Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Iobenzamic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iobenzamic acid is a molecule used as a contrast medium.

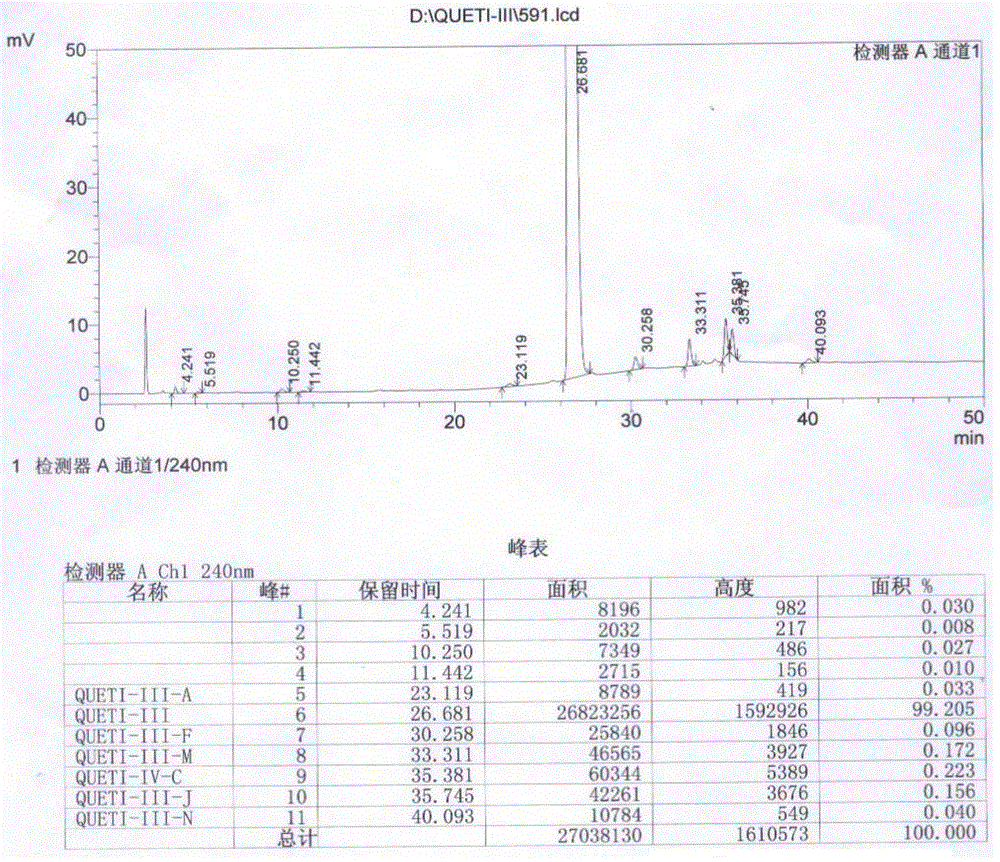

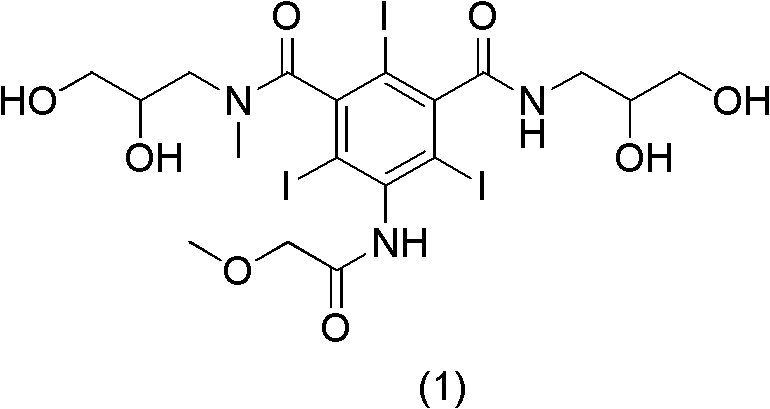

Preparation method of Iopromide

ActiveCN102351735AIncrease productionHigh purityOrganic compound preparationCarboxylic acid amides preparationBenzoic acidTriiodide

The invention relates to a preparation method of Iopromide. 3-methoxy acetamino-5-(2,3-dihydroxy n-propylamine formyl)-2,4,6-triiodide benzoic acid shown as a formula (9) is used as an intermediate to provide a cheaper and more reasonable method for synthesizing Iopromide with high yield and purity.

Owner:ZHEJIANG STARRY PHARMA

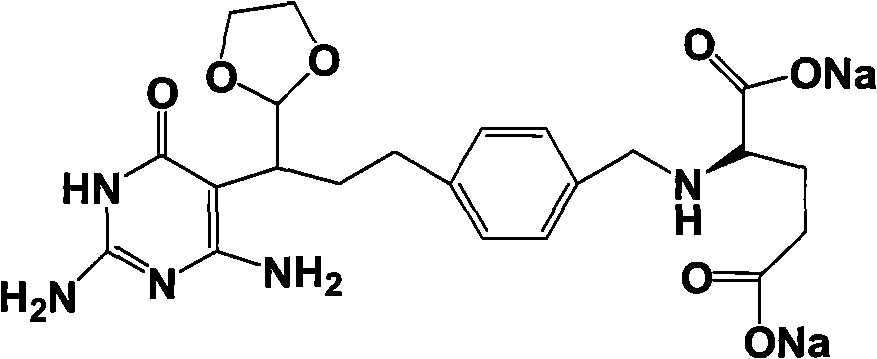

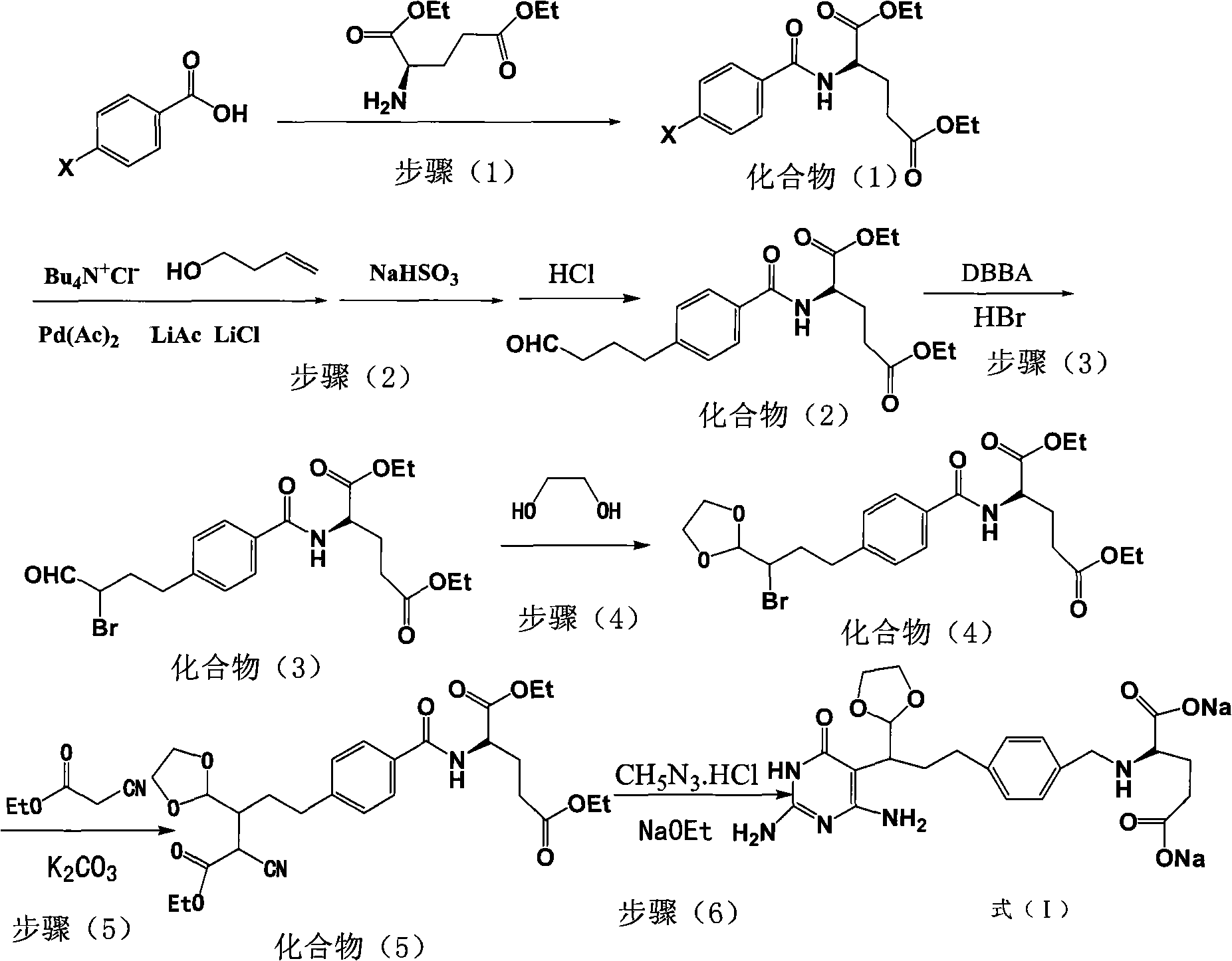

Intermediate of pemetrexed disodium, preparation method thereof and method for preparing pemetrexed disodium thereby

ActiveCN101560206AHigh yieldReduce manufacturing costOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidGlutaric acid

The invention relates to an intermediate of pemetrexed disodium, a preparation method thereof and a method for preparing pemetrexed disodium thereby; and the intermediate is (2-(4-(3-(2,4-diamino-6-oxy-1,6-dihydro-pyridine-5-group)-3-(1,3)dioxolane-2-group-propyl) benzylamine)sodium glutaric acid. The synthesis of the intermediate comprises the following steps: firstly, condensation reaction is conducted on 4-bromobenzoic acid or 4-iodobenzoic acid and L-glutamate diethylester, then Hack reaction is conducted, 4-bromo is replaced and 4-butyraldehyde is formed, then selective bromo replacement is conducted and the 4-butyladehyde is converted into 2-bromobutyraldehyde, and then condensation reaction of aldehyde and ethylene glycol is utilized for protecting the aldehyde, and pyrimidine ring is further synthesized, and finally the intermediate is obtained. Acid hydrolysis ring-closing reaction and sodium hydroxide salification are respectively conducted for once on the intermediate so as to obtain the pemetrexed disodium. The method for preparing pemetrexed disodium in the invention has high yield, low cost and easy operation and is applicable to industrialized production.

Owner:山东立新制药有限公司

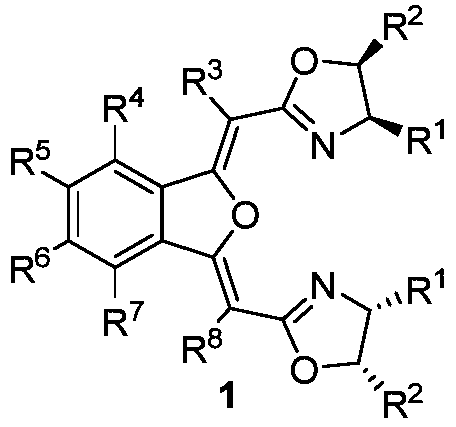

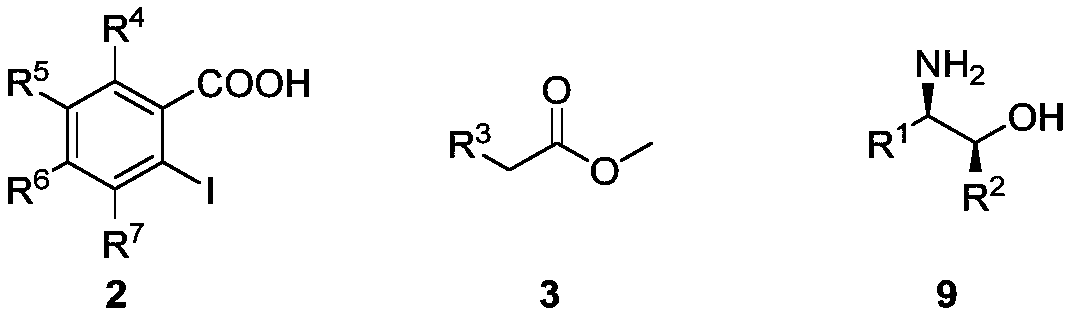

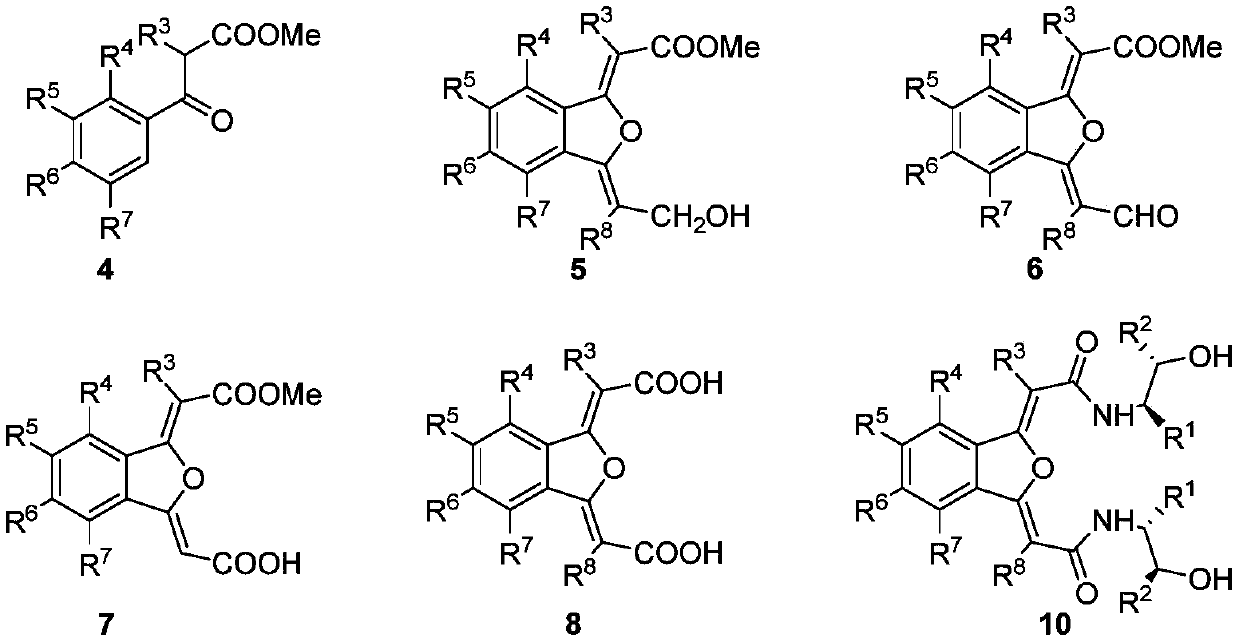

NON type chiral bisoxazoline ligand nd synthesis method and application thereof

ActiveCN111233852ASynthetic conditions are mildEasy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidIobenzamic acid

The invention relates to an NON type chiral bisoxazoline ligand and a synthesis method and application thereof. The ligand has a bisoxazoline structure as shown in a general formula 1, the synthesis method of the NON type chiral bisoxazoline ligand comprises the following steps: taking an o-iodobenzoic acid compound as an initial raw material, performing acylating chlorination on a benzoisofuranylalkylene dicarboxylic acid skeleton prepared through multi-step reaction, performing condensation with chiral amino alcohol, and finally performing cyclization to obtain a ligand 1 which is used for catalytic synthesis of chiral fluorinated beta-ketone ester. Compared with the prior art, the synthesis method disclosed by the invention is simple and efficient, mild in synthesis condition and easy to operate and good in repeatability, and the corresponding metal complex shows good catalytic activity and stereoselectivity in the asymmetric fluorination reaction of beta-ketone ester.

