Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31 results about "GAS RAISING" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

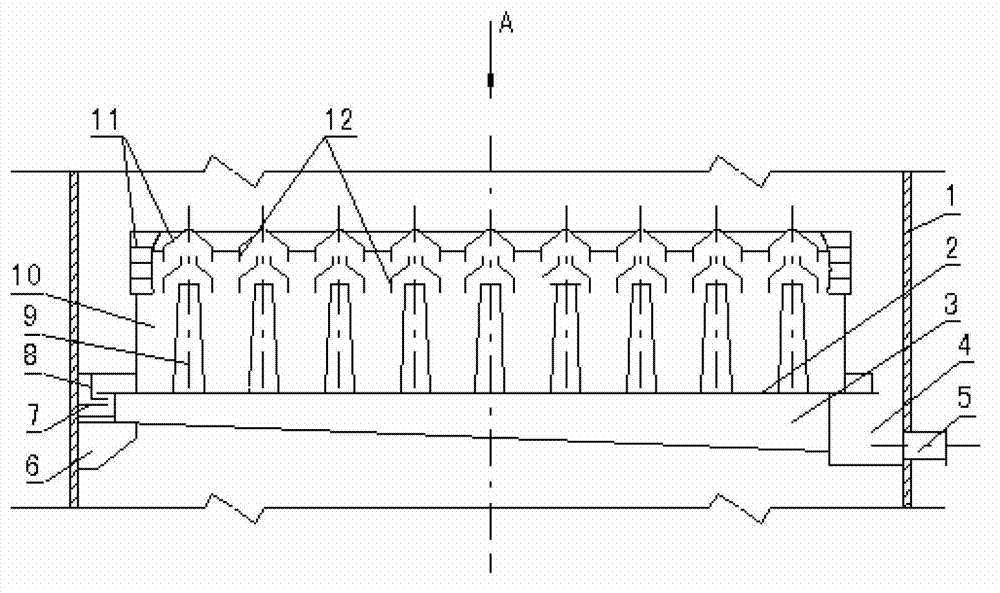

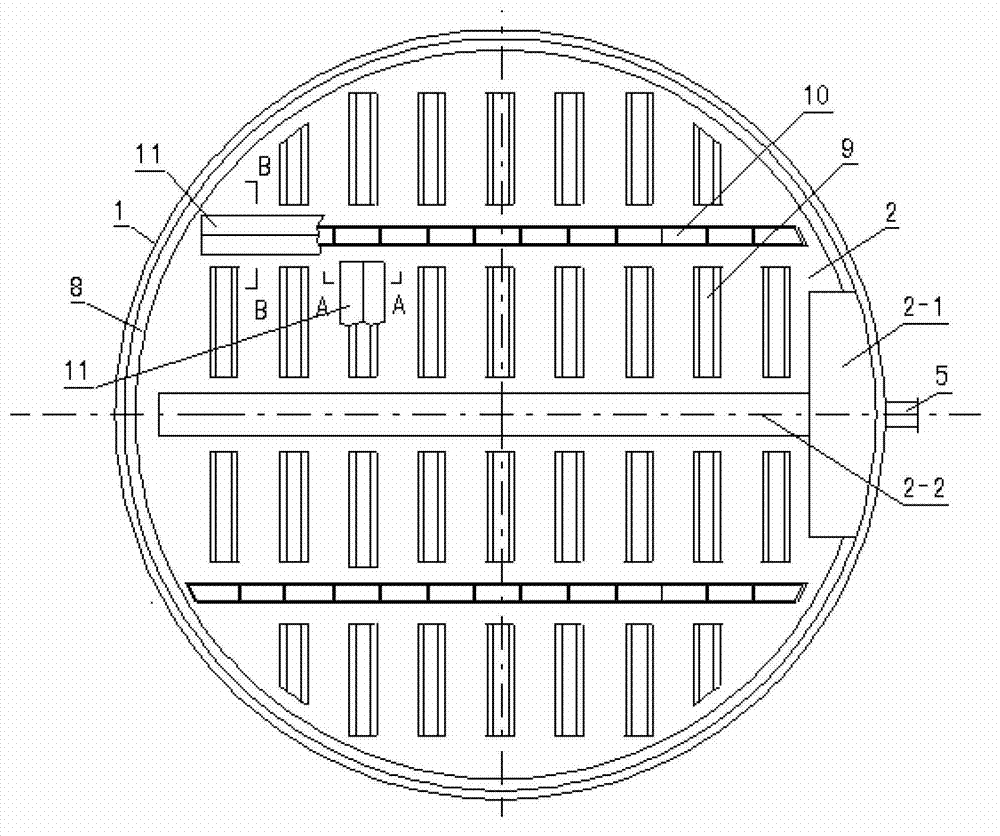

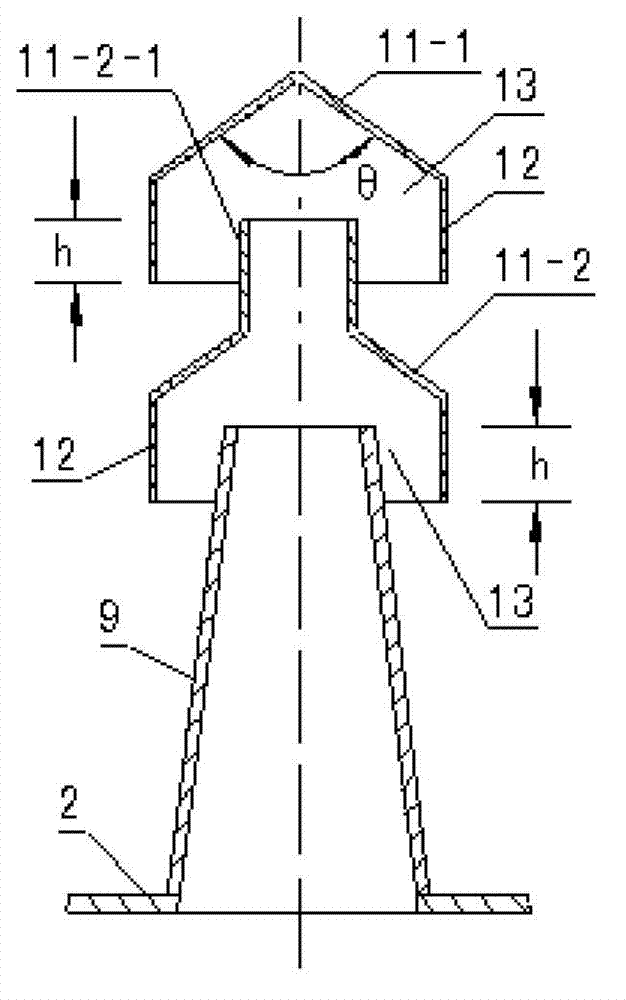

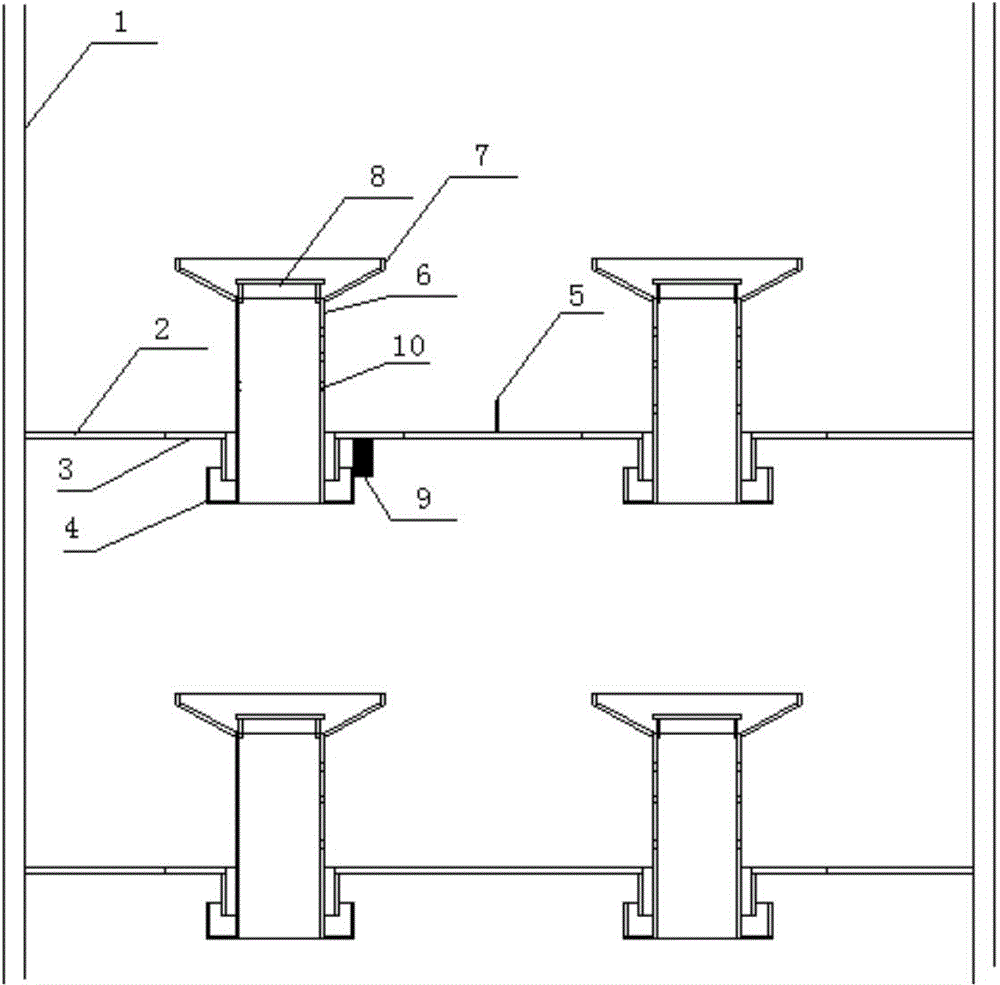

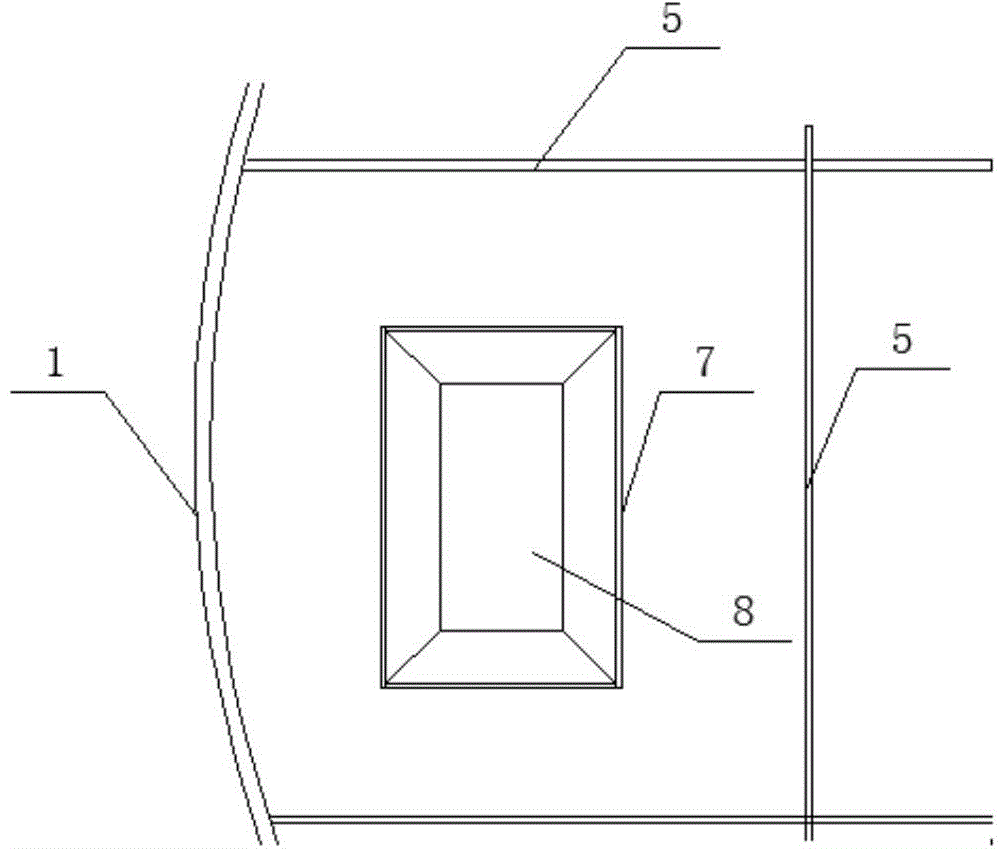

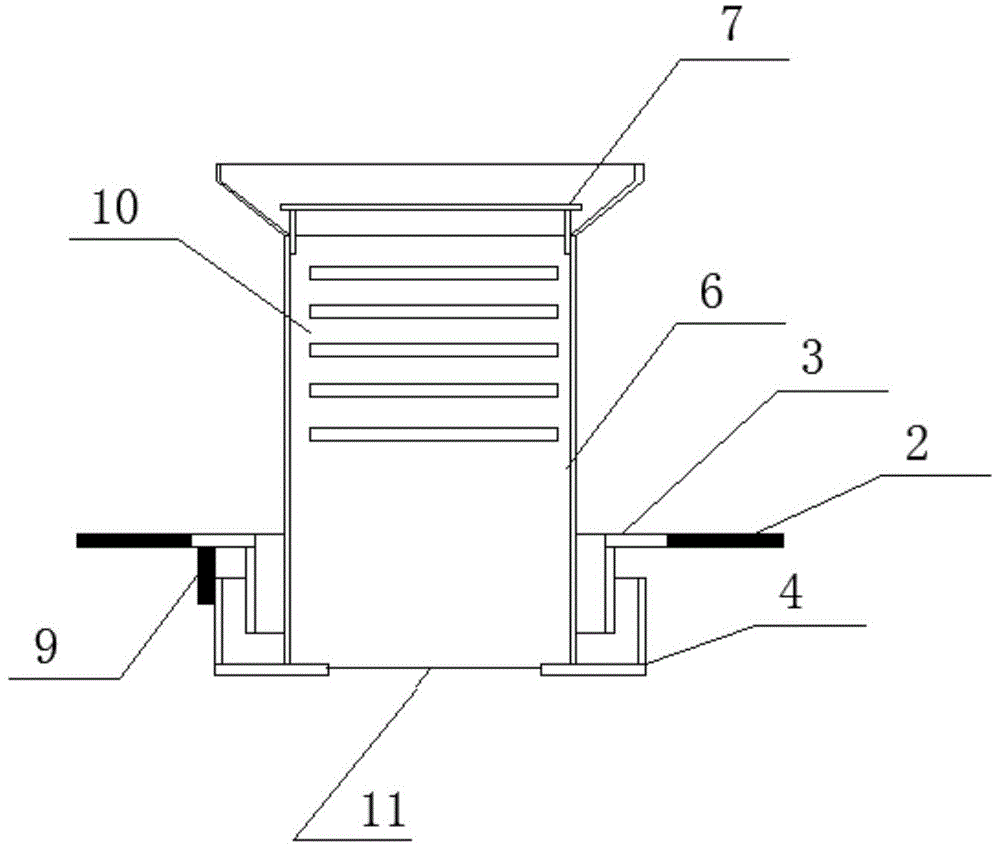

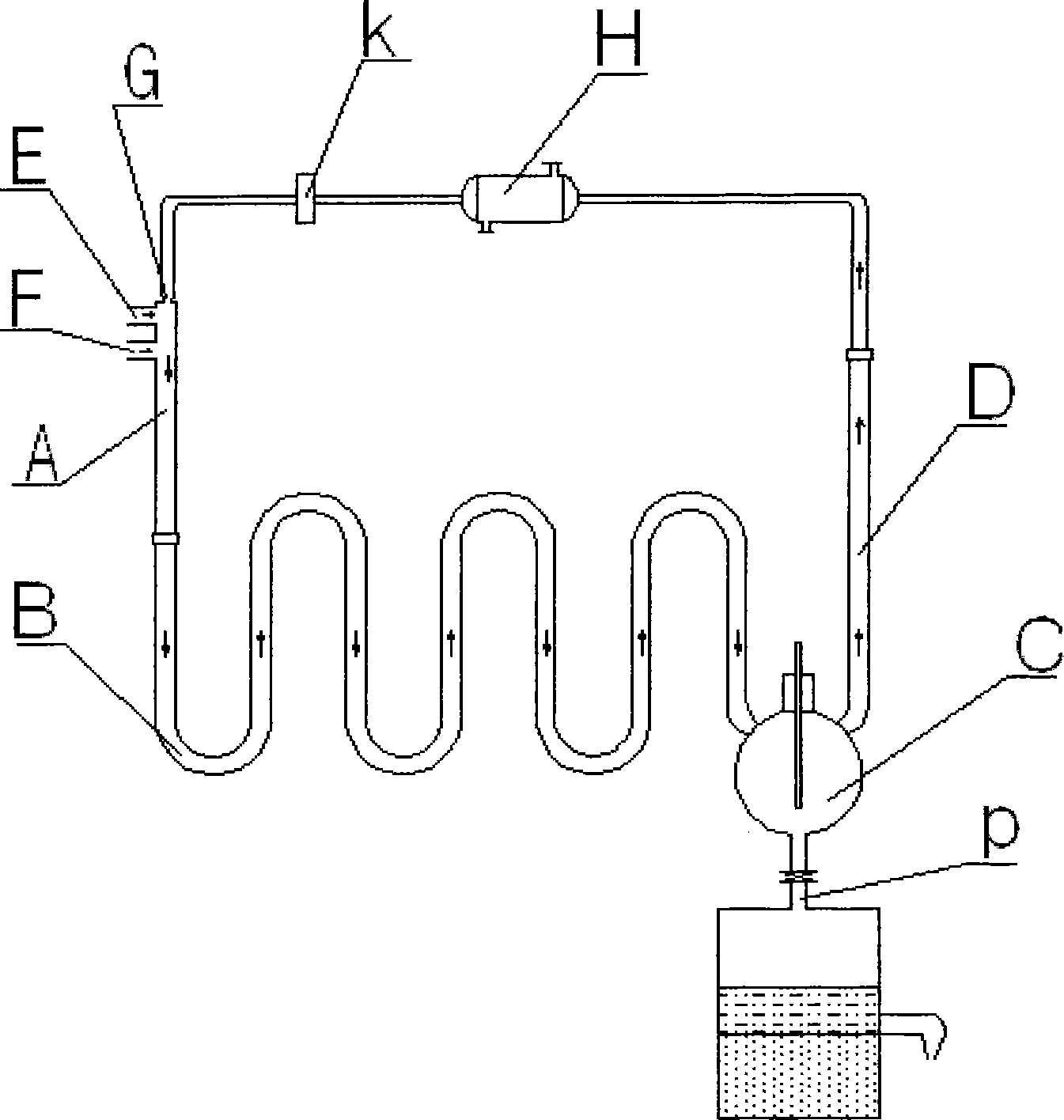

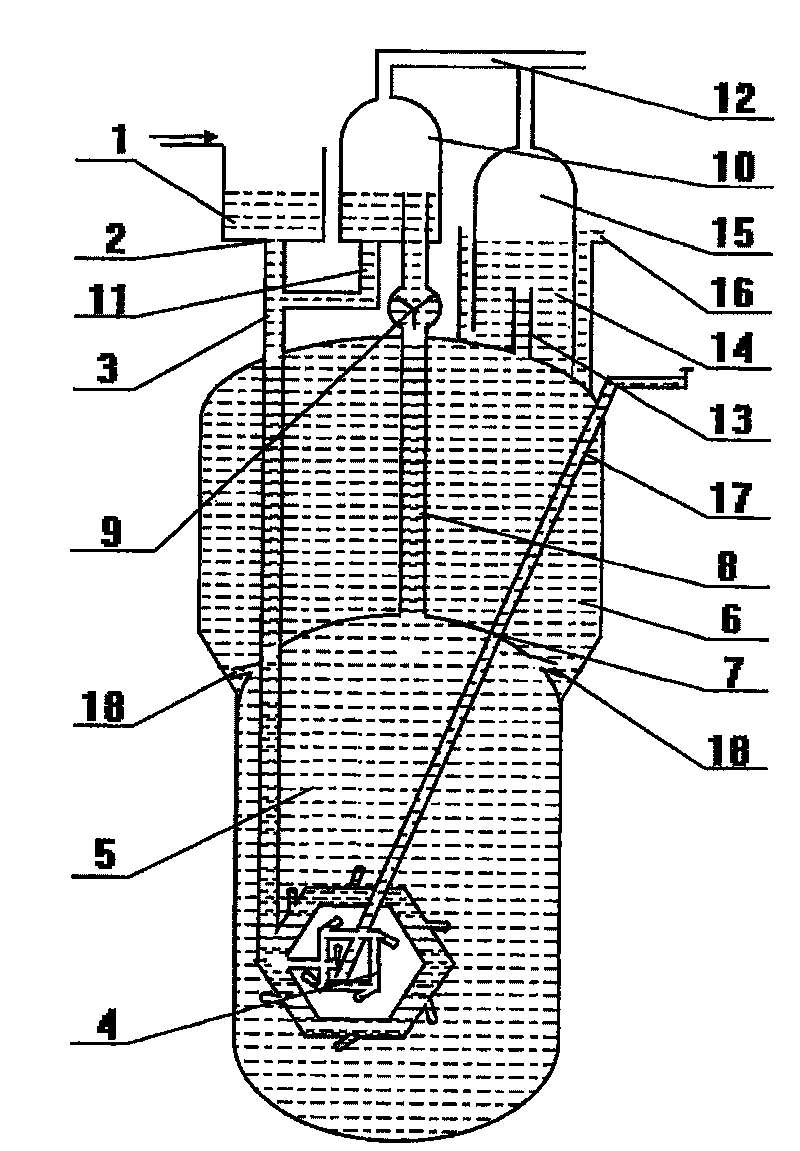

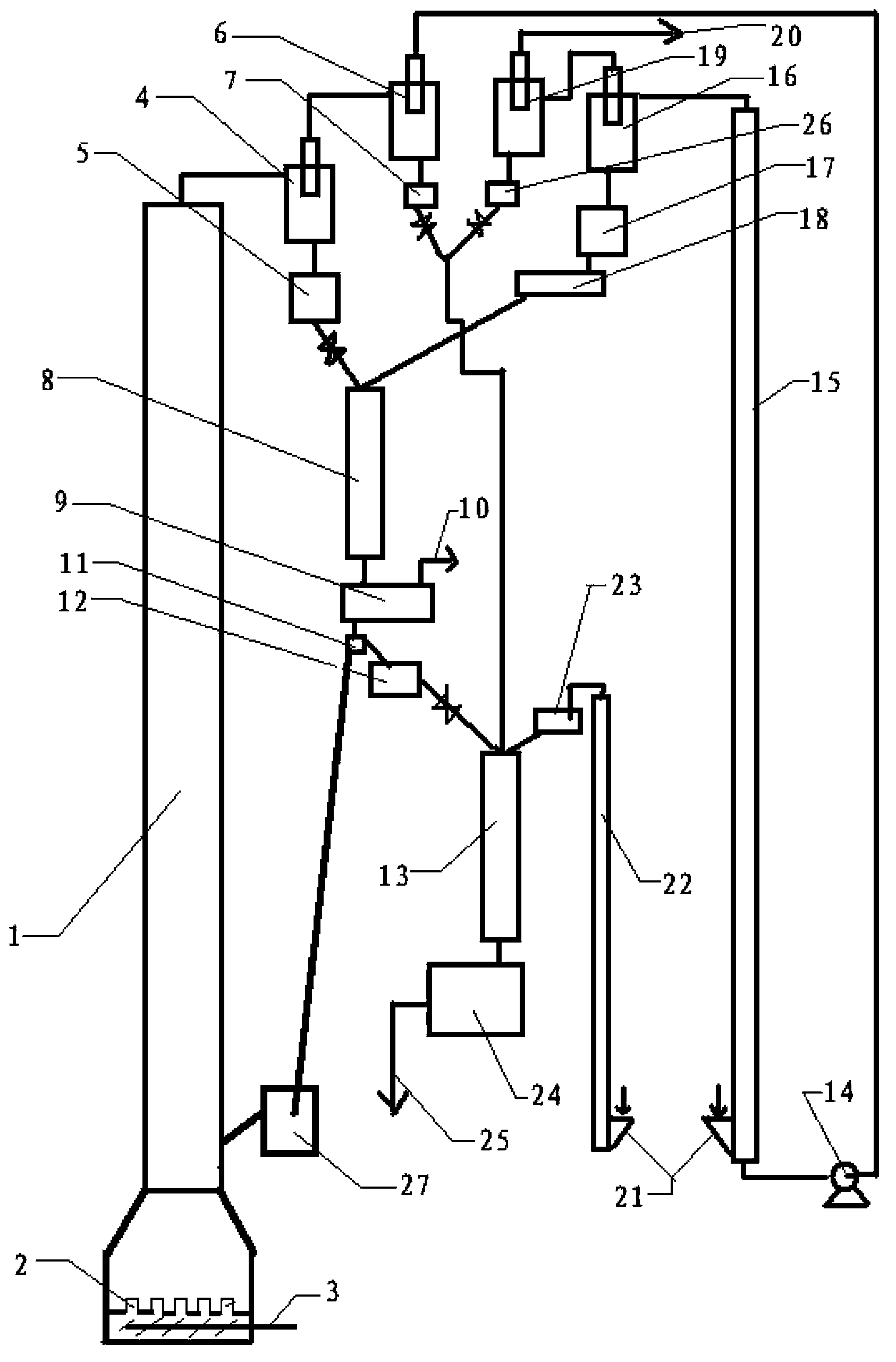

