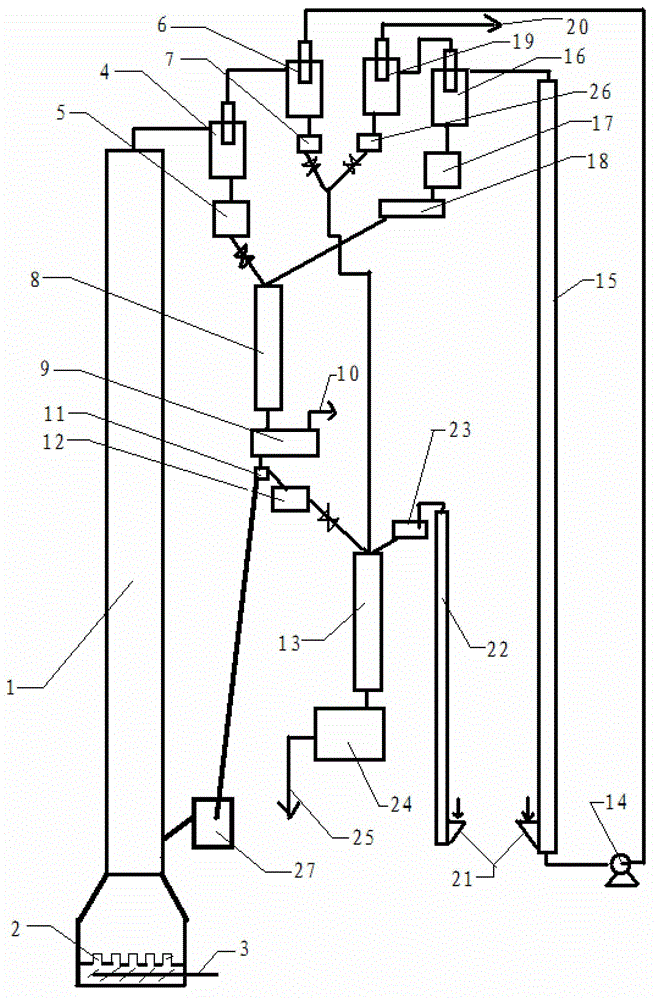

Low-rank coal downward circulating fluidized bed pyrolysis quality improvement process

A circulating fluidized bed, pyrolysis upgrading technology, which is applied in the field of providing low-rank coal down-flow circulating fluidized bed pyrolysis upgrading technology, can solve the long-term stable operation of high-temperature wear equipment of mechanical moving parts, and restrict the rapid operation of low-rank coal. Pyrolysis and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1, a large amount of low-rank coal less than 6mm enters the flue gas riser (15) through the low-rank coal inlet (21) for drying and lifting, and the low-rank coal particles are collected by the flue gas primary gas-solid separator (16) and flue gas The secondary gas-solid separator (19) separates the gas into stages, the flue gas is discharged from the flue gas outlet (20), the large and medium particles enter the upper silo (17), and the fine particles enter the hot coal silo (26) and flow in through the material valve Downward mixing pipe (13) for low-rank coal upgrading; large and medium-sized low-rank coal passes through the rotary feeder (18) and quickly realizes self-mixing with the high-temperature circulating semi-coke falling through the material valve at the top of the downward pyrolysis reactor (8) , heating up, and pyrolysis, the oil gas and semi-coke in the lower part of the standpipe of the descending pyrolysis reactor (8) are quickly separated unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com