Gas phase distribution device of baffle plate tower

A distribution device and partition tower technology, which is applied in the field of chemical engineering rectification and separation, can solve the problems of not being able to achieve the optimal operating condition of the partition tower, and difficult to control the gas distribution of the partition tower, and achieve easy control and installation, and flexible operation Big, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

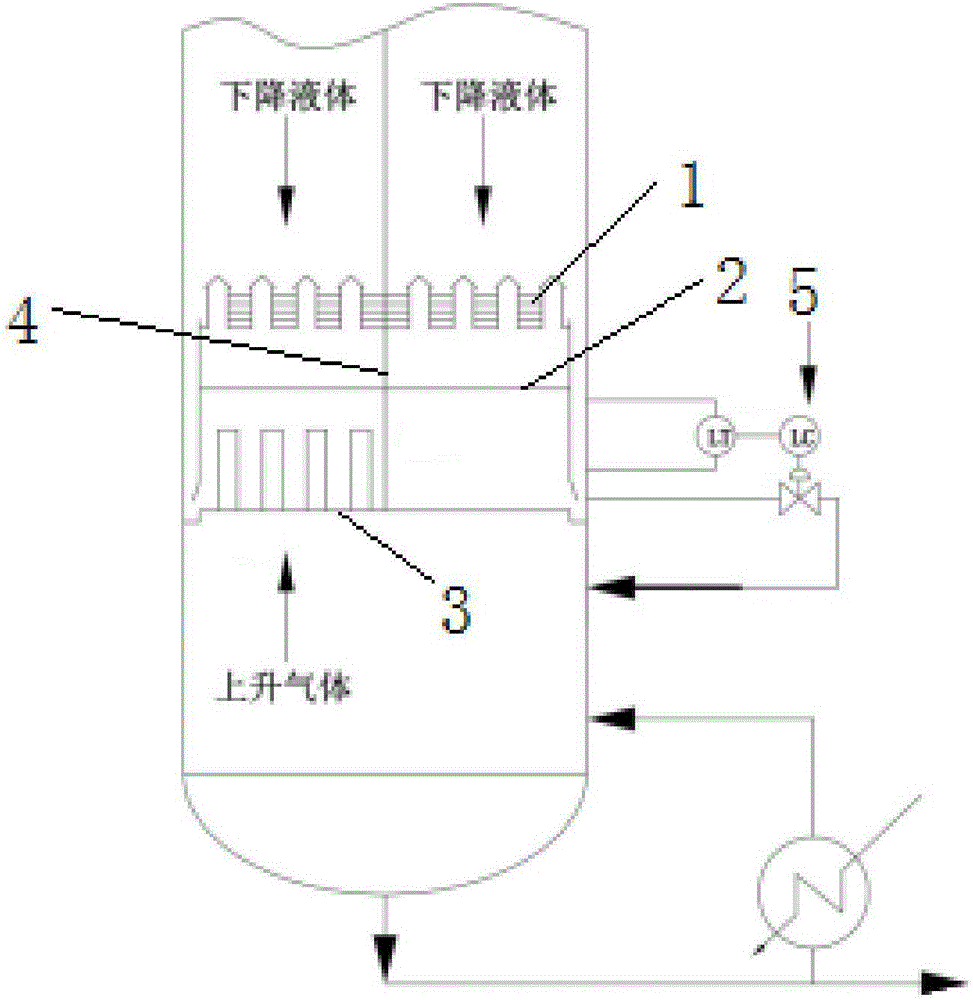

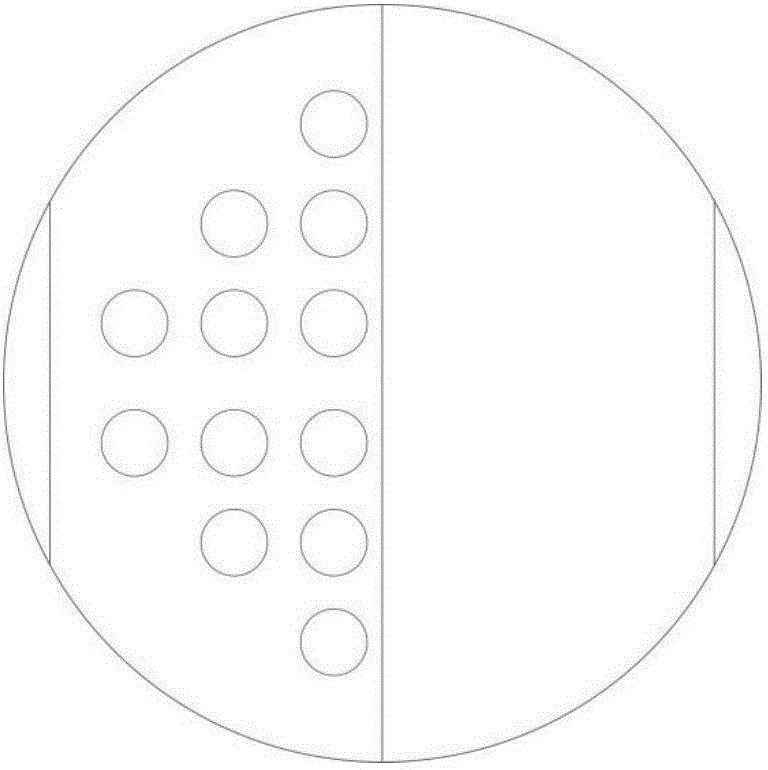

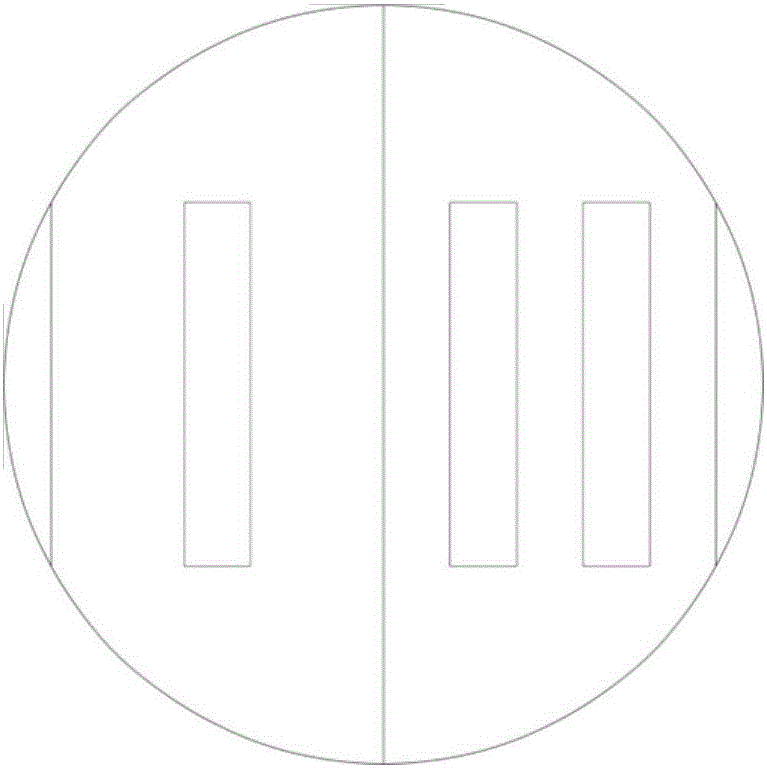

[0034] The gas phase distribution device of the partition tower in this embodiment includes an automatic liquid level control system 5, a gas distributor 1, a pressure drop regulating plate 2 and a tray 3 with a gas-lifting pipeline, and the tray 3 with a gas-lifting pipeline is arranged on In the tower, and located below the packing in the tower, the pressure drop regulating plate 2 is located above the tray 3 with the gas lift pipe, the gas distributor 1 is located above the pressure drop regulating plate 2, the gas distributor 1, the pressure drop regulating plate 2 and The edge of the tray 3 with the gas riser is connected to the tower wall of the partition tower, and an automatic liquid level control system is installed outside the partition tower between the pressure drop regulating plate 2 and the tray 3 with the gas riser. 5; long holes are arranged on the partition plate 4 between the pressure drop regulating plate 2 and the tray 3 with the gas-lifting pipe, and a part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com