Multi-pipe inner circulation three-phase fluidized bed

A three-phase fluidized bed and internal circulation technology, which is applied in the field of three-compartment fluidized bed, can solve the problems that the gas velocity and liquid velocity cannot be too large, hinder the release of bubbles, and be easily carried out of the reactor, etc., and achieve compact structure, The effect of stable operation and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

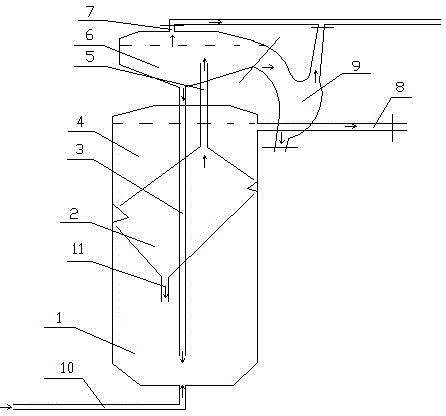

[0013] Multi-pipe internal circulation three-phase fluidized bed, the fluidized bed includes a water inlet pipe 10, an outlet pipe 8, a first reaction zone 1, and a gas-liquid separation zone 6, and the water outlet pipe 8 is connected to the first fluidized bed lower part A reaction zone 1, the top of the first reaction zone 1 is provided with a second reaction settling zone 2, the bottom of the second reaction settling zone 2 is provided with a sewage return pipe 11, and the top is provided with a riser pipe 5 and is connected to A gas-liquid separation zone 6, a filter zone 4 is provided above the second reaction settling zone 2, and the outlet pipe 8 is connected to the filter zone 4, and a gas-liquid separation zone 6 is provided above the filter zone 4, so The top of the gas-liquid separation zone 6 is provided with a biogas pipe 7, and the bottom is provided with a sewage return pipe 2 3 and is connected to the first reaction zone 1. The gas-liquid separation zone 6 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com