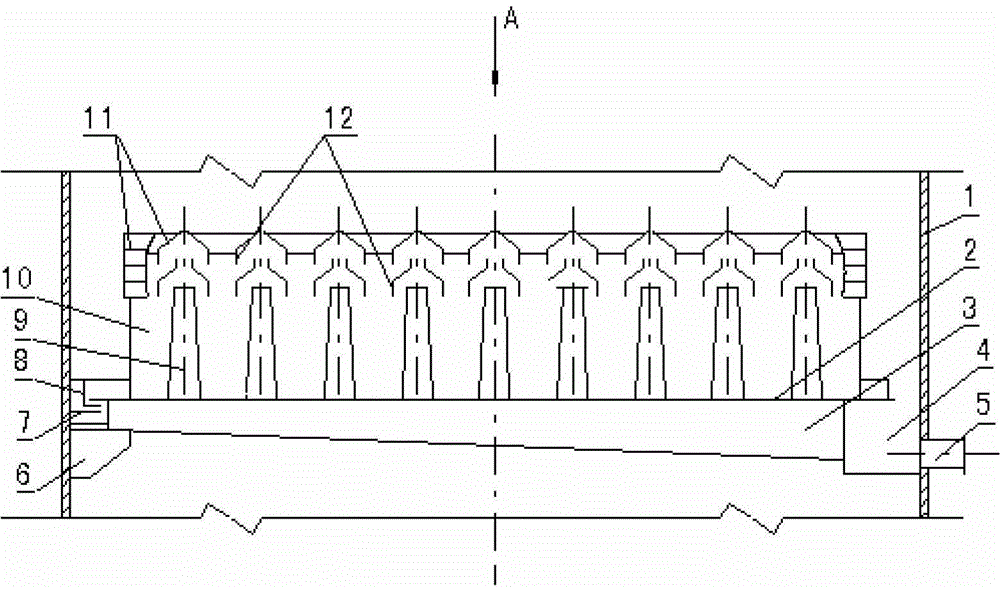

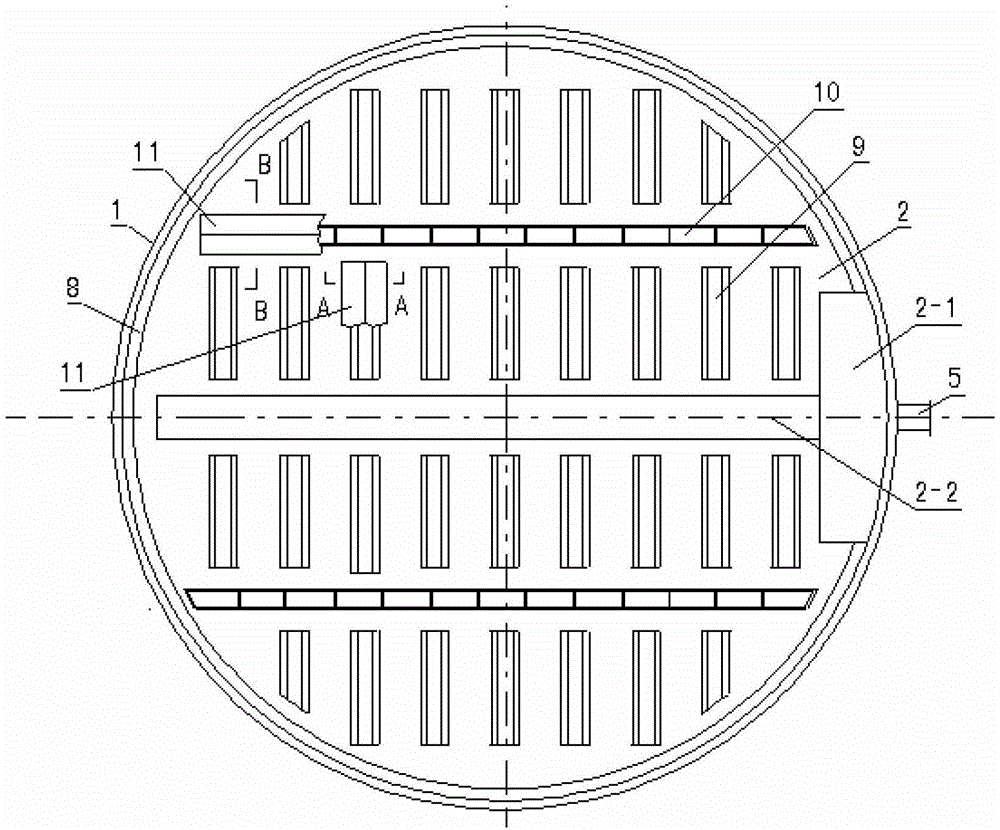

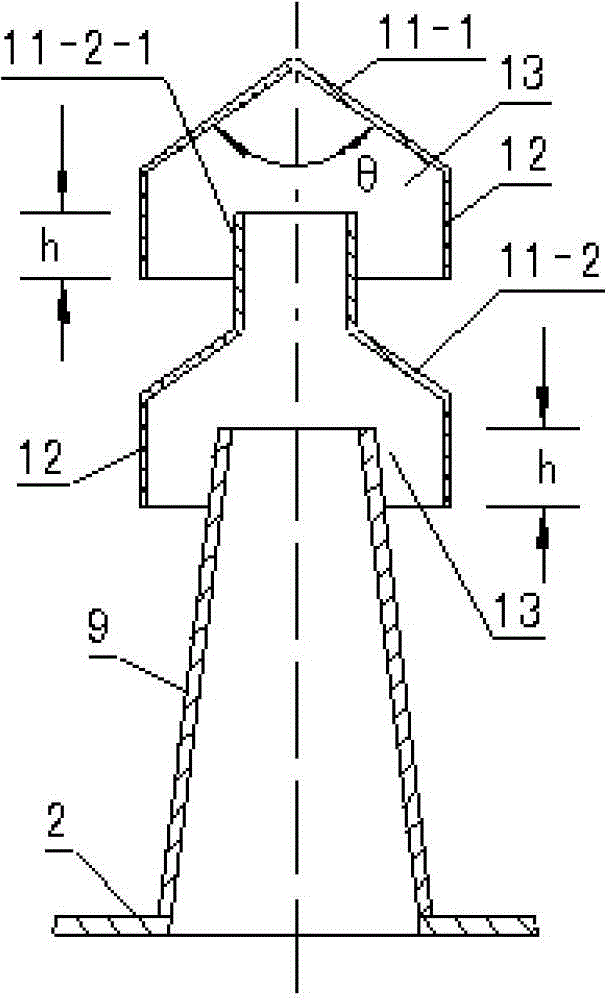

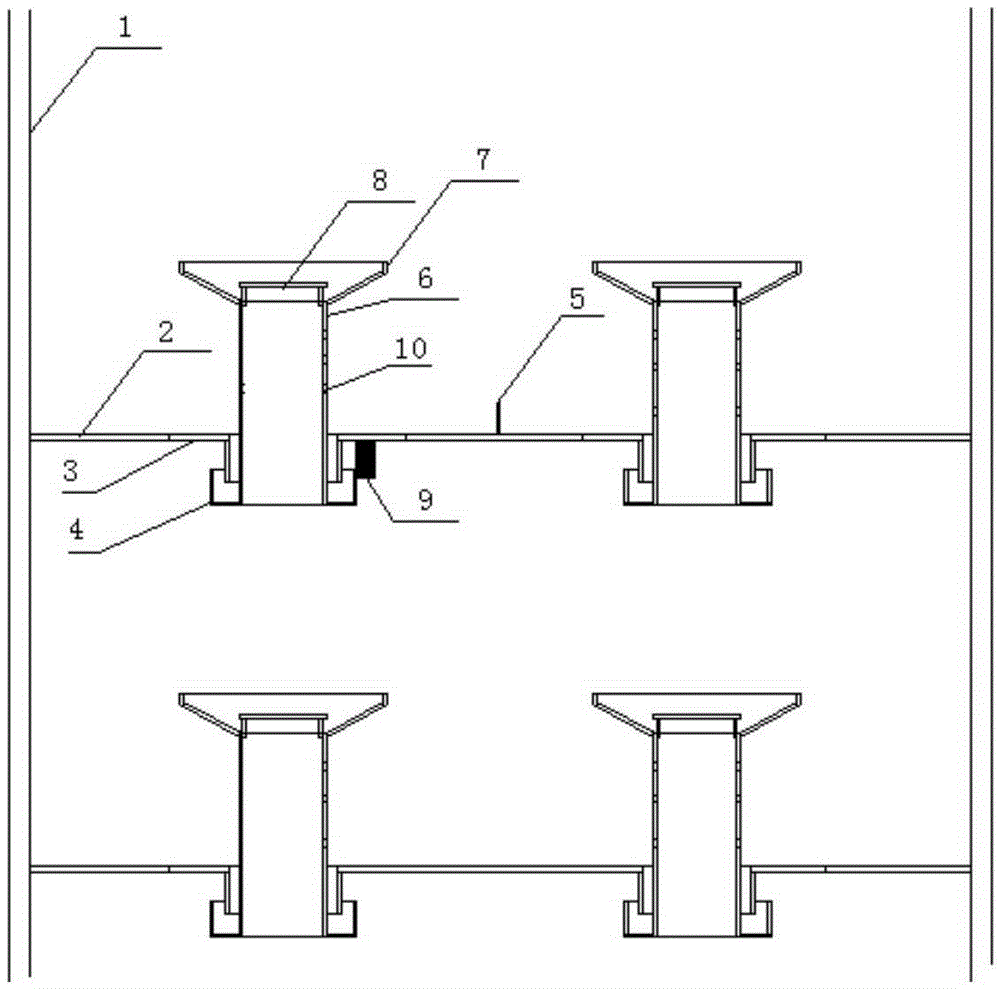

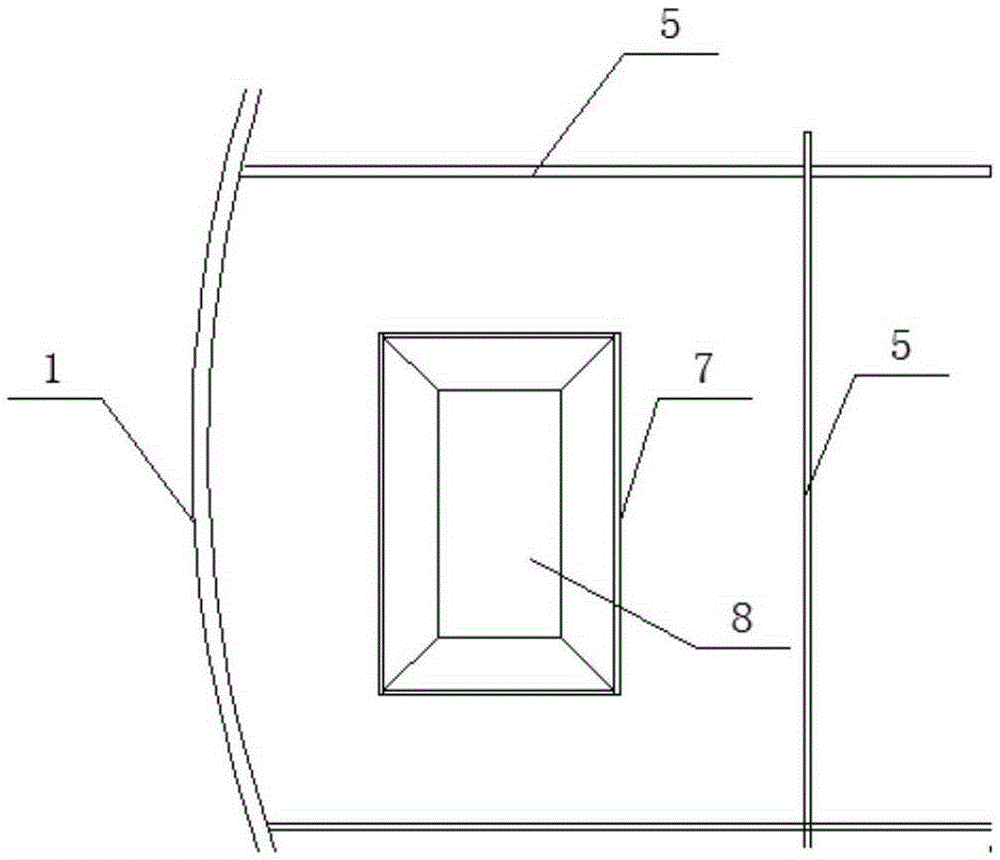

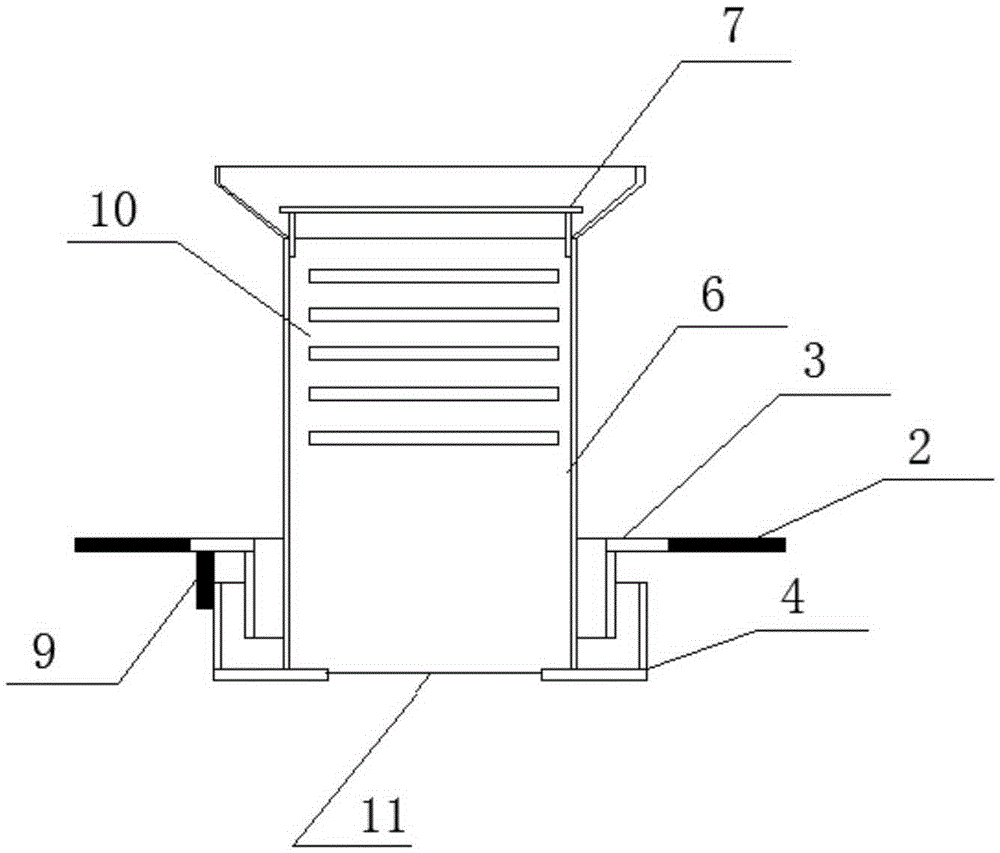

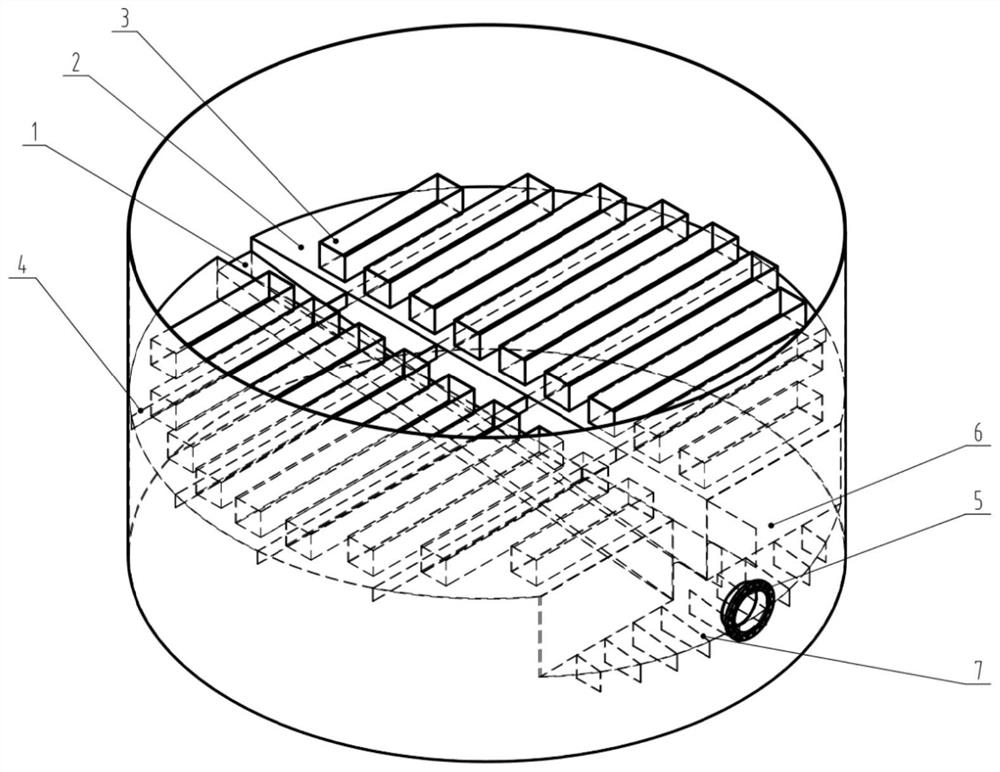

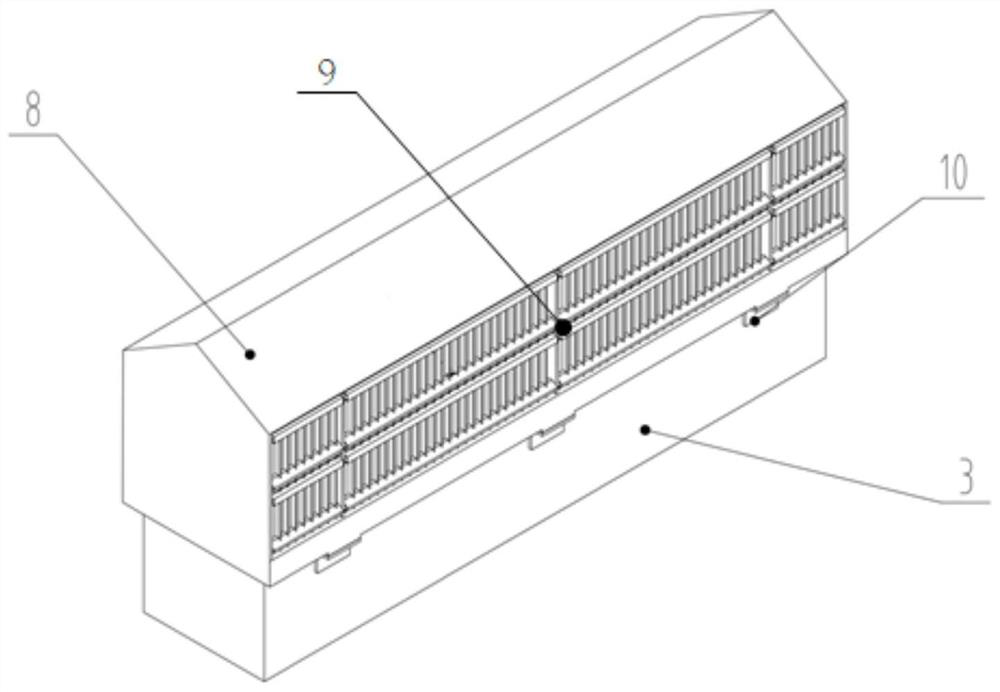

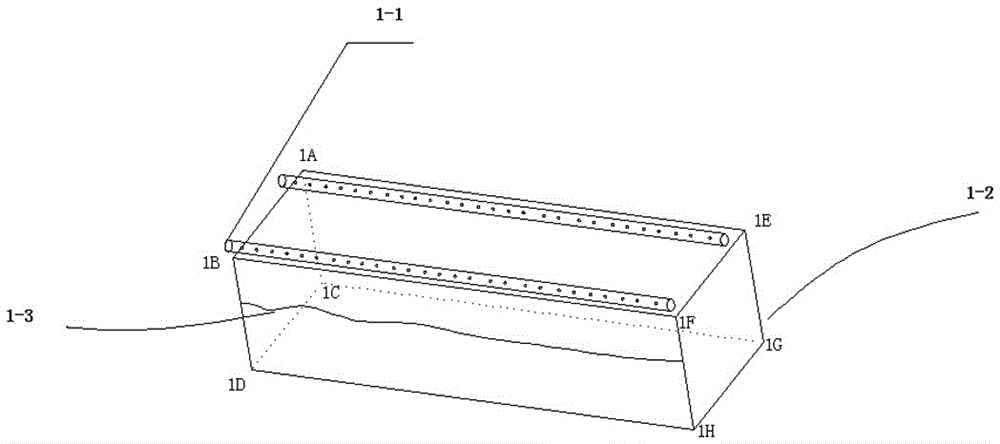

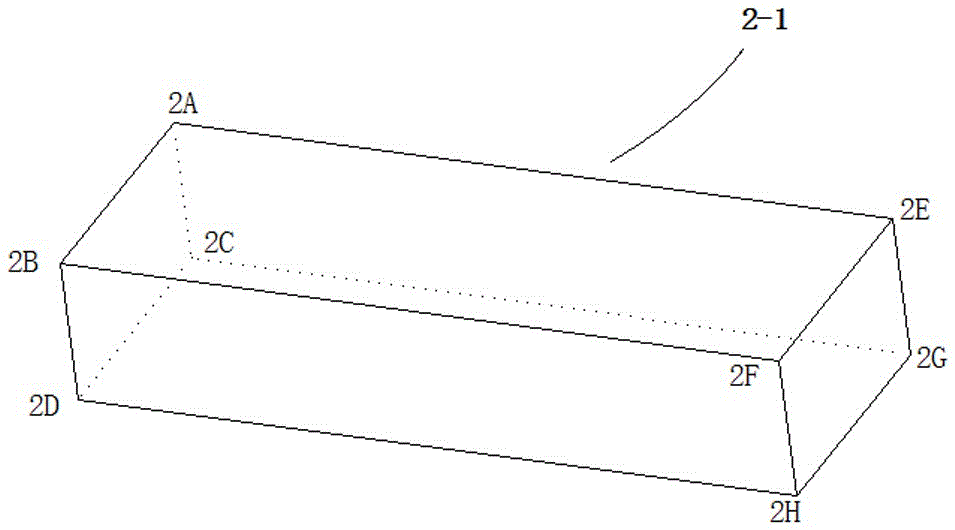

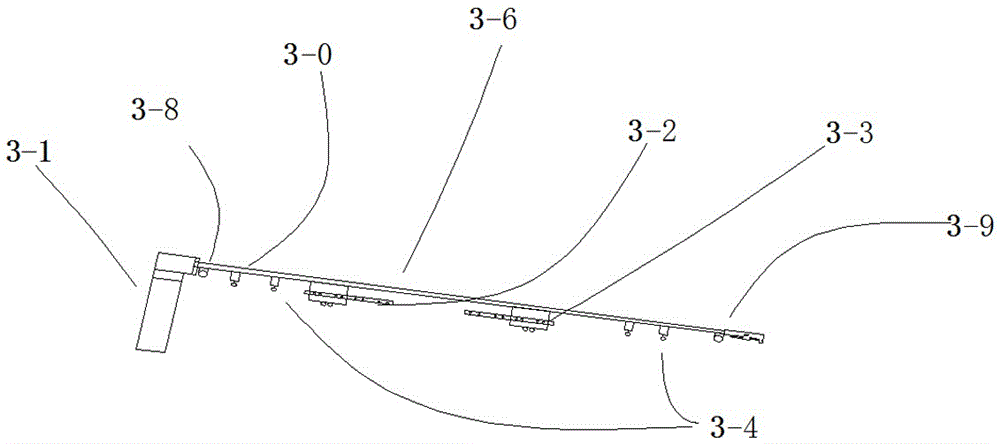

Liquid collecting and gas distributing device for large-scale flue gas desulfurization tower