Owner:SHANGHAI NORMAL UNIVERSITY

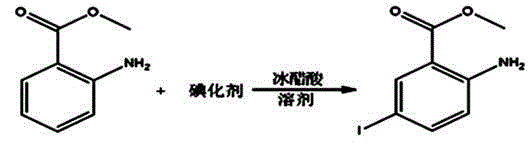

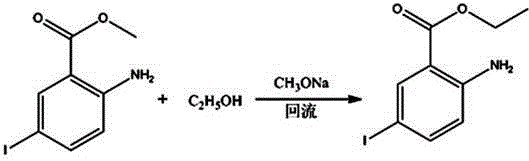

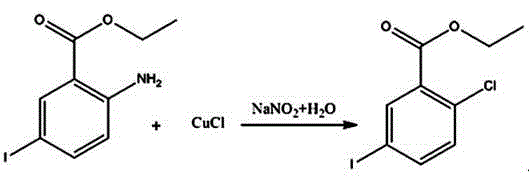

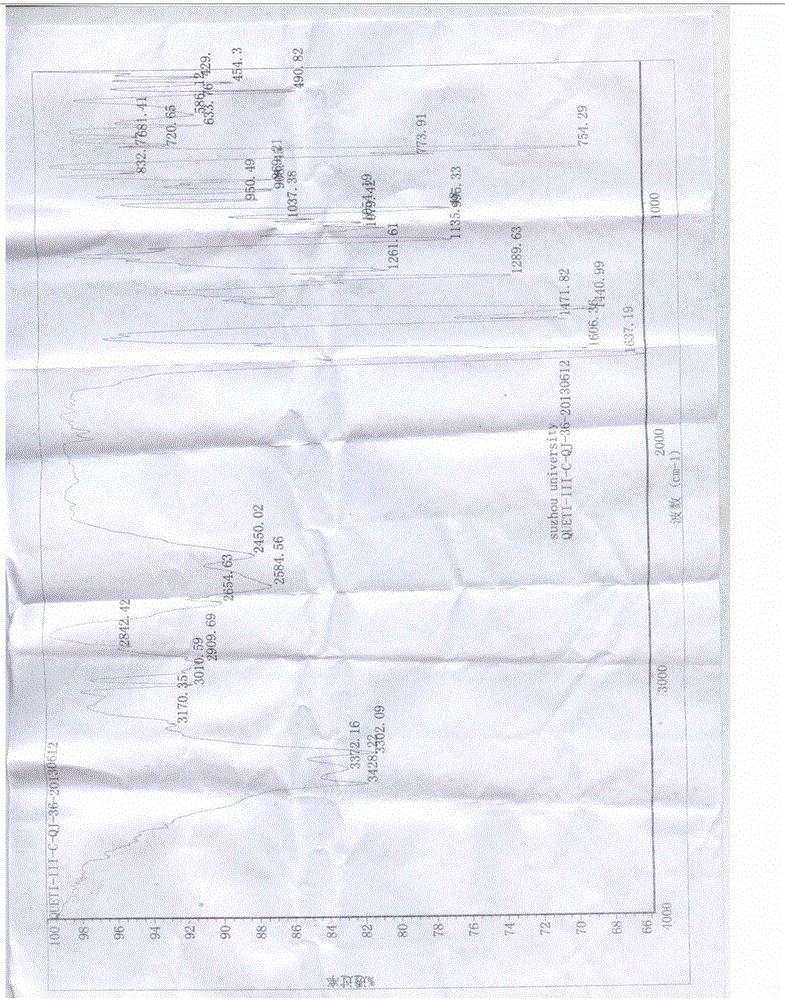

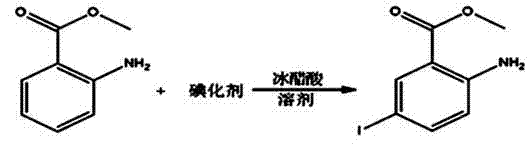

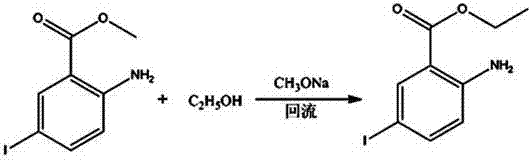

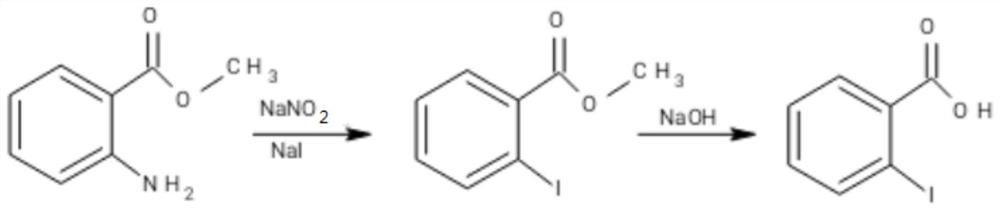

A synthetic method of 2-chloro-5-iodobenzoic acid

InactiveCN104193616ASimple processEasy to operateOxygen-containing compound preparationOrganic compound preparationSandmeyer reactionBenzoic acid

A synthetic method of 2-chloro-5-iodobenzoic acid is disclosed. The target product is obtained by subjecting methyl 2-aminobenzoate to iodination, substitution, a Sandmeyer reaction and hydrolysis under alkaline conditions. The method is characterized by modification or optimization of process steps and parameters based on traditional iodination, substitution, the Sandmeyer reaction and hydrolysis. The method is simple in process, easy in operation, safe in production process, free of pollution, and high in yield of each step. The purity of the product is 95-98%. The total yield of the product is 64-70%.

Owner:姜树林

Preparation method of key intermediate of anti-hepatitis C drug ledipasvir

InactiveCN109678686ARaw materials are easy to getLow priceOrganic compound preparationCarboxylic acid esters preparationN-methylacetamideIobenzamic acid

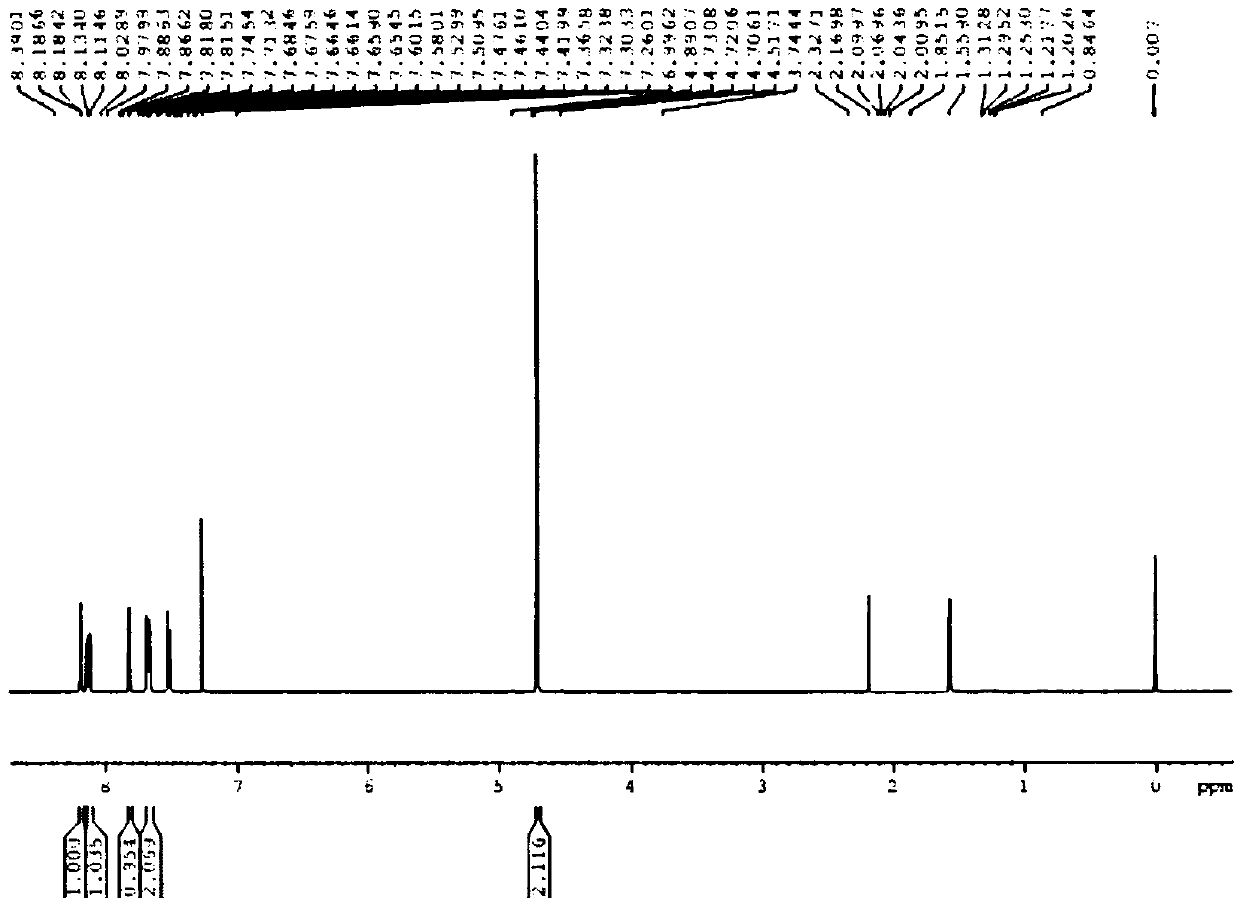

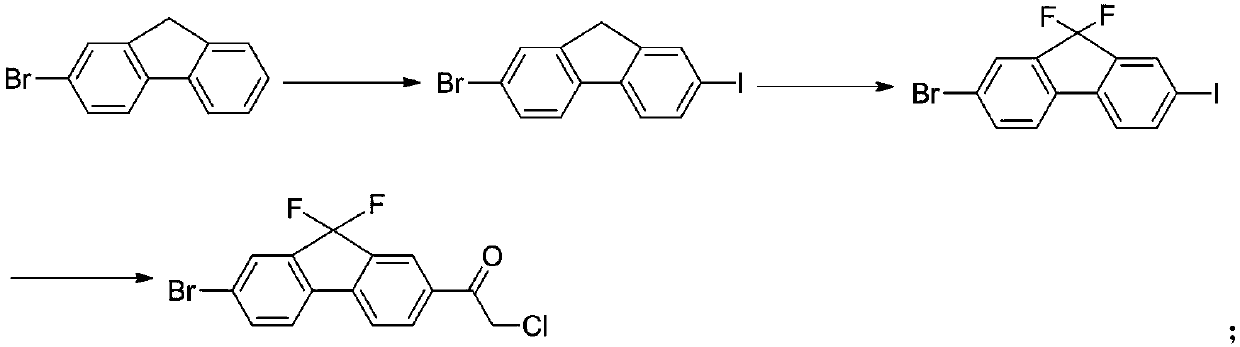

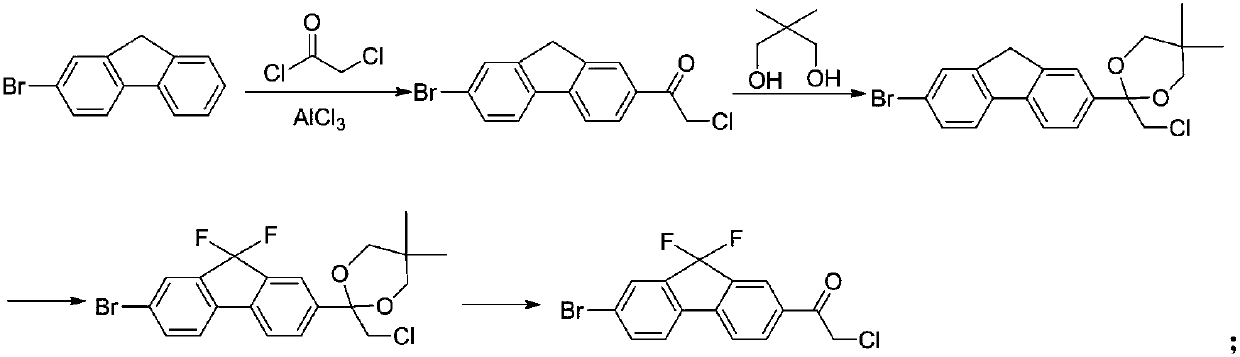

The invention provides a preparation method of a key intermediate 1-(7-bromo-9,9-difluoro-9H-fluoren-2-yl)-2-chloroethanone. The method comprises the steps as follows: 2-amino-5-bromobenzoic acid is taken as a raw material, and subjected to diazotization, iodination,synthesis of 5-bromo-2-iodobenzoic acid, methylation, coupling reaction with phenylboronic acid, ester hydrolysis, acyl chlorination,intramolecular Friedel-Crafts alkylation, carbonyl reduction, iodization, fluorination and final reaction with 2-chloro-N-methoxy-N-methylacetamide to prepare the target product. The process adopts easily available starting raw materials, is low in price and free of hazardous process and has mild reaction conditions..

