Liquid collecting and gas distributing device for large-scale flue gas desulfurization tower

A technology of gas distribution device and desulfurization tower, which is applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of poor prevention effect, facilitate anti-corrosion construction, ensure side line recovery, and reduce impact foaming The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

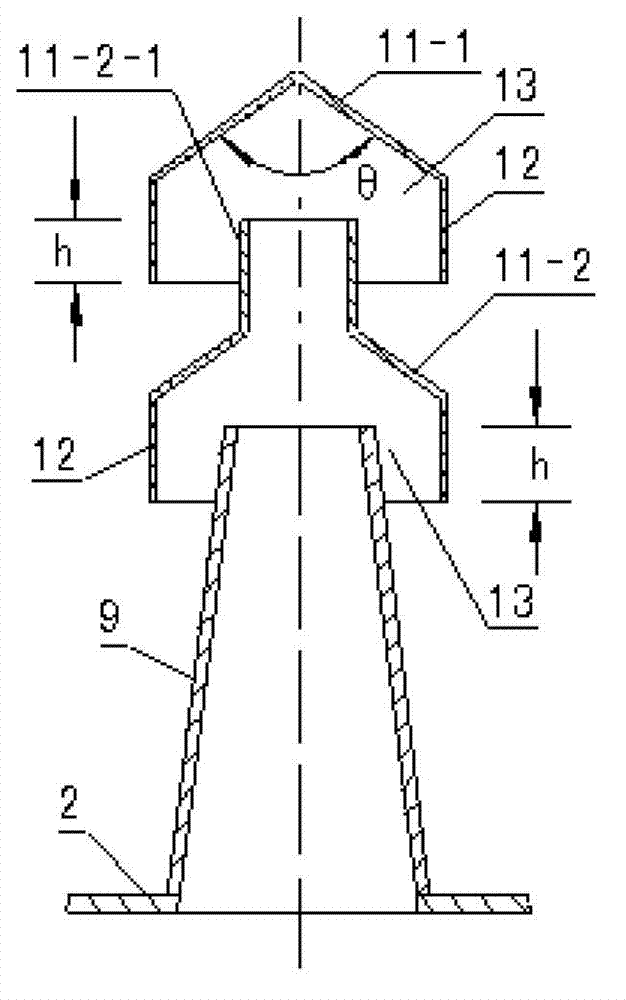

[0027] Further illustrate the present invention below in conjunction with embodiment and accompanying drawing.

