation is reduced, the ventilation effect of the bearing chamber is improved and the engine oil mist separation requirement of an oil mist separator outside an engine is reduced. The structure has an important engineering application value for the ground gas turbine engine or an aircraft engine with further reduced lubricating oil consumption.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Comprehensive utilization method of arsenic-containing materials

ActiveCN106834715AHarmlessImprove resource utilizationProcess efficiency improvementLead smeltingHydrometallurgy

The invention relates to a comprehensive utilization method of arsenic-containing materials. According to the method, production of comprehensive recovery of valuable metals such as arsenic, antimony, lead, bismuth and the like from smelting dust containing the arsenic, the antimony and the lead is performed, accumulation of the arsenic in the system is reduced, and harmless treatment is performed on the arsenic. With the method, through normal pressure alkaline leaching, soluble arsenic in the dust is removed, leaching residues are subjected to procedures of washing, reduction smelting, oxidizing blowing and the like, and various valuable elements are recycled. With the method, the arsenic is removed from the dust and enters a leaching solution, and impurities such as antimony, lead, tin and the like are separated out in the form of precipitates through purification and impurity removal of the leaching solution. A purified solution is used for arsenic salt purification of a zinc sulfate solution during zinc hydrometallurgy, and purification residues are sent for lead smelting, so that separation and harmless treatment of the arsenic and the valuable metals are realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV +1

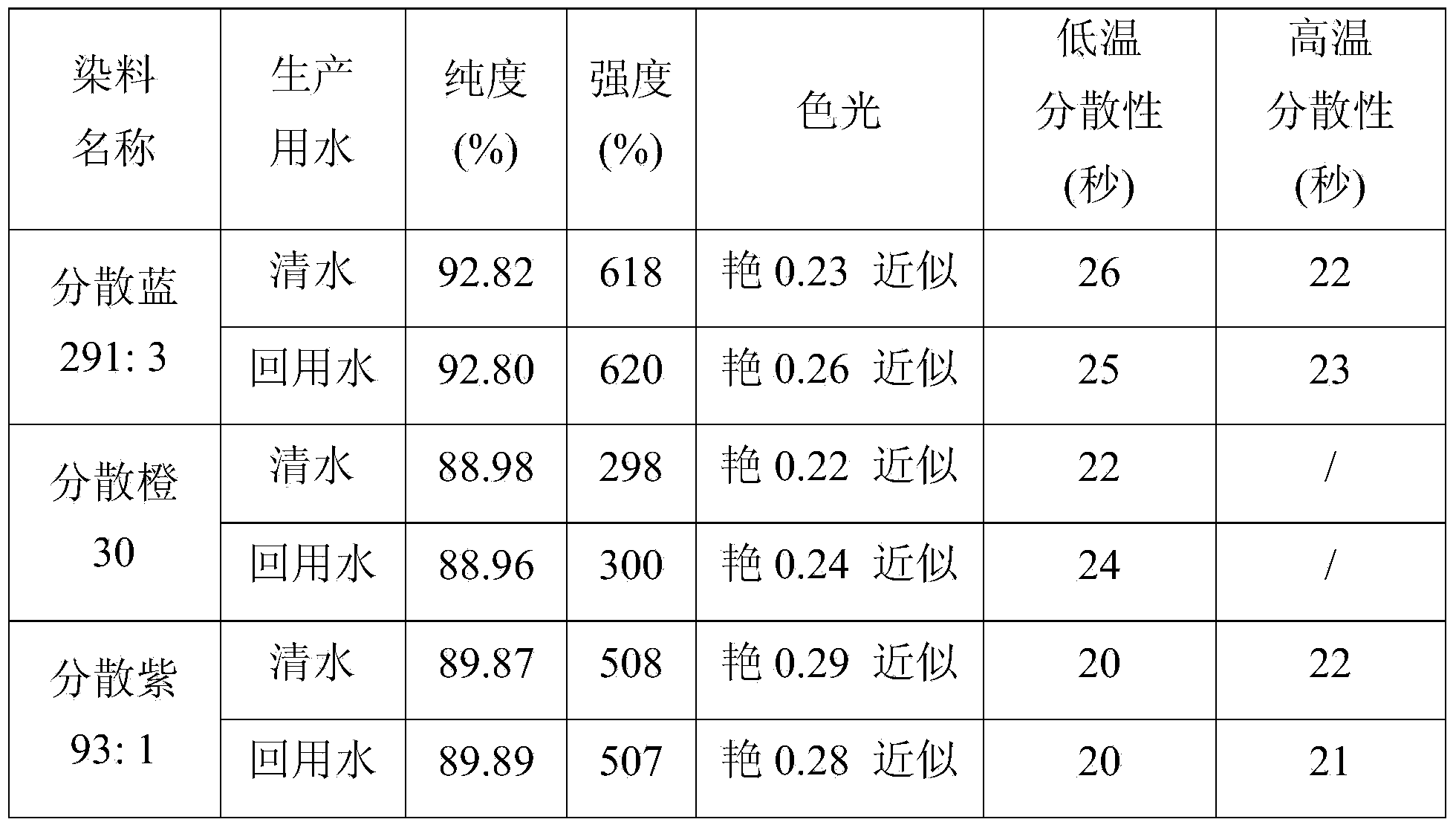

Treating and recycling process of acid wastewater generated in disperse dye production

ActiveCN103880210AAvoid pollutionMeet the requirements of pollution reduction and emission reductionMultistage water/sewage treatmentDisperse dyeCarbonate

The invention discloses a treating and recycling process of acid wastewater generated in disperse dye production. The process comprises the steps of collecting acid wastewater generated by a same disperse dye, and separately collecting mother liquor water and washing water; adding at least one of magnesium oxide, magnesium hydroxide and magnesium carbonate to the collected mother liquor water and washing water, and adjusting the pH value to be 7-8; adding solid soda to the wastewater after adjustment until the pH value of the wastewater is 9-12, thereby obtaining first filtrate and first filter residues; adding a mixture of aluminium trichloride and solid soda to the first filtrate, thereby obtaining second filtrate and second filter residues; recycling part of the second filtrate in washing of dye filter cakes, carrying out condensation crystallization on the remaining filtrate, and recycling the condensed water. According to the process, recycling of the wastewater and magnesium is achieved by neutralizing acid water generated in the dye and intermediate production process by utilizing magnesium oxide, magnesium hydroxide or magnesium carbonate and then precipitating magnesium ions with solid soda, therefore, the process meets the requirement for clean production of resources.