Owner:IANGSU COLLEGE OF ENG & TECH

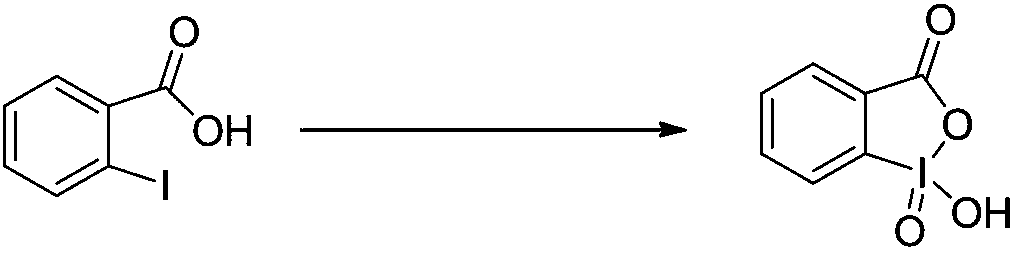

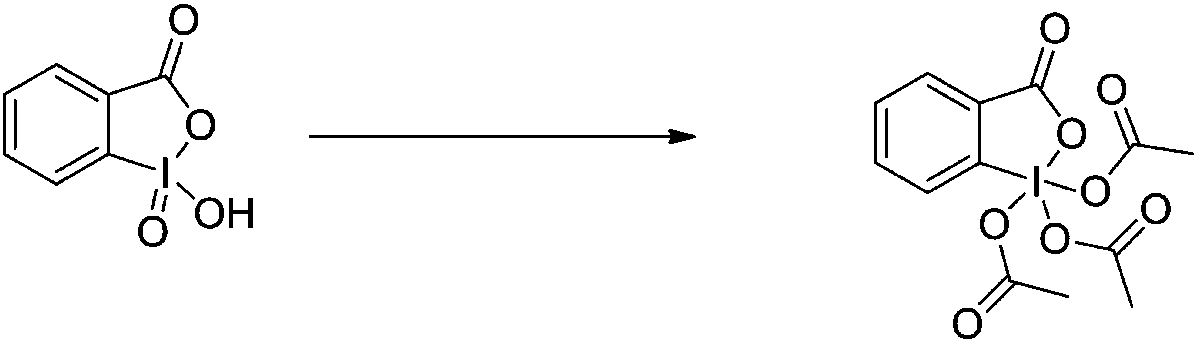

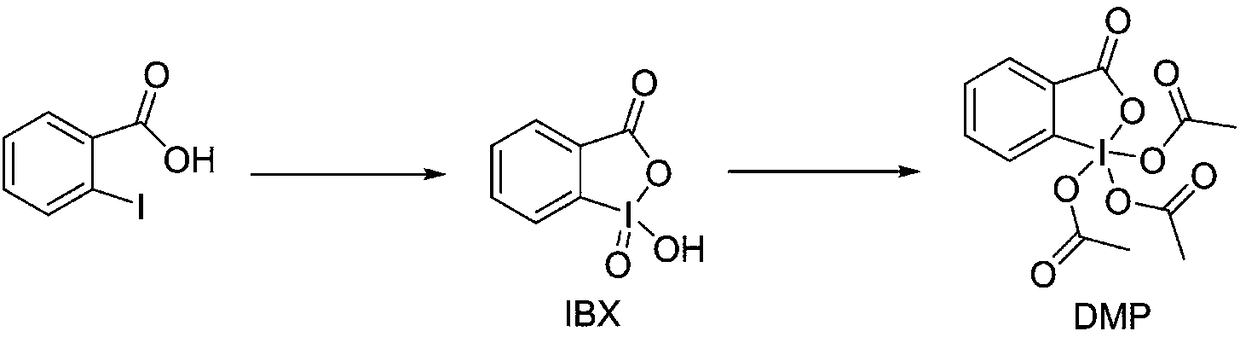

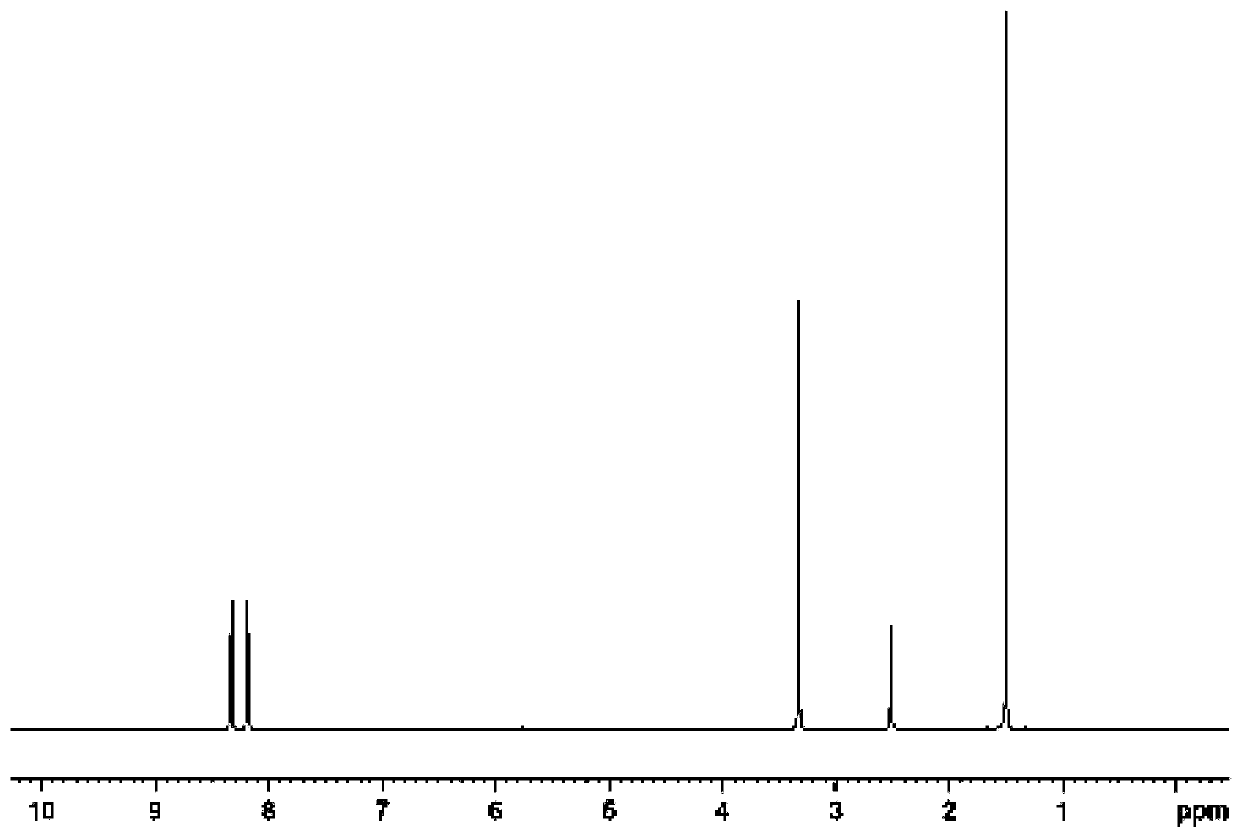

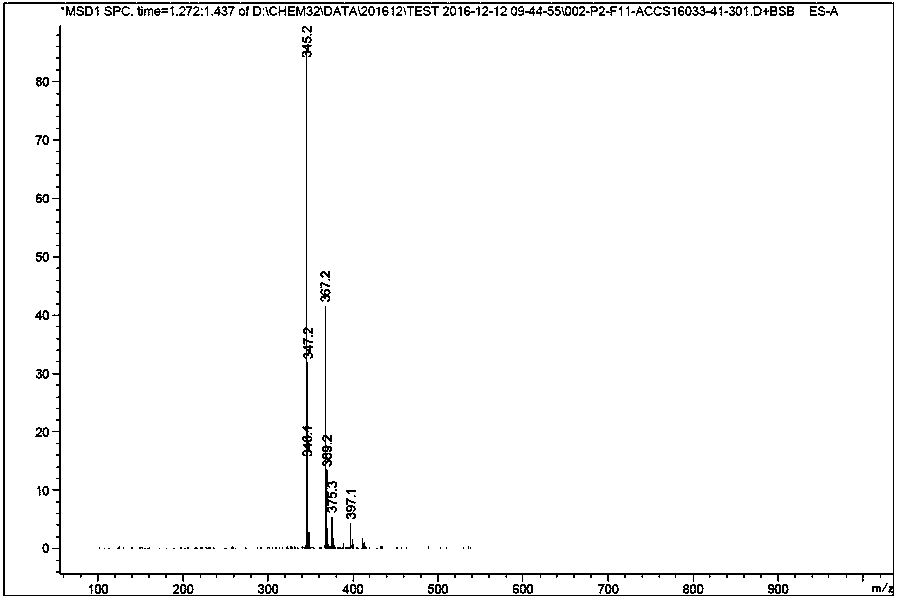

Preparation method of DMP (Dess-Martin periodinane)

The invention discloses a preparation method of a DMP (Dess-Martin periodinane). The target product DMP is obtained through two steps of reactions with 2-iodobenzoic acid, potassium hydrogen persulfate, glacial acetic acid, acetic anhydride and the like as raw materials. The process is convenient and stable, the product is easy to separate and high in yield, the method is environmentally friendly,the comprehensive yield is 82% or above, the raw materials are cheap and easy to obtain, and industrial mass production is facilitated.

Owner:SHANGHAI ZAIQI BIO TECH

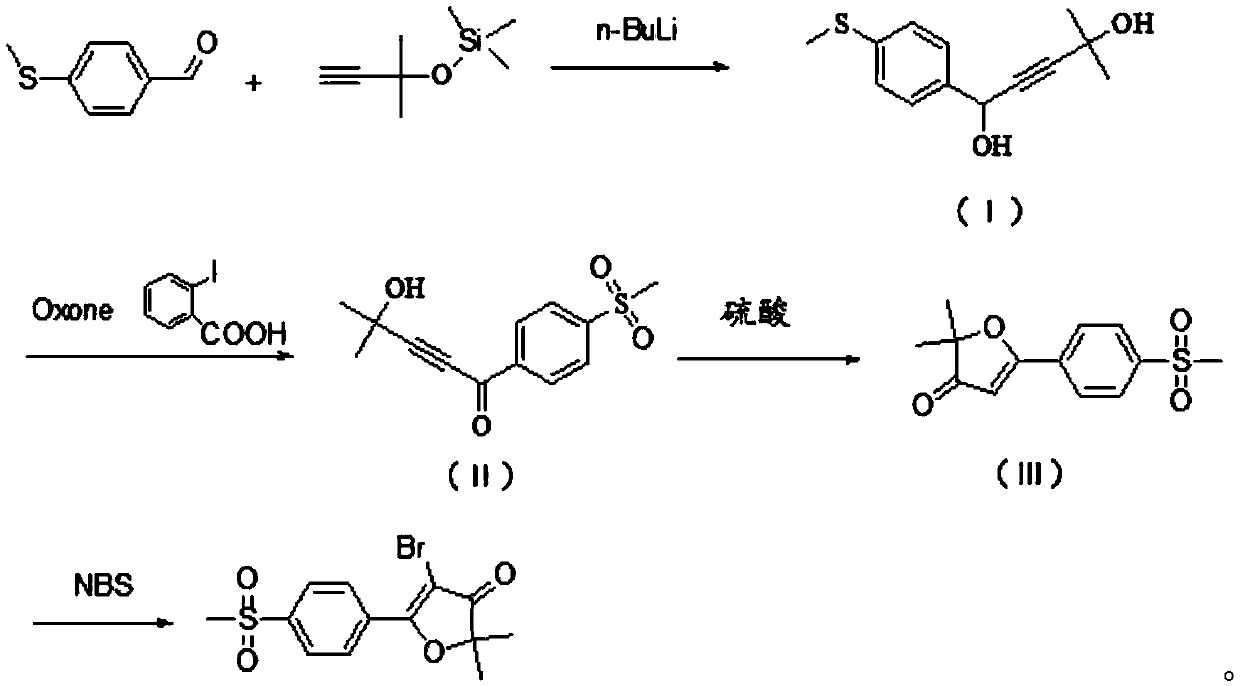

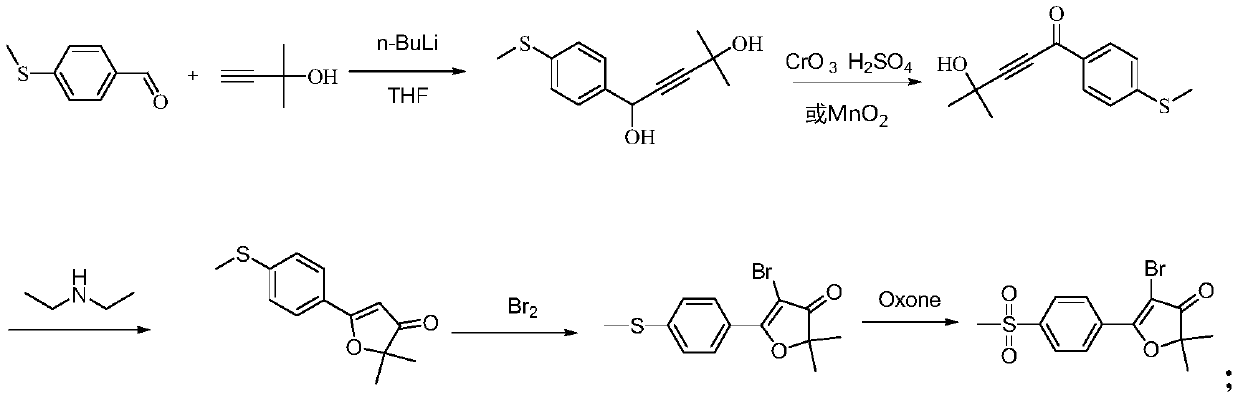

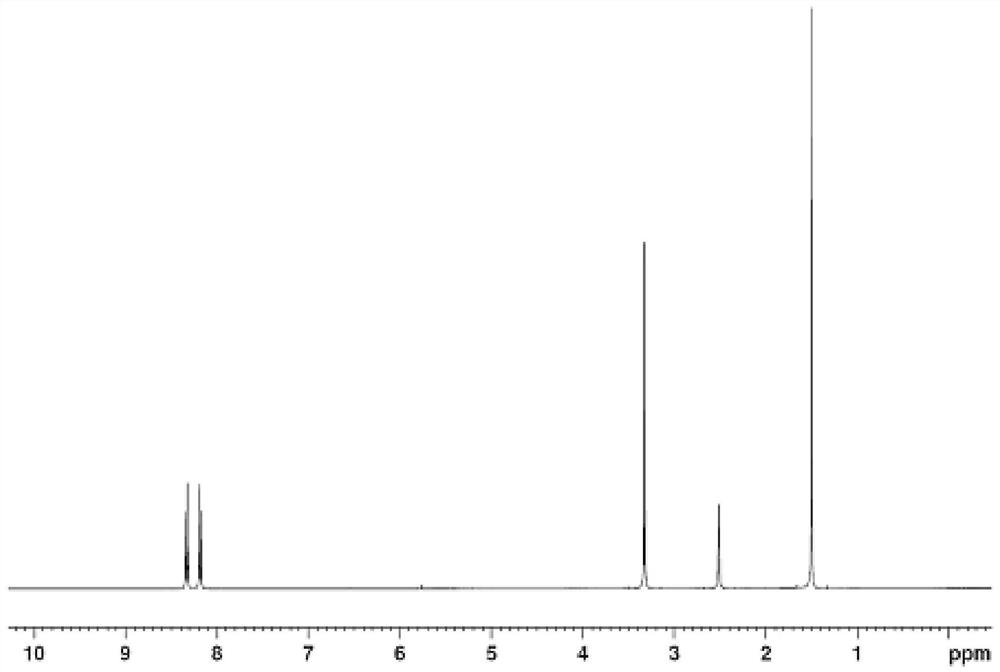

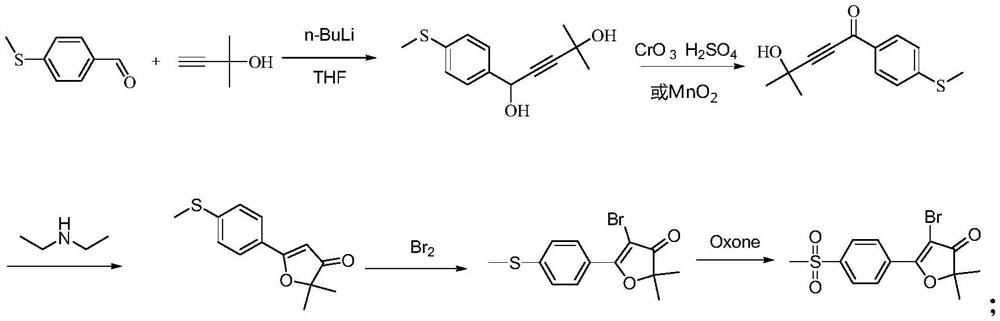

Synthesis method of 5-bromo-2, 2-dimethyl-5-(4-methylsulfonylphenyl) furan-3 (2H)-one

The invention discloses a synthesis method of 5-bromo-2, 2-dimethyl-5-(4-methylsulfonylphenyl) furan-3 (2H)-one, which belongs to the technical field of organic synthesis, and comprises the followingsteps: reacting 4-methylthiobenzaldehyde with a lithium salt of [(1, 1-dimethyl-2-propynyl) oxy] trimethylsilane to generate a compound shown in a formula (I); carrying out oxidation reaction on the compound shown in the formula (I), Oxone and o-iodobenzoic acid to generate a compound shown in a formula (II); reacting the compound shown in the formula (II) with sulfuric acid to generate a compoundshown in a formula (III); and reacting the compound shown in the formula (III) with NBS to obtain a target product. The method has the advantages of simple raw materials, low price, simple operation,short production period, no generation of chromium acidic wastewater, nitrogen-containing wastewater and the like, small environmental protection pressure, and easy realization of industrial production.

Owner:XIAN RUILIAN NEW MATERIAL CO LTD

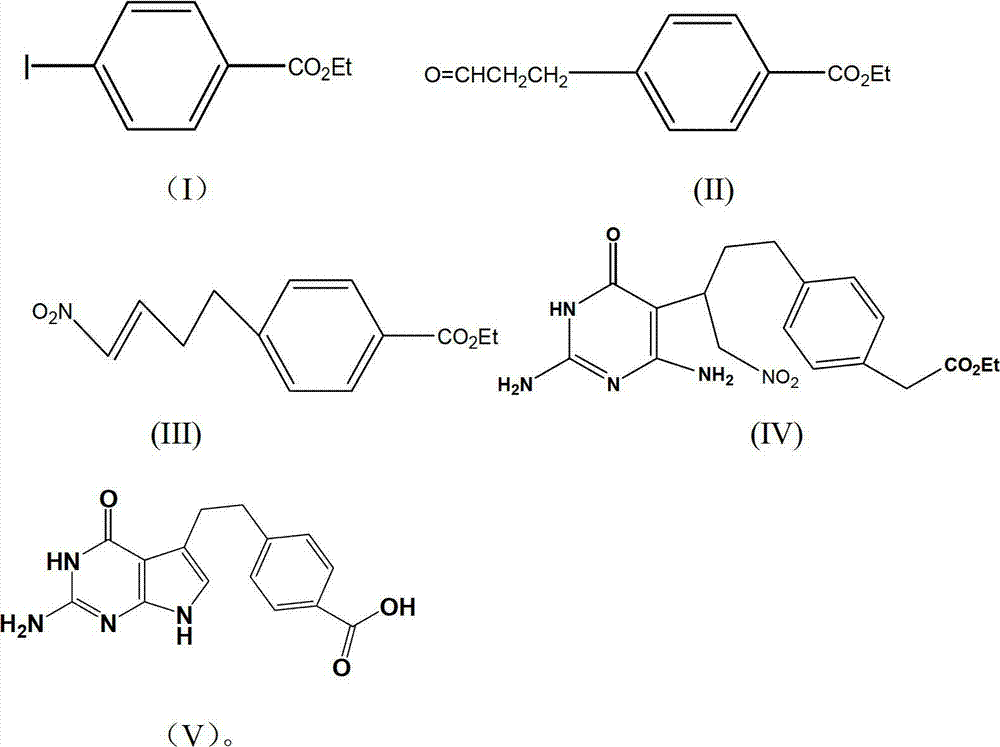

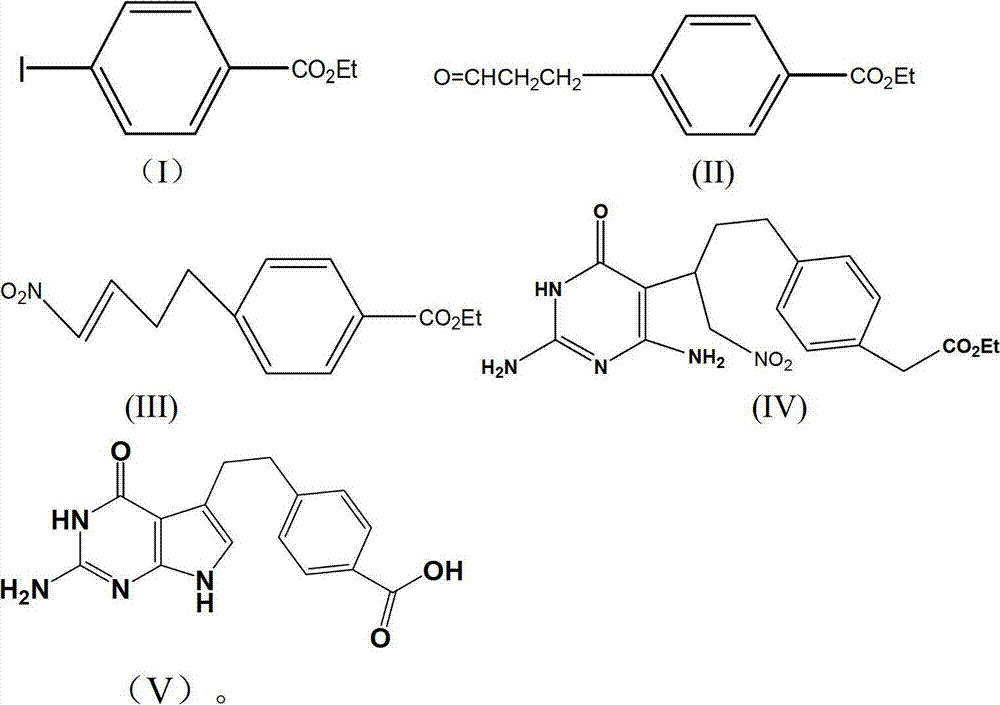

Preparation method of pemetrexed or pemetrexed salt

ActiveCN103030642AHigh yieldImprove reaction efficiencyOrganic chemistryAlkaline earth metalIobenzamic acid

The invention relates to a preparation method of pemetrexed or a pemetrexed salt, more specifically to a high-yield preparation method of pemetrexed or the pemetrexed salt. The preparation method comprises the following steps of (a) with ethyl 4-iodobenzoate of a formula (I) as a raw material, carrying out a Heck reaction with allyl alcohol to obtain a compound of a formula (II); (b) removing one molecule of water after condensing the compound of the formula (II) with nitromethane to obtain a compound of a formula (III); (c) carrying out a Michael addition reaction on the compound of the formula (III) to generate a compound of a formula (IV); (d) carrying out a Nef reaction on the compound of the formula (IV) to obtain a compound of a formula (V); and (e) esterifying the compound of the formula (V) into an active ester to react with L-glutamic acid salt to finally obtain pemetrexed, wherein optionally, pemetrexed can be salified with alkali metal or alkaline-earth metal to obtain corresponding pemetrexed salt, and the step (c) is carried out in a water and tetrahydrofuran solvent system. The preparation method of pemetrexed or the pemetrexed salt disclosed by the invention has the advantages of being capable of remarkably improving the yield of pemetrexed or the pemetrexed salt and shortening the reaction time.