ActiveCN103111180AGuaranteed outputPrevent leakageDispersed particle separationChemical industryThermal deformation

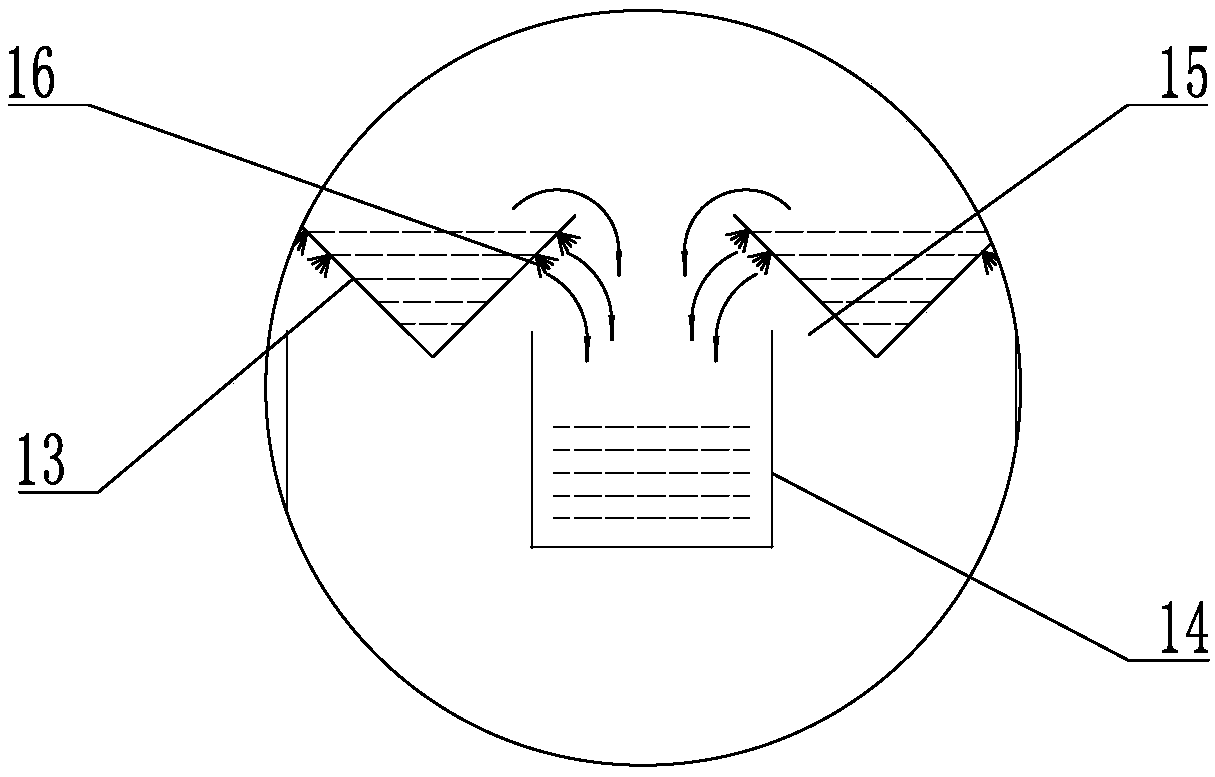

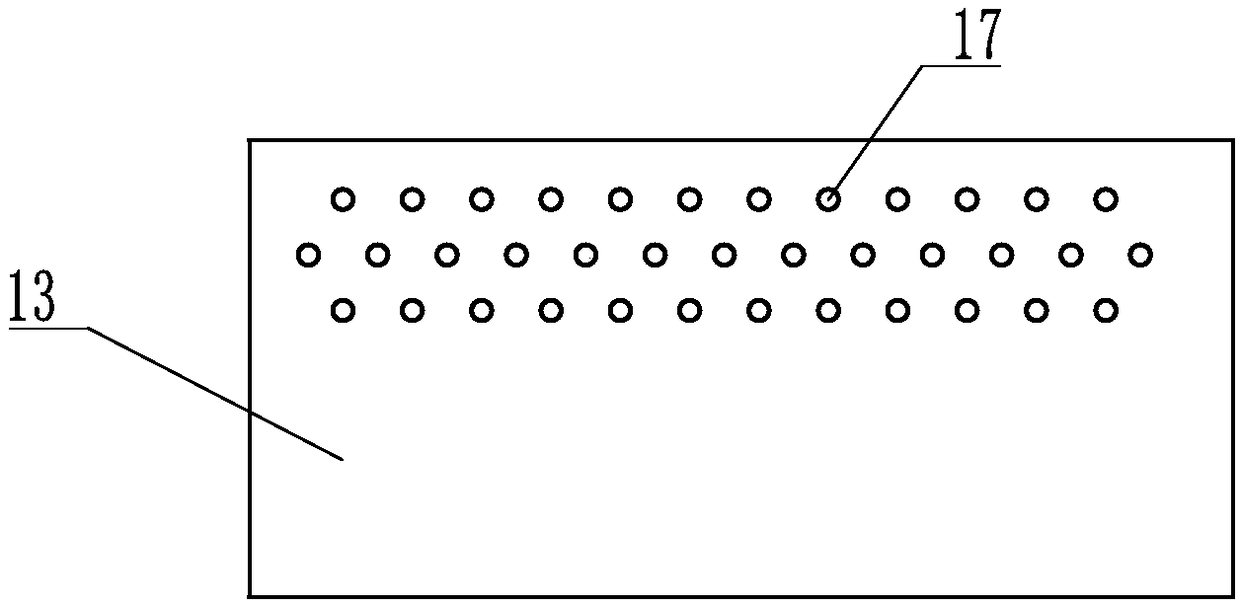

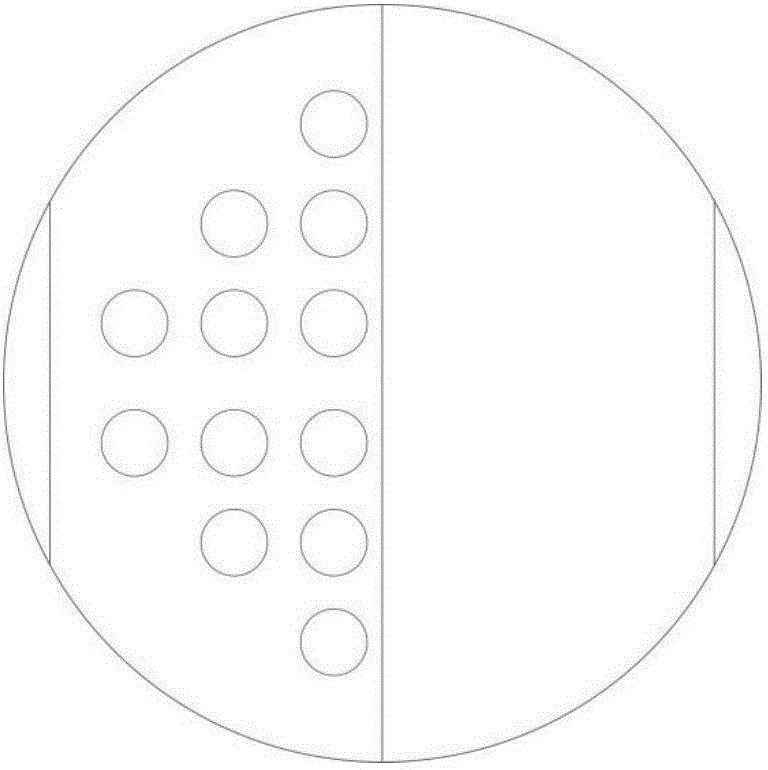

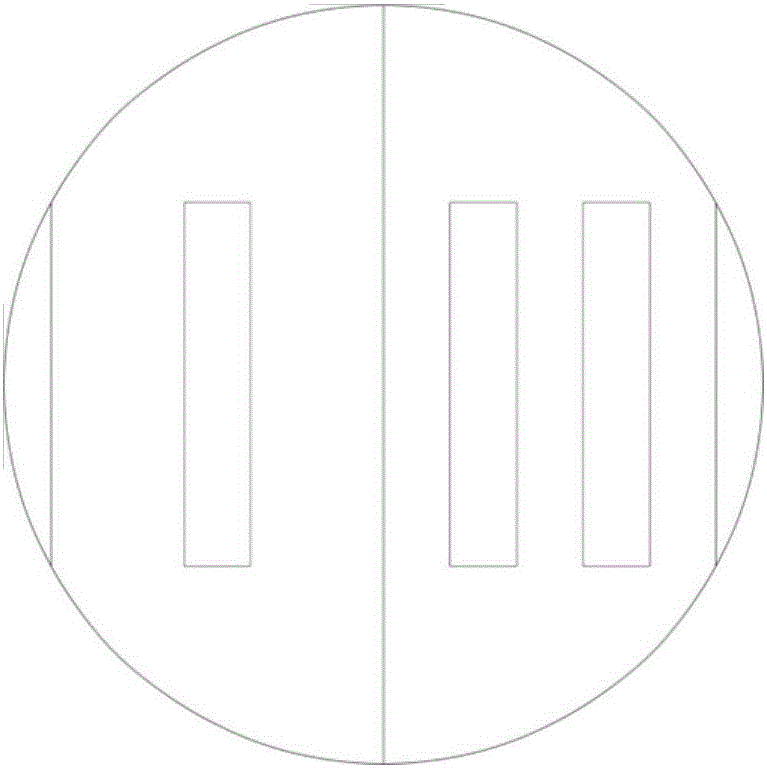

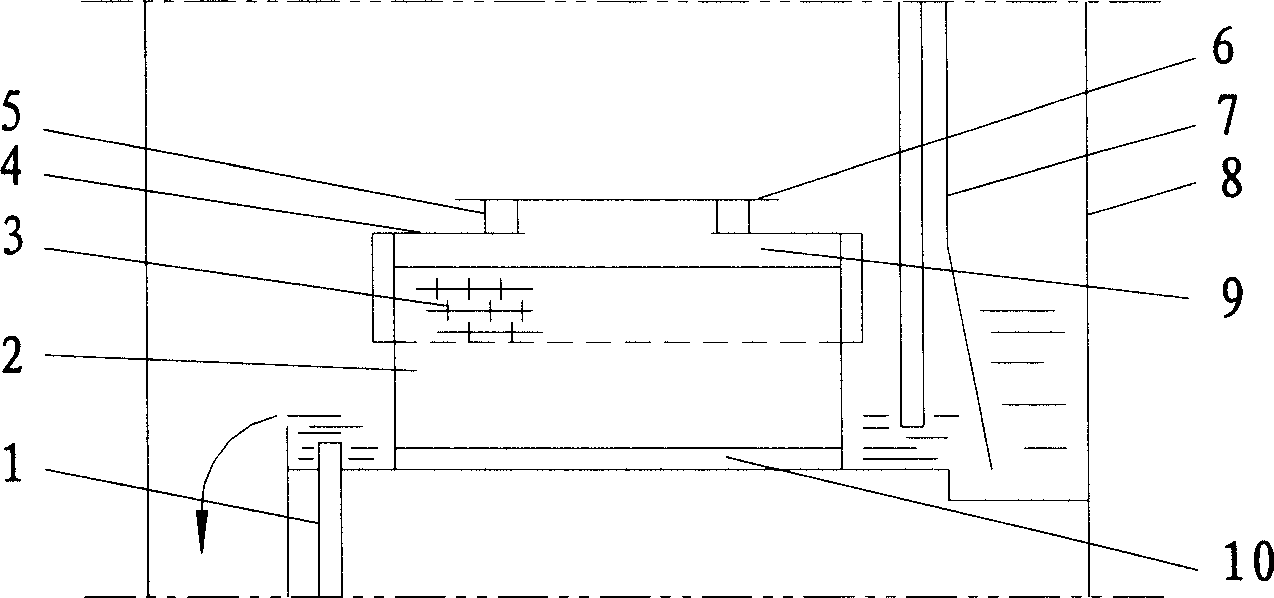

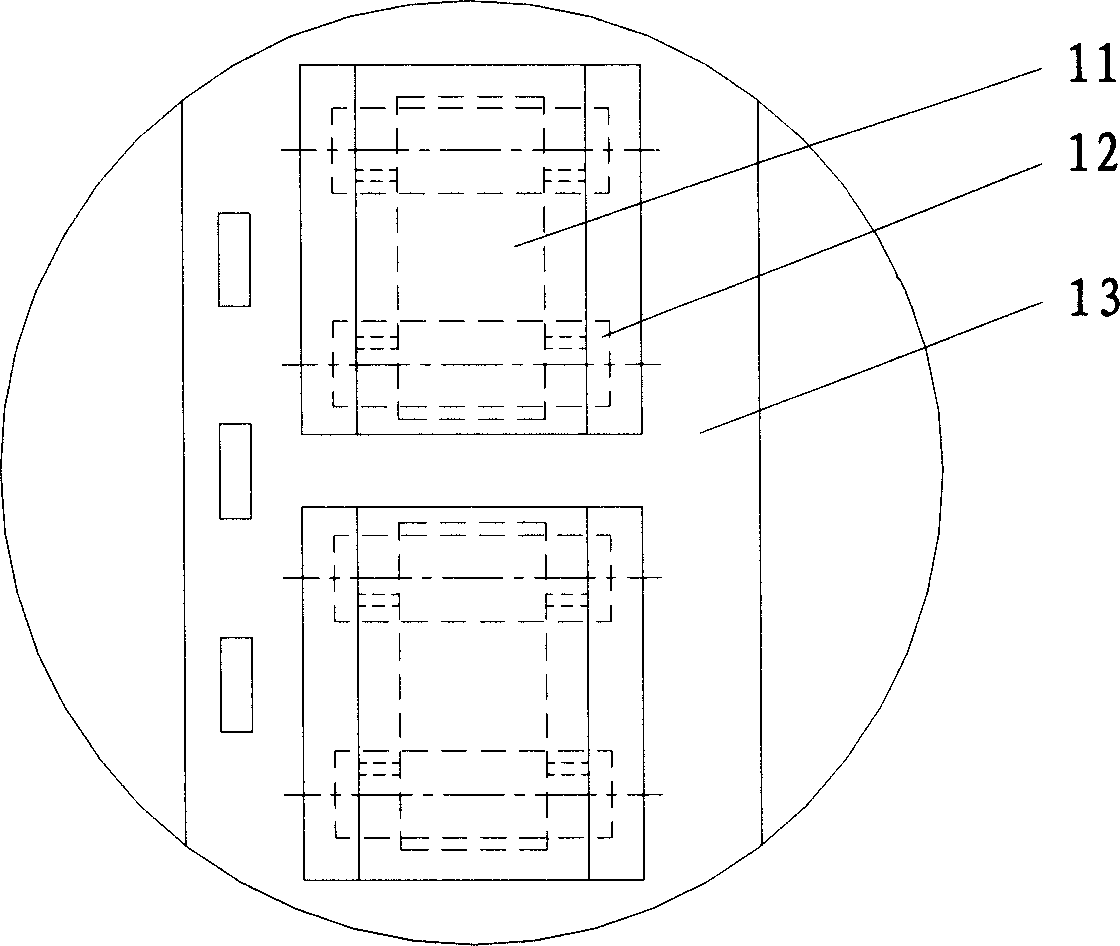

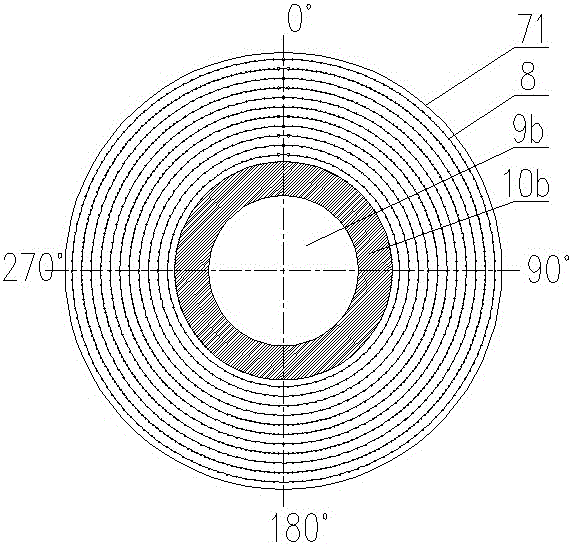

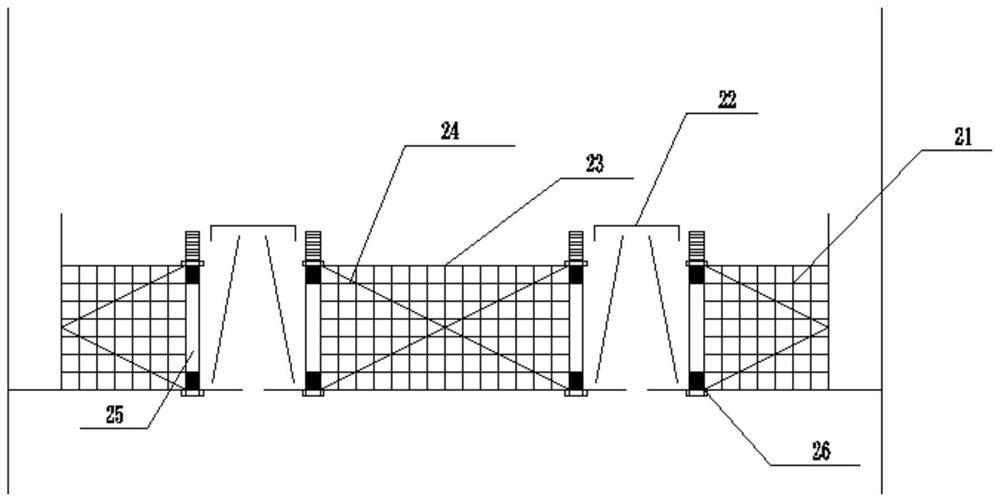

The invention provides a liquid collecting and gas distributing device for a large-scale flue gas desulfurization tower. The device consists of a cross section-variable base plate gas raising pipe, a grid beam type gas raising pipe, a double-layer type liquid baffling hood, an inclined channel type main beam with a function of guiding liquid flow, an extracting hopper, an extracting pipe and a plane expansion joint. The device has an all-welded structure for preventing liquid from escaping, the liquid falling, the liquid drop sputtering and the zero escaping of liquid fog and the lower pressure drop can be realized due to the double-layer type liquid baffling hood, the aperture ratio of the device can be increased and the convenient corrosion prevention can be carried out due to the grid beam type gas raising pipe, the impacting foaming can be reduced and the lateral line extraction quantity can be guaranteed due to the deep extracting hopper and inclined channel; a detachable sealed liquid leakage device can be completely eradicated due to the plane expansion joint, and the thermal deformation caused by high temperature can be skillfully absorbed; and the gas distributing evenness can be guaranteed due to the gas raising pipes which are geometrically and evenly distributed. The device can be widely used for the desulfurization tower in the steel mill, the electric power plant and the like, and the large-scale packed tower in the industries of oil refining, petrifaction, chemical industry and the like.

