Intelligent gas collection device for waste gas treatment of hot-dip galvanizing production process

A production process and waste gas treatment technology, which can be used in cleaning methods and utensils, smoke removal, chemical instruments and methods, etc., and can solve problems such as one-time investment cost and operating cost increase, unfavorable operation by production personnel, and poor occupational hygiene environment. , to achieve the effect of reducing one-time investment costs and operating costs, facilitating promotion and popularization, and ensuring health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

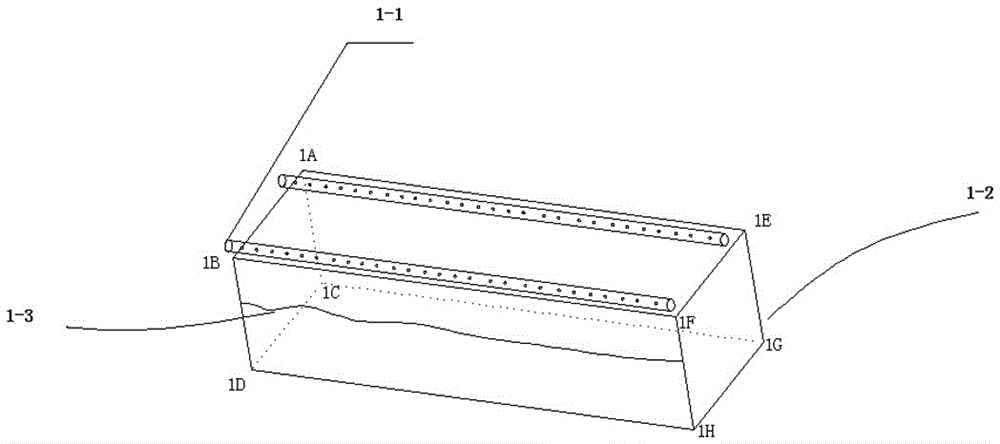

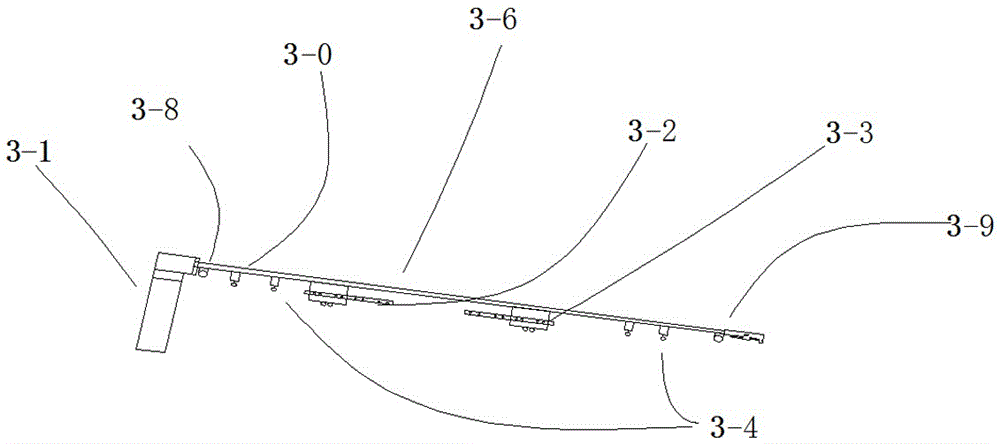

[0053] Below in conjunction with specific embodiment and Figure 1 to Figure 6 The present invention will be described in detail.

[0054] An intelligent gas collection device for waste gas treatment in a hot-dip galvanizing production process, comprising a gas collection hood main body 2-1, an air duct 1-1, a gas collection hood position sensor 4-2 and an electric control system.

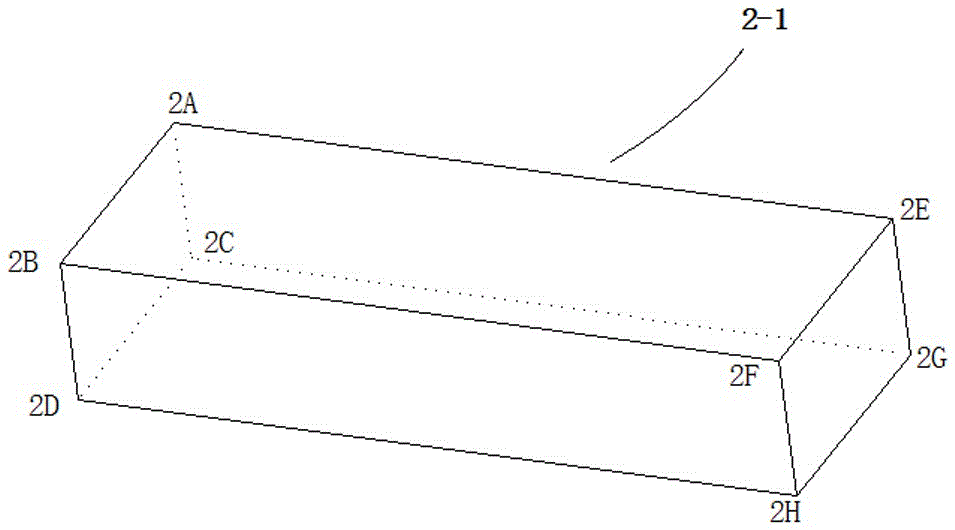

[0055] The main body of the gas collecting hood is mainly composed of a frame, a fixed surface, a docking surface and a movable surface. In this specific embodiment, a common cuboid is used as the main body of the gas collecting hood matching the hot-dip tank 1-2 for illustration. The specific structure can be found in figure 2 shown.

[0056] The frame of the main body of the air collecting hood is composed of 12 frame rods (2A-2B, 2A-2E, 2A-2C, 2B-2D, 2B-2F, 2C-2G, 2D-2C, 2D-2H, 2E-2F, 2E -2G, 2F-2H, 2G-2H) composed of a skeleton, mainly to support the cover body and toilet

[0057] -6-

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com