Owner:JIANGSU HANSOH PHARMA CO LTD

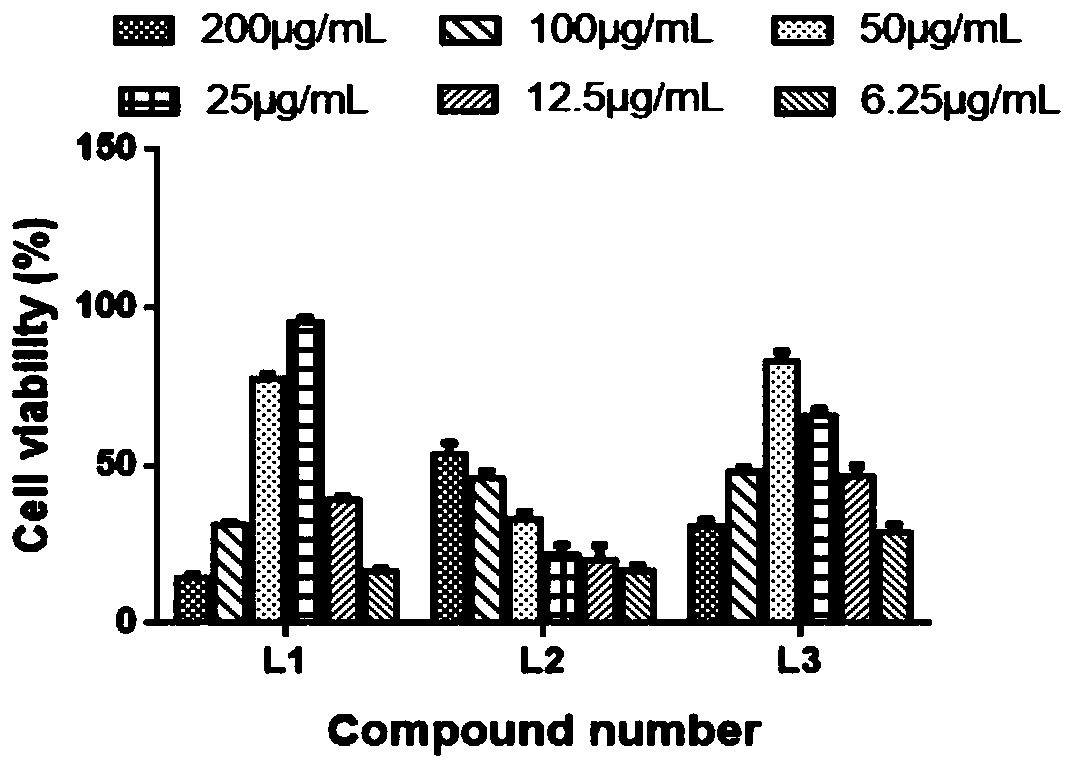

Monoiodobenzoic acid compound and application thereof in resisting ADV7 virus

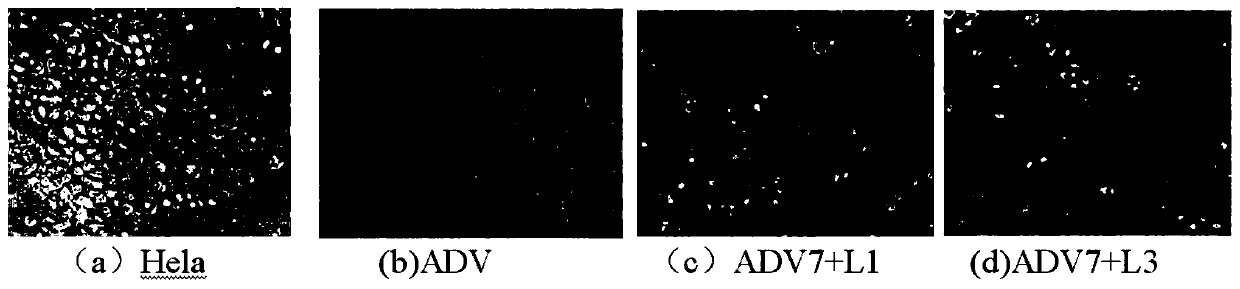

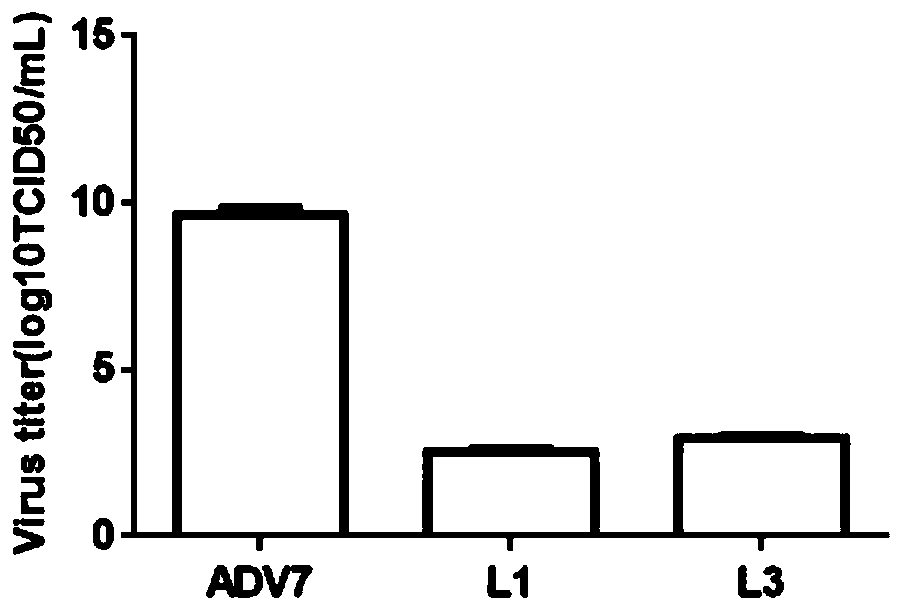

ActiveCN111012770AThe synthesis process is simpleEconomical and fastOrganic active ingredientsAntiviralsBenzoic acidCytopathic effect

The invention discloses a monoiodobenzoic acid compound and an application thereof in resisting ADV7 virus. Through the research experiments on anti-ADV7 activity by monoiodobenzene comprising o-iodobenzoic acid (L1), m-iodobenzoic acid (L2) and p-iodobenzoic acid (L3), the compounds L1 and L3 inhibit cytopathic effect (CPE) generated by ADV7 on host cells Hela, enhance cell survival rate and reduce filial generation virus yield, and can be applied to preparation of anti-ADV7 virus drugs.