Owner:ZHEJIANG DIBANG CHEM

Treatment process for arsenic sulfide containing material

InactiveCN108315571AShort processHigh recovery rateProcess efficiency improvementChemistrySulfur dioxide

The invention discloses a treatment process for an arsenic sulfide containing material. The treatment process for the arsenic sulfide containing material comprises three main steps: pulpifying of theraw material, oxygen pressure acid leaching, and reducing and separating. The liquid-solid mass ratio is 3:1 to 10:1 in the pulpifying of the raw material, the pulpifying lasts for 2-4 hours at the temperature of 80-100 DEG C; the oxygen pressure acid leaching lasts for 2-4 hours at the temperature of 90-180 DEG C at the pressure of 0.1-3 MPa at the speed of 100-3000 r / min; an arsenic containing leaching agent is reduced and separated through sulfur dioxide, sodium thiosulfate or sulfite, and is then secondarily pulpified and separated to obtain a sulfite product. The arsenic content in a leaching residue is less than 5%, the recovery rate of arsenic is more than 80%; a surfactant is added in the pulpifying process, so that the oxidation reaction is more thorough; a vacuum pulpifying tankprovided with an exhaust system is used to prevent the waste gas from overflowing, and is beneficial for improving the operation environment. The technological process is short, and the treatment process has the advantages of environmental protection, economical efficiency, energy saving, and efficient utilization of resources, etc.

Owner:CHINA NERIN ENG

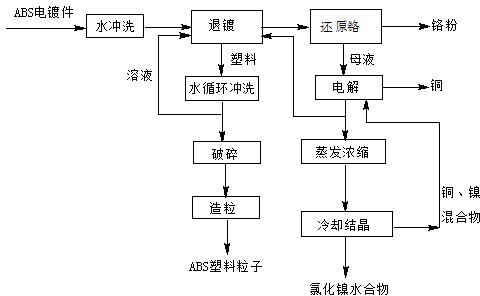

Method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts

InactiveCN102534222AReduce lossMaximize recyclingPlastic recyclingProcess efficiency improvementRecovery methodEvaporation

A method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts belongs to the field of solid waste recovery. The method comprises the steps of crushing, deplating, ABS plastic recovery, chromium reduction, electrolytic reduction of copper, and evaporation and concentration for preparing nickelous chloride. According to the method, the dynamic closed cycle of all working solution is realized, the primary recovery of ABS plastic is achieved, the recovery rate is above 99 percent, both the electrolytic copper and the nickelous chloride reach the national primary standards, the recovery rate of copper is above 97 percent, and the recovery rate of nickelous chloride is above 98 percent. The method is simple to operate, low in energy consumption and environmental-friendly.

Owner:NANCHANG UNIV

Adjustable heat collecting device for rotary kiln body

ActiveCN101979943AAchieve economical operationRealize comprehensive utilizationRotary drum furnacesIncreasing energy efficiencyEngineeringSafe operation

The invention relates to an adjustable heat collecting device for collecting heat dissipated by a rotary kiln body. The device is formed by connecting a plurality of independent heat collection units, wherein each heat collection unit comprises a heat collecting cover, a bracket and a position adjusting system; the heat collecting cover comprises a heated surface, a heat preserving material, a frame, a protective shield and the like; brackets are arranged on two sides of the rotary kiln body, the brackets on one side are directly connected with heat collecting shields, while the position adjusting systems are arranged between the brackets on the other side and the heat collecting covers; and each position adjusting system consists of a support mechanism and an execution mechanism. The heat collected from the rotary kiln body and the temperature of a heating working medium can be adjusted through the change of positions of the heat collection units, the connecting assembly way between the units of the heat collecting device and the change of the number of switching so as to ensure that the reclaimed heat and the surface temperature of the rotary kiln body are in a safe range, guarantee safe operation of the rotary kiln, and realize harmonization and unification of equipment safety, operation economy and heat reclaiming maximization.

Owner:NANJING KESEN KENEN ENVIRONMENT & ENERGY

Poultry manure collection and treatment method

ActiveCN107686222AMaximize recyclingIncrease productivitySpecific water treatment objectivesClimate change adaptationSlurryPoultry manure

The invention relates to a poultry manure collection and treatment method. Poultry manure collection and treatment equipment involved in the poultry manure collection and treatment method comprises apretreatment chamber, a heating chamber, a reaction chamber, a biogas collection bag and an organic fertilizer treatment chamber. The poultry manure collection and treatment method includes the stepsof pretreatment, disinfection, reaction fermentation, production of organic fertilizer by using biogas residues and biogas slurry and the like. Through improvement of the equipment and the steps, poultry manure can be decomposed into biogas and the organic fertilizer maximumly, and waste use is maximized.

Owner:荆门华牧生物科技有限公司

Preparation and application of wool dye prepared by walnut plant

InactiveCN102153883AMaximize recyclingRich in plant resourcesNatural dyesDyeing processWalnut NutPulp and paper industry

The invention relates to preparation and application of a wood dye prepared by a walnut plant in the technical field of wood dyeing. Powder of the walnut plant is extracted at a temperature of 10 to 150 DEG C and is concentrated by vacuum water bath to obtain walnut powder concentrate, i.e. the walnut plant dye. In the invention, the natural and nontoxic walnut plant is used for wood dyeing so as to provide technical basis for reducing the usage of a synthetic dye and developing a natural dye and also provide basis for really realizing large-scale industrial production and high-efficiency recycling of agriculture resources.

