Method for reducing olefin sulfur content in gasoline

A technology of sulfur content and gasoline, applied in the petroleum industry, processing hydrocarbon oil, hydrotreating process, etc., can solve problems such as difficulty in meeting the requirements of gasoline quality, decrease in gasoline octane number, etc., and achieve no loss of gasoline octane number. , The effect of reducing total hydrogen consumption and high liquid yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

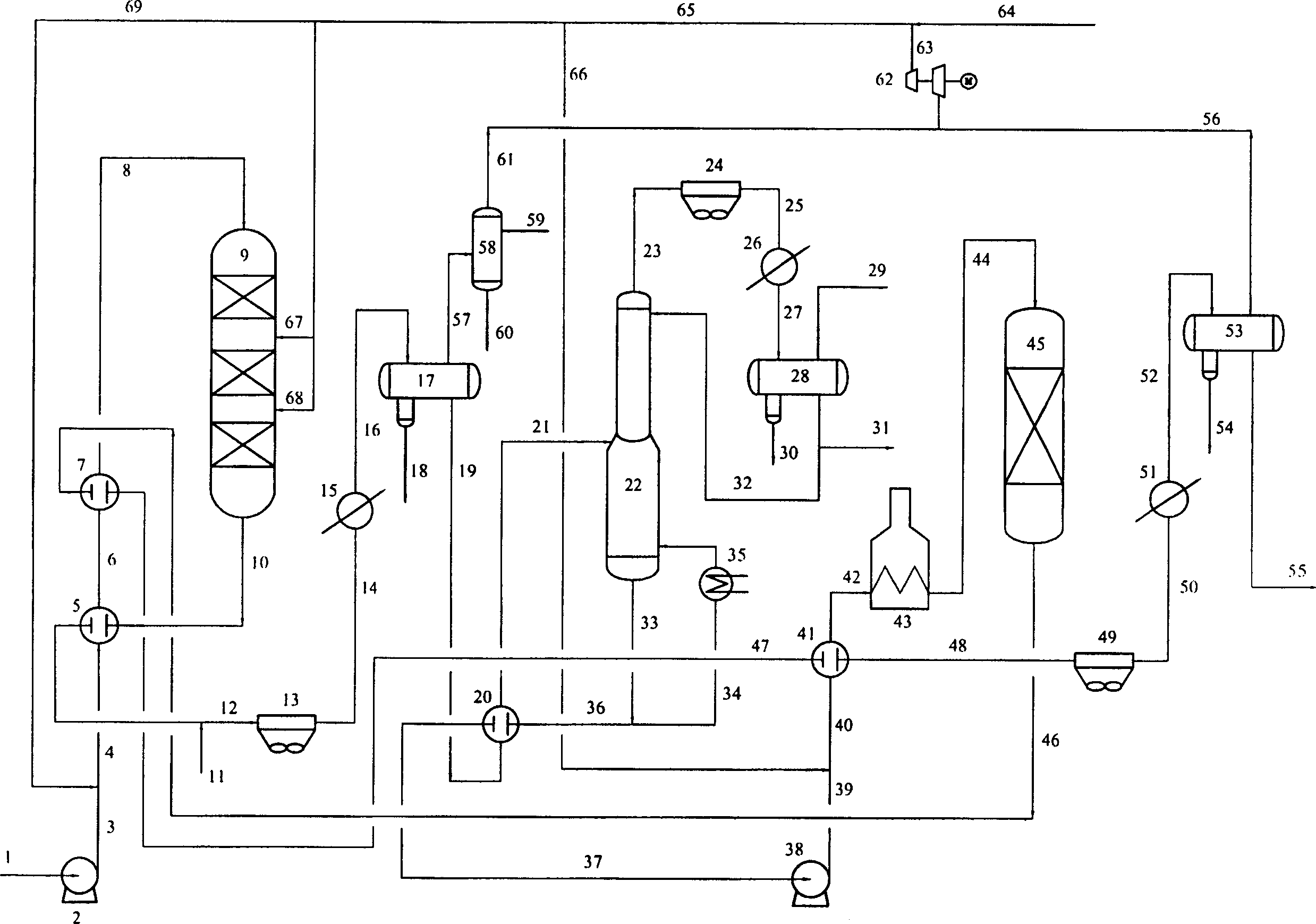

Image

Examples

Embodiment

[0035] This example gives the reaction conditions and reaction results of a medium-scale test of 100,000 tons / year of catalytic cracking gasoline heavy fraction. In this embodiment, the front hydrogenation reaction system and the rear dehydrogenation reaction system each have an independent hydrogen circulation system.

[0036] The research method of the whole distillate raw material of catalytic cracking gasoline has an octane number of 90.5, an olefin content of 50.3v%, a sulfur content of 130ppm, and a flow rate of 18657kg / h.

[0037] 1. Cutting of gasoline whole distillate raw materials

[0038] The light and heavy fraction cut point is 73°C, and the cut ratio is: light fraction 33.0% by weight, heavy fraction 67.0% by weight, then the flow rate of light fraction is 6157kg / h, and the flow rate of heavy fraction is 12500kg / h.

[0039] 2. Alkali washing treatment of light gasoline fraction

[0040] The sulfur content of the light gasoline fraction is 59ppm, and the mercapt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

| research octane number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com