Owner:TIANJIN TIANDA TIANJIU TECH CO LTD

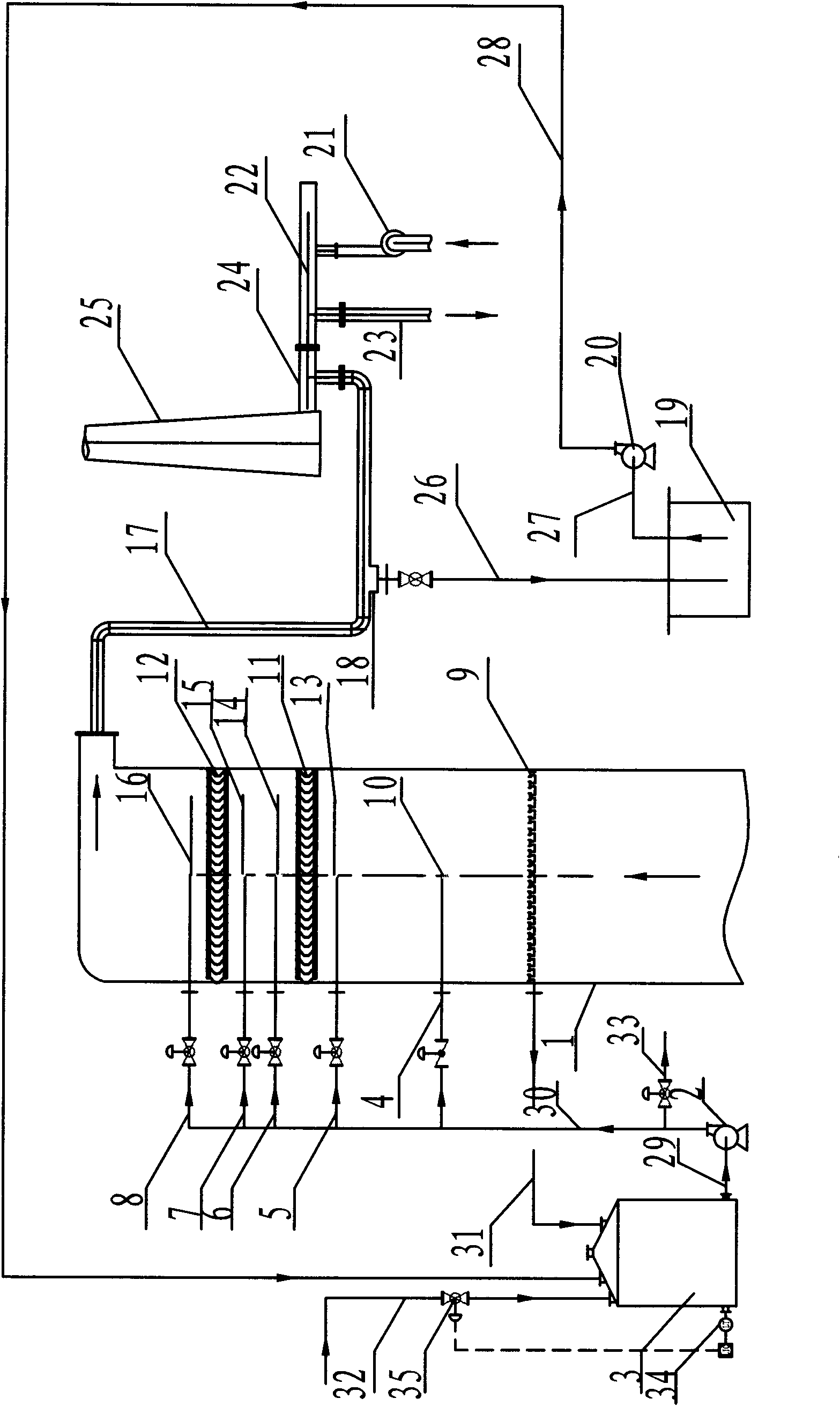

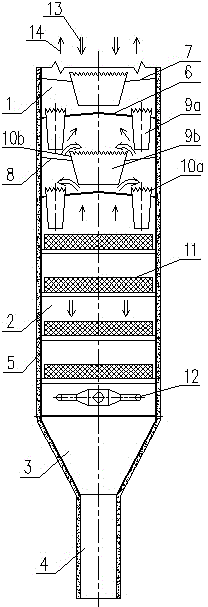

Process and device for dehumidifying wet flue gas purification tail gas

InactiveCN101956991AAvoid corrosionReduce corrosionLighting and heating apparatusDispersed particle separationLiquid waterLiquid storage tank

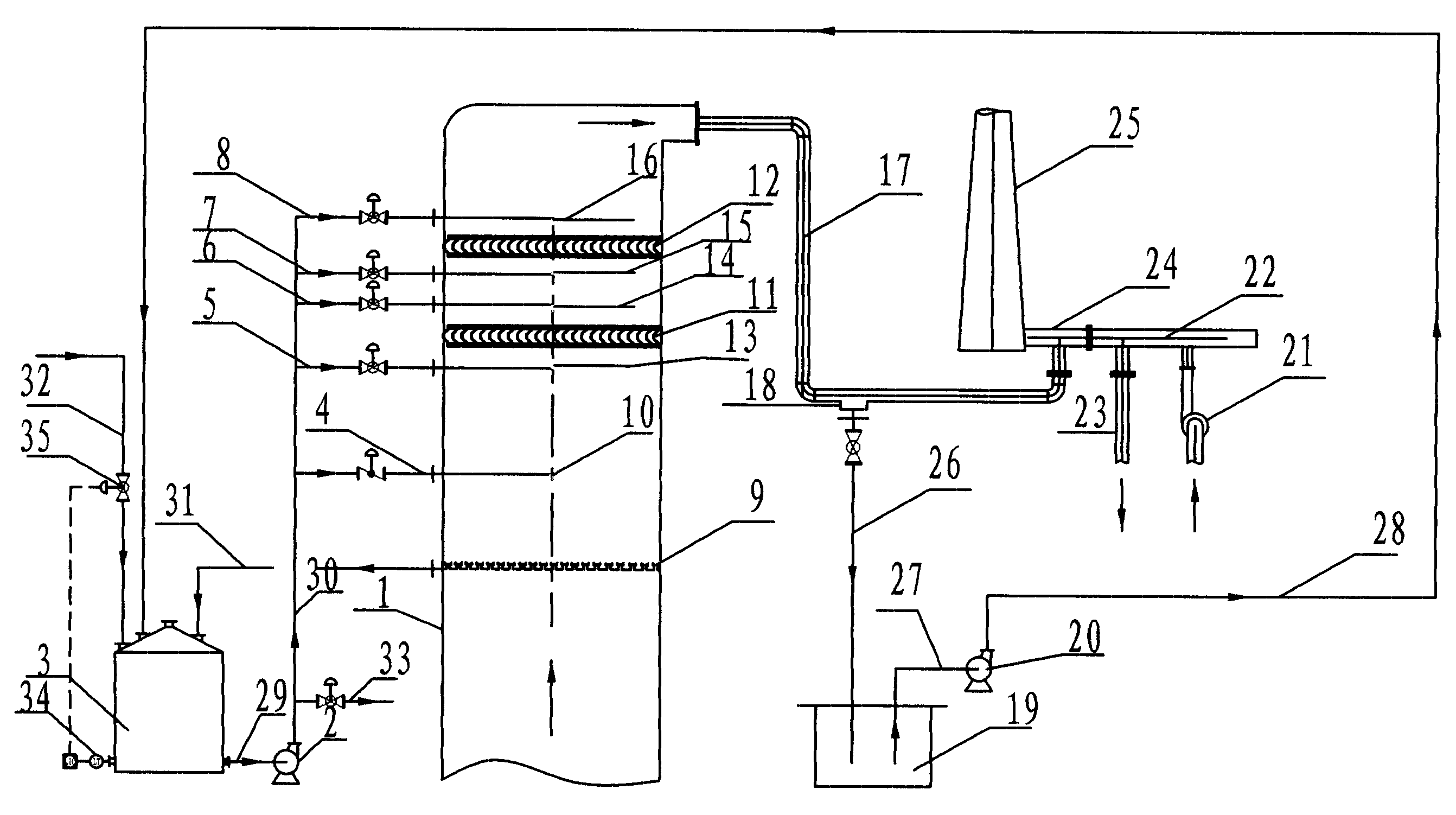

The invention belongs to the technical field of boiler flue gas purification and discloses a process and a device for dehumidifying wet flue gas purification tail gas. The process comprises the following steps that: desulfurized flue gas enters the washing section of a desulfurizing tower from a gas raising cap (9) and washing liquid sprayed by a washing nozzle (10) is sprayed to remove SO2 and NH3 escaping along with the desulfurized flue gas; the flue gas rises continually and enters a two-stage baffle plate demister, the two-stage baffle plate demister removes liquid drops of which the particle sizes are more than 5 microns from the flue gas and nozzles above and below the baffle plate demister rinse inorganic salt and fume attached to the baffle plate demister out; and the flue gas enters a smoke pipe (17), a water collecting sump (18) on the lower part of a horizontal pipe at the tail end of the smoke pipe (17) intercepts condensate in the smoke pipe and the condensate enters a condensate collecting groove (19) and is recycled into a liquid storage tank (3) through a liquid return pipe (28). In the process and the device, water spraying, demisting, liquid flow intercepting, recycling and the like are performed on the desulfurized flue gas, so that purified flue gas entering a flue and a chimney does not contain liquid water, desulfurization efficiency is improved and byproduct recovery rate is increased.

Owner:洛阳市天誉环保工程有限公司

All-condition wet desulphurization exhaust gas dehumidifying and white smoke removing system and method

PendingCN109364730AAchieve zero water consumptionReduce processing costsDispersed particle separationCooling towerEngineering

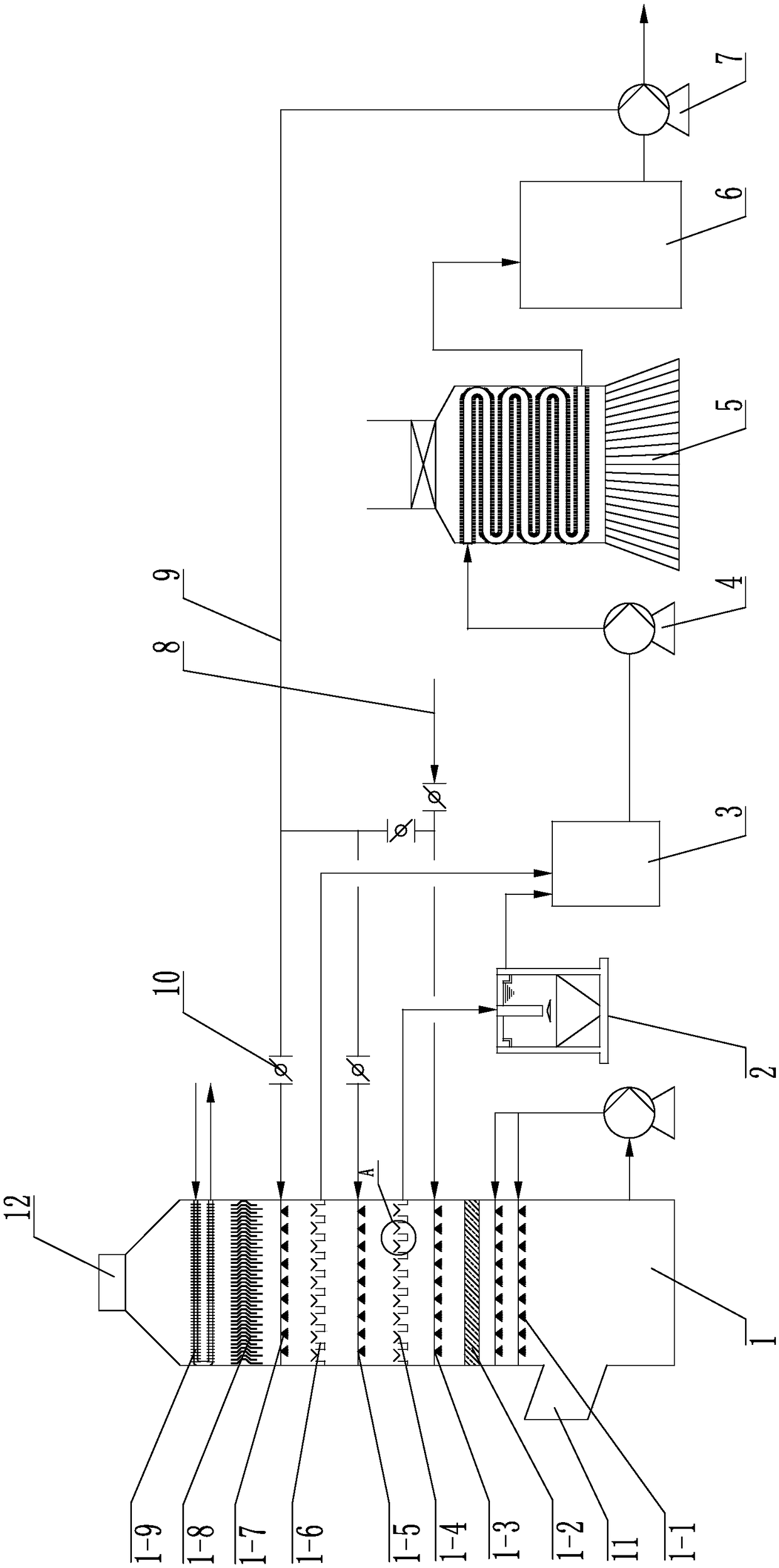

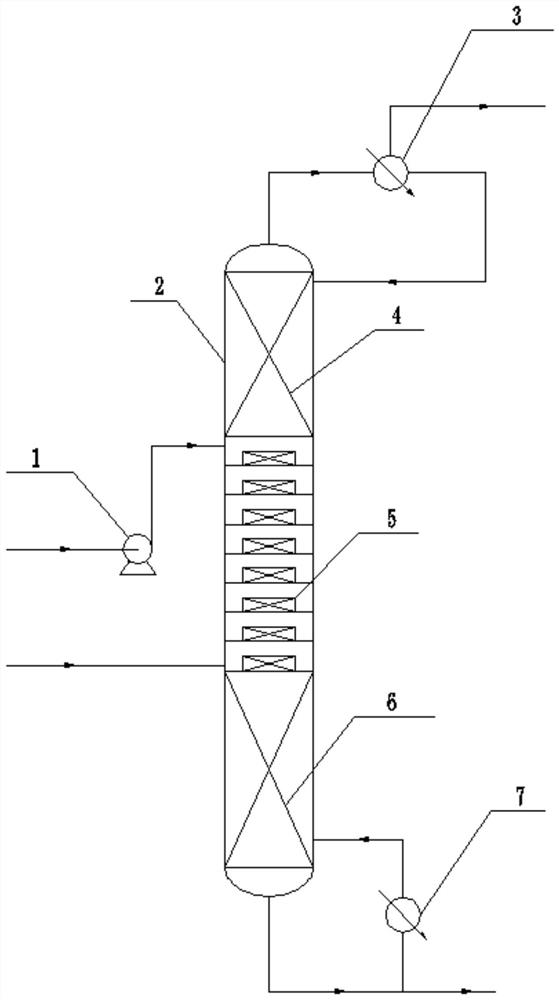

The invention discloses an all-condition wet desulphurization exhaust gas dehumidifying and white smoke removing system and method. The system is characterized by mainly comprising a desulphurizationtower (1), a deposition tank (2), a clean water tank (3), a temperature decrease pump (4), a cooling tower (5), a circulating water tank (6) and a condensing pump (7), wherein a gas inlet (11) and a gas outlet (12) are formed in the desulphurization tower (1); a desulphurization spraying layer (1-1), a demister layer (1-2), a demister flushing layer (1-3), a first gas raising plate (1-4), a first-stage condensing spraying layer (1-5), a second gas raising plate (1-6), a second-stage condensing spraying layer (1-7), a demisting dehumidifying layer (1-8) and a heater layer (1-9) are sequentiallyarranged in the desulphurization tower (1) from the bottom up. Compared with the prior art, the system and the method have the advantages of being low in investment cost and running energy consumption; all-condition, all-reason and all-weather smoke dehumidifying and white smoke removing can be performed based on the environmental temperature and the boiler load change.

Owner:新疆天富集团有限责任公司 +2

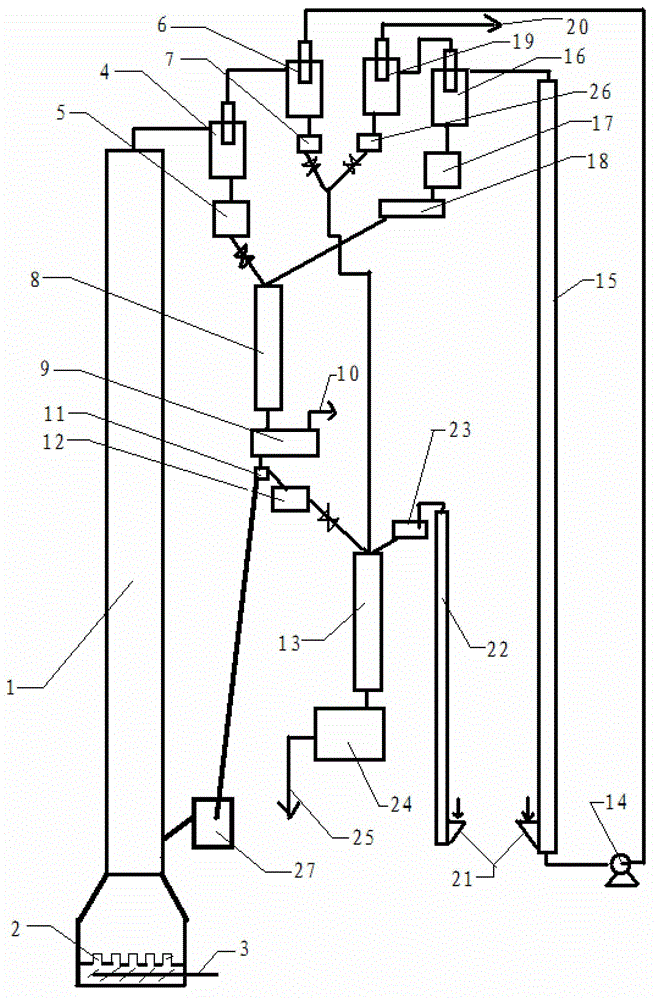

Low-rank coal downward circulating fluidized bed pyrolysis quality improvement process

The invention provides a low-rank coal downward circulating fluidized bed pyrolysis quality improvement process. A low-rank coal is dried and raised by a gas raising pipe, low-rank coal particles separate from each other in a hierarchical mode, flue gas exhausts outwards, fine particles enter a downward hybrid tube of low-rank coal quality improvement, and self-mixing, temperature rising and pyrolysis of large-medium particle low-rank coals with high temperature cycling carbocoal is achieved quickly at the top end of a downward pyrolytic reactor. Oil gas quickly separates from the carbocoal under a reactor vertical pipe. Through a condenser, a liquid product and coal gas are obtained from pyrolytic oil gas. The carbocoal is divided into two parts through a sub-material valve. Part of carbocoal flows into the downward hybrid tube of the low-rank coal quality improvement, and part of carbocoal enters a burning raising pipe and is burned and heated. High temperature carbocoals separate from each other in a hierarchical mode. The flue gas preheats air, and then is led to the bottom of the flue gas raising pipe to promote and dry a low-rank coal with a size less than six millimeters. The large-medium particles enter the top portion of the downward pyrolytic reactor to act as the high temperature cycling carbocoal. Fine carbocoal inflows the hybrid tube of the low-rank coal quality improvement and mixes with the low-rank coal and exchanges heat with the low-rank coal, and further, the fine carbocoal partially softens and pyrolyzes a thermoforming machine to produce a quality improvement type coal.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

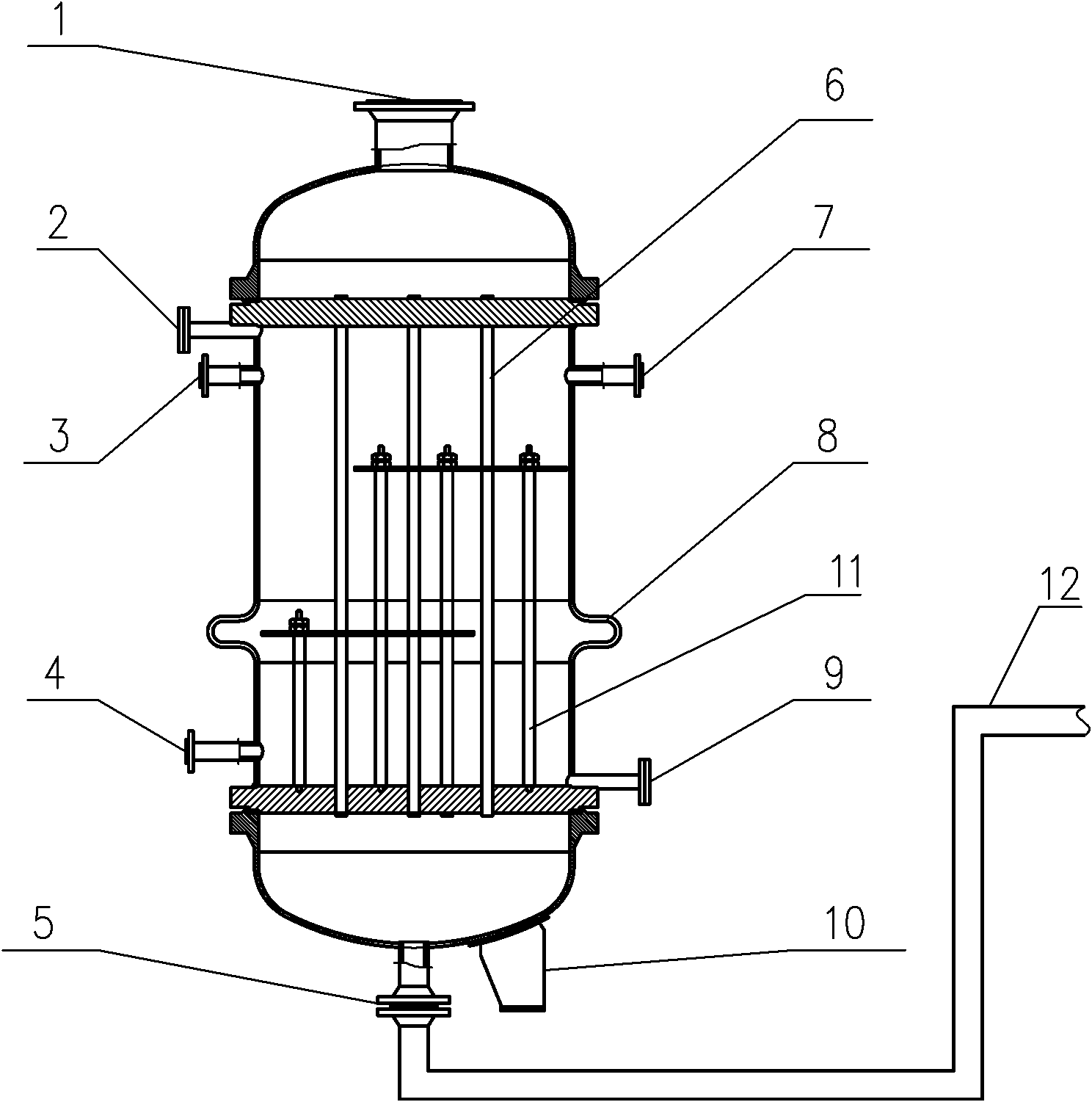

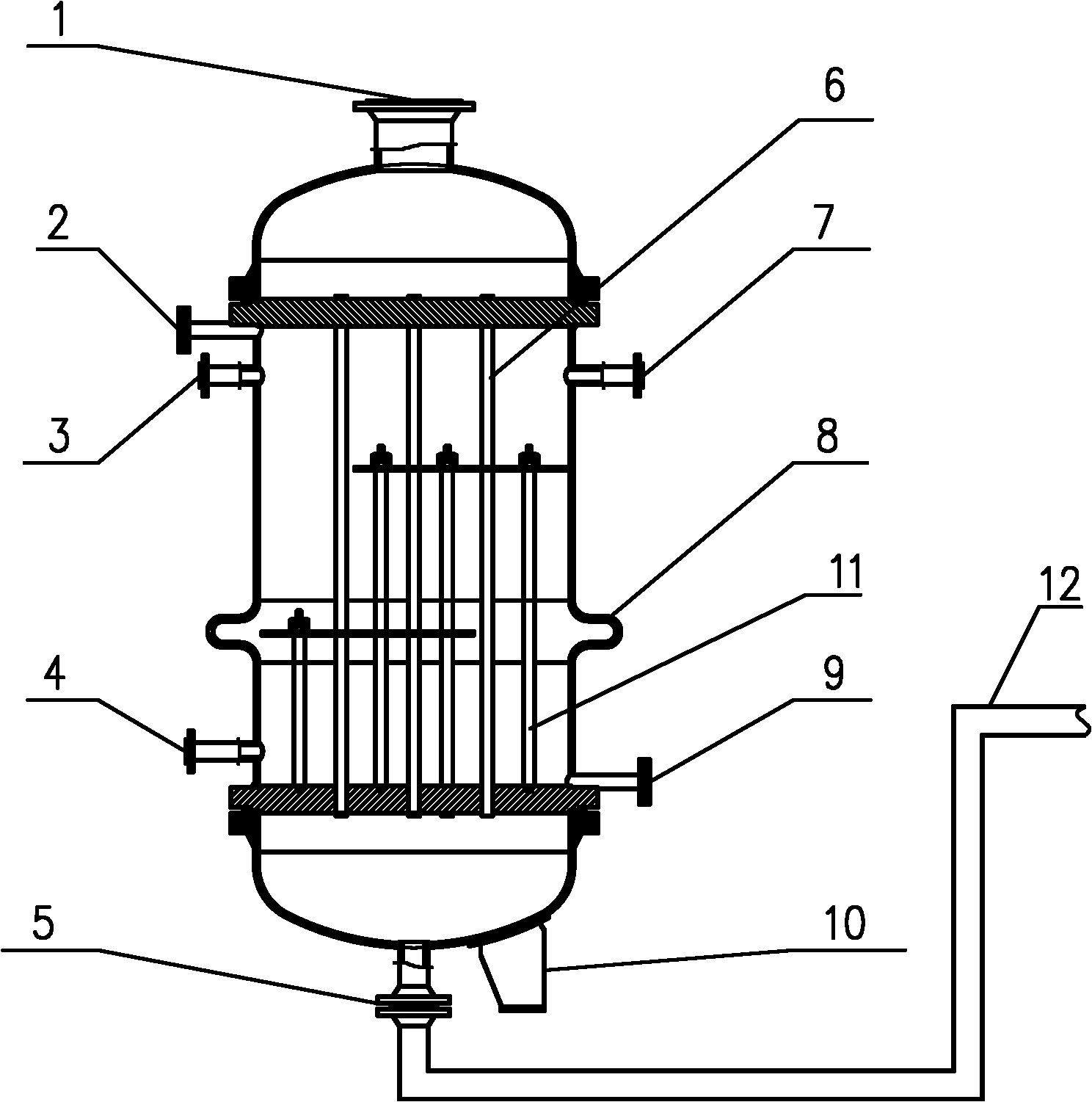

Method and equipment for condensing and cooling flash oil

InactiveCN102022925AImprove cooling efficiencyReduce water consumptionSteam/vapor condensersNuclear engineeringWater flow