Owner:SHANGHAI JIAO TONG UNIV

Method for closed-circuit microorganism desulfurization and elemental sulfur recovery

ActiveCN107537293AInhibit excessive oxidationReduce secondary processing stepsMethane captureDispersed particle separationEnvironmental resistanceSulfur containing

The invention belongs to the environmental protection industry and the field of three-waste environmental protection purification, and relates to a method for closed-circuit microorganism desulfurization and elemental sulfur recovery, particularly to a process for biological desulfurization treatment of sulfur-containing industrial gases (such as biogas, natural gas, coal chemical industry processgas, refinery gas, sulfur-containing industrial waste gas, and the like, wherein the purposes of closed-circuit biological desulfurization, maximized recovery of elemental sulfur, standard emission of waste gas and near-zero emission of waste liquids can be achieved through chemical absorption, biological oxidation, elemental sulfur recovery, membrane separation, anaerobic reduction and other processes. According to the present invention, the treatment method can meet the biological desulfurization requirements, can solve the difficult problem of elemental sulfur production through sulfide oxidation and enhanced separation, and can be used for biogas, natural gas, coal-to-gas, refinery gas, sulfur-containing industrial waste gas and other industrial large-scale engineering.

Owner:CHINA PETROLEUM & CHEM CORP +1

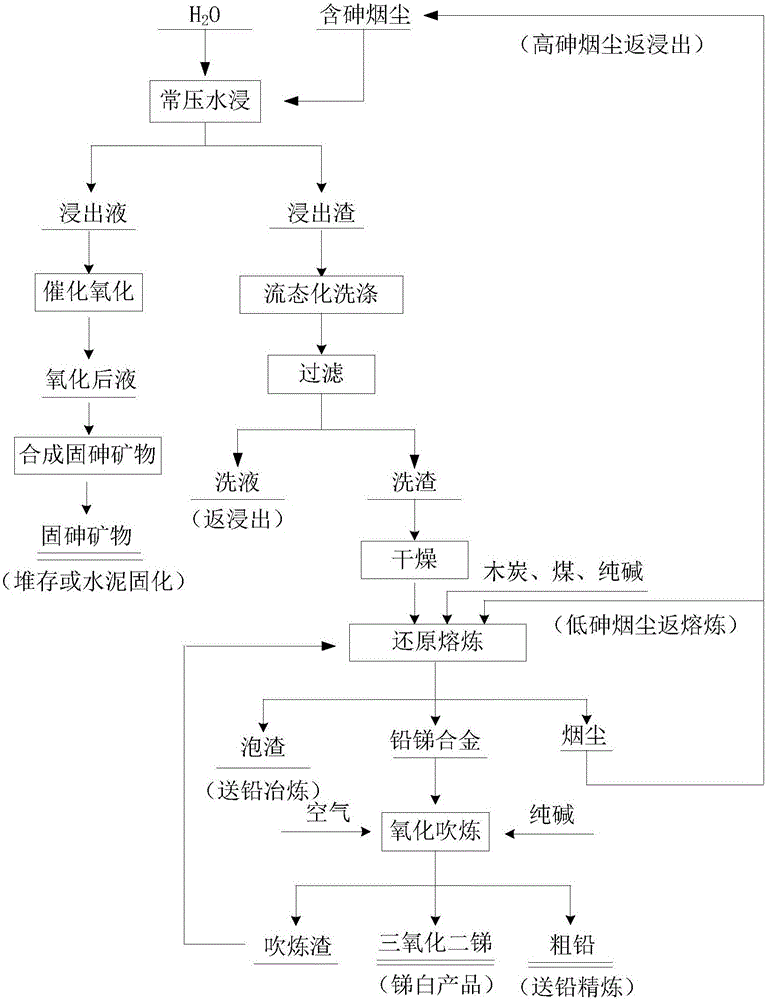

Method for arsenic removal of arsenic-containing dust and comprehensive recycling of valuable elements

ActiveCN106834716AReduce contentImplement resourcesProcess efficiency improvementCatalytic oxidationZinc smelting

The invention relates to a method for arsenic removal of arsenic-containing dust and comprehensive recycling of valuable elements. According to the method, production of comprehensive recovery of valuable metals such as arsenic, antimony, lead, bismuth and the like from smelting dust containing the arsenic, the antimony and the lead is performed, accumulation of the arsenic in the system is reduced, and harmless treatment is performed on the arsenic. With the method, through normal pressure alkaline leaching, soluble arsenic in the dust is removed, after trivalent arsenic in a leaching solution becomes pentavalent arsenic through catalytic oxidation, stable arsenic-fixing minerals are synthesized with the method for arsenic precipitation with lime and the precipitation transforming method and are solidified through piling, leaching residues are subjected to procedures of washing, reduction smelting, oxidizing blowing and the like, and the various valuable elements are recycled to the maximum extent. With the method, the arsenic is removed from the dust, the antimony, the lead, the bismuth and the like are left in the arsenic-removed residues as much as possible, and separation and harmless treatment of the arsenic and the valuable metals can be realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

Steel bar rust removal device having recovery function

ActiveCN112692693ARealize pretreatment and dust removalAchieve recyclingDispersed particle filtrationGrinding drivesDust controlRebar

The invention discloses a steel bar rust removal device having a recovery function, and particularly relates to the technical field of steel bar rust removal. The steel bar rust removal device comprises a conveyor, a first box body is arranged on one side of the conveyor, a dust removal mechanism is arranged on one side of the first box body, the dust removal mechanism is arranged on the outer side of the conveyor, a first rust removal mechanism is arranged in the first box body, the front end of the first rust removal mechanism extends out of the front end of the first box body, a spraying mechanism is arranged at the top end of the first box body, the bottom end of the spraying mechanism extends into the first box body, a pushing mechanism is arranged on the other side of the first box body, a second rust removal mechanism is arranged at the front end of the pushing mechanism, and the second rust removal mechanism is arranged on the other side of the front end of the first box body. According to the steel bar rust removal device, steel shot accurate rust removal is conducted after spraying type large-area rust removal is conducted through a rust removal liquid, and the rust removal effect is good.

