Gas-liquid separator and gas-liquid separation method

A technology of gas-liquid separator and cyclone separator, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as adverse effects of separation effects and changes in gas-liquid incoming flow parameters, and reduce the separation load. , Improve the effect of separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

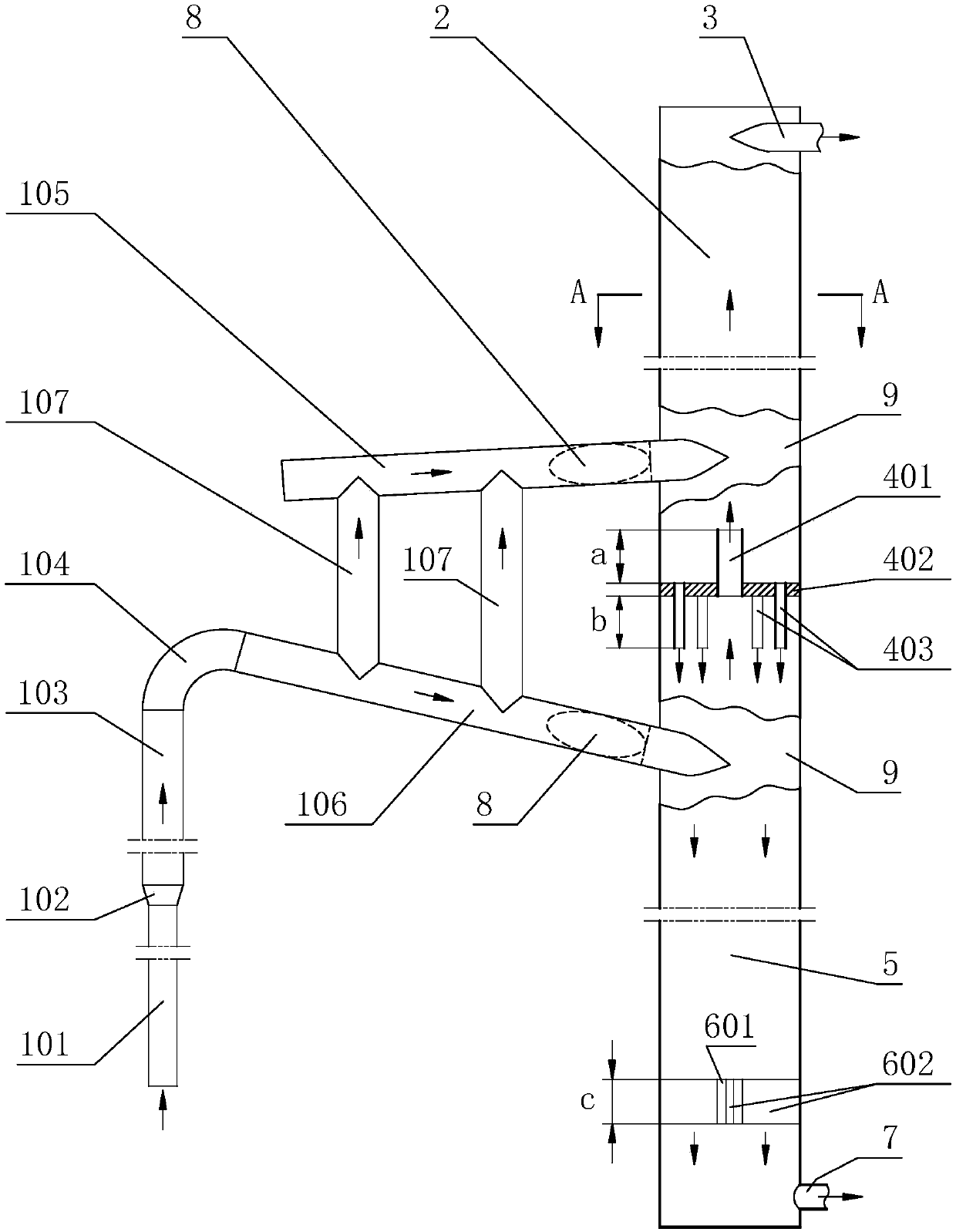

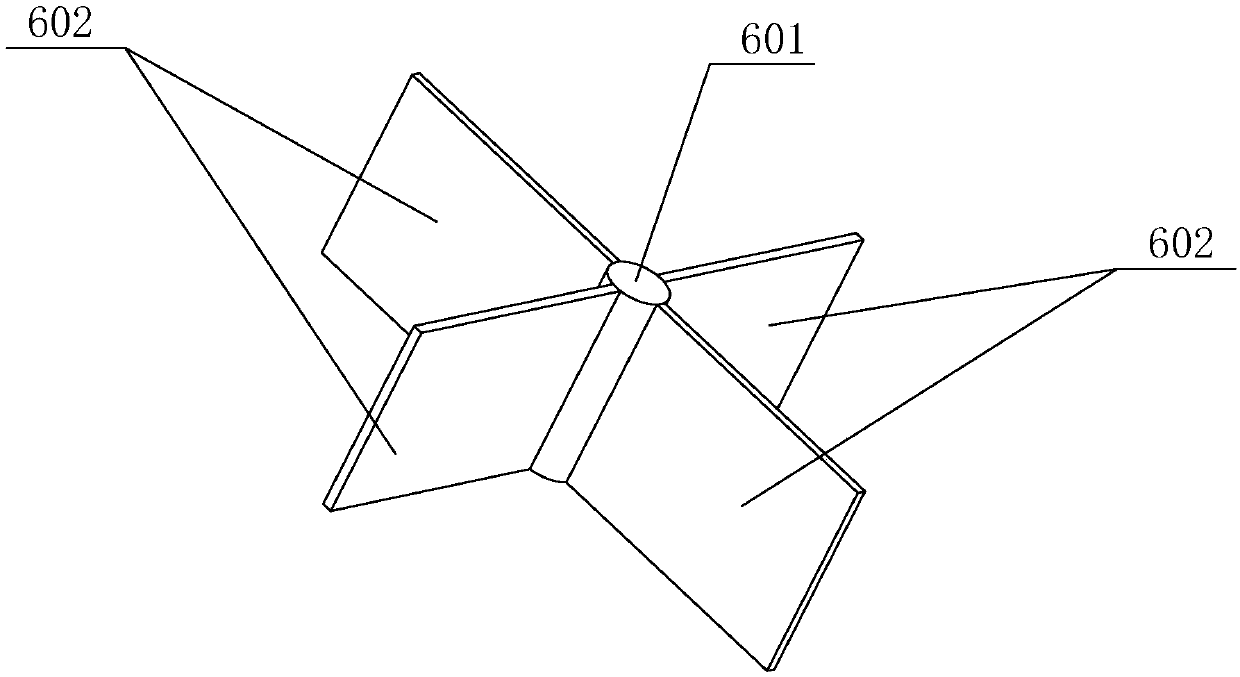

[0014] see figure 1 , figure 2 and image 3 , The gas-liquid separator of the present invention is provided with a columnar cyclone separator. The columnar cyclone separator comprises a cylindrical standpipe shell 9, the top of the standpipe shell 9 is provided with a standpipe shell top plate and an air outlet pipe 3, and the bottom of the standpipe shell 9 is provided with a standpipe shell bottom plate, Outlet pipe 7. The air outlet pipe 3 is connected with the standpipe cylinder 9 along the tangential direction of the standpipe cylinder 9 , and the axis line of the liquid outlet pipe 7 passes through the axis line of the standpipe cylinder 9 . The various pipelines used in the present invention are straight tubes with circular cross-sections except as stated.

[0015] A partition 402 is arranged inside the riser cylinder 9 , and the partition 402 is a horizontal circular flat plate whose edge is connected to the inner side wall of the riser cylinder 9 . The middle pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com