The invention relates to a method and equipment for condensing and cooling flash oil. The method is characterized in that oil gas generated by a modified pitch agitated reactor enters from an inlet at the upper part of condensing and cooling equipment, flash oil generated through condensation flows from top to bottom in the tube pass inside the condensing and cooling equipment, cooling water flows from bottom to top in the tube pass inside the condensing and cooling equipment, the upper mouth of each cooling tube is positioned at the inlet of the condensing and cooling equipment, the lower mouth of each cooling tube is positioned at an outlet of the condensing and cooling equipment; and a cooling water inlet is positioned at the lower part of the condensing and cooling equipment, and a cooling water outlet is positioned at the upper part of the condensing and cooling equipment. The oil gas generated by the modified pitch agitated reactor enters the top of the condensing and cooling equipment through a gas raising tube of the modified pitch agitated reactor, wherein the oil gas flowing speed is 0.5-1.5m / s, the temperature is 350-400 DEG C, and the pressure is 0.02-0.1 MPa. The invention has the advantages of being capable of effectively saving water resources, lowering the production cost, stabilizing the product quality, being simple in operation and high in safety, reducing the environment pollution, saving energy and increasing the efficiency.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

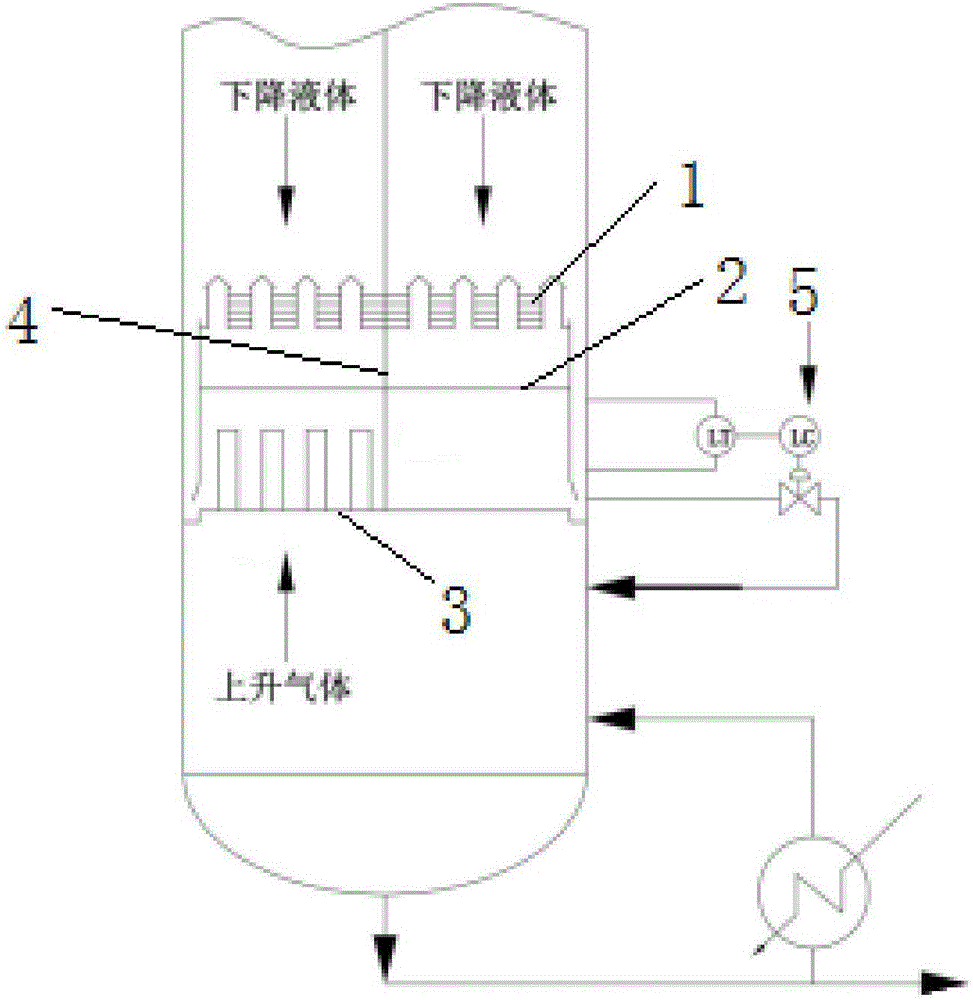

Gas phase distribution device of baffle plate tower

ActiveCN106310696AReduce wasteSimple structureDistillation regulation/controlFractional distillationControl systemGas phase

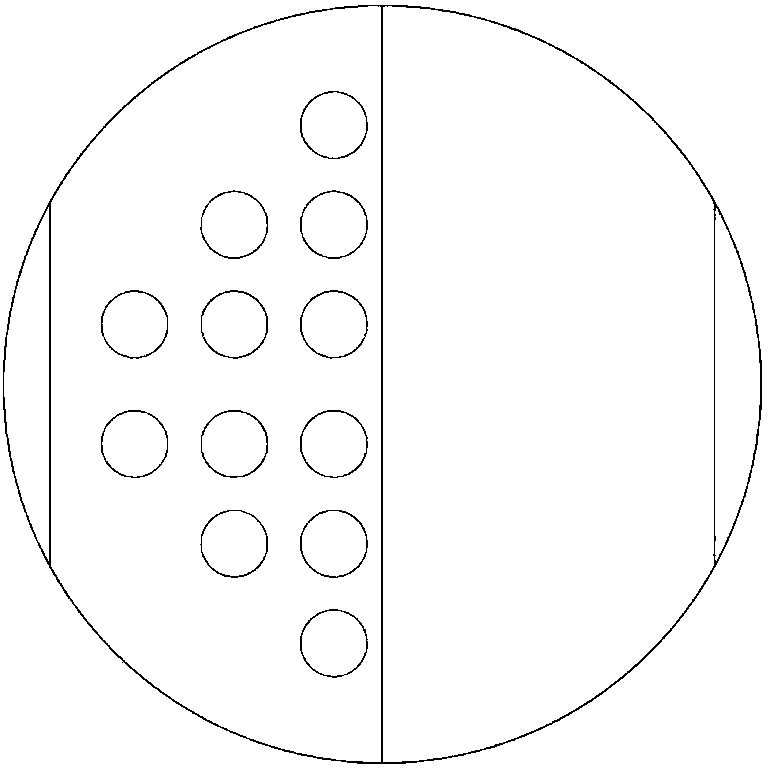

The invention relates to a gas phase distribution device of a baffle plate tower. The gas phase distribution device is characterized by comprising an automatic liquid-level control system, a gas distributor, a pressure dropping adjusting plate and a tower plate with gas raising pipelines, wherein the tower plate with the gas raising pipelines is arranged in the baffle plate tower and is located below tower filling; the pressure dropping adjusting plate is located above the tower plate with the gas raising pipelines; the edge of the tower plate with the gas raising pipelines is connected to the tower wall of the baffle plate tower in a sealing manner; gaps are formed at two sides between the gas distributor and the tower wall of the baffle plate tower and between the pressure dropping adjusting plate and the tower wall of the baffle plate tower; the automatic liquid-level control system is arranged between the pressure dropping adjusting plate and the tower plate with the gas raising pipelines and is located on the external of the baffle plate tower; long holes are formed in a baffle plate located between the pressure dropping adjusting plate and the tower plate with the gas raising pipelines; a plurality of openings are formed in an area, located at a prefrationation section of the baffle plate tower, of the tower plate with the gas raising pipelines; and a gas raising pipeline is arranged at each opening.

Owner:HEBEI UNIV OF TECH

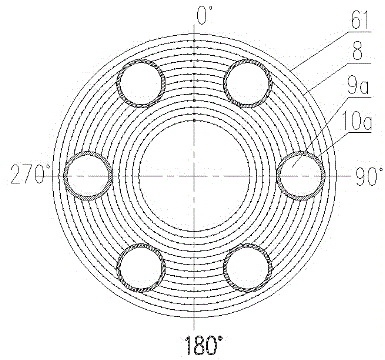

Compound jet tower disk

InactiveCN1597036AEasy to operateGreat operating flexibilityFractional distillationGAS RAISINGPulp and paper industry

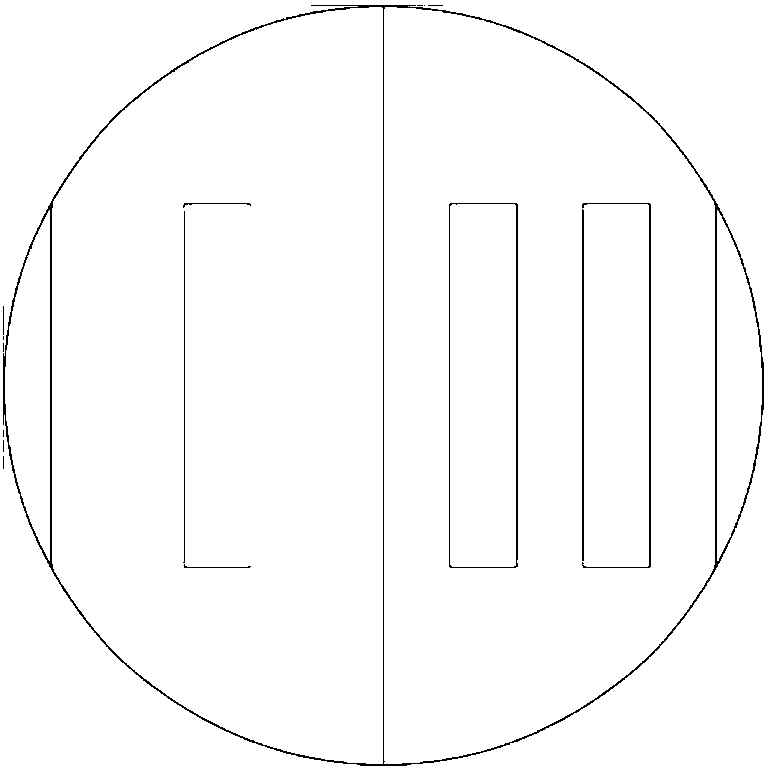

A combined tower tray is composed of tower plate with regularly arranged gas-raising holes, spray unit on said tower plate, liquid collector, down-flow spout and secondary down-flow spout. Said spray unit has a spray cover above said tower plate and with spray holes, and two-layer gas-liquid separating unit above said spray cover and consisting of a perforated plate and a blind plate.

Owner:HEBEI UNIV OF TECH

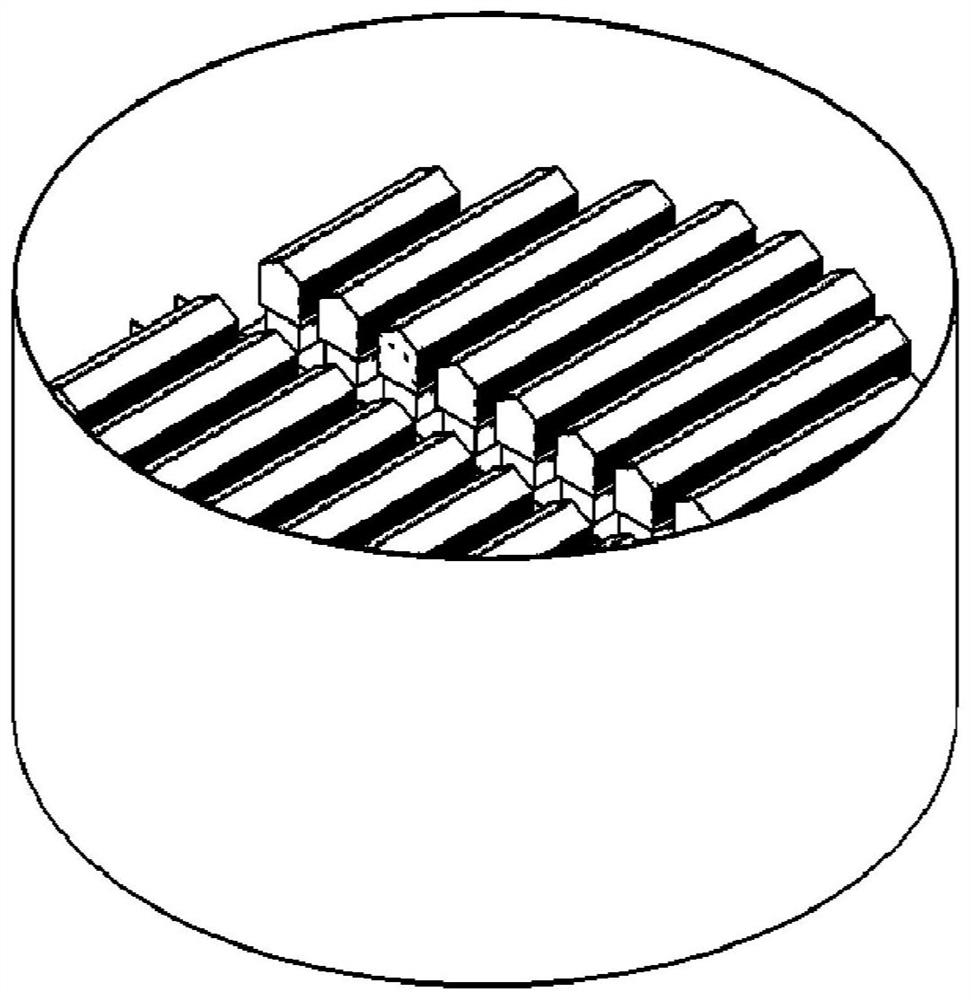

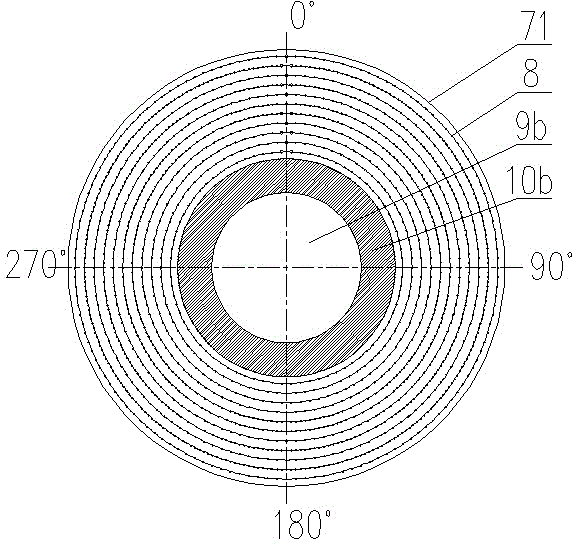

Three-dimensional film spraying and perforating tray

ActiveCN104083891AExtended flow timeReduce leakageFractional distillationContact timeCompound (substance)

The invention provides a three-dimensional film spraying and perforating tray belonging to the field of mass transfer and heat transfer equipment in chemical engineering. The three-dimensional film spraying and perforating tray comprises a tower body and a tower plate arranged inside the tower body, and spraying covers arranged on the tower plate. The three-dimensional film spraying and perforating tray is characterized in that a plurality of fixing holes are formed in the tower plate, a guide cylinder is fixed in each fixing hole, a liquid seal trough is arranged at the outer ring of the side wall of each guide cylinder, a gas raising hole is formed at the bottom of each liquid seal trough and is concentric with each fixing hole, the spraying cover is arranged at the inner ring of the side wall of each guide cylinder, the lower end face of the side wall of each spraying cover is welded with the bottom of each liquid seal trough, a plurality of spraying holes are formed in the side wall of each spraying cover, a top cover is arranged at the top of each spraying cover, a liquid receiving trough is arranged at the upper end of each spraying cover, the side wall of each guide cylinder is coaxially connected with the outer wall of each spraying cover and the side wall of each liquid seal trough, gaps are reserved between the side wall of each guide cylinder and the outer wall of each spraying cover and between the outer wall of each spraying cover and the side wall of each liquid seal trough, and a gap is reserved between each top cover and each spraying cover. According to the three-dimensional film spraying and perforating tray, by adopting a perforating technology, on the one hand, the problem caused by liquid streaming and mixing is solved, and on the other hand, the gas-liquid contact time is increased and through perforation, and thus the mass transfer efficiency is increased.

Owner:衡水酷祥生物科技有限公司

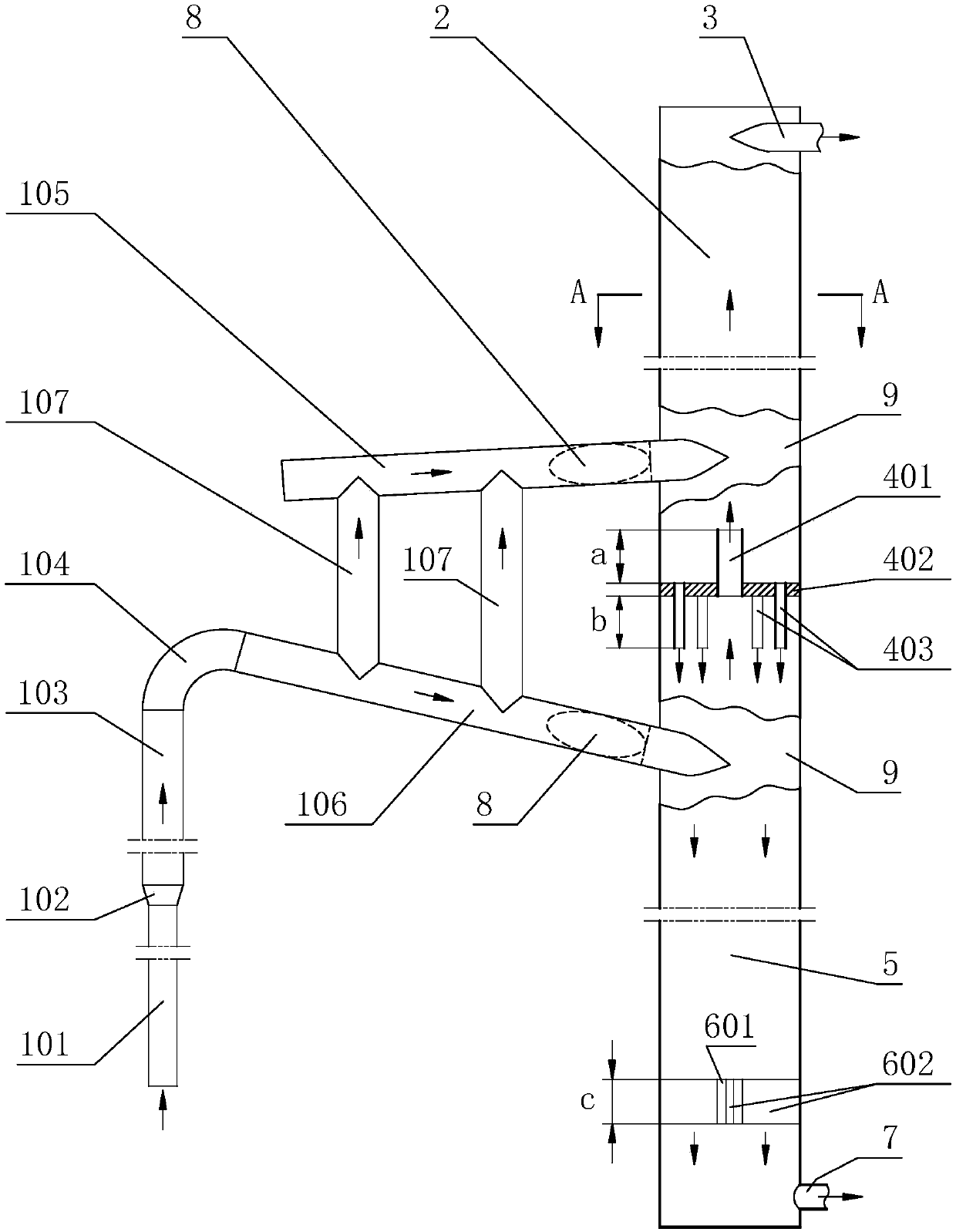

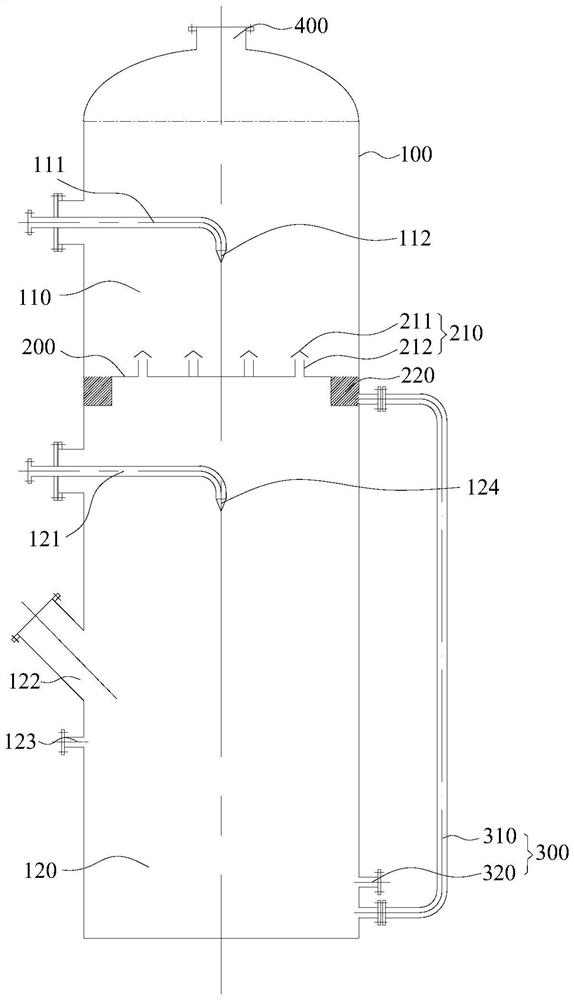

Gas-liquid separator and gas-liquid separation method

ActiveCN107596797AReduce separation loadEasy to separateDispersed particle separationCycloneVertical tube

The invention discloses a gas-liquid separator and a gas-liquid separation method. The gas-liquid separator is provided with a columnar cyclone separator; the columnar cyclone separator comprises a vertical tube body (9); a partition plate (402) is arranged in the vertical tube body; an air lifting pipe (401) is arranged in the middle of the partition board; a circle of downcomer tubes (403) are arranged downwards, and are close to the edge of the partition board; the gas-liquid separator is also provided with a tubular preseparator; the tubular preseparator is provided with a gas phase tube (105) and a liquid phase tube (106); the gas phase tube and the liquid phase tube are both connected with the vertical tube body along the tangential direction of the vertical tube body; the outlet ofthe gas phase tube is located above the top outlet of the gas-raising tube; the outlet of the liquid phase tube is located below the bottom outlets of the downcomer tubes; and a liquid drop sedimentation region (2) and a bubble floating region (5) are arranged in the vertical tube body. The invention discloses the gas-liquid separation method by adopting the gas-liquid separator. The gas-liquid separator provided by the invention is mainly used for gas-liquid separation in the technical field of oil-gas treatment in oil and gas fields.