Owner:HUBEI UNIV OF TECH

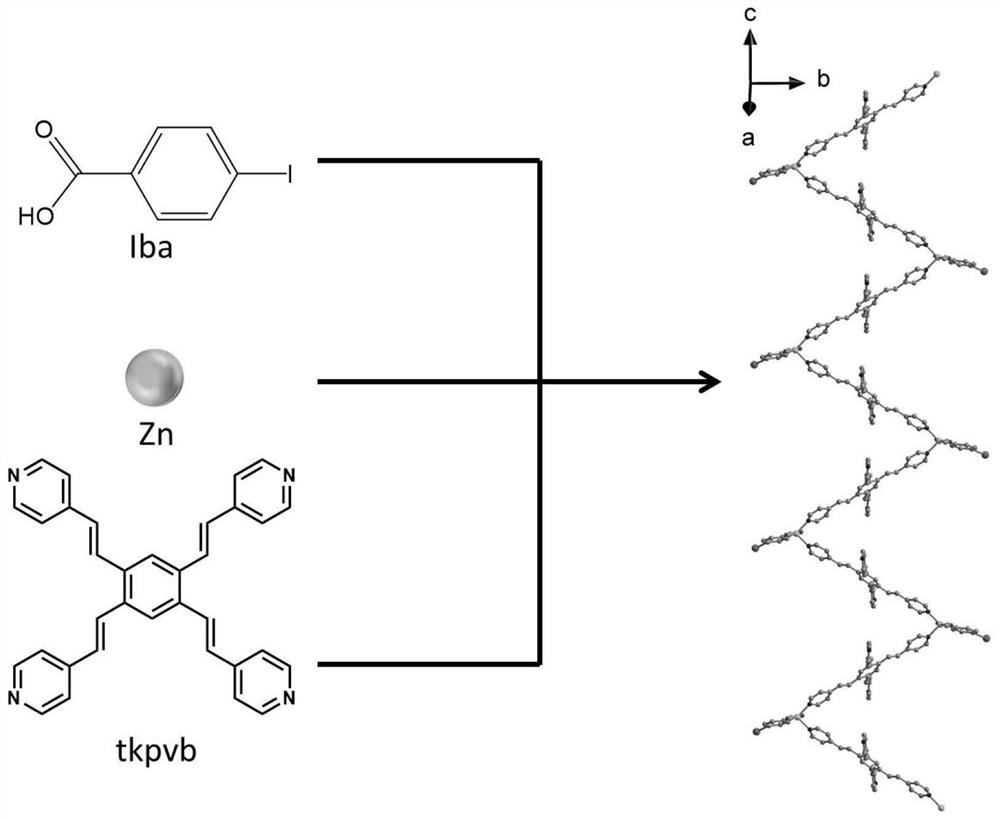

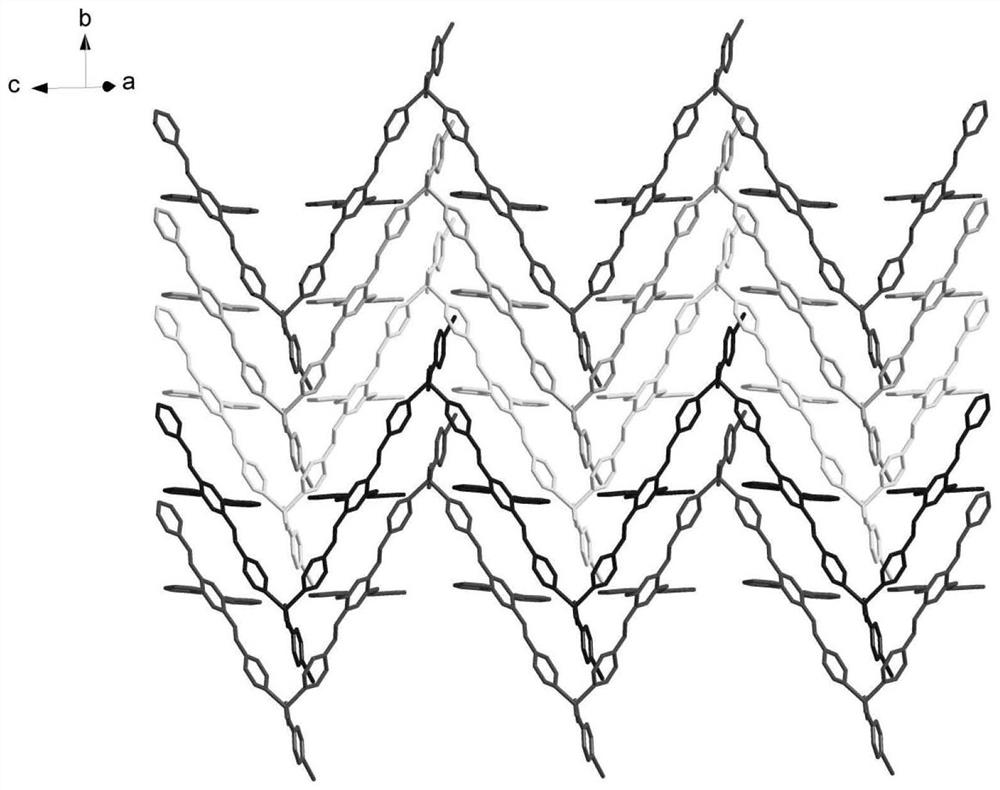

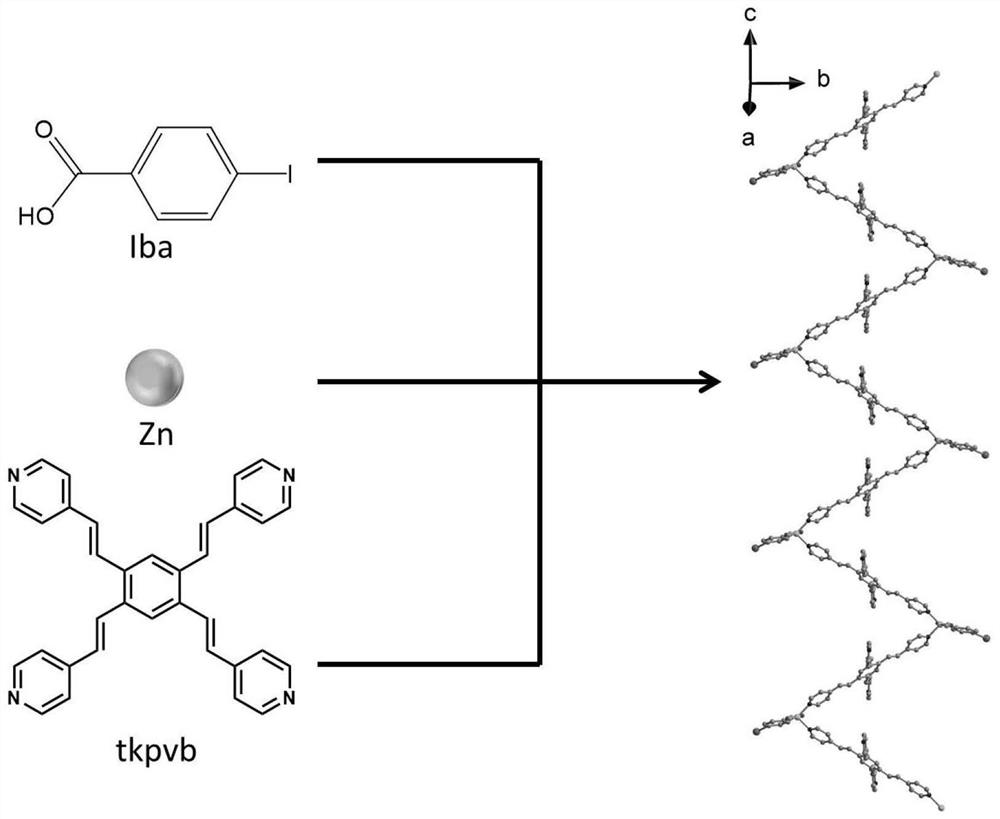

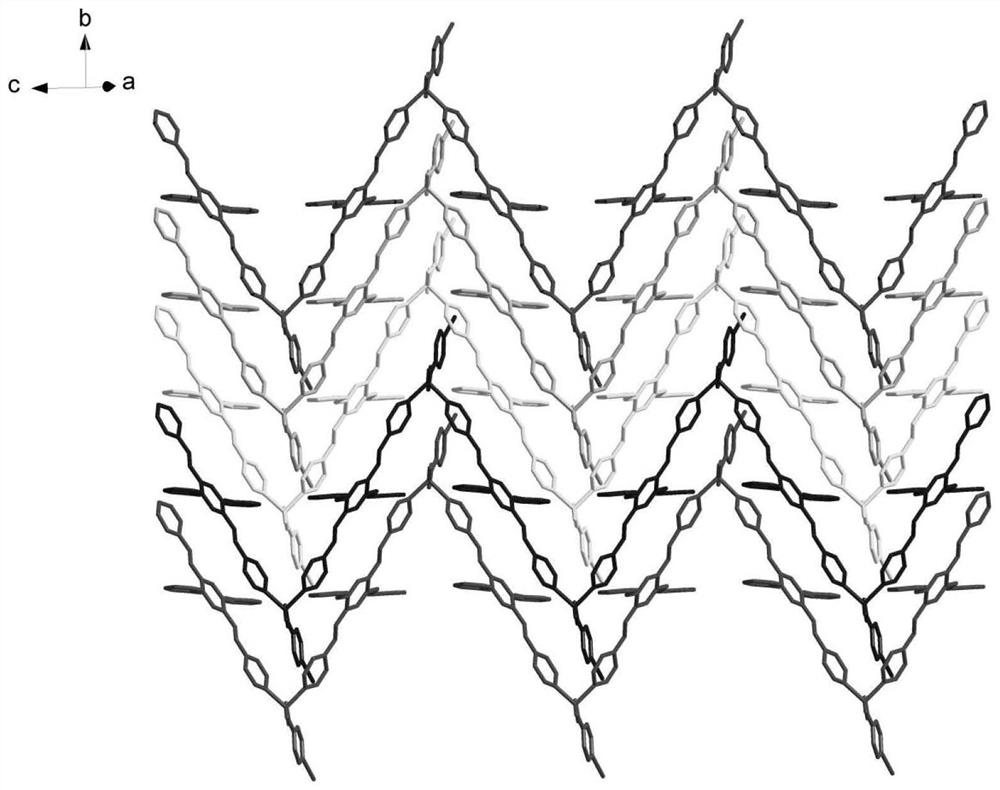

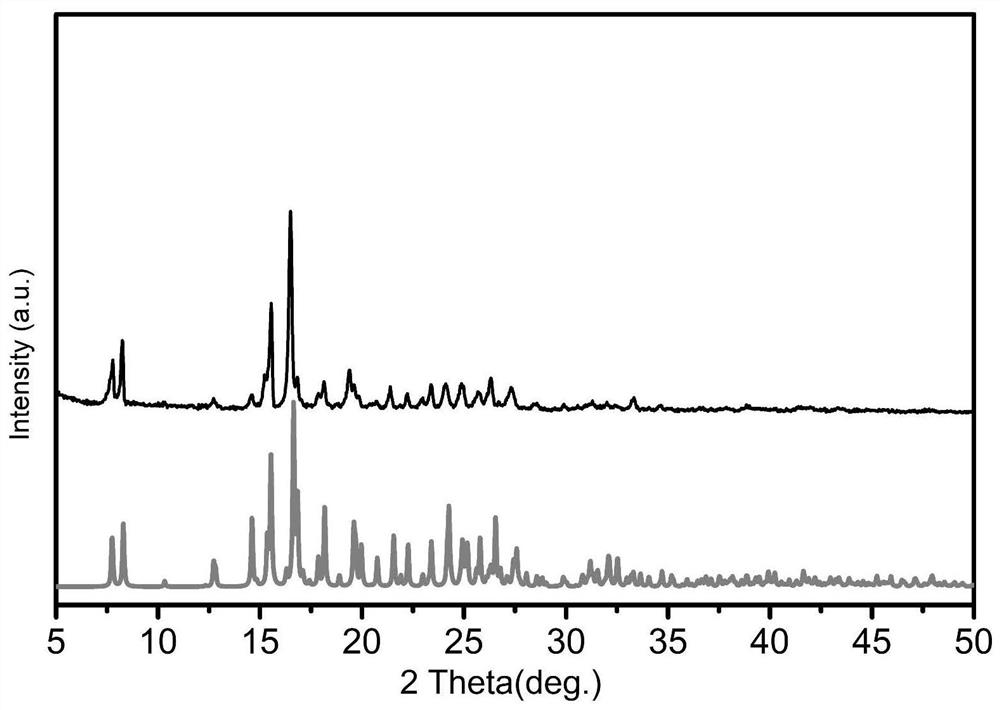

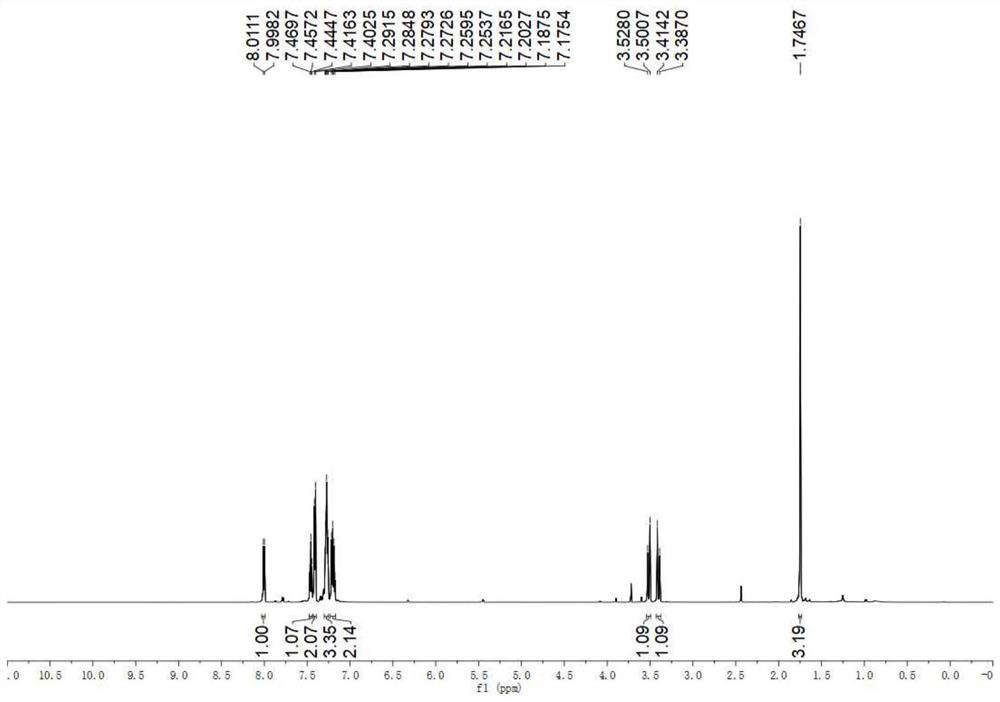

Photoinduced nonlinear expansion coordination polymer and preparation method thereof

The invention belongs to the technical field of photosensitive materials, and particularly relates to a photoinduced nonlinear expansion coordination polymer and a preparation method thereof. The coordination polymer is a bright yellow bulk crystal, and the chemical formula of the coordination polymer is [Zn (iba) (tkpvb) Cl] n1, wherein iba represents p-iodobenzoic acid radical, tkpvb represents 1, 2, 4, 5-tetra ((E)-2-(4-pyridyl) vinyl) benzene, and n is equal to 3000-60000; crystal parameters are as follows: (1) the crystal system is a monoclinic system; (2) the space group is Cc; (3) the values of a, b, c and V are shown in the description, beta is equal to 127.430(4) degrees; (4) Z is equal to 4; (5) F (000) is equal to 1680, R1 is equal to 0.1363, wR2 is equal to 0.3788, and GOF is equal to 1.620; and iba represents a p-iodobenzoic acid radical, tkpvb represents 1, 2, 4, 5-tetra ((E)-2-(4-pyridyl) vinyl) benzene, and n1 is equal to 3000 to 60000. The preparation method of the coordination polymer is simple, the reaction condition is mild, and the light conversion rate is high; and meanwhile, addition reaction can be carried out under irradiation of light with different wavelengths, the light-induced nonlinear expansion performance of the material is shown, and a corresponding isomeride compound is obtained.

Owner:SUZHOU UNIV

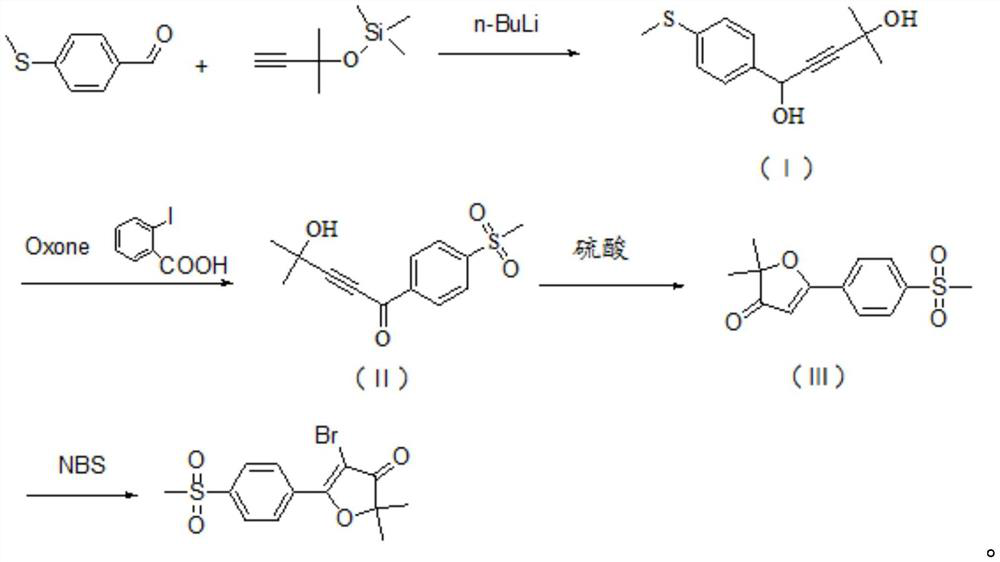

Synthesis of 5-bromo-2,2-dimethyl-5-(4-methylsulfonylphenyl)furan-3(2h)-one

The invention discloses a synthesis method of 5-bromo-2,2-dimethyl-5-(4-methylsulfonylphenyl)furan-3(2H)-one, which belongs to the technical field of organic synthesis and comprises the following steps : 4-methylthiobenzaldehyde reacts with lithium salt of [(1,1-dimethyl-2-propynyl)oxy] trimethylsilane to generate formula (I) compound; formula (I) compound Oxidation reaction with Oxone and o-iodobenzoic acid generates the compound of formula (II); the compound of formula (II) reacts with sulfuric acid to generate the compound of formula (III); the compound of formula (III) reacts with NBS to obtain the target product; the present invention The raw material is simple, the price is low, the operation is simple, the production cycle is short, and the generation of chromium-acid waste water and nitrogen-containing waste water is avoided, the environmental protection pressure is small, and industrial production is easy to realize.

Owner:XIAN RUILIAN NEW MATERIAL CO LTD

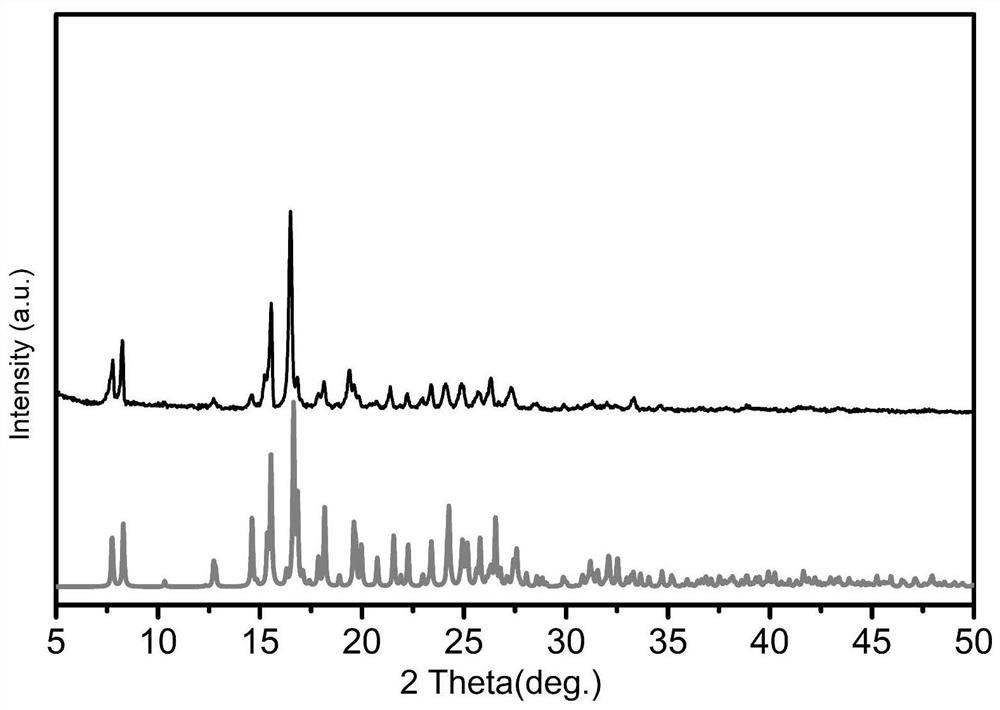

A kind of photoinduced nonlinear expansion coordination polymer and preparation method thereof

The invention belongs to the technical field of photosensitive materials, in particular to a photo-induced nonlinear expansion coordination polymer and a preparation method thereof. The coordination polymer is a bright yellow bulk crystal with the chemical formula [Zn(iba)(tkpvb)Cl] n1 , where iba represents p-iodobenzoate, tkpvb represents 1,2,4,5-tetrakis((E)-2-(4-pyridyl)vinyl)benzene, n=3000-60000; crystallographic parameters are : (1) Crystal system: monoclinic system; (2) Space group: Cc; (3) β=127.430(4)°, (4) Z=4; (5) F(000)=1680, R 1 =0.1363, wR 2 =0.3788, GOF=1.620; wherein, iba represents p-iodobenzoate, tkpvb represents 1,2,4,5-tetrakis((E)-2-(4-pyridyl)vinyl)benzene, n1=3000- 60000. The preparation method of the coordination polymer of the invention is simple, the reaction conditions are mild, and the light conversion rate is fast; at the same time, the addition reaction can occur under the irradiation of light of different wavelengths, the photo-induced nonlinear expansion performance of the material is exhibited, and the corresponding isomeric compounds.

Owner:SUZHOU UNIV

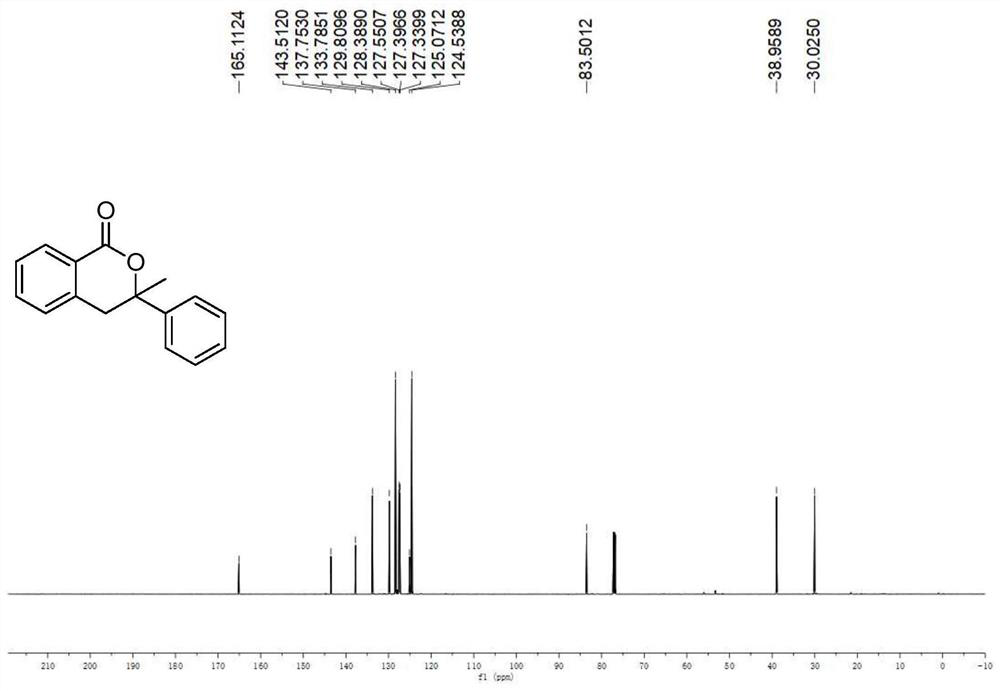

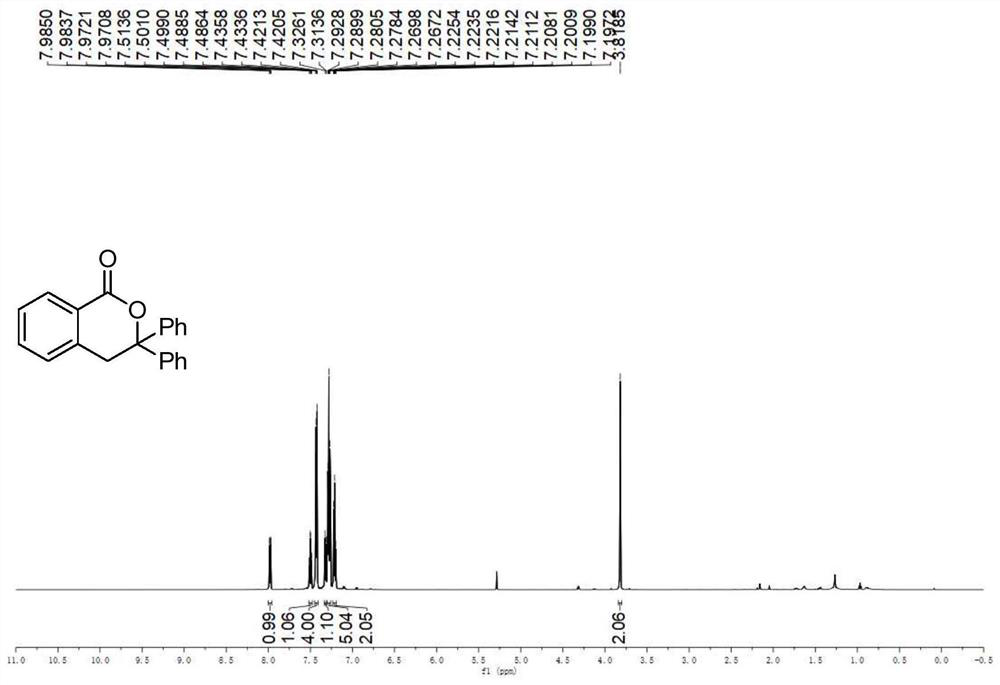

A kind of preparation method of the compound containing isochroman-1-one skeleton

ActiveCN108774206BImprove toleranceThe reaction steps are simpleOrganic chemistryBenzoic acidNatural product

The invention provides a method for preparing a compound containing isochroman-1-one skeleton, specifically methyl o-iodobenzoate substituted with substituents and 1, The 1-disubstituted olefin is used as a raw material, and a compound containing an isochroman-1-one skeleton is prepared through a cross-coupling reaction. The method does not use any directing group, and no additional steps are required to introduce or remove the directing group; the method has a wide range of functional groups and the tolerance of the functional group; the method has the advantages of cheap and easy-to-obtain raw materials, simple steps, and high overall yield of synthesis , The advantages of low total cost of synthesis. The prepared isochroman-1-one skeleton-containing compound has broad application prospects in the synthesis of pesticides, pharmaceutical intermediates, complex natural products, and the like.