Owner:XUZHOU COLLEGE OF INDAL TECH

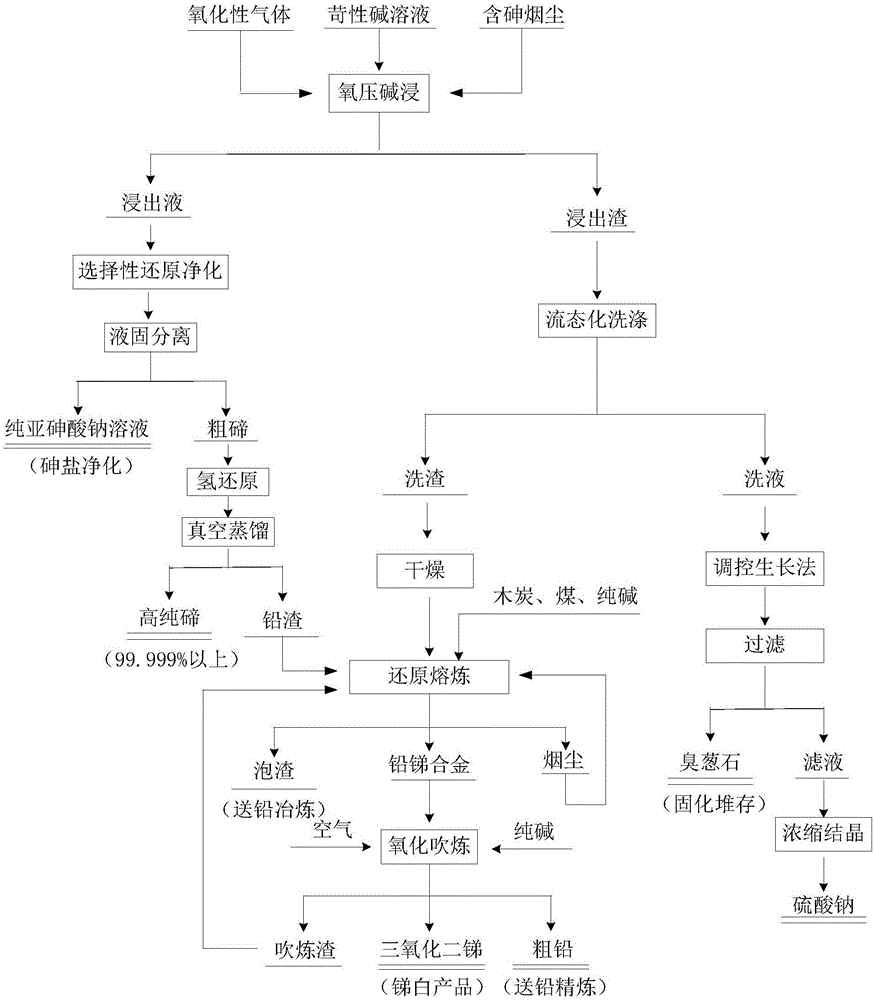

Method for comprehensively treating arsenic-contained smoke and synthesizing arsenic fixing minerals by control growth method

ActiveCN106834720AComprehensive utilization of resources is highRaw material adapts to a wide rangeProcess efficiency improvementSmelting processBismuth

The invention belongs to the technical field of metallurgy, and in particular, relates to a method for comprehensively treating arsenic-contained smoke and synthesizing arsenic fixing minerals by a control growth method. The method comprises four steps of oxygen pressure water leaching, leaching liquid arsenic fixation, leaching slag washing and recovery of valuable metal from washing slag in sequence; the method uses the oxygen pressure water leaching for removing solvable arsenic in the smoke; arsenic in leaching liquid is synthesized as high-stability arsenic fixing minerals by the control growth method; and then, the arsenic fixing minerals are cured by a stockpiling mode. All valuable elements are recycled from leaching slag to the greatest extent by such procedures as washing, reduction smelting and oxidation blowing. The method removes arsenic from the smoke and synthesizes the stable arsenic fixing minerals, but retains antimony, lead, bismuth and the like in the leaching slag as far as possible, and realizes separation of arsenic from the valuable metal and harmlessness. The method is high in resource comprehensive utilization rate and wide in raw material application range, solves the pollution problem in the traditional extracting process, in particular the smoke generated in the lead-zinc smelting process, and is more obvious in advantages.

Owner:CENT SOUTH UNIV

Safe treatment method for recycling valuable metals and arsenic from arsenic-containing smoke

ActiveCN106834717AReduce contentReduce arsenic levelsProcess efficiency improvementCatalytic oxidationZinc smelting

The invention relates to a safe treatment method for recycling valuable metals and arsenic from arsenic-containing smoke. The safe treatment method comprises the following steps: carrying out water leaching under normal pressure; carrying out catalytic oxidation on leachate; after oxidization, solidifying arsenic in the leachate; washing leaching residues; and recycling valuable metals from the washed residues. According to the method, soluble arsenic is removed from the smoke through normal-pressure water leaching; trivalent arsenic is oxidized into pentavalent arsenic after a catalytic oxidation procedure is carried out on the leachate; after oxidation, high-stability solid arsenic minerals are obtained by synthesizing the leachate by a lime arsenic precipitation process, and then, cementation treatment is carried out; and after the leaching residues are treated by the procedures of washing, reduction smelting and oxidization blowing, all valuable elements are recycled and utilized. The method has the advantages that the arsenic is removed from the smoke and solidified, the valuable elements, such as stibium, lead and bismuth, are kept in the leaching residues as much as possible, and the harmless separation of the arsenic from the valuable metals is realized. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved. The method has more remarkable advantages over smoke produced in lead and zinc smelting processes.

Owner:CENT SOUTH UNIV

Comprehensive treatment method of arsenic-containing materials

ActiveCN106834714AHarmlessAchieve recyclingProcess efficiency improvementCatalytic oxidationZinc smelting

The invention relates to a comprehensive treatment method of arsenic-containing materials. According to the method, production of comprehensive recovery of valuable metals such as arsenic, antimony, lead, bismuth and the like from smelting dust containing the arsenic, the antimony and the lead is performed, accumulation of the arsenic in the system is reduced, and harmless treatment is performed on the arsenic. With the method, through normal pressure alkaline leaching, soluble arsenic in the dust is removed, trivalent arsenic in a leaching solution becomes pentavalent arsenic through catalytic oxidation, stable arsenic-fixing minerals are synthesized with the fractional crystallization method and then are solidified through stockpiling, leaching residues are subjected to procedures of washing, reduction smelting, oxidizing blowing and the like, and various valuable elements are recycled to the maximum extent. With the method, the arsenic is removed from the dust, the antimony, the lead, the bismuth and the like are left in the arsenic-removed residues as much as possible, and separation and harmless treatment of the arsenic and the valuable metals can be realized. According to the method, the comprehensive utilization rate of resources is high, the raw material application range is wide, the problem of pollution in the extraction process of the traditional technology is solved, and the method has the more obvious advantages for the dust produced in the lead and zinc smelting process particularly.