Owner:SINOPEC GUANGZHOU ENG +1

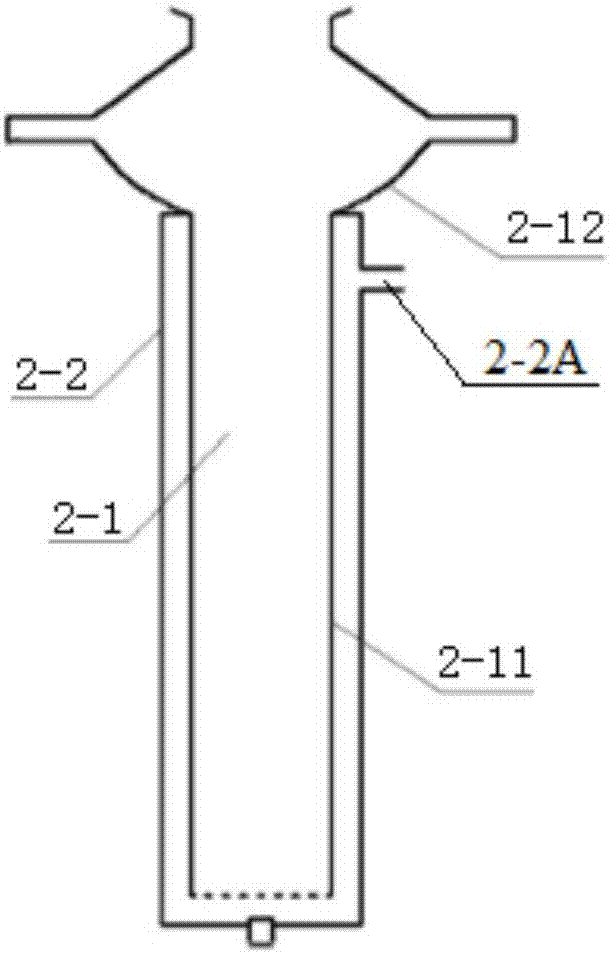

Reactor component for thermogravimetry equipment and thermogravimetry equipment

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Compound jet tower disk

InactiveCN1246062CEasy to operateGreat operating flexibilityFractional distillationGAS RAISINGPulp and paper industry

A combined tower tray is composed of tower plate with regularly arranged gas-raising holes, spray unit on said tower plate, liquid collector, down-flow spout and secondary down-flow spout. Said spray unit has a spray cover above said tower plate and with spray holes, and two-layer gas-liquid separating unit above said spray cover and consisting of a perforated plate and a blind plate.

Owner:HEBEI UNIV OF TECH

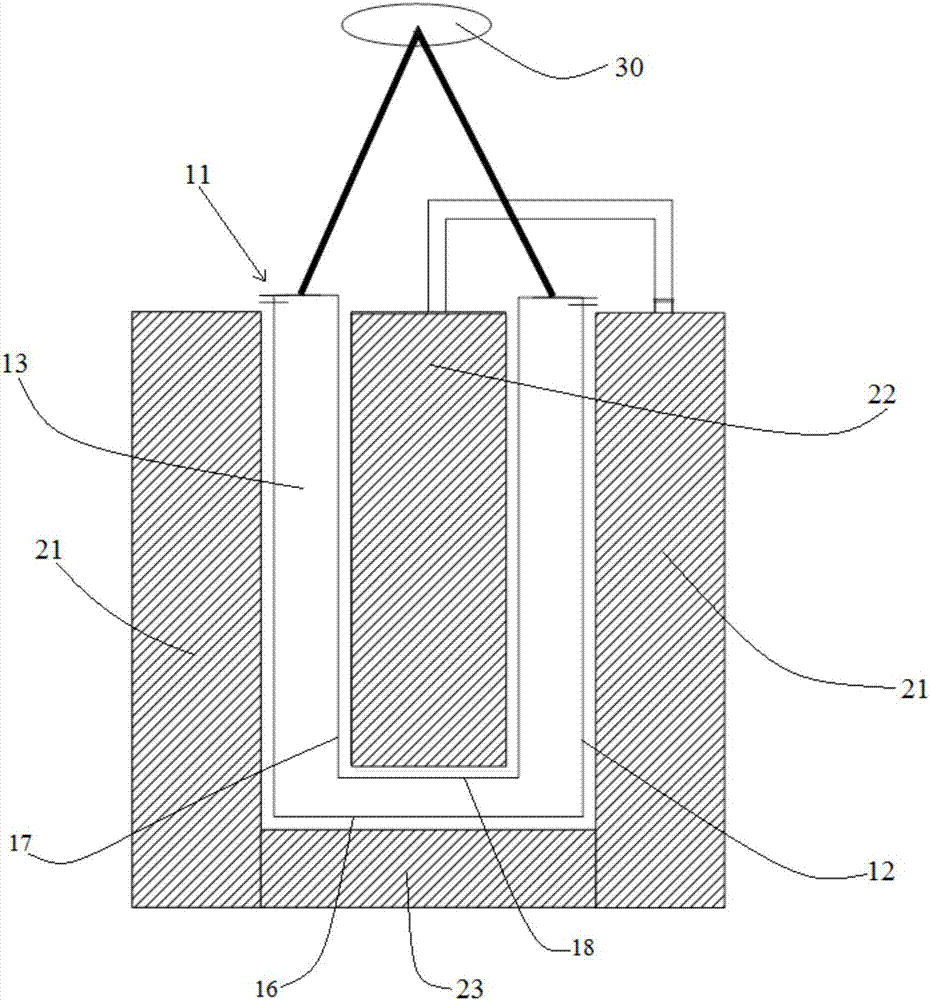

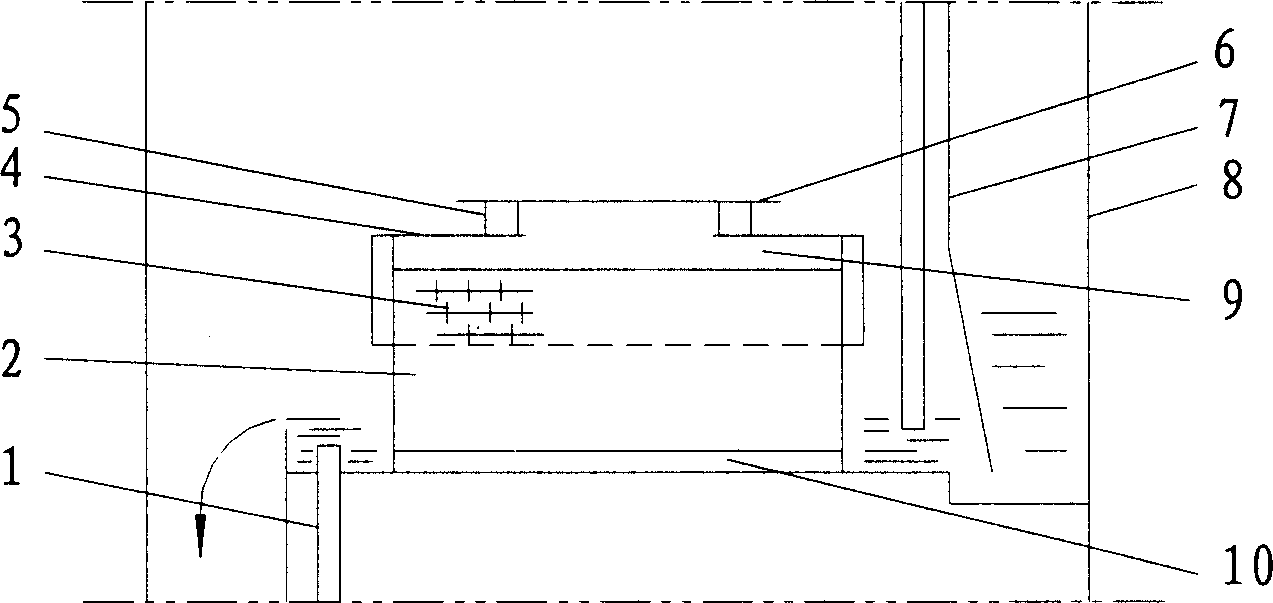

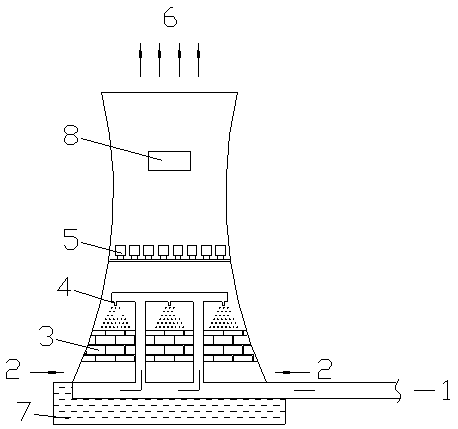

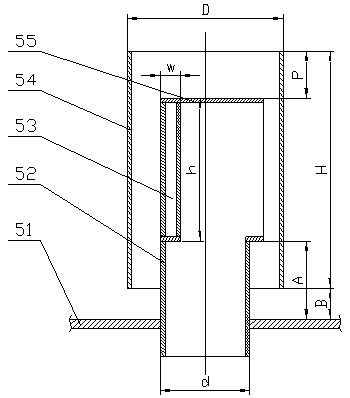

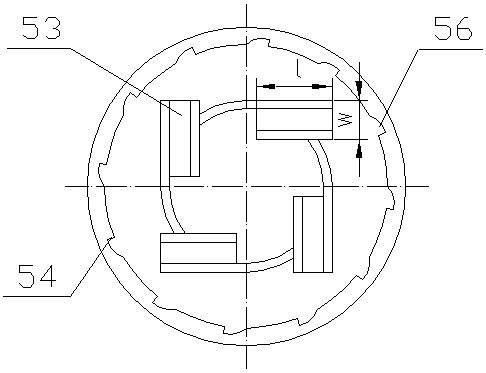

Water cooling tower with demister

InactiveCN108692581AEasy to installSimple structureDispersed particle separationTrickle coolersWater resourcesDistribution system

The invention discloses a water cooling tower with a demister. The water cooling tower comprises a water cooling pond, heat-dissipating filler, a water distribution system, the demister and a fan sequentially from top to bottom. A wind inlet is formed above the water cooling pond. The water distribution system is connected with a hot water pipeline. A gas outlet is formed in the top of the water cooling tower. The demister is composed of a tower plate and a plurality of demisting assemblies. Each demisting assembly comprises a gas raising pipe and an outer cylinder. The outer cylinder is arranged on the outer side of the gas raising pipe. The outer cylinder and the gas raising pipe are located on the same axis. The gas raising pipe is fixed to a tower disc. A sealing cover plate is arranged on the top of the gas raising pipe. A rectification channel is formed in the periphery of the gas raising pipe. According to the water cooling tower, the demister gathers a large quantity of liquidstate mist drops carried away by airflow in the convection contact heat exchange process, severe waste of water resources is avoided, pollution to surrounding environment is reduced, the structure issimple, the pressure drop is small, installing is convenient, and recovery treatment of exhausted water mist of the water cooling tower can be achieved effectively.

Owner:CHINA PETROLEUM & CHEM CORP +1

Precoated sand for casting instruments

Precoated sand for casting instruments comprises the following raw materials in parts by weight: 1-2 parts of matrix resin, 0.02-0.06 part of a coupling agent, 0.2-0.5 part of urotropine, 0.2-0.5 part of a curing agent, 0.5-1 part of sulfonated lignin fiber, 0.2-0.5 part of montmorillonite powder, 10-20 parts of electric fused zircon sand and 80-100 parts of magnesia. Compared with conventional precoated sand, the precoated sand for casting instruments has the performance of the conventional precoated sand, also has the performance of gas raising speed delay and nitrogen production inhibition, and can effectively reduce nitrogen porosity production so as to improve the rate of finished products of casted instruments, the universality of the precoated sand is increased, the precoated sand meets iron castings and steel castings, the product rate of castings is improved, molding material cost of casting enterprises is saved, and the precoated sand has excellent casting performance.

Owner:无锡市三峰仪器设备有限公司

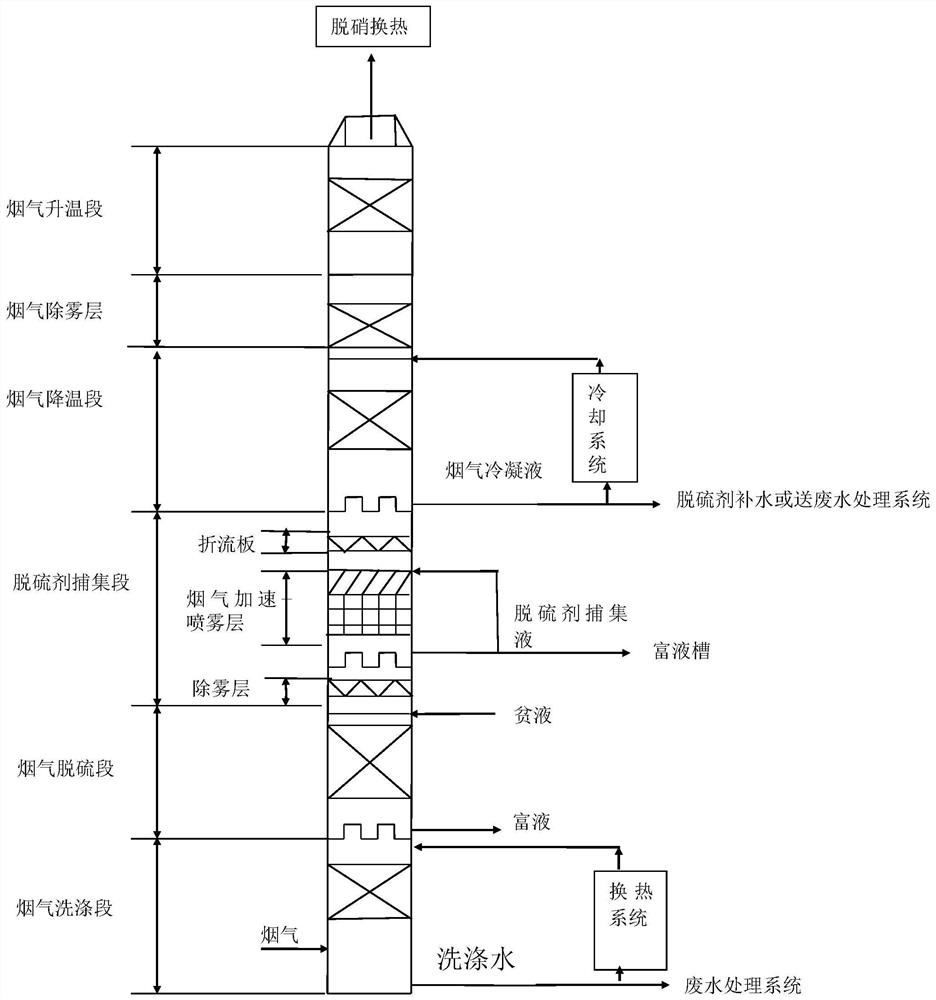

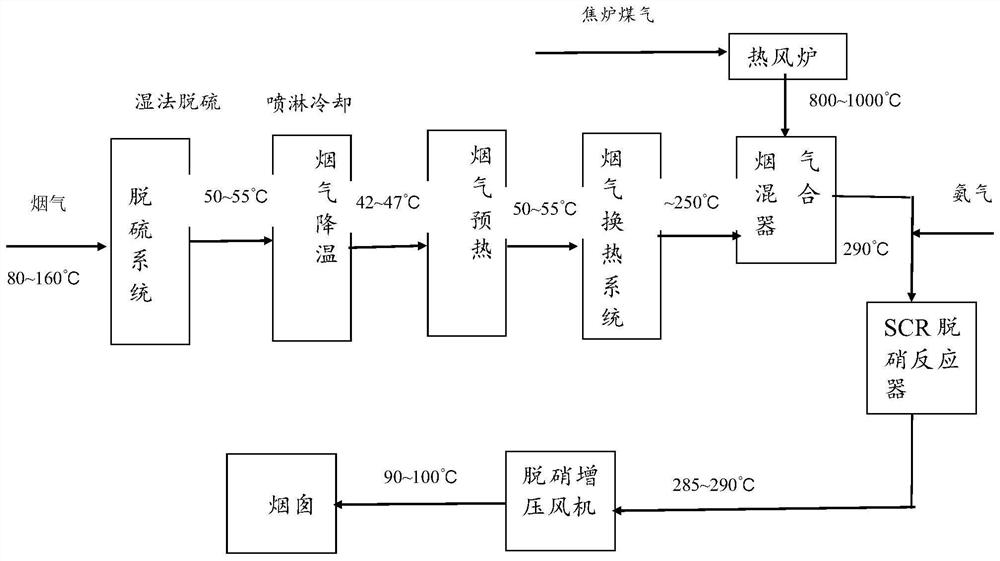

Flue gas desulfurization and SCR denitration combined system and flue gas treatment process

InactiveCN112742178ARealize capture and recoveryReduce escapeGas treatmentDispersed particle separationFlue gasProcess engineering

The invention provides a flue gas desulfurization and SCR denitration combined system and process. The flue gas desulfurization system comprises: a desulfurization tower, wherein the desulfurization tower comprises a flue gas washing section, a flue gas desulfurization section, a desulfurization liquid capturing section, a flue gas cooling section, a demisting section and a flue gas preheating section which are sequentially arranged from bottom to top; a gas rising hole is formed in a smoke rotation accelerating device in the trapping section, and smoke is accelerated after passing through the gas rising hole; and the opening degree of the gas raising hole is greater than or equal to 25% and less than 100%; a flue gas heat exchange unit connected with the flue gas preheating section; a flue gas mixer sequentially connected with the flue gas heat exchange units; and an SCR denitration reactor and a heat exchanger. The desulfurization liquid trapping section is arranged, so that a desulfurization agent entrained in flue gas can be trapped and recycled, escape of the desulfurization agent and secondary pollution caused by escape of the desulfurization agent are reduced, and the emission concentration of SO2 and NOx is relatively low.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

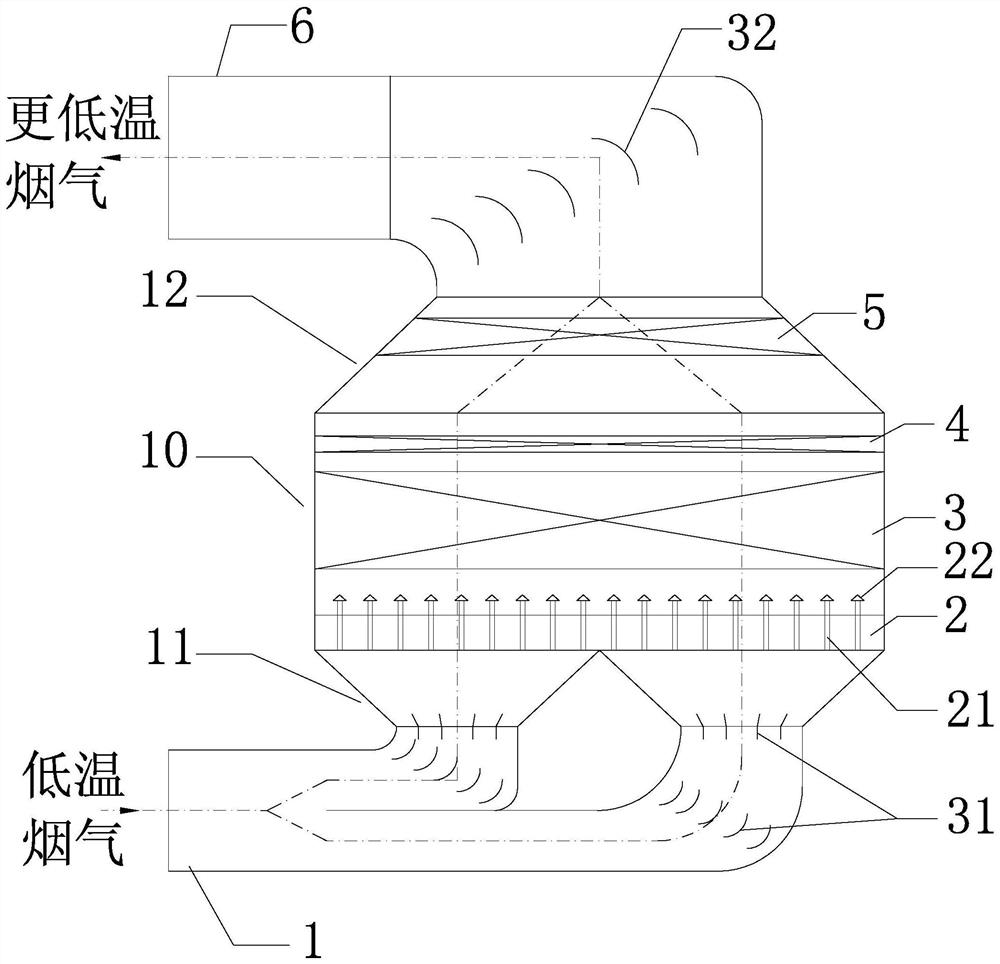

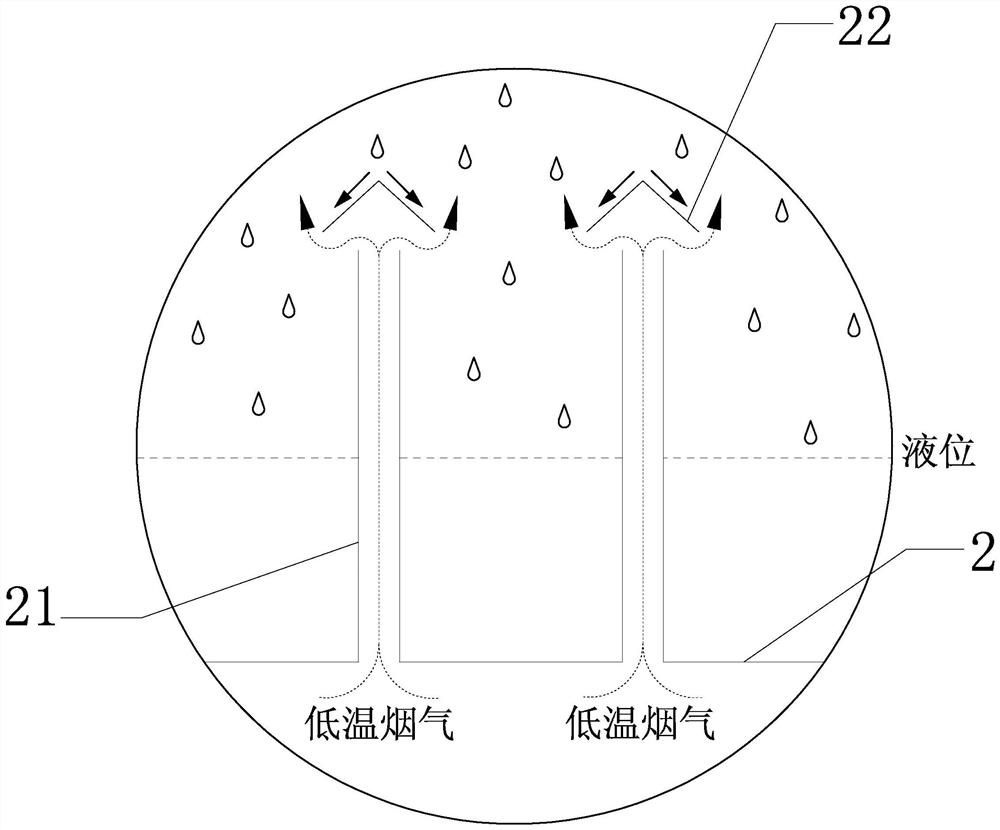

Deep extraction device for flue gas waste heat of thermal power plant

PendingCN112944373AHigh thermal efficiencyLow costCombustion technology mitigationTrickle coolersProcess engineeringGAS RAISING

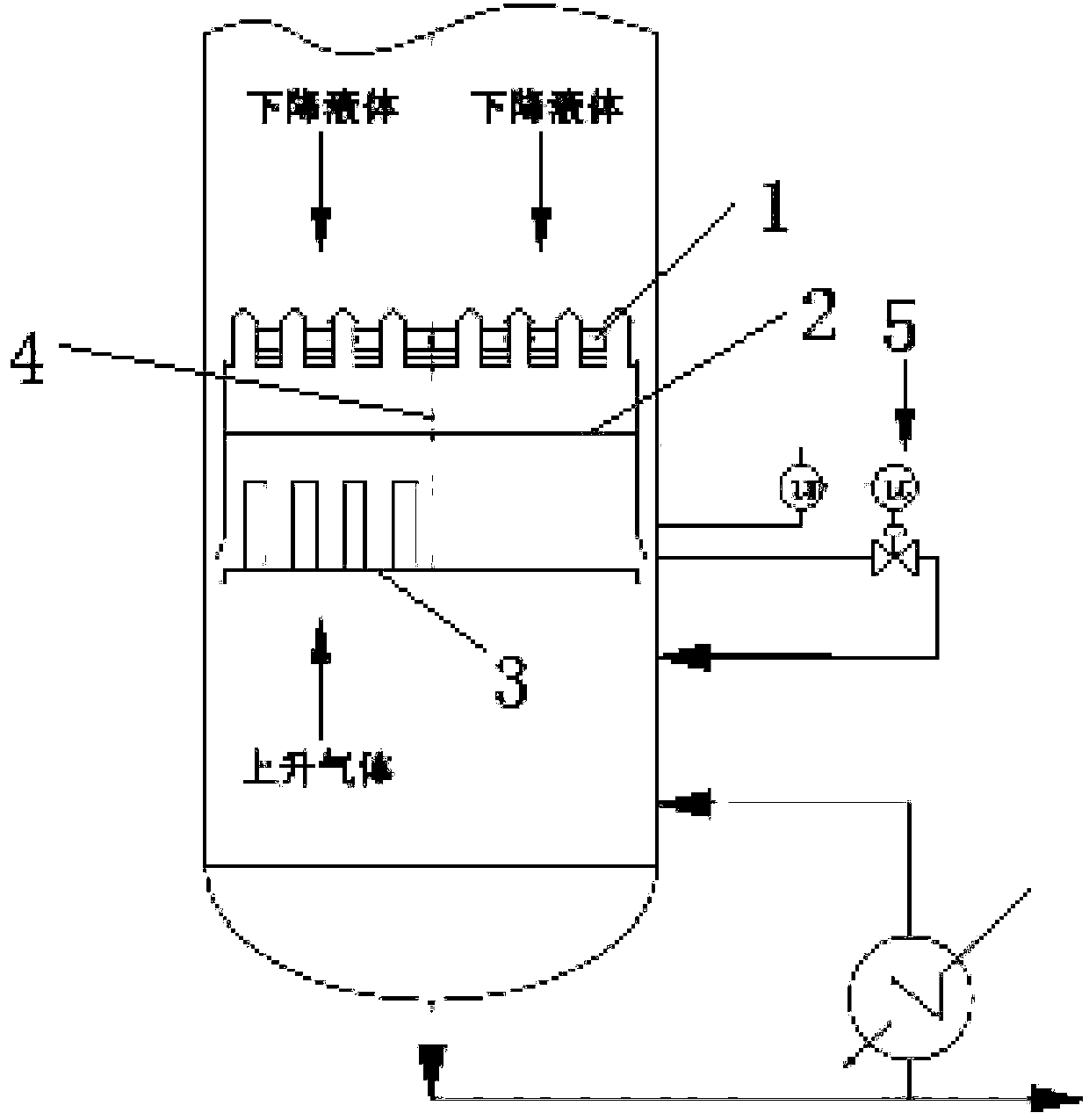

The invention provides a deep extraction device for flue gas waste heat of a thermal power plant. The device comprises an absorption tower, wherein an inlet flue of the absorption tower is connected to a low-temperature flue gas pipeline, at least one outlet of the inlet flue communicates with the bottom of the absorption tower, a liquid collection disc is arranged at the bottom in the absorption tower, filler is arranged in the middle of the absorption tower, a circulating water distributor is arranged at the top of the absorption tower, the liquid collection disc is a gas raising pipe liquid collection disc, a flue gas outlet of the absorption tower communicates with an outlet flue, and a mist eliminator is arranged at the flue gas outlet of the absorption tower. According to the deep extraction device for the flue gas waste heat, direct contact heat exchange between circulating water and low-temperature flue gas can be utilized, waste heat in low-temperature flue gas can be effectively recycled, the heat efficiency of a unit is improved, the requirement for environmental protection is met, and meanwhile the structure is simple, and the equipment cost is low.