Owner:SHANXI UNIV

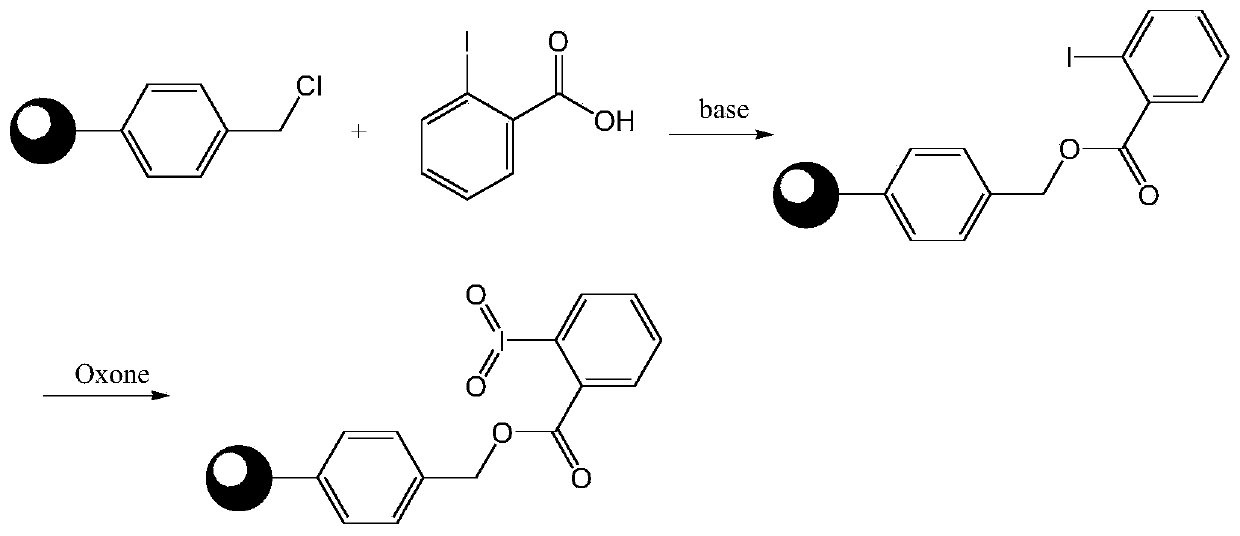

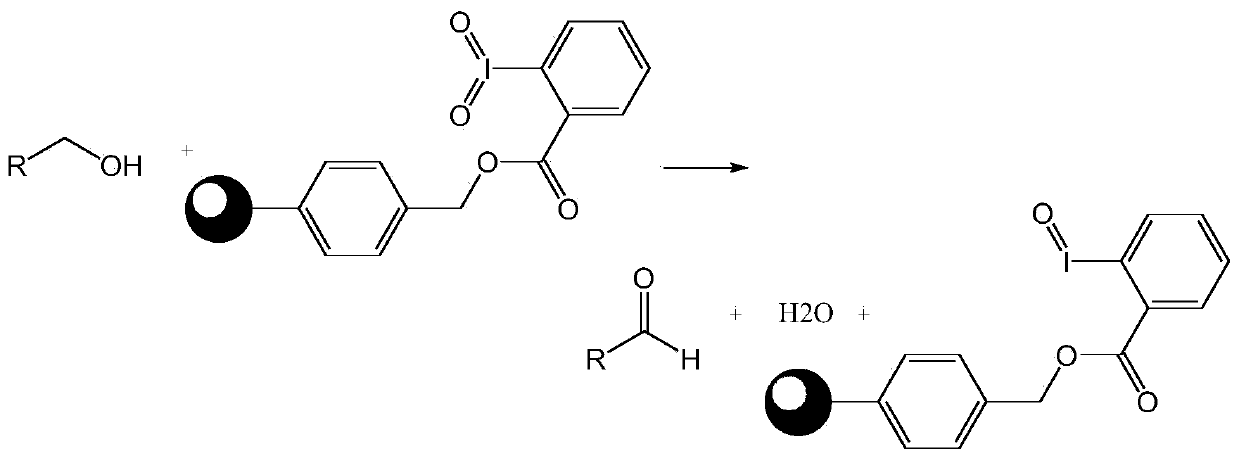

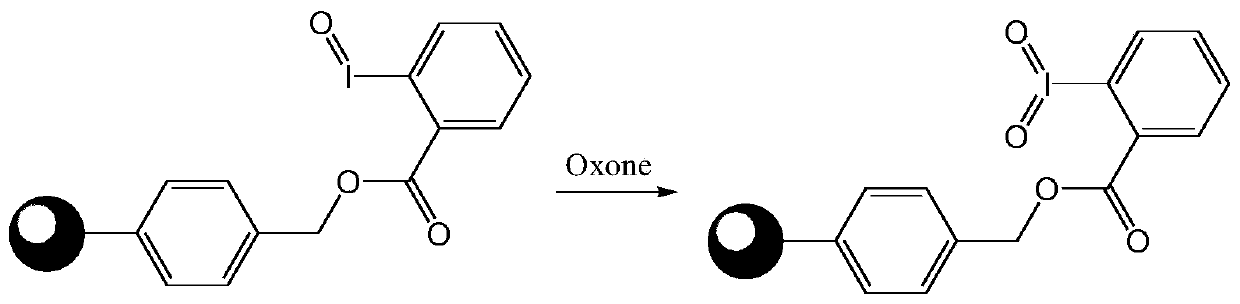

Macromolecule-loaded oxidizing agent containing iodine with high valence, and preparation method and application thereof

PendingCN111116333AEasy to manufactureReduce the impactOrganic compound preparationCarbonyl compound preparationBenzoic acidIobenzamic acid

The invention discloses a macromolecule-loaded oxidizing agent containing iodine with high valence, and a preparation method and an application thereof. 2-iodobenzoic acid is used as a raw material and is loaded on chloromethyl polystyrene resin under an alkaline condition, and iodine is oxidized into high valence by using potassium monopersulfate. The macromolecule-loaded oxidizing agent containing iodine with high valence, prepared through the method can oxidize primary alcohol into aldehyde and, secondary alcohol into ketone, and a reaction byproduct is water; the reaction conditions are mild, the post-treatment is convenient, and the macromolecular-loaded oxidizing agent containing iodine with high valence can be separated from the reaction system only by simple filtration; and the macromolecule-loaded oxidizing agent containing iodine with high valence can be recycled for multiple times, so that the influence on the environment and the production cost are reduced. Besides, the macromolecular-loaded oxidizing agent containing iodine with high valence is simple and convenient to prepare, effectively solves the problems of stability and high cost of a micromolecular iodine-containing oxidizing agent, and has a wide application prospect in the field of fine chemical engineering.

Owner:PANASIA OLAUGHLIN BIO TECH WUHAN CO LTD

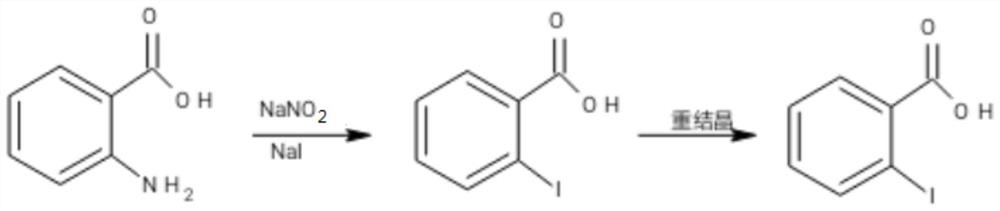

Preparation method of o-iodobenzoic acid

InactiveCN112225662AEase of production and purchaseProduction and operation will not be affectedOxygen-containing compound preparationOrganic compound preparationBenzoic acidBiochemical engineering

The invention relates to a preparation method of o-iodobenzoic acid. According to the invention, methyl anthranilate is used as an initial raw material instead of anthranilic acid, so that the management of I type easily-prepared toxic raw materials of anthranilic acid is avoided; and according to product properties, methyl o-iodobenzoate is purified in a distillation manner by using a new purification method, so that the purity is high, and the safety is high.

Owner:苏州华鑫医药科技有限公司

Organic acid glycidyl ester preparation method

InactiveCN103204829ALow reaction temperatureShort reaction timeOrganic chemistryOrganic synthesisIobenzamic acid

The invention relates to an organic acid glycidyl ester preparation method, and belongs to the field of organic synthesis. According to the method, a catalyst is utilized to catalyze the transesterification of organic ester and glycidol, wherein the organic ester is methyl acrylate, methyl benzoate, 4-nitrobenzoic acid methyl ester, methyl 4-iodobenzoate, 4-(methoxycarbonyl) phenylacetylene or methyl p-methoxy cinnamate; and the catalyst is 4dimethylaminopyridine. The invention has the beneficial effects that the 4dimethylaminopyridine serves as the catalyst, so that the reaction time is effectively shortened, and energy conservation and emission reduction are benefited.

Owner:DALIAN UNIV OF TECH

Clozapine impurity as well as preparation method and application thereof

InactiveCN108129347AHigh purityHigh yieldOrganic compound preparationPreparing sample for investigationHalogenPhosphate

The invention discloses a clozapine impurity and a preparation method thereof. The preparation method comprises the following steps: carrying out a reaction by taking o-iodobenzoic acid and 4-chloro-2-nitroaniline as starting reactants and using one or more of halogen copper salts, carbonates and phosphates as catalysts so as to generate an intermediate SM1; mixing the intermediate SM1, oxalyl chloride and N-methyl piperazine, and using a one-pot method to synthesize an intermediate SM2; reducing the intermediate SM2 in an acid environment by using metal powder so as to obtain the clozapine impurity. The invention discloses a clozapine impurity compound and a preparation method thereof for the first time, and the technology of the preparation method of the impurity appears for the first time; furthermore, the method is simple to operate and easy in aftertreatment; the prepared clozapine impurity is high in purity and yield.

Owner:艾希尔(深圳)药物研发有限公司

Stable and medium-yield oxidant for oil production and preparation method of stable and medium-yield oxidant

PendingCN114854446AStable in natureStable physical and chemical propertiesHydrocarbon oils refiningSodium bicarbonateBenzoic acid

The invention discloses a stable and medium-yield oxidant for oil production and a preparation method thereof, and the stable and medium-yield oxidant comprises the following components in parts by weight: 3-6 parts of potassium permanganate, 20-30 parts of a 0.5 mol / L potassium hydrogen persulfate aqueous solution, 5-8 parts of sodium chlorate, 10-15 parts of 2-iodobenzoic acid, 3-5 parts of a stabilizer, 1-2 parts of an accelerant, 1-2 parts of a buffer agent, 10-15 parts of ammonium peroxydisulfate, 3-5 parts of 3-(2, 3-epoxypropoxy) propyltrimethoxysilane and 100-120 parts of a high-boiling-point solvent. 1-5 parts of a 3% sodium bicarbonate aqueous solution and 200 parts of pure water. Taking a strong oxidant potassium permanganate as a raw material to react with a potassium hydrogen persulfate aqueous solution and sodium chlorate to obtain a first preparation participant; according to the method, 2-iodobenzoic acid is used for preparing turbid liquid, the turbid liquid and a first participant are stirred, washed and dispersed and then cooled to separate out a product, the prepared oxidizing agent is stable in property, the viscosity of the turbid liquid is controlled through ionization, and the purity of the oxidizing agent in the preparation process is further controlled.

Owner:江苏品和石油科技有限公司

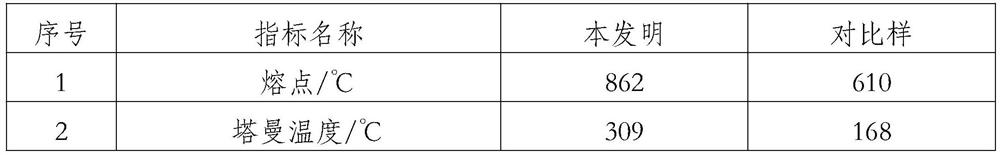

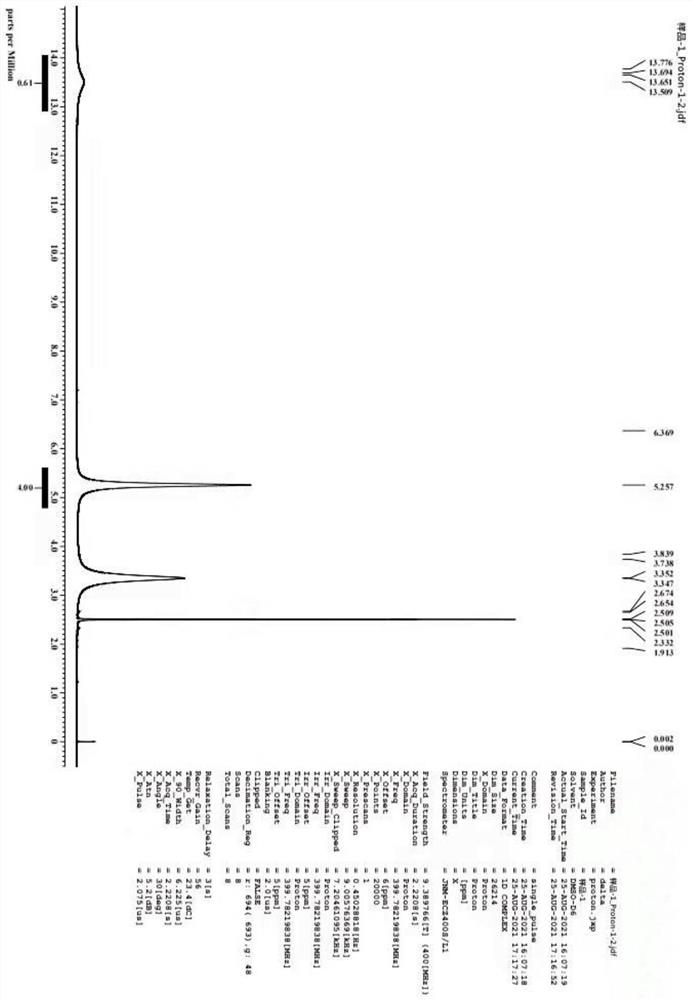

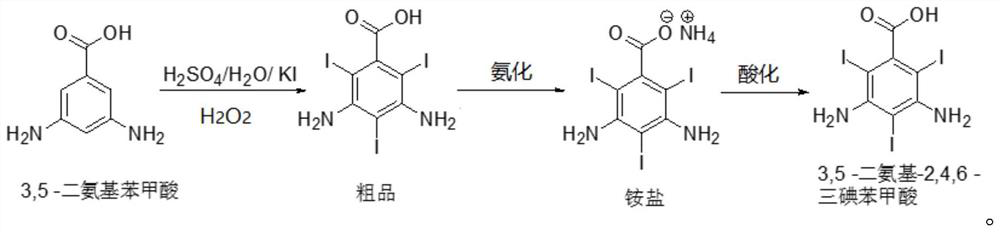

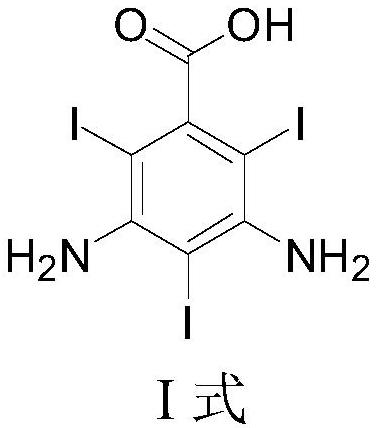

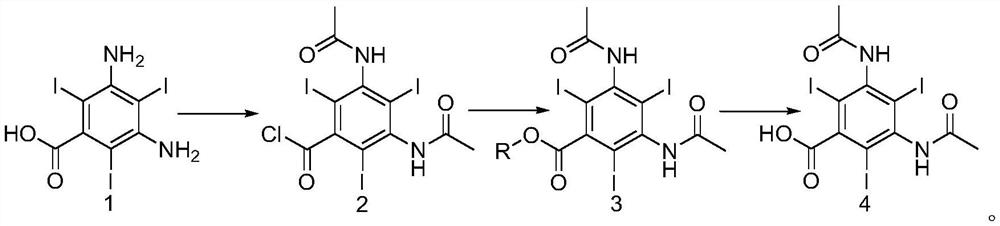

Synthesis method of key intermediate of diatrizoic acid

PendingCN114213268AReduce usageLow production costOrganic compound preparationAmino-carboxyl compound preparationBenzoic acidIobenzamic acid