Owner:CENT SOUTH UNIV

Method for comprehensive utilization of arsenic-containing smoke and harmless treatment of arsenic

ActiveCN106834718ASeparation and detoxificationImprove resource utilizationProcess efficiency improvementPollutionPrecipitation

The invention provides a method for the comprehensive utilization of arsenic-containing smoke and the harmless treatment of arsenic. The method adopts the operation of carrying out oxygen pressure water leaching, solidifying arsenic in leachate, washing leaching residues and recycling valuable metals from the washed residues. Soluble arsenic is removed from the smoke through oxygen pressure water leaching. The arsenic in the leachate is synthesized into stable solid arsenic minerals by combining one or more than two of a controlled growth process, a distribution and crystallization process, a lime arsenic precipitation process and a precipitation and converting process. Then, the solid arsenic minerals are solidified by adopting a stacking or cementation manner, and all valuable elements in the leaching residues are recycled and utilized to an utmost extent through the procedures of washing, reduction smelting, oxidization blowing and the like. According to the method, the arsenic is removed from the smoke, stibium, lead, bismuth and the like are kept in the residues from which the arsenic is removed as much as possible, and the harmless separation of the arsenic from the valuable metals is realized. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved. The method has more remarkable advantages over smoke produced in lead and zinc smelting processes.

Owner:CENT SOUTH UNIV

Method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts

InactiveCN102534222BReduce lossMaximize recyclingPlastic recyclingProcess efficiency improvementAcrylonitrileEvaporation

A method for recovering acrylonitrile butadiene styrene (ABS) plastic galvanized parts belongs to the field of solid waste recovery. The method comprises the steps of crushing, deplating, ABS plastic recovery, chromium reduction, electrolytic reduction of copper, and evaporation and concentration for preparing nickelous chloride. According to the method, the dynamic closed cycle of all working solution is realized, the primary recovery of ABS plastic is achieved, the recovery rate is above 99 percent, both the electrolytic copper and the nickelous chloride reach the national primary standards, the recovery rate of copper is above 97 percent, and the recovery rate of nickelous chloride is above 98 percent. The method is simple to operate, low in energy consumption and environmental-friendly.

Owner:NANCHANG UNIV

Water-retention multifunctional greenhouse system for producing water from air based on new energy resources

InactiveCN106134851AAvoid getting lostLoss GuaranteeClimate change adaptationRenewable energy machinesGreenhouseNew energy

The invention relates to a water-retention multifunctional greenhouse system for producing water from air based on new energy resources. The water-retention multifunctional greenhouse system comprises a base pit and a base frame, wherein the base pit is filled with soil, and the base frame is arranged on the base pit; a top frame is fixedly arranged on the top of the base frame, a greenhouse film is arranged along the peripheries of the base frame and the top frame, and waterproof films are arranged on the side surface and bottom surface of the base pit; a cross frame is further fixed at the upper part of the base frame, a first air water producer and a controller are arranged on the cross frame, the controller is connected with the first air water producer, the first air water producer is connected with a water storage tank fixedly arranged on the base frame through a pipeline, the water storage tank is connected with a water pump fixedly arranged on the base frame through a pipeline, the water pump is connected with a water spraying-conveying pipe through a pipe, a plurality of spray heads are arranged on the water spraying-conveying pipe, and a photovoltaic board assembly is arranged on the top of the top frame. According to the water-retention multifunctional greenhouse system, the problem that crops cannot be well cultivated in drought areas due to the deficiency of water is thoroughly solved, the defects of high manufacturing cost and maintenance cost, long cycle and the like caused by a pipeline water conveying manner are overcome, and the resources are saved and recycled. The water-retention multifunctional greenhouse system further has functions of preserving moisture, detecting multiple parameters and actively supplementing light.

Owner:四川东政电子技术股份有限公司

Treatment method for waste printed circuit board

ActiveCN102191383BSolve the problem of occupying a large amount of land resourcesSolve pollutionProcess efficiency improvementElectrostatic separationEngineering

The invention provides a treatment method for a waste printed circuit board, which comprises the following steps of: wet sealing-off treatment, separation of lead and tin, rough crushing, magnetic separation of iron, vortex separation, fine crushing and separation of fine nonmetal powder, electrostatic separation of metal and nonmetal in coarse mixture, recovery of heat energy through fire burning and harmless treatment of harmful tail gas. The invention combines wet sealing-off, decomposing classification and fire burning to reasonably recover usable resources, and is environment-friendly.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