Owner:NORTH CHINA POWER ENG

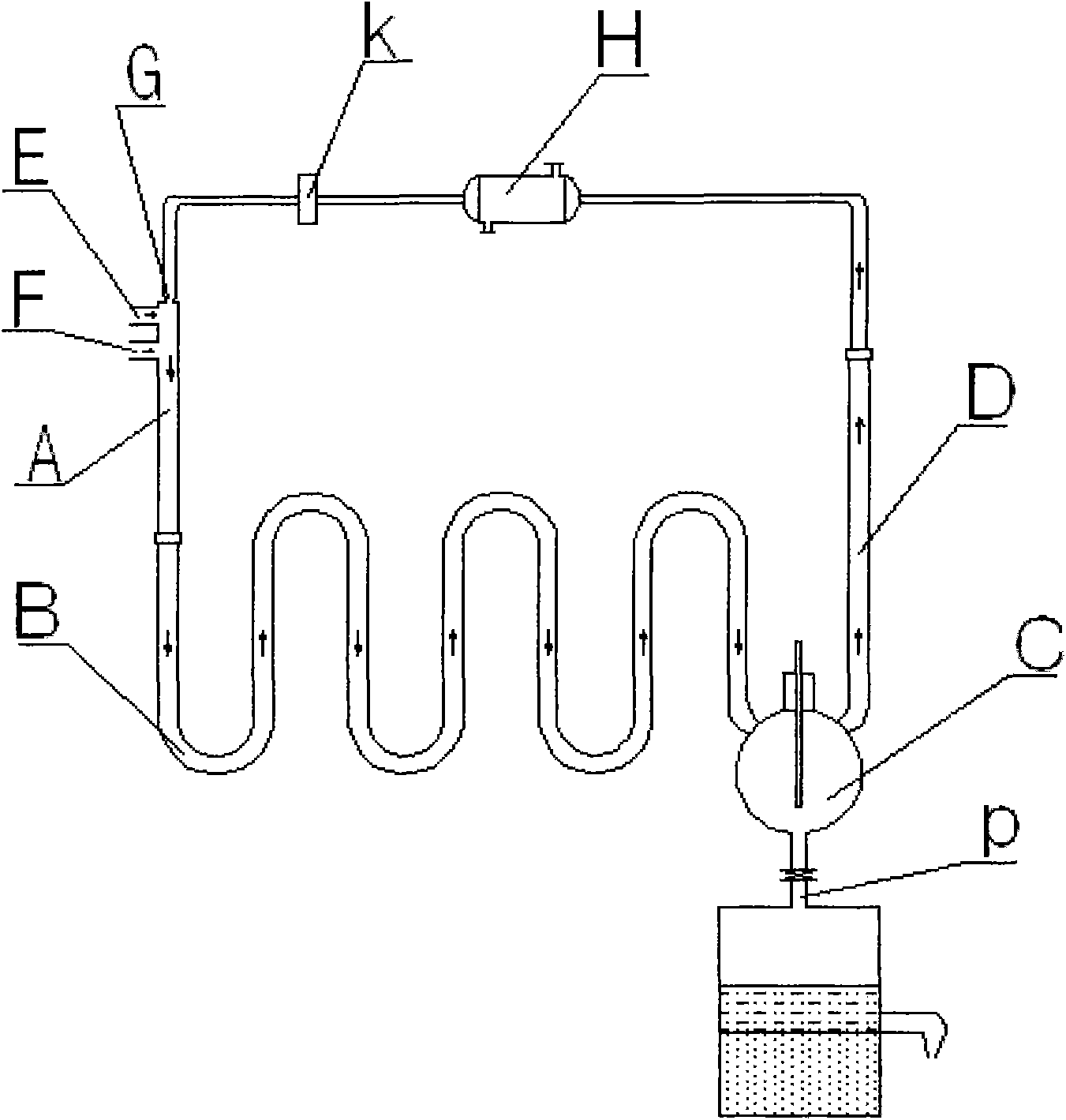

Novel amination process of amino silane

InactiveCN101768179AHigh yieldGuaranteed uptimeGroup 4/14 element organic compoundsSilanesBiochemical engineering

The invention relates to a novel amination process of amino silane, which is characterized in that the bottom of a reaction tower A is communicated with an inlet of a coiled pipe B; an outlet of the coiled pipe B is communicated with an upper feed port of a product receiving device C; the bottom of the product receiving device C is provided with a discharge port P; the upper part of the product receiving device C is also communicated with the bottom end of a gas raising pipe D; the upper end of the gas raising pipe D is communicated with the top of the reaction tower A through a reflux feed inlet G of a condenser H; and the upper part of the reaction tower A is sequentially provided with a first feed inlet E and a second feed inlet F. The new amination process of the amino silane comprises the following steps of: uniformly adding quadrol at the speed of 1530-2000 g / 5h; and uniformly adding gamma-chloropropyl methyl dimethoxy silane at the speed of 1000 g / 5h to complete amination so as to obtain a final product. The invention designs a novel device matched with the good process and has the advantages of high product yield, reasonable and compact device, stable operation and continuous reaction.

Owner:蓝星安迪苏股份有限公司

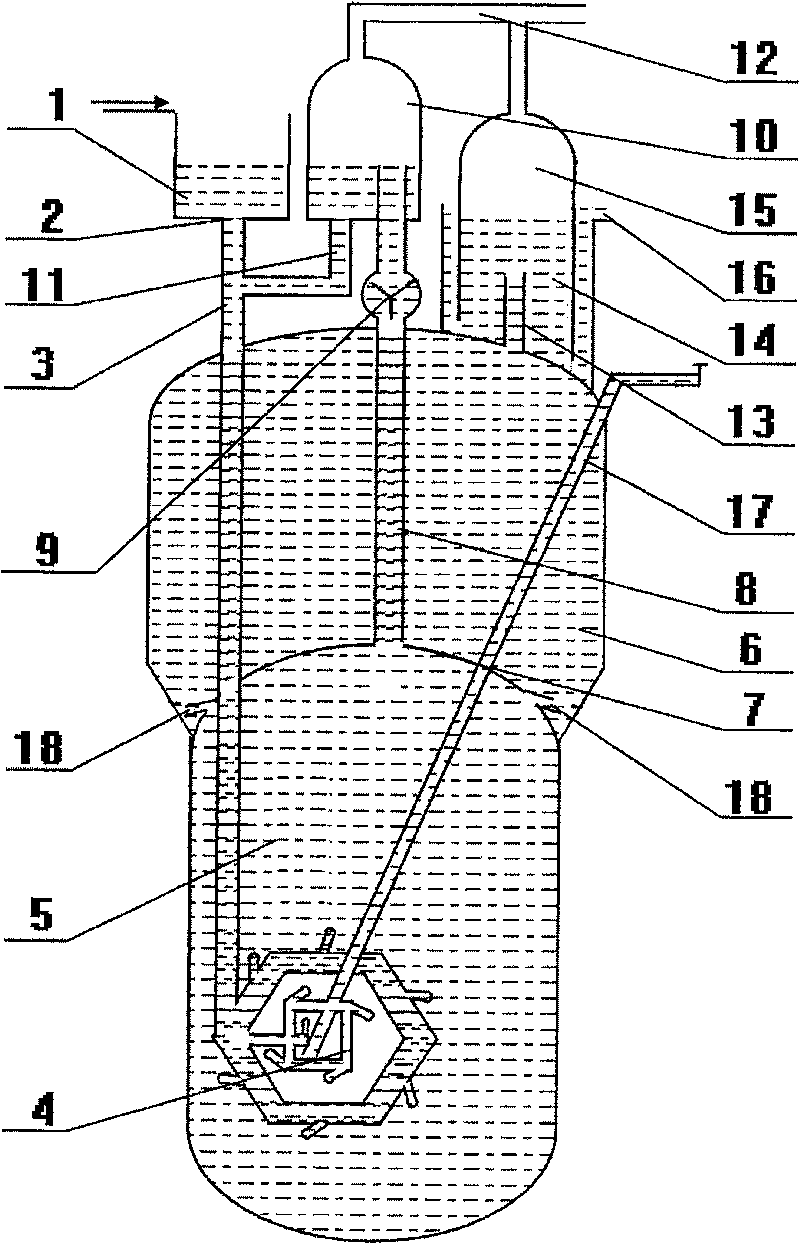

Multi-pipe inner circulation three-phase fluidized bed

InactiveCN105984936ACompact structureGuaranteed uptimeBiological water/sewage treatmentFluidized bedGAS RAISING

The invention relates to a multi-pipe inner circulation three-phase fluidized bed. The fluidized bed comprises a water inlet pipe, a water outlet pipe, a first reaction region and a gas-liquid separation region; the water outlet pipe is communicated into the first reaction region on the lower portion of the fluidized bed, a second reaction sedimentation region is arranged above the first reaction region, a first sewage return pipe is arranged below the second reaction sedimentation region, a gas raising pipe is arranged on the upper portion and communicated to the gas-liquid separation region, a filtering region is arranged above the second reaction sedimentation region, the water outlet pipe is communicated to the filtering region, the gas-liquid separation region is arranged above the filtering region, a marsh gas pipe is arranged at the top of the gas-liquid separation region, a second sewage return pipe is arranged at the bottom of the gas-liquid separation region and communicated into the first reaction region, and a skimming region is arranged in the gas-liquid separation. The fluidized bed is compact in structure, stable in operation and low in operation cost and integrates biochemical treatment, gas and marsh solid separation and marsh gas collection.

Owner:JIANGSU KEYUAN ENVIRONMENTAL PROTECTION TECH

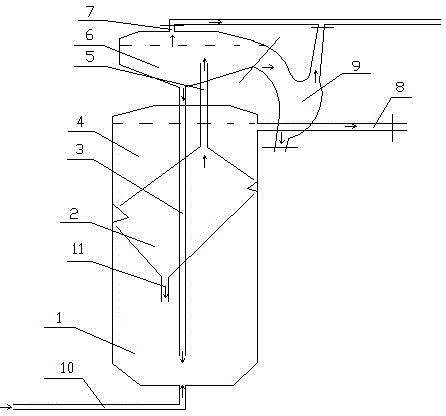

TAIC anaerobic reactor

InactiveCN101323487BHigh volume load rateIncrease gas production rateWaste based fuelTreatment with anaerobic digestion processesHigh rateWater quality

The invention discloses a TAIC high-rate anaerobic reactor, comprising a first reaction chamber and a second reaction chamber which are superposed, a charging tube, a discharging tube, a gas raising tube, a sludge circulation backflow tube, a tri-phase separator and a steam-liquid separating tank. The invention is characterized in that the height and diameters of the two superposed reaction chambers are different, and the upper second reaction chamber is larger than the lower first reaction chamber; the tri-phase separator relates to a ball-crown inclined connecting tri-phase separator; a circulation backflow pump provided with speed-adjusting function is arranged on the gas raising tube; the sludge circulation backflow tube is directly communicated with the lower part of a nozzle of a charging header tube; an automatic pressure-regulating charging tank is arranged on the charging tube; the charging header tube is connected with a cloth system arranged at the bottom of the first reaction chamber. The reactor is provided with super-high volume load rate, small occupied area, low capital outlay, high gas-generation, better purified water quality and strong anti-impact capability andcan be widely used for the anaerobic processing to organic waste liquids of various concentrations.

Owner:赵泽明

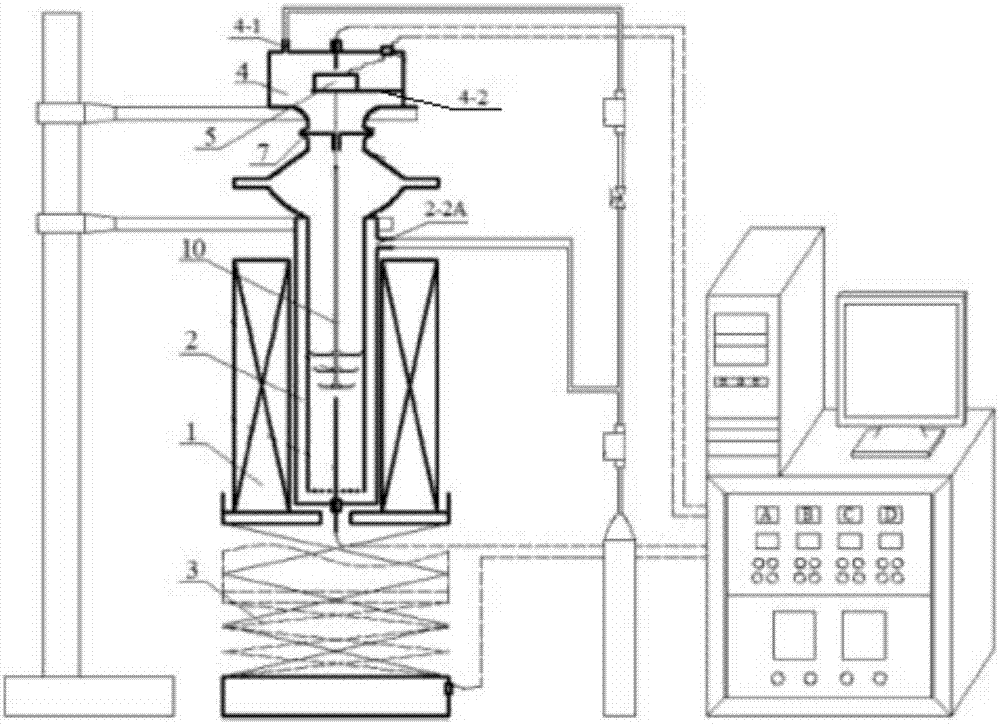

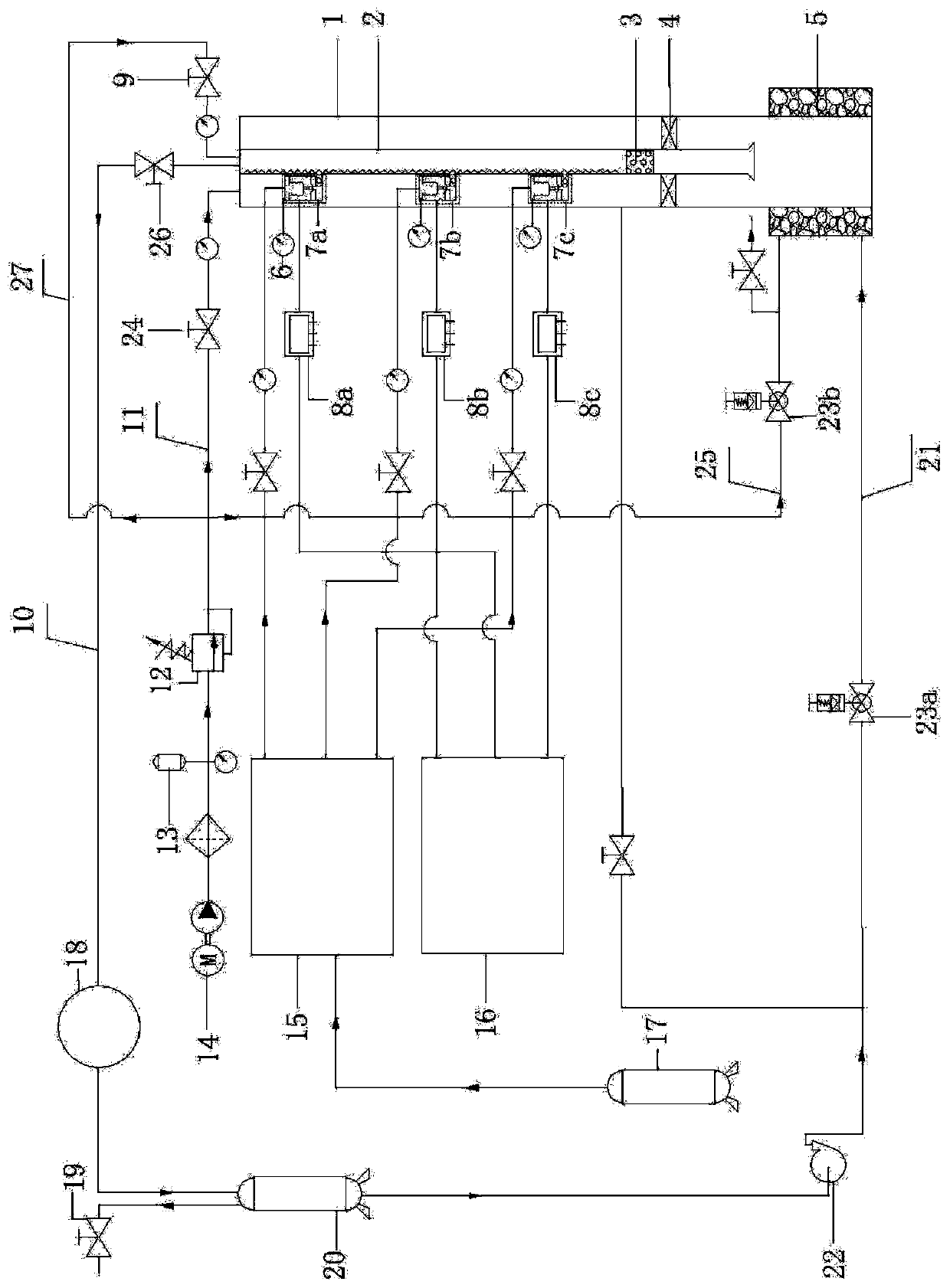

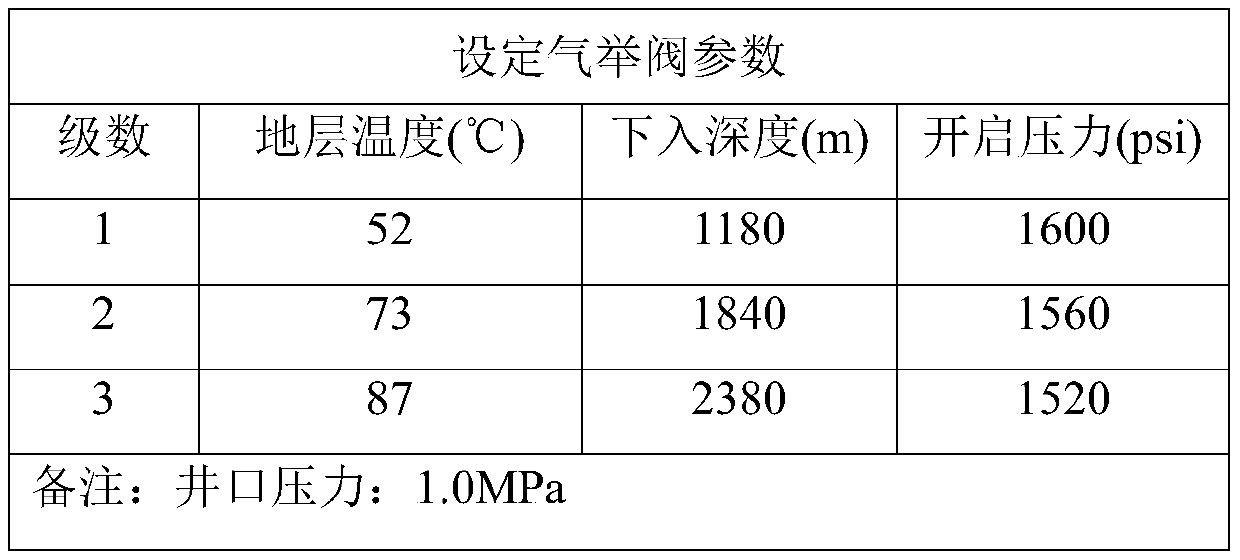

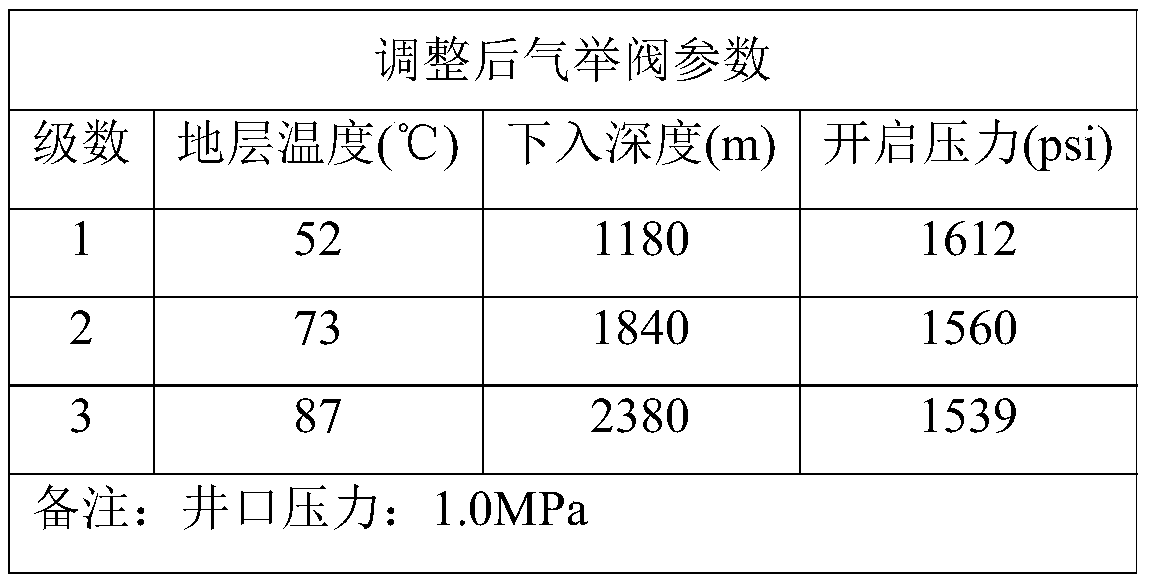

Gas lift well drainage simulation test device and test method

The invention relates to a gas lift well drainage simulation test device and a test method, and belongs to the technical field of gas lift well drainage in oil and gas fields. The gas lift well drainage simulation test device is composed of a wellbore simulation system, a liquid supply system, a gas supply system and a temperature and pressure control device; the gas lift well drainage simulation test method is based on the actual production well conditions, and the fluid drainage simulation test is set For the test parameters of the device, establish a gas lift well drainage simulation test device, adjust the test parameters of the liquid drainage simulation test device according to the operation status of the liquid drainage simulation test device, and determine the actual operating parameters of the actual production well. The beneficial effects are: using the opening and closing working conditions of the gas lift valve in the wellbore simulation system, observing the gradual reduction process of the liquid level in the wellbore simulation system with the working condition of the gas lift valve, and adjusting the operating parameters of the gas lift valve in the wellbore simulation system, Determine the operating parameters of the gas lift valve in the actual production well to ensure that the gas lift valve is in the best condition and ensure that the wellbore effusion is discharged step by step.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process and device for dehumidifying wet flue gas purification tail gas