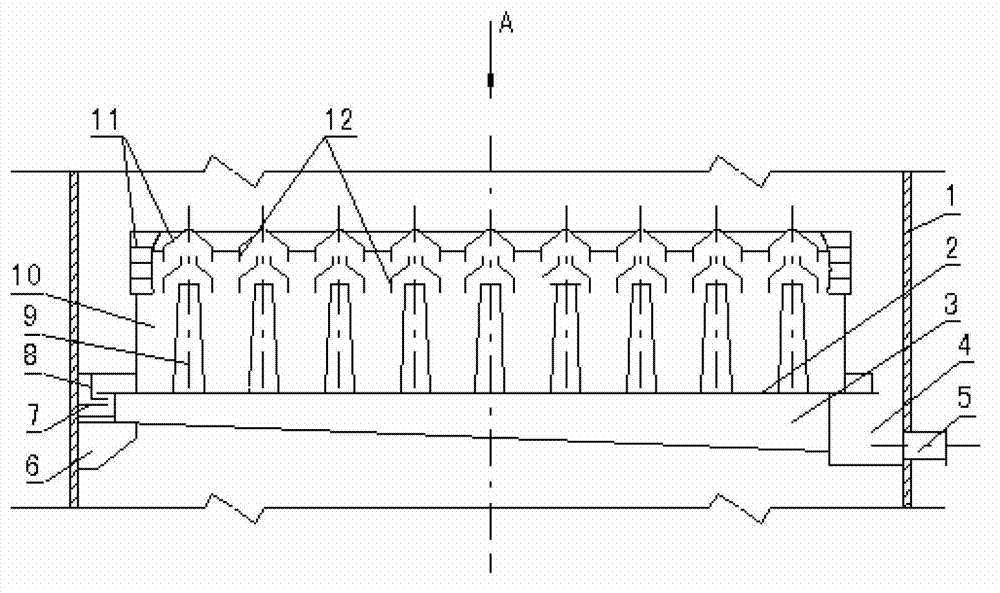

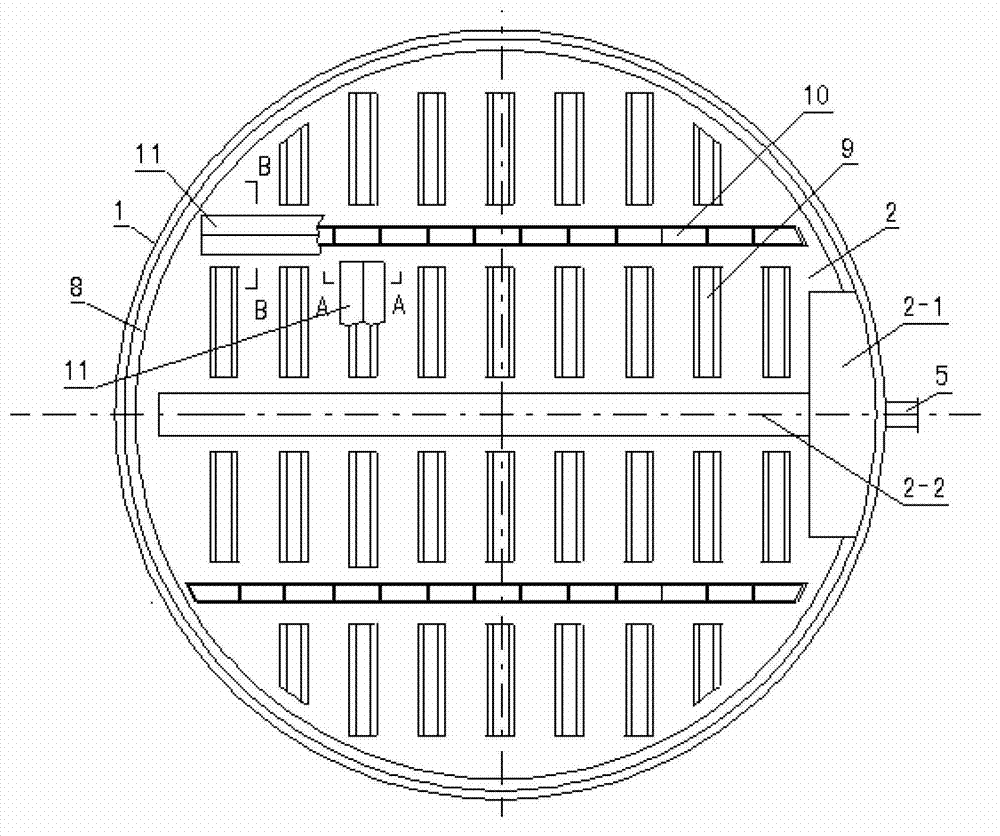

[0028] Such as figure 1 , 2 The example shown,

[0029] One side notch 2-1 of the bottom plate 2 of the liquid collecting and gas distribution device is provided with an extracting bucket 4 whose bottom surface is lower than the bottom plate 2, and the tower wall 1 is provided with a production pipe 5 communicating with the extracting bucket 4.

[0030] The main girder 3 in the center of the support base plate 2 has a through groove which doubles as an inclined channel for guiding liquid flow, and the base plate is provided with an opening 2-2 corresponding to the inclined channel of the main beam. One end of the main beam 3 corresponding to the shallow end of the inclined channel is supported on the support 6 fixed to the tower wall 1, and the other end of the main beam 3 corresponding to the deep end of the inclined channel is supported on one side of the extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com