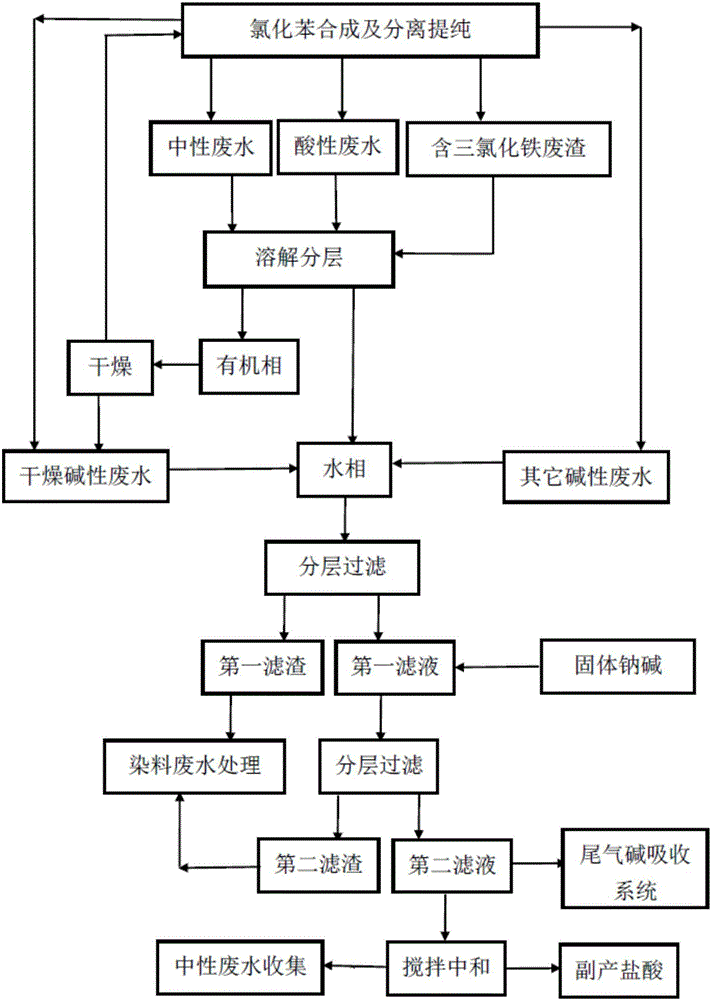

Comprehensive treatment and recycling method for chlorobenzene waste liquor and waste residues

ActiveCN106186435AAchieve infinite recyclingAvoid pollutionSolid waste disposalMultistage water/sewage treatmentBenzeneFiltration

The invention discloses a comprehensive treatment and recycling method for chlorobenzene waste liquor and waste residues. The method comprises the steps that the waste liquor generated in chlorobenzene production is added into waste residues containing iron ions, and the pH is controlled to range from 4 to 5; organic matter is recycled after being dried; the pH of an aqueous phase is adjusted to range from 9 to 10, the temperature ranges from 40 DEG C to 60 DEG C, suction filtration is conducted, and a first filtrate and first filter residues are obtained; the pH of the first filtrate is adjusted to range from 10 to 12, the temperature ranges from 40 DEG C to 60 DEG C, suction filtration is conducted, and a second filtrate and second filter residues are obtained; the second filtrate is partially returned back to a chlorobenzene production tail gas absorption system, the rest of the second filtrate is neutralized with collected acidic waste liquor, one part of the neutralized second filtrate returns back to a by-product hydrochloric acid synthesis system, the other part of the neutralized second filtrate serves as neutral waste liquor to be collected, and the first filter residues and the second filter residues are directly used in dispersed dyestuff wastewater treatment. The acidic waste liquor produced in chlorobenzene production is utilized for dissolving the waste residues, the products and the iron ions are recycled, wastewater recycling is achieved, zero release of wastewater and the waste residues is achieved, and the method meets the requirement of clean production.

Owner:ZHEJIANG RUNTU NEW MATERIAL CO LTD

Harmless treatment method for recycling valuable metal and arsenic resources from arsenic-containing smoke

The invention provides a harmless treatment method for recycling valuable metal and arsenic resources from arsenic-containing smoke. All valuable elements are recycled and utilized through the procedures of carrying out oxygen pressure leaching via caustic alkali; carrying out selective reduction purification on leachate; during purification, carrying out hydrogen reduction and vacuum distillation on obtained crude tellurium so as to obtain high-purity tellurium; after purification, obtaining a pure sodium arsenite solution, and using the solution for the arsenic salt purification of a zinc sulfate solution so as to remove cobalt and nickel; carrying out fluidization washing on leaching residues; after washing, solidifying arsenic in the solution, and carrying out reduction smelting on the residues; and carrying out oxidization blowing and the like. The arsenic is removed from the smoke, stibium, lead, bismuth, stannum and the like are kept in the residues from which the arsenic is removed as much as possible, and the deep separation of the arsenic and the stibium is realized. The obtained pure sodium arsenite solution is used for the arsenic salt purification of the zinc sulfate solution used for wet-process zinc smelting so as to remove the cobalt and nickel raw materials, part of sodium arsenate with high impurity content is solidified, the arsenic is precipitated, the harmless recycling of the arsenic resource is realized, and the valuable elements, such as the tellurium, the stibium, the lead and the bismuth are recycled. The comprehensive utilizing rate of the resources is high, the application range of the raw materials is wide, and a pollution problem in the extracting process of a traditional technology is solved.

Owner:CENT SOUTH UNIV

Method for comprehensively using arsenic-containing smoke dust and synthesizing solid arsenic minerals through precipitate conversion method

ActiveCN106834709ASeparation and detoxificationImprove resource utilizationProcess efficiency improvementResource utilizationSoot

The invention relates to the technical field of metallurgy, in particular to a method for comprehensively using arsenic-containing smoke dust and synthesizing solid arsenic minerals through a precipitate conversion method. The method comprises 5 steps of oxygen pressure water leaching, obtaining of solid arsenic in leach liquor, precipitate conversion, leaching residues washing and residue washing to recycling valuable metals: by the oxygen pressure water leaching, removing dissolvable arsenic from the smoke dust, synthesizing stable solid arsenic minerals through lime arsenic settling and precipitate conversion, curing the solid arsenic minerals by adopting a stockpiling mode, and carrying out procedures of washing, reducing smelting, oxidizing blowing and the like on leaching residues, so as to recycle and use all valuable elements to the maximum extent. According to the method, arsenic is removed from the smoke dust and synthesized into the stable solid arsenic minerals, and antimony, lead and bismuth are retained in arsenic-removed residues as much as possible, so that separation and harmlessness of the arsenic and the valuable metals can be realized. The method is high in comprehensive resource utilization rate and wide in raw material application range; the problem of pollution in an extraction process of a conventional technology is solved, and particularly soots produced in lead-zinc smelting process can be avoided. The method has a better advantage.

