Process and device for dehumidifying wet flue gas purification tail gas

A flue gas purification and tail gas technology, applied in the field of boiler flue gas purification, can solve the problems of polluting the environment, corrosion of components, affecting the recovery rate of by-products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

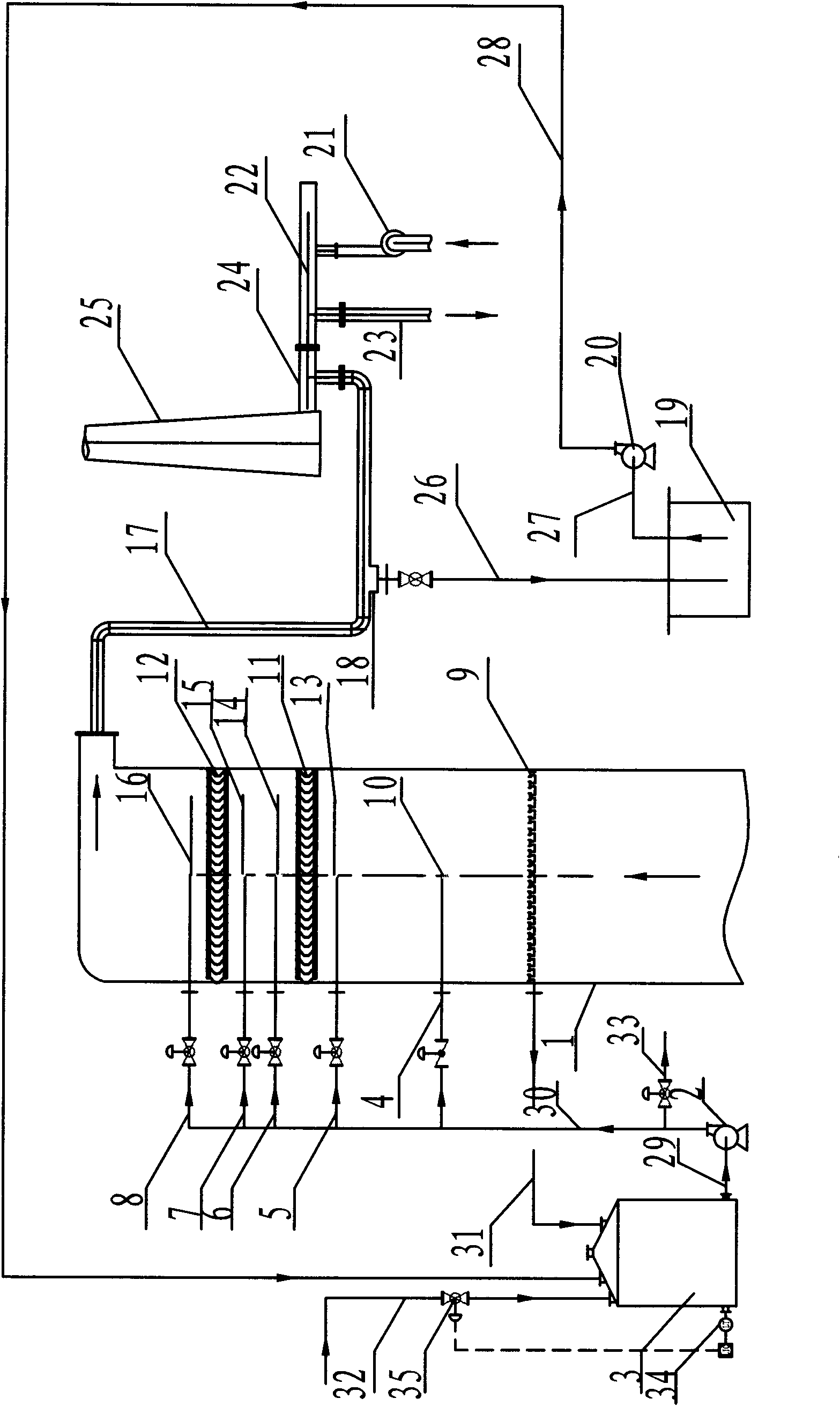