InactiveCN101956991BAvoid corrosionReduce corrosionLighting and heating apparatusDispersed particle separationLiquid waterLiquid storage tank

Owner:洛阳市天誉环保工程有限公司

Low-rank coal downward circulating fluidized bed pyrolysis quality improvement process

The invention provides a low-rank coal downward circulating fluidized bed pyrolysis quality improvement process. A low-rank coal is dried and raised by a gas raising pipe, low-rank coal particles separate from each other in a hierarchical mode, flue gas exhausts outwards, fine particles enter a downward hybrid tube of low-rank coal quality improvement, and self-mixing, temperature rising and pyrolysis of large-medium particle low-rank coals with high temperature cycling carbocoal is achieved quickly at the top end of a downward pyrolytic reactor. Oil gas quickly separates from the carbocoal under a reactor vertical pipe. Through a condenser, a liquid product and coal gas are obtained from pyrolytic oil gas. The carbocoal is divided into two parts through a sub-material valve. Part of carbocoal flows into the downward hybrid tube of the low-rank coal quality improvement, and part of carbocoal enters a burning raising pipe and is burned and heated. High temperature carbocoals separate from each other in a hierarchical mode. The flue gas preheats air, and then is led to the bottom of the flue gas raising pipe to promote and dry a low-rank coal with a size less than six millimeters. The large-medium particles enter the top portion of the downward pyrolytic reactor to act as the high temperature cycling carbocoal. Fine carbocoal inflows the hybrid tube of the low-rank coal quality improvement and mixes with the low-rank coal and exchanges heat with the low-rank coal, and further, the fine carbocoal partially softens and pyrolyzes a thermoforming machine to produce a quality improvement type coal.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Liquid collecting and gas distributing device for large-scale flue gas desulfurization tower

ActiveCN103111180BGuaranteed outputPrevent leakageDispersed particle separationChemical industryThermal deformation

The invention provides a liquid collecting and gas distributing device for a large-scale flue gas desulfurization tower. The device consists of a cross section-variable base plate gas raising pipe, a grid beam type gas raising pipe, a double-layer type liquid baffling hood, an inclined channel type main beam with a function of guiding liquid flow, an extracting hopper, an extracting pipe and a plane expansion joint. The device has an all-welded structure for preventing liquid from escaping, the liquid falling, the liquid drop sputtering and the zero escaping of liquid fog and the lower pressure drop can be realized due to the double-layer type liquid baffling hood, the aperture ratio of the device can be increased and the convenient corrosion prevention can be carried out due to the grid beam type gas raising pipe, the impacting foaming can be reduced and the lateral line extraction quantity can be guaranteed due to the deep extracting hopper and inclined channel; a detachable sealed liquid leakage device can be completely eradicated due to the plane expansion joint, and the thermal deformation caused by high temperature can be skillfully absorbed; and the gas distributing evenness can be guaranteed due to the gas raising pipes which are geometrically and evenly distributed. The device can be widely used for the desulfurization tower in the steel mill, the electric power plant and the like, and the large-scale packed tower in the industries of oil refining, petrifaction, chemical industry and the like.

Owner:TIANJIN UNIVTECH CO LTD

A three-dimensional film spray through-flow tray

The invention provides a three-dimensional film spraying and perforating tray belonging to the field of mass transfer and heat transfer equipment in chemical engineering. The three-dimensional film spraying and perforating tray comprises a tower body and a tower plate arranged inside the tower body, and spraying covers arranged on the tower plate. The three-dimensional film spraying and perforating tray is characterized in that a plurality of fixing holes are formed in the tower plate, a guide cylinder is fixed in each fixing hole, a liquid seal trough is arranged at the outer ring of the side wall of each guide cylinder, a gas raising hole is formed at the bottom of each liquid seal trough and is concentric with each fixing hole, the spraying cover is arranged at the inner ring of the side wall of each guide cylinder, the lower end face of the side wall of each spraying cover is welded with the bottom of each liquid seal trough, a plurality of spraying holes are formed in the side wall of each spraying cover, a top cover is arranged at the top of each spraying cover, a liquid receiving trough is arranged at the upper end of each spraying cover, the side wall of each guide cylinder is coaxially connected with the outer wall of each spraying cover and the side wall of each liquid seal trough, gaps are reserved between the side wall of each guide cylinder and the outer wall of each spraying cover and between the outer wall of each spraying cover and the side wall of each liquid seal trough, and a gap is reserved between each top cover and each spraying cover. According to the three-dimensional film spraying and perforating tray, by adopting a perforating technology, on the one hand, the problem caused by liquid streaming and mixing is solved, and on the other hand, the gas-liquid contact time is increased and through perforation, and thus the mass transfer efficiency is increased.

Owner:衡水酷祥生物科技有限公司

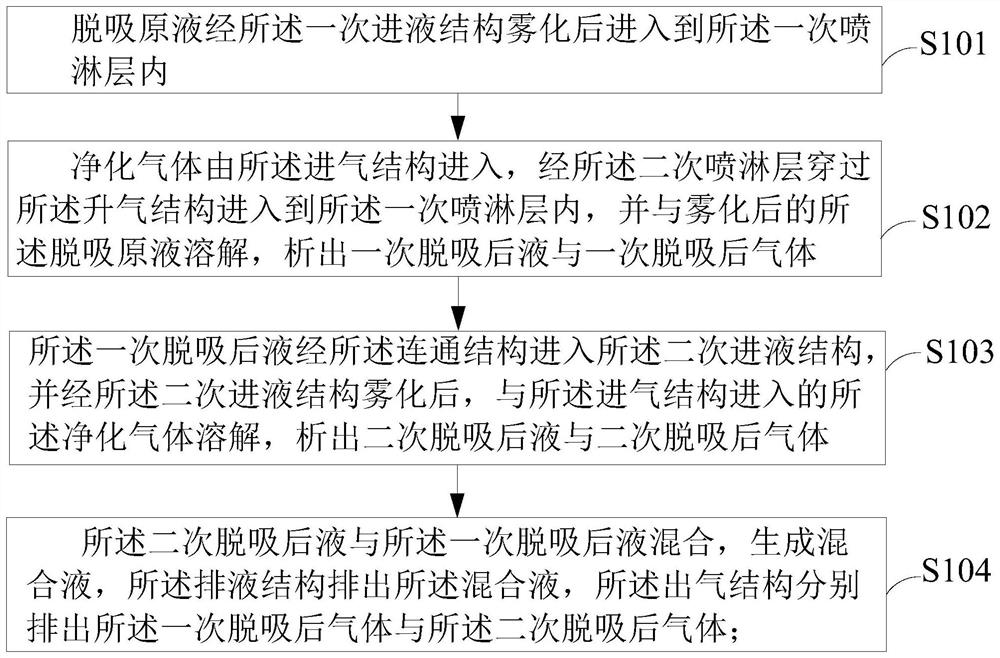

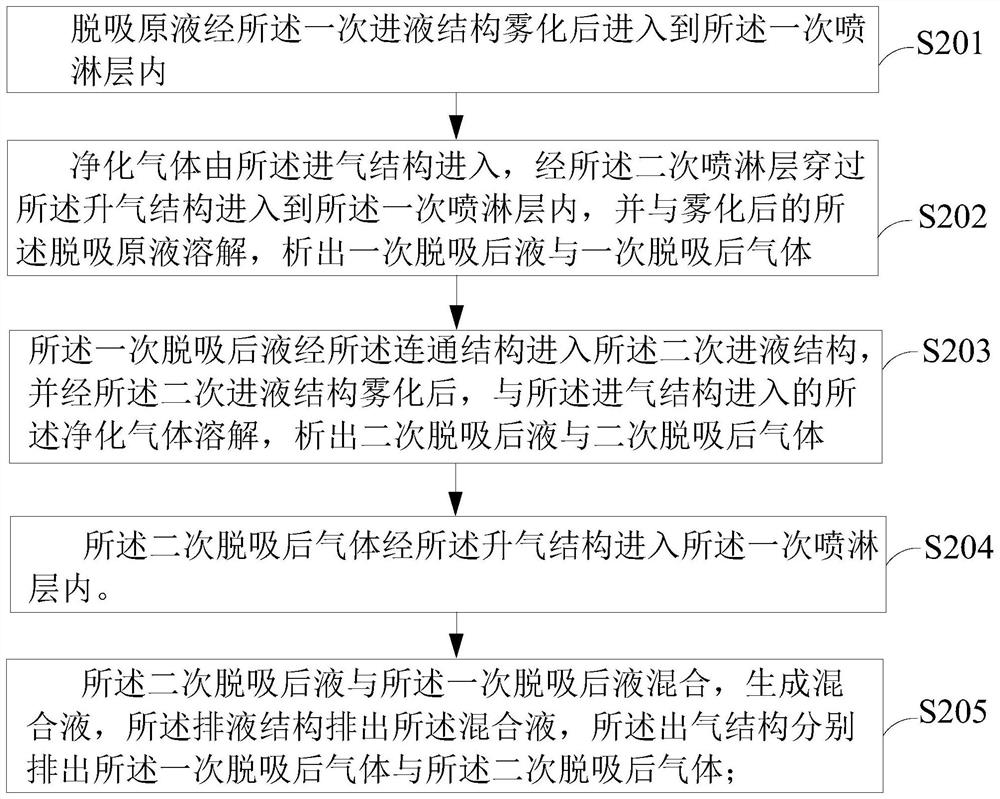

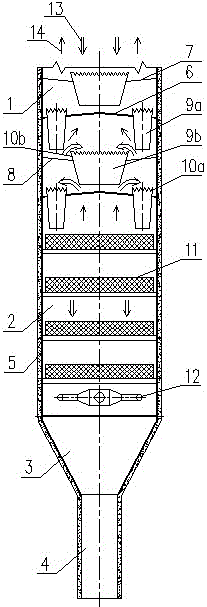

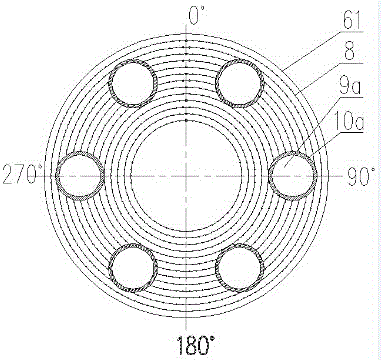

Desorption device and method

The invention provides a desorption device and method. The desorption device comprises a tower body and a gas lifting tower tray, the tower tray divides the internal space of the tower body into a primary spraying layer and a secondary spraying layer which are relatively independent and communicated, a plurality of gas lifting structures are arranged on the tower tray, and the device comprises a primary liquid inlet structure arranged above the gas lifting structures and a gas outlet structure arranged below the gas lifting structures. The device further comprises a communicating structure, and a secondary liquid inlet structure, a gas inlet structure and a liquid discharging structure which are arranged in order from top to bottom. according to the desorption device and method, the gas raising tower tray is additionally arranged in the device, the internal space of the device is divided into the two relatively independent and communicated spraying layers, and desorption separation operation is achieved; meanwhile, the gas lifting structure prevents liquid from entering the secondary spraying layer, so that the desorption effect is improved; in addition, the communicating structure enables the liquid to enter the secondary spraying layer again to realize multiple desorption operations. The problems that in the prior art, due to the fact that all stages of desorption operation are completed in the same space, final desorbed liquid is repeatedly polluted, and the desorption effect is reduced are solved.

Owner:CHINA NERIN ENG

A combined catalyst stripper

InactiveCN104927893BLess oil and gas entrainmentReduce oil and gasCatalytic crackingCatalyst regeneration/reactivationPhase gratingContact time

The invention discloses a stripper for a combined catalyst or other solid particles, and belongs to the field of gas-solid catalytic reaction. The combined catalyst stripper consists of a plate type overflow stripping region without backmixing at the upper part and a dense-phase grating stripping region at the lower part, wherein stripping gas raising hole plates, catalyst overflow weirs and catalyst descending channels are arranged on an overflow stripping plate; the cross section of the stripper is divided into many channels communicated from top to bottom through gratings in the grating stripping region, so that the high-efficiency contact between a gas phase and a solid phase can be realized, the free flow and the free exchange of the catalyst and stripping gas are realized, and the enough contact time of the catalyst and the stripping gas can also be ensured. The combined catalyst stripper disclosed by the invention is suitable for stripping various catalyst entraining reaction products and various entrainment impurities in the catalytic conversion technology.

Owner:QINGDAO JINGRUN PETROCHEM ENG

A gas phase distribution device for a partition tower

ActiveCN106310696BReduce wasteSimple structureDistillation regulation/controlFractional distillationGas phaseControl system

The invention relates to a gas phase distribution device of a baffle plate tower. The gas phase distribution device is characterized by comprising an automatic liquid-level control system, a gas distributor, a pressure dropping adjusting plate and a tower plate with gas raising pipelines, wherein the tower plate with the gas raising pipelines is arranged in the baffle plate tower and is located below tower filling; the pressure dropping adjusting plate is located above the tower plate with the gas raising pipelines; the edge of the tower plate with the gas raising pipelines is connected to the tower wall of the baffle plate tower in a sealing manner; gaps are formed at two sides between the gas distributor and the tower wall of the baffle plate tower and between the pressure dropping adjusting plate and the tower wall of the baffle plate tower; the automatic liquid-level control system is arranged between the pressure dropping adjusting plate and the tower plate with the gas raising pipelines and is located on the external of the baffle plate tower; long holes are formed in a baffle plate located between the pressure dropping adjusting plate and the tower plate with the gas raising pipelines; a plurality of openings are formed in an area, located at a prefrationation section of the baffle plate tower, of the tower plate with the gas raising pipelines; and a gas raising pipeline is arranged at each opening.

Owner:HEBEI UNIV OF TECH

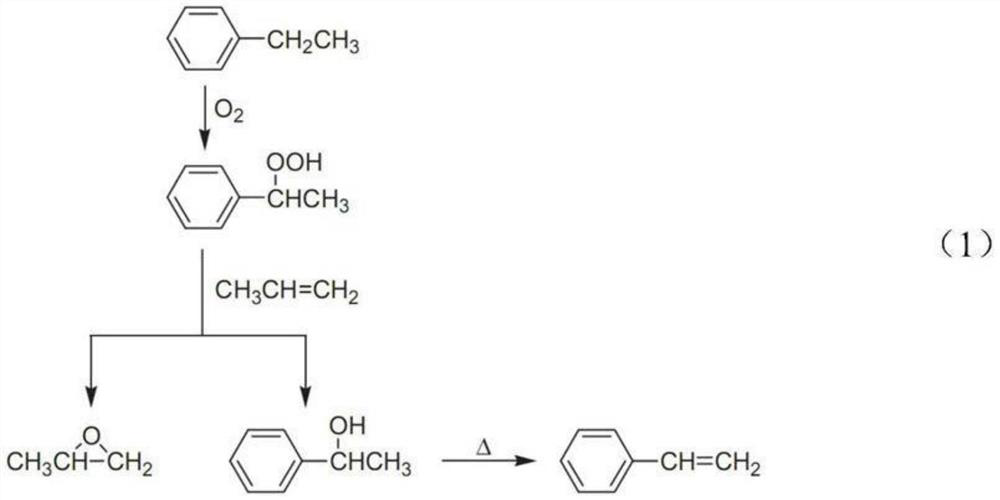

Method for preparing ethylbenzene hydroperoxide through ethylbenzene reactive distillation and reactive distillation tower thereof

ActiveCN112174868AImprove efficiencyMeet the reaction contact timeOrganic compound preparationChemical industryEthylbenzene hydroperoxidePtru catalyst

The invention discloses a method for preparing ethylbenzene hydroperoxide through ethylbenzene reactive distillation and a reactive distillation tower thereof. A catalyst bag is fixed between gas raising covers of a tower plate, and the catalyst bag further comprises a strip-shaped catalyst. The method is high in efficiency, raw materials pass through the catalyst and the tower plate separation and purification element repeatedly, and the conversion rate and selectivity are improved. Meanwhile, the manufacturing is easy, the mounting and dismounting are convenient, and follow-up treatment is simplified.

Owner:HEBEI UNIV OF TECH

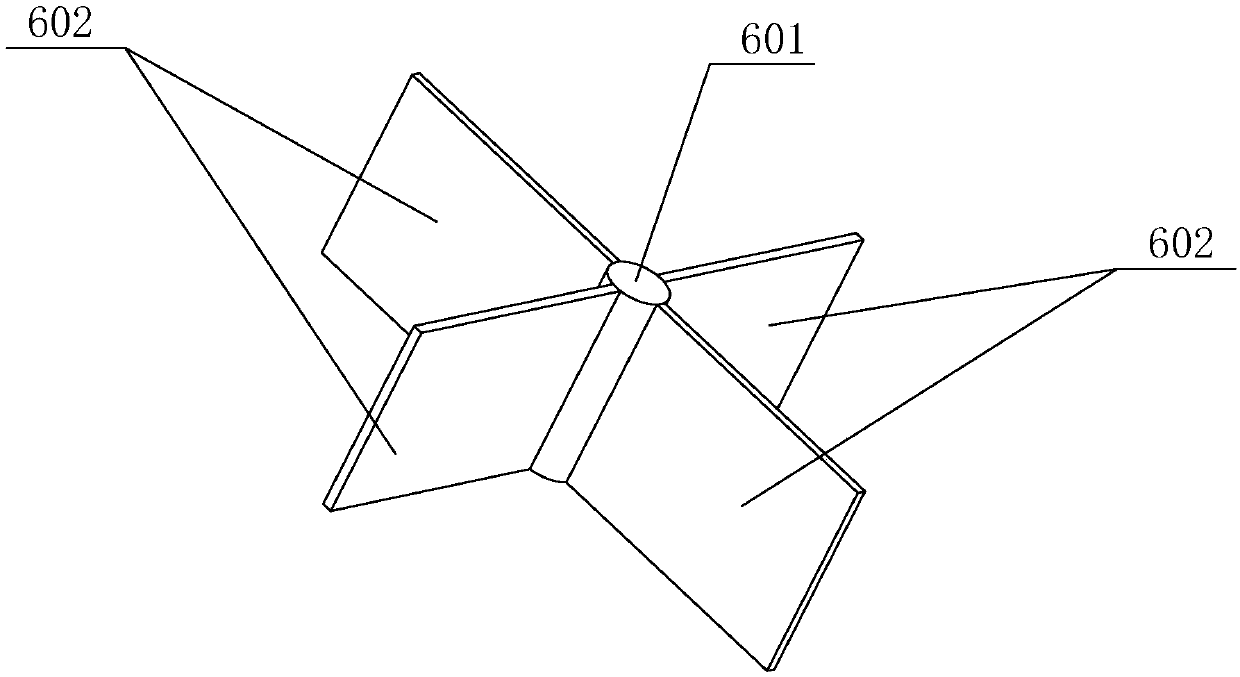

Gas raising device applied to efficient absorption liquid separation of staged absorption tower

ActiveCN112169543AAchieve separationHigh precisionAdditive manufacturing apparatusDispersed particle separationEngineeringGAS RAISING

The invention relates to the technical field of tower internals of industrial staged absorption towers, in particular to a gas rising device applied to efficient separation of an absorption liquid ofa staged absorption tower. The invention provides a gas raising device applied to efficient absorption liquid separation of a staged absorption tower. The device comprises a bottom plate, a liquid receiving part, a gas lifting cylinder and a gas lifting cap assembly, the gas lifting cap assembly comprises a gas lifting cap body, a baffle plate assembly, a fastener and a mounting bottom plate, thebottom plate is arranged at the bottom of the gas lifting device applied to efficient absorption liquid separation of the staged absorption tower, and the gas lifting cylinder is arranged at the upperpart of the bottom plate, and the gas lifting cap assembly is mounted at the upper part of the gas lifting cylinder.

Owner:HEIMDALLR SHANGHAI ENERGY SAVING TECH

Intelligent gas collection device for waste gas treatment of hot-dip galvanizing production process

The invention discloses an intelligent gas collecting device for waste gas treatment in a hot galvanizing production technology. A movable cover face on the top face of a gas collecting cover body, communicated with the gas raising face of a hot galvanizing tank, of the device is connected to a cover face driving motor and driven by the cover face driving motor so that the top face of the gas collecting cover body can be opened and closed. An air pipe is positioned and installed between a tank liquid line in the hot galvanizing tank and the top face of the gas collecting cover body. A gas collecting cover position sensor is arranged between the tank liquid line in the hot galvanizing tank and the top face of the gas collecting cover body. The cover face driving motor, a draught fan and the gas collecting cover position sensor are electrically connected with an electric control device and controlled by signals sent by the electric control gear. By means of the device, 100 percent of the collection rate of technological waste gas can be reached, the proportion of target gas collecting objects is larger than 90 percent, the investment cost is reduced, the occupied space is small, operation and observation of workers are not affected, and automatic control and remote control of a whole waste gas treatment system can be achieved through a PLC according to needs.

Owner:开平市中青环保技术服务有限公司

Combined catalyst stripper

InactiveCN104927893AMeet the needs of normal operationRealize gas-solid separationCatalytic crackingCatalyst regeneration/reactivationGas solidPhase grating

The invention discloses a stripper for a combined catalyst or other solid particles, and belongs to the field of gas-solid catalytic reaction. The combined catalyst stripper consists of a plate type overflow stripping region without backmixing at the upper part and a dense-phase grating stripping region at the lower part, wherein stripping gas raising hole plates, catalyst overflow weirs and catalyst descending channels are arranged on an overflow stripping plate; the cross section of the stripper is divided into many channels communicated from top to bottom through gratings in the grating stripping region, so that the high-efficiency contact between a gas phase and a solid phase can be realized, the free flow and the free exchange of the catalyst and stripping gas are realized, and the enough contact time of the catalyst and the stripping gas can also be ensured. The combined catalyst stripper disclosed by the invention is suitable for stripping various catalyst entraining reaction products and various entrainment impurities in the catalytic conversion technology.

Owner:QINGDAO JINGRUN PETROCHEM ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com