Combined catalyst stripper

A stripper and stripping technology, applied in catalyst regeneration/reactivation, physical/chemical process catalysts, catalytic cracking, etc., can solve the problems of inability to separate catalysts, reduce stripping mass transfer efficiency, etc., and prevent catalyst backmixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Example: The amount of catalyst to be stripped is 1000t / h, the temperature is 500°C, the average particle diameter of the catalyst is 50 μm, the particle density of the catalyst is 850kg / m3, the stripping medium is steam, and the steam temperature is 400°C.

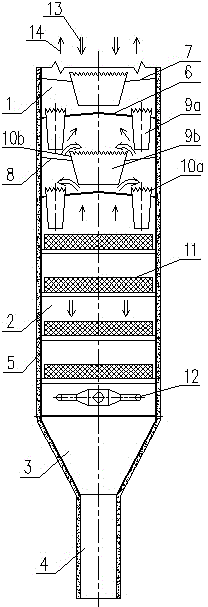

[0027] Stripper of the present invention sees figure 1 .

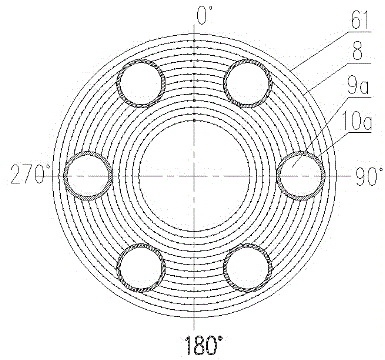

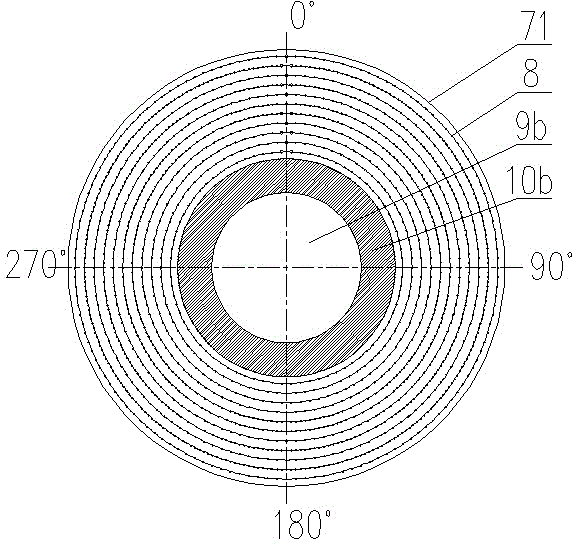

[0028]The diameter of the stripper is 3000mm, and the height is 9500mm. There are 4 layers of stripping plates in the plate stripping area, and the distance between the stripping plates is 1000mm; The angle α between the surface radial line and the horizontal line is 5°. The first layer of stripping plate is equipped with a catalyst downcomer. The height of the overflow weir H1 is 150mm. The catalyst downcomer is a positive cone (θ is zero degree), and the upper inlet diameter is 1300mm, the diameter of the lower outlet is 1100mm, the distance H3 between the outlet of the catalyst downcomer and the lower stripping plate is 200mm; The angle α with the hori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com