The embodiment of the invention relates to a synthesis method of a key intermediate of diatrizoic acid, the intermediate is 3, 5-diamino-2, 4, 6-triiodobenzoic acid, and the synthesis method is characterized by comprising the following steps: taking 3, 5-diaminobenzoic acid, sulfuric acid, potassium iodide and hydrogen peroxide as reactants, and reacting in a solvent environment to prepare the 3, 5-diamino-2, 4, 6-triiodobenzoic acid. A 2, 6-triiodobenzoic acid crude product is obtained; then, the 3, 5-diamino-2, 4, 6-triiodobenzoic acid crude product is subjected to ammoniation, and ammonium salt is obtained; and acidifying the ammonium salt to obtain the intermediate 3, 5-diamino-2, 4, 6-triiodobenzoic acid. In the embodiment, a novel method for synthesizing the key intermediate of the diatrizoic acid is provided, the production cost can be effectively controlled, toxic chlorine unfriendly to the environment is prevented from being used, meanwhile, a dangerous reagent potassium iodate is prevented from being used, the reaction is safer, and the method is more suitable for industrial production.

Owner:安康市农业科学研究院

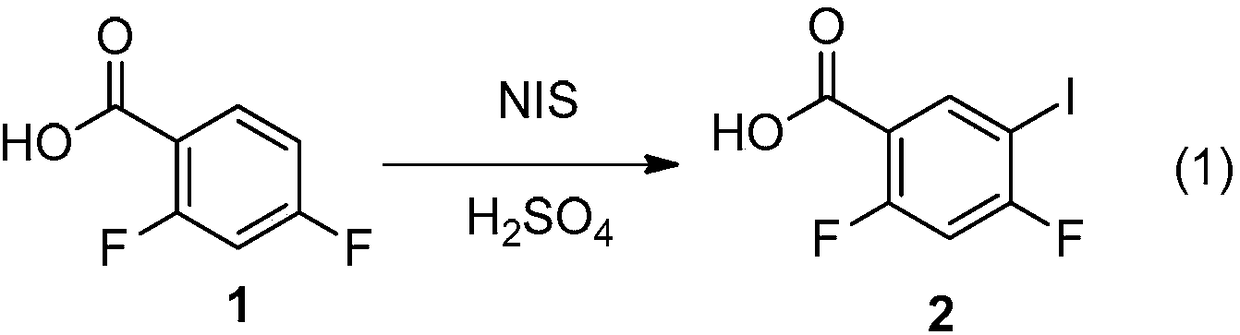

A kind of preparation method of 2,4-difluoro-5-iodobenzoic acid

ActiveCN106008195BMild temperatureSimple post-processingOrganic compound preparationCarboxylic compound preparationIobenzamic acidIodination reaction

The invention discloses a preparation method of 2,4-difluoro-5-iodobenzoic acid. 2,4-difluorobenzoic acid is taken as a starting material, sodium percarbonate and elemental iodine are taken as green iodination reagents, a mild iodination reaction is performed under an acidic condition, and a high-purity target product is obtained. The synthetic process is environment-friendly and suitable for large-scale industrial production, and aftertreatment is convenient.

Owner:苏州智高嘉华科技有限公司

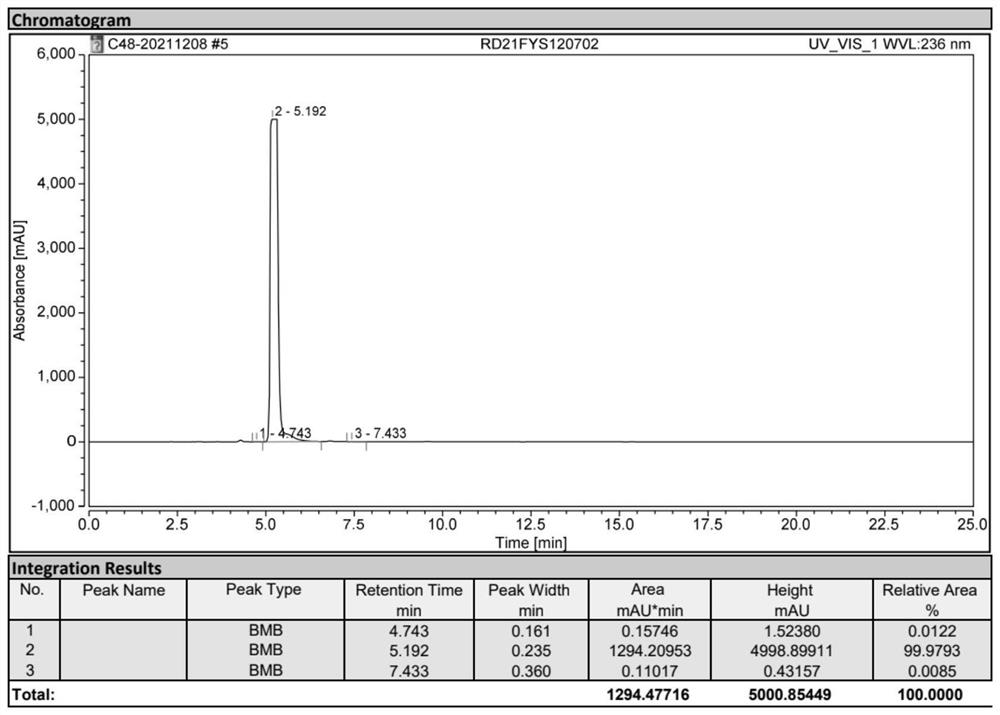

Synthesis method of diatrizoic acid

PendingCN114478295AAvoid Incomplete Response ProblemsThree wastes lessOrganic compound preparationCarboxylic acid amide separation/purificationBenzoic acidIobenzamic acid

According to the synthesis method of the diatrizoic acid, 3, 5-diamino-2, 4, 6-triiodobenzoic acid serves as a raw material, an acyl chloride compound is prepared through an acyl chloride and amidation one-pot method, then esterification and hydrolysis are conducted through lower alcohol, dissolution is conducted in an ammonia water-methanol solution, and acid precipitation is conducted to obtain a finished diatrizoic acid product. According to the method, one-time recrystallization is needed, three wastes generated in the recrystallization process are greatly reduced, the yield is greatly improved (the molar yield can reach 80% or above), and the reaction cost is reduced.

Owner:ZHEJIANG HAIZHOU PHARMA CO LTD

Preparation method of 1-fluorin-6-iodo-benzoic acid

The invention provides a preparation method of 1-fluorin-6-iodo-benzoic acid. The 1-fluorin-6-iodo-benzoic acid is synthesized by taking 1-fluorin-6-iodo-methyl formate as a raw material and taking methanol as a solvent. The method has the advantages of reaction operability, easiness, practicability and industrial production application value.

Owner:SHANGHAI SINOFLUORO SCI

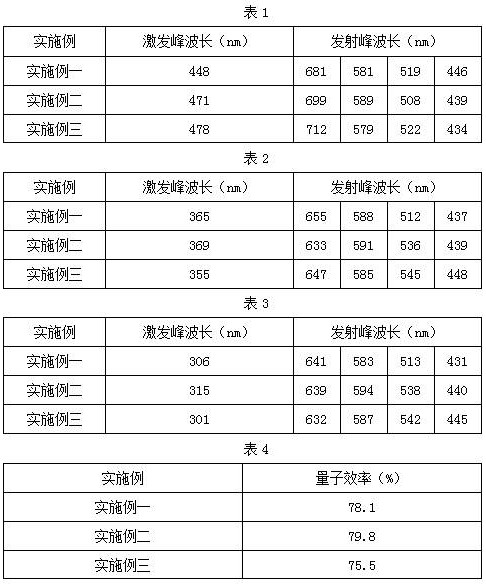

Novel OLED luminescent material for display equipment and preparation method of novel OLED luminescent material

PendingCN112510158AImprove quantum efficiencySolving the technical problem of quantum inefficiencySolid-state devicesSemiconductor/solid-state device manufacturingBenzoic acidFluorescence spectra

