Gas lift well drainage simulation test device and test method

A simulation test and gas lift well technology, applied in earthwork drilling, wellbore/well components, production fluid, etc., can solve problems such as inability to discharge wellbore fluid, low drainage efficiency, and mismatched operating parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

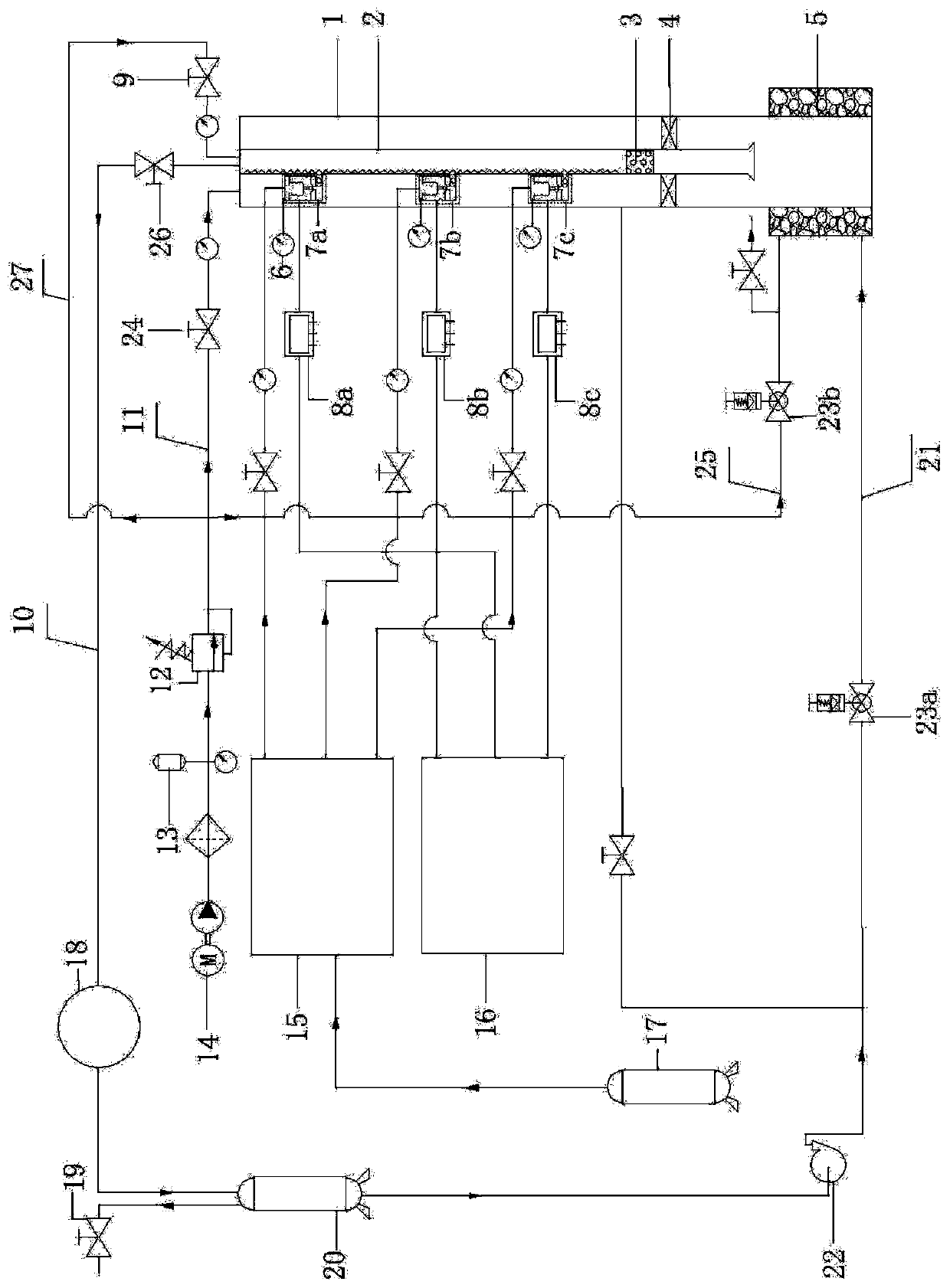

[0024] Attached below figure 1 The present invention is further described.

[0025] Depend on figure 1 It can be seen that the gas lift well drainage simulation test device is composed of a wellbore simulation system, a liquid supply system, a gas supply system and a temperature and pressure control device;

[0026] The wellbore simulation system is a wellbore composed of casing 1, tubing 2, gas lift valve, screen 3, packer 4, and sand-packing pipe 5. The sand-packing pipe 5 is a cylindrical tubular body filled with simulated reservoirs. Sand, the sand filling pipe 5 is installed on the base of the liquid drainage simulation experiment device, the casing 1 is set in the sand filling pipe 5, and the bottom pipe wall has a through hole connected with the sand filling pipe 5, and the oil pipe 2 is installed in the casing In 1, the tubing string of tubing 2 is installed with packer 4, screen 3 and stage 3 gas lift valve in sequence from bottom to top;

[0027] The liquid supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com