Owner:CENT SOUTH UNIV

Method for floating silicon from silicon slag

ActiveCN111822154AMaximize recyclingSimple extraction methodFlotationSilicon compoundsFoaming agentSlag

The invention discloses a method for recovering metallic silicon from silicon slag through flotation, comprising the following steps of: 1) silicon slag crushing: crushing the silicon slag by using acrusher, and putting the crushed silicon slag into a ball milling tank made of stainless steel for ball milling; 2) sieving: sieving the ground silicon slag to obtain silicon slag powder with the particle size of not more than 170 meshes; 3) surface treatment: carrying out surface treatment on the silicon slag powder by using a surface treatment agent, and stirring to fully mix the silicon slag powder to form silicon slag slurry; 4) flotation: adding a collecting agent foaming agent into the fully-mixed silicon slag slurry and stirring uniformly, putting the mixture into a flotation machine for flotation, and starting foam scraping after foam is rich, thereby obtaining a silicon-rich phase and a silicon-poor phase; and 5) silicon-rich phase treatment: filtering the silicon-rich phase, washing and drying to obtain a silicon-rich product, so that efficient recycling of silicon slag resources is achieved.

Owner:UNIV OF JINAN

Flue gas treatment method and system

InactiveCN104437053AAchieve desulfurizationAchieve dehalogenationZinc sulatesDispersed particle separationZinc bromideFiltration

The invention discloses a flue gas treatment method and a flue gas treatment system. Flue gas contains sulfur dioxide, hydrogen chloride and hydrogen bromide. The method comprises the following steps: (1) enabling the flue gas to be reversely in contact with absorption liquid containing zinc oxide to obtain purified flue gas and after-absorption liquid containing zinc sulfite, zinc chloride and zinc bromide; (2) performing filtration treatment on the after-absorption liquid to obtain filtrate and filter residues, wherein the filtrate contains zinc chloride and zinc bromide, and the filter residues contain zinc sulfite; (3) performing slurrying treatment on the filter residues; (4) performing oxidization treatment on slurry containing zinc sulfite to convert the zinc sulfite in the slurry into zinc sulfate to obtain a solution containing zinc sulfate; (5) performing evaporation and concentration treatment on the solution containing zinc sulfate to obtain a zinc sulfate heptahydrate product. By the method, the flue gas can be simultaneously desulfurized and dehalogenated to reach an emission standard; meanwhile, sulfur dioxide in the flue gas can be recycled, so that resources can be maximally recycled.

Owner:江西华赣瑞林稀贵金属科技有限公司

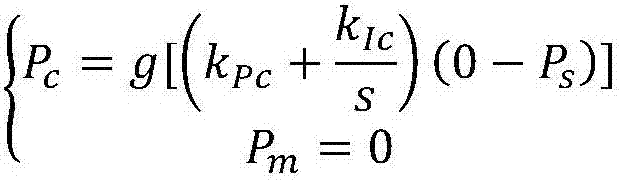

Photovoltaic energy-wind power-methane-based rural household energy system and control method thereof

ActiveCN106877405AMaximize recyclingMaximize recycling effectivelySingle network parallel feeding arrangementsWind energy generationCyclic processMicrogrid

The invention relates to the new energy microgrid technology and is to provide a photovoltaic energy-wind power-methane-based rural household energy system and a control method thereof. According to the system, a methane tank serves as an intermediate device to enable a methane generator, a micro gas turbine and a household gas stove to be connected, and carbon dioxide generated by the micro gas turbine and carbon dioxide generated by the household gas stove are fed back to the methane generator to serve as raw material for generating the methane, thereby realizing a complete chain of methane generation, storage, consumption and exhaust feedback, and forming gas interconnection; and meanwhile, with the methane generator serving as a controllable load and the micro gas turbine serving as a controllable power source, an energy management device carries out power scheduling on the micro gas turbine and the methane generator, and the methane serves as an energy buffer to ensure power utilization stability. In the whole circulation process, lowest carbon emission and maximum utilization of renewable energy sources are realized, thereby protecting environment and helping rural residents to save electricity cost.

Owner:ZHEJIANG UNIV

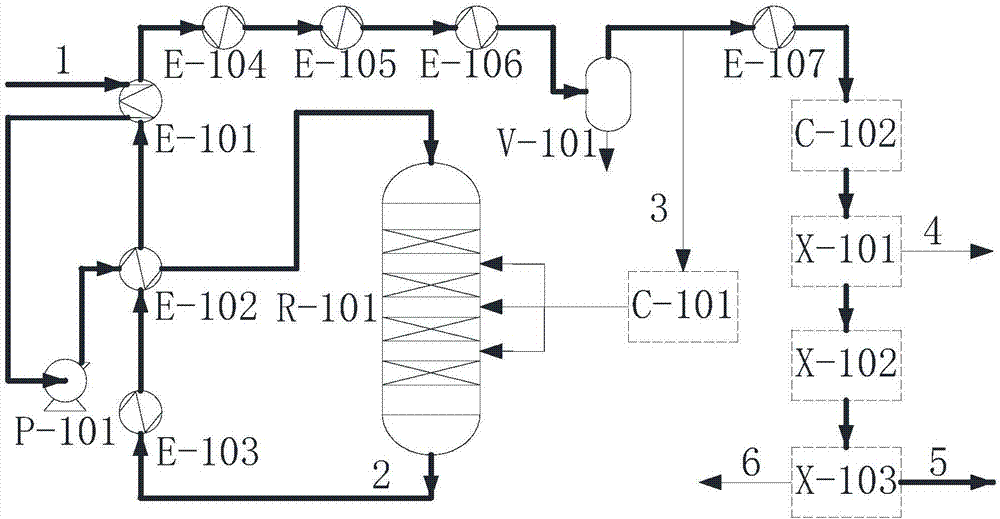

Method for recovering tail gas of propane oxidation preparation of acrylic acid

ActiveCN107162895AAchieving zero emissionsAchieve coolingNitrogen purification/separationOrganic compound preparationGas phaseCatalytic oxidation

The invention provides a method for recovering tail gas of propane oxidation preparation of acrylic acid and belongs to the technical field of acrylic acid tail gas treatment. The method comprises preheating and pressurizing tail gas, feeding the tail gas into an oxidation reactor, carrying out oxidation, orderly treating the reaction tail gas through a steam generator, a tail gas preheater II, a tail gas preheater I, a boiler water preheater and a desalted water preheater, recovering heat, treating the tail gas through a cooler and a gas-liquid separator, returning a part of the gas phase as recycling gas to the oxidation reactor, wherein the recycling gas is used as quenching gas, cooling and pressurizing the other part of the gas phase through a water cooler, carrying out decarburization and drying, feeding the dried gas into a cryogenic separation device, carrying out cryogenic separation to obtain a product containing greater than or equal to 99.9% of propane and fully discharging cryogenic tail gas. Through a catalytic oxidation method, oxygen and volatile organic matters in the tail gas are removed, propane, carbon dioxide and nitrogen gas are recovered and zero emission of the exhaust gas is realized. The method has the advantages of low investment in the process, low wastes, low pollutant discharge and good economic benefits, and provides guarantee for the large-scale industrialization of propane oxidation preparation of acrylic acid.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Method for recovering valuable metal from smoke containing arsenic and conducting arsenic harmless treatment

ActiveCN106756057AReduce contentIdeal open circuitProcess efficiency improvementPregnant leach solutionCatalytic oxidation

The invention relates to a method for recovering valuable metal from smoke containing arsenic and conducting arsenic harmless treatment. The method comprises the following steps that normal-pressure water leaching is conducted; catalytic oxidation of a leaching solution is conducted; arsenic solidification of the oxidized solution is conducted; a leaching residue is washed; and the valuable metal in the washed residue is recovered. By the adoption of the method, soluble arsenic in the smoke is removed through normal-pressure water leaching, trivalent arsenic in the leaching solution is converted into pentavalent arsenic through catalytic oxidation, arsenic in the oxidized solution is converted into stable solid arsenic minerals through synthesis, then the solid arsenic minerals are solidified in a stockpiling or cement solidification mode, the leaching residue is processed through the working procedures of washing, reduction smelting and oxidation blowing, and therefore various valuable elements are recycled to the maximum extent. According to the method, arsenic is removed from the smoke, stibium, lead, bismuth and the like can be left in the residue without arsenic as far as possible, and therefore separation between arsenic and the valuable metal and harmless treatment are achieved. By means of the method, the resource comprehensive utilization ratio is high, the application range of raw materials is broad, the problems that pollution is caused in the conventional technological extraction process, and especially smoke is generated in the lead and zinc smelting process are solved, and the advantages of the method are more obvious.

Owner:CENT SOUTH UNIV

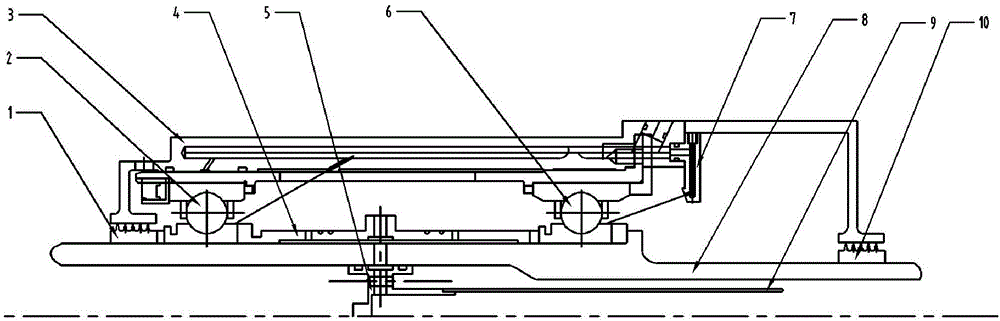

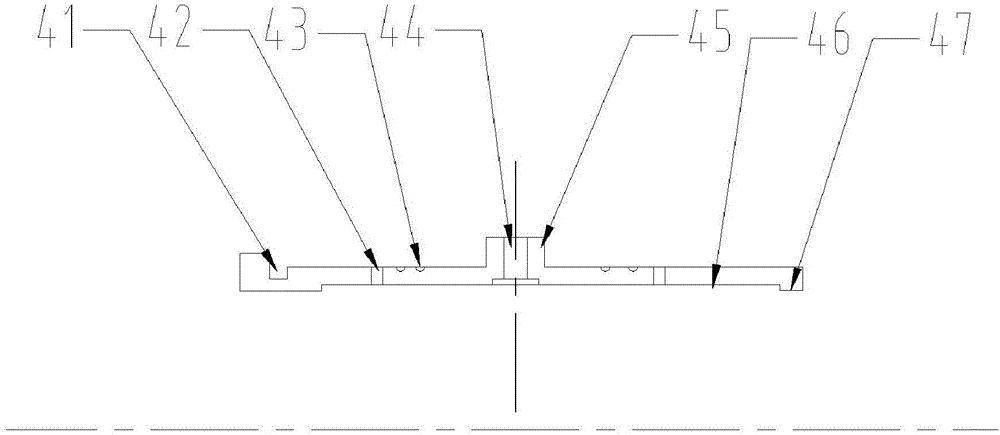

Intelligent sorting trash can

ActiveCN106275949BImprove classificationEasy to recycle laterWaste collection and transferRefuse receptaclesDrive motorEngineering

The invention relates to an intelligent classification dustbin. The intelligent classification dustbin is characterized by comprising a base, a rotating driving mechanism, a center shaft, a rotary table, a classification bin and a bin lid unit, the base and the bottom of the center shaft are fixedly installed, the rotating driving mechanism comprises a driving plate and a driving motor, the driving plate is rotatably installed at the bottom of the center shaft, the rotary table which is located above the driving plate is rotatably installed on the center shaft, the rotary table is connected with the driving plate through a connecting column, the classification bin is installed on the rotary table and comprises multiple bin bodies, the bin lid unit is installed on the upper portion of the center shaft, the bin lid unit comprises a support, a bin lid covering the classification bin and an intelligent starting control panel located on the bin lid, the support is horizontally fixed on the top of the center shaft, the bin lid is installed on the support, and the bin lid is provided with an inlet opening capable of being opened and closed automatically. According to the intelligent classification dustbin, the structural design is scientific and reasonable, garbage can be subjected to detailed classification and recycled, maximized recycling of the garbage can be achieved, bacterial infection can be avoided, and odor dispersion is prevented.

Owner:TIANJIN LIGHT IND VOCATION TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com