Owner:李梦林

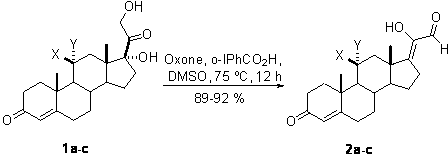

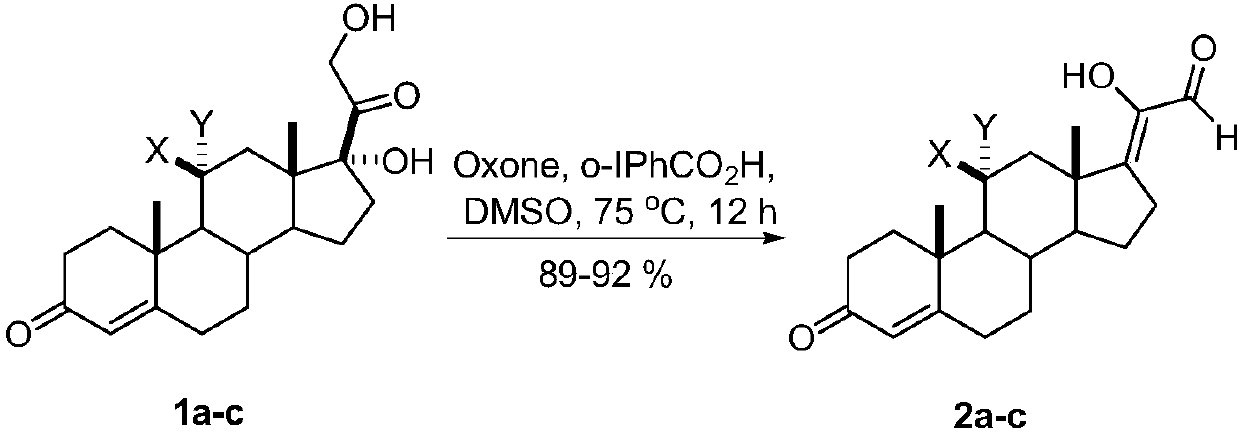

Synthetic method of 17z-(1-hydroxyl-2-oxo-1-ethylene) androstenone derivatives

Owner:TAIZHOU POLYTECHNIC COLLEGE +1

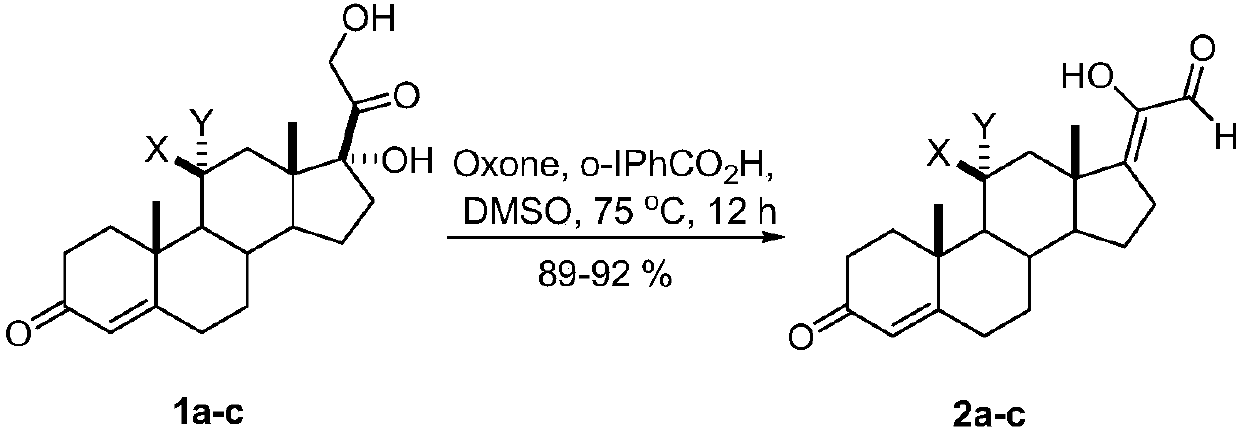

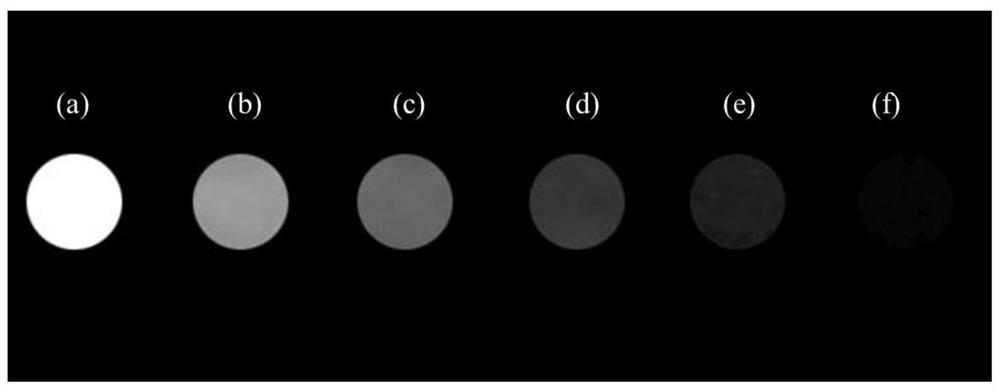

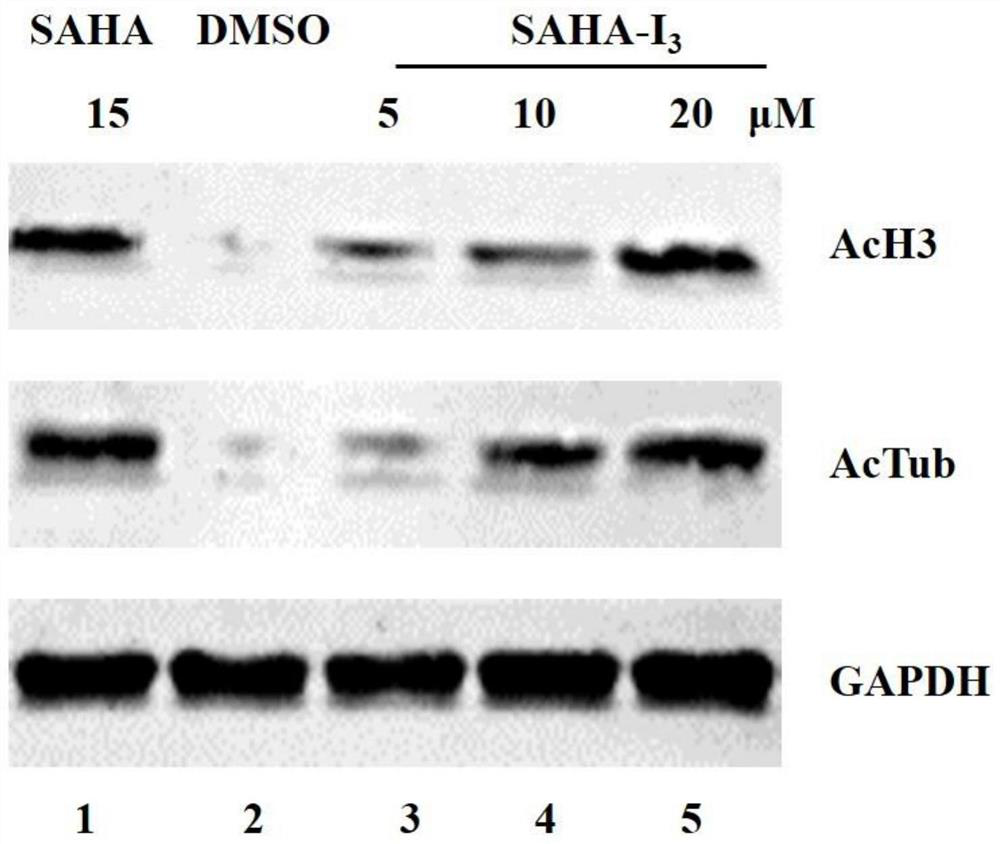

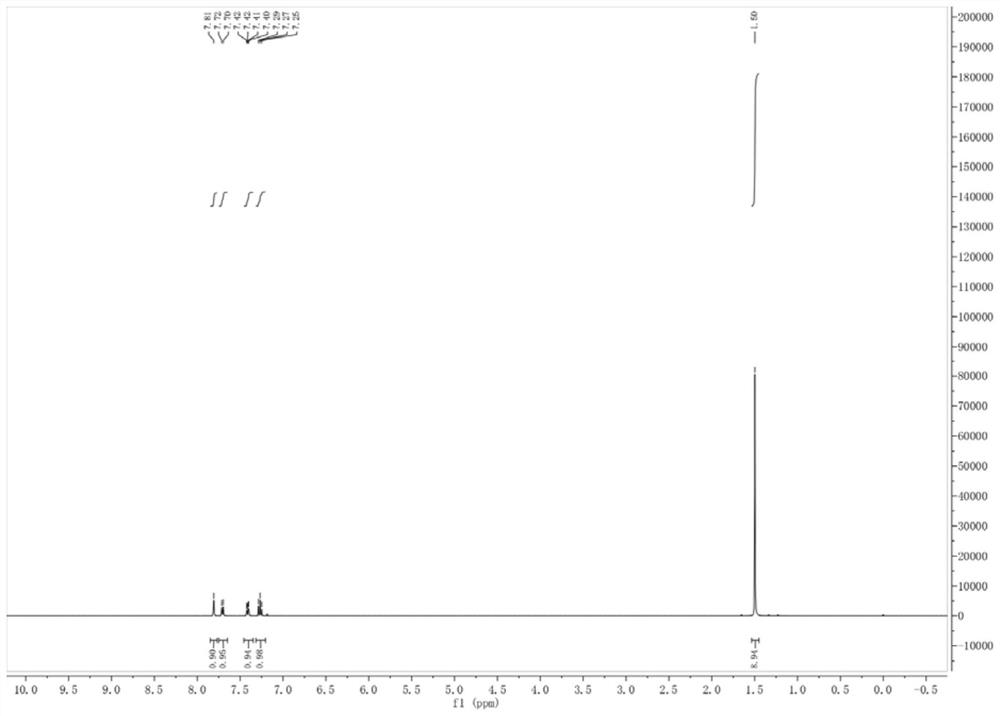

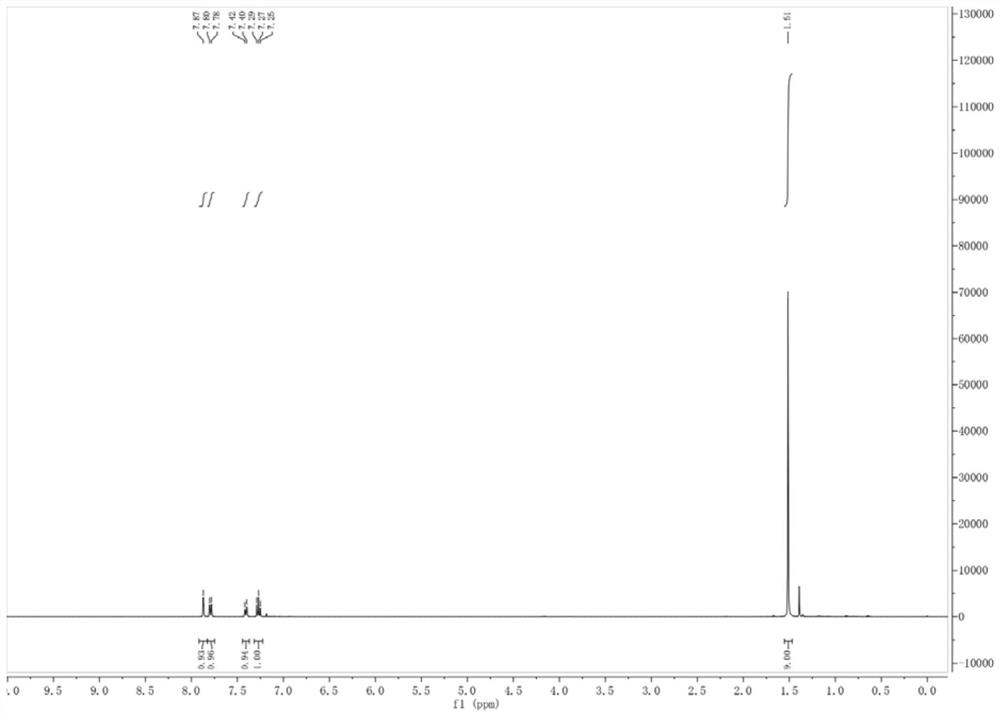

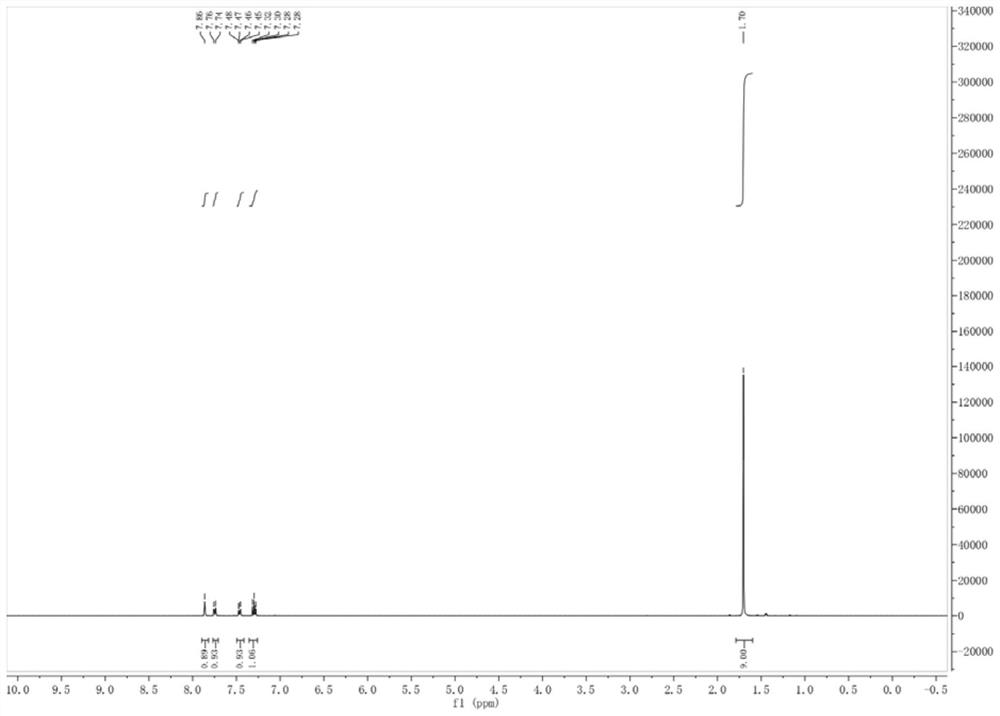

Diagnosis and treatment integrated compound as well as preparation method and application thereof

PendingCN111704560AReduced activityMaintain binding activityOrganic chemistryX-ray constrast preparationsBenzoic acidIobenzamic acid

The invention relates to the technical field of medicines, and particularly discloses a diagnosis and treatment integrated compound as well as a preparation method and application thereof. The diagnosis and treatment integrated compound is a vorinostat derivative, wherein at least one iodine atom is introduced to a benzene ring of vorinostat; the compound not only has anti-tumor activity, but alsohas a diagnostic imaging function. The preparation method of the diagnosis and treatment integrated compound comprises the following steps that Boc-2,3,5-triiodobenzoic acid is synthesized, 2,3,5-triiodobenzidine is synthesized, and the 8-oxo-8-((2,3,5-triiodobenzyl) amino) methyl caprylate is synthesized. The preparation methos is simple; the invention also discloses application of a diagnosis and treatment integrated compound, wherein the compound is applied to antitumor medicines so as to be used for anti-tumor treatment and diagnosis imaging functions of tumor patients.

Owner:JIANGSU FOOD & PHARMA SCI COLLEGE

Preparation method of sulfur/oxygen ester-containing aromatic hydrocarbon compound

PendingCN114163369AVarious formsSimple preparation processOrganic compound preparationCarboxylic acid esters preparationBenzoic acidDicarbonate

The invention discloses a preparation method of a sulfur / oxygen ester-containing aromatic hydrocarbon compound. The preparation method comprises the following steps: A, carrying out reaction on substituted benzoyl chloride and tert-butyl mercaptan to obtain substituted tert-butyl thiobenzoate; b, reacting substituted bromobenzene with an isopropylmagnesium chloride Grignard reagent, then cooling, adding di-tert-butyl dicarbonate, and reacting to obtain substituted tert-butyl benzoate; c, carrying out reflux reaction on the substituted benzoic acid tert-butyl thioester and a Lawson reagent to obtain substituted benzyl dithio-tert-butyl ester; and D, reacting the substituted tert-butyl benzoate or the substituted tert-butyl benzoate with TMPMgCl.LiCl, and then carrying out a demetallization reaction by adopting an iodine elementary substance to obtain substituted 2-iodobenzoic acid tert-butyl thioester or substituted 2-iodobenzoic acid tert-butyl ester. The sulfur / oxygen ester-containing aromatic hydrocarbon compound obtained by the method has various forms, the preparation process is simple, green, efficient, low in cost, high in speed and easy to operate, an important material source is provided for modification of the sulfur / oxygen ester-containing aromatic hydrocarbon compound, and the method has important application value.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A kind of synthetic method of 2-halogen-5-iodobenzoic acid

ActiveCN110078613BReduce pollutionImprove product qualityOrganic compound preparationCarboxylic compound preparationBenzoic acidHalogen

The invention discloses a method for synthesizing 2-halo-5-iodobenzoic acid. The method comprises the following steps: 2-halogen-5-iodobenzoic acid can be obtained by one-step iodination of o-halobenzoic acid in an iodo reagent. The post-treatment is quenched by pouring the reaction liquid into a cold reducing aqueous solution, evaporating the solvent to dryness, recrystallizing, and filtering to obtain the product. The method of the invention has short reaction route, simple operation, environmental friendliness, safety, economy and wide application prospect.

Owner:杭州科耀医药科技有限公司

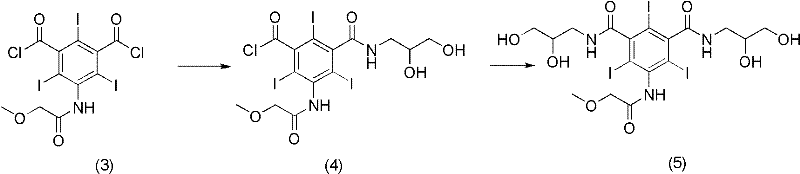

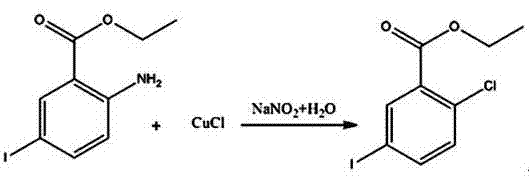

Anidulafungin side chain intermediate 4''-(pentyloxy)-[1,1':4',1''-terphenyl]-4-carboxylic acid

ActiveCN109574811ALow costSimple and safe process operationOxygen-containing compound preparationOrganic compound preparationIobenzamic acidFormate

The invention relates to the preparation method of anidulafungin side chain intermediate 4''-(pentyloxy)-[1,1':4',1''-terphenyl]-4-carboxylic acid. The preparation method includes the steps of S1, subjecting 4 hydroxy-4'-bromobiphenyl and 1-bromopentane to nucleophilic substitution to obtain 4'-bromo-4-n-amyloxybiphenyl; S2, subjecting the 4'-bromo-4-n-amyloxybiphenyl and tetrahydroxydiboron to Suzuki coupling reaction to obtain 4-pentyloxy-4'-biphenylboronic acid; S3, subjecting the 4-pentyloxy-4'-biphenylboronic acid and methyl 4-iodobenzoate to Suzuki coupling reaction to obtain methyl 4''-(pentyloxy)-[1,1',4'-1''-terphenyl]-4-formate; S4, hydrolyzing to obtain 4''-(pentyloxy)-[1,1':4',1''-terphenyl]-4-carboxylic acid. arylboronic acid is prepared through Suzuki coupling; the target product is then prepared through Suzuki coupling and alkali hydrolysis; the preparation method has the advantages of low cost and good process operation simplicity and safety.

Owner:SUN YAT SEN UNIV

A kind of synthetic method of 2-chloro-5-iodobenzoic acid

InactiveCN104193616BSimple processEasy to operateOxygen-containing compound preparationOrganic compound preparationSandmeyer reactionBenzoic acid

A synthetic method of 2-chloro-5-iodobenzoic acid is disclosed. The target product is obtained by subjecting methyl 2-aminobenzoate to iodination, substitution, a Sandmeyer reaction and hydrolysis under alkaline conditions. The method is characterized by modification or optimization of process steps and parameters based on traditional iodination, substitution, the Sandmeyer reaction and hydrolysis. The method is simple in process, easy in operation, safe in production process, free of pollution, and high in yield of each step. The purity of the product is 95-98%. The total yield of the product is 64-70%.

Owner:姜树林

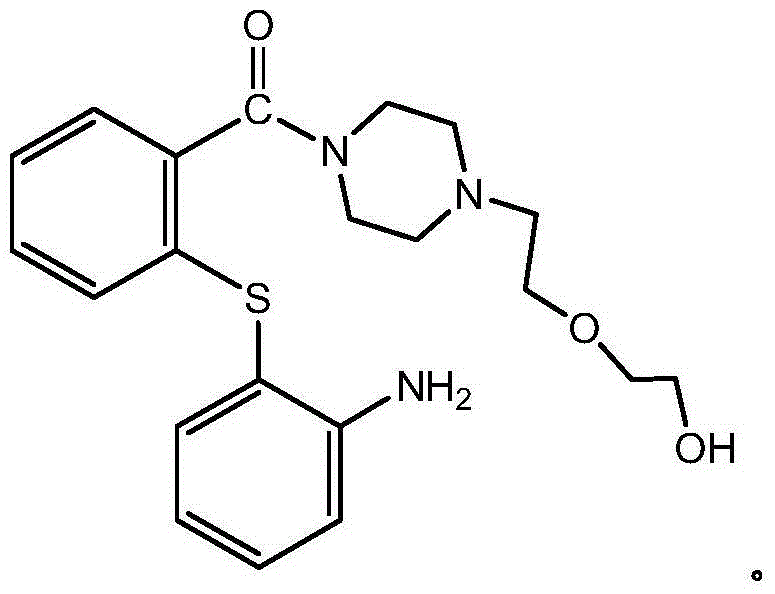

Preparation method of quetiapine intermediate

ActiveCN103396382BRaw materials are easy to getEasy to operateOrganic chemistryIobenzamic acidQuetiapine

The invention relates to a preparation method of (2-(2-amino-phenyl-mercapto)-phenyl)-(4-(2-(2-hydroxy-ethoxy)-ethyl)-piperazine-1-yl)-ketone and a hydrochloride thereof. The preparation method comprises the following steps of (1) enabling 2-iodobenzoic acid and thionyl chloride to perform substitution reaction so as to generate 2-iodoebenzoyl chloride; (2) enabling the 2-iodoebenzoyl chloride and 1-(2-(2-hydroxyethoxy)-ethyl)-piperazine to perform the substitution reaction so as to generate a compound 1; and (3) enabling the compound 1 and 2-amino-thiophenol to perform the substitution reaction in the presence of an acid binding agent so as to generate the (2-(2-amino-phenyl-mercapto)-phenyl)-(4-(2-(2-hydroxy-ethoxy)-ethyl)-piperazine-1-yl)-ketone. By adopting the synthesis route disclosed by the invention, the total yield can be above 40%, the purity of the obtained product can achieve 99%, and the preparation method disclosed by the invention has the advantages of easiness in obtaining the used raw materials, simplicity in operation, mild reaction conditions and lower cost.

Owner:太仓市茜泾化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Anidulafungin side chain intermediate 4''-(pentyloxy)-[1,1':4',1''-terphenyl]-4-carboxylic acid Anidulafungin side chain intermediate 4''-(pentyloxy)-[1,1':4',1''-terphenyl]-4-carboxylic acid](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/c90e9291-88ad-488d-a3e5-50c2b96f131a/RE-HDA0001956958100000011.png)

![Anidulafungin side chain intermediate 4''-(pentyloxy)-[1,1':4',1''-terphenyl]-4-carboxylic acid Anidulafungin side chain intermediate 4''-(pentyloxy)-[1,1':4',1''-terphenyl]-4-carboxylic acid](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/c90e9291-88ad-488d-a3e5-50c2b96f131a/RE-GDA0001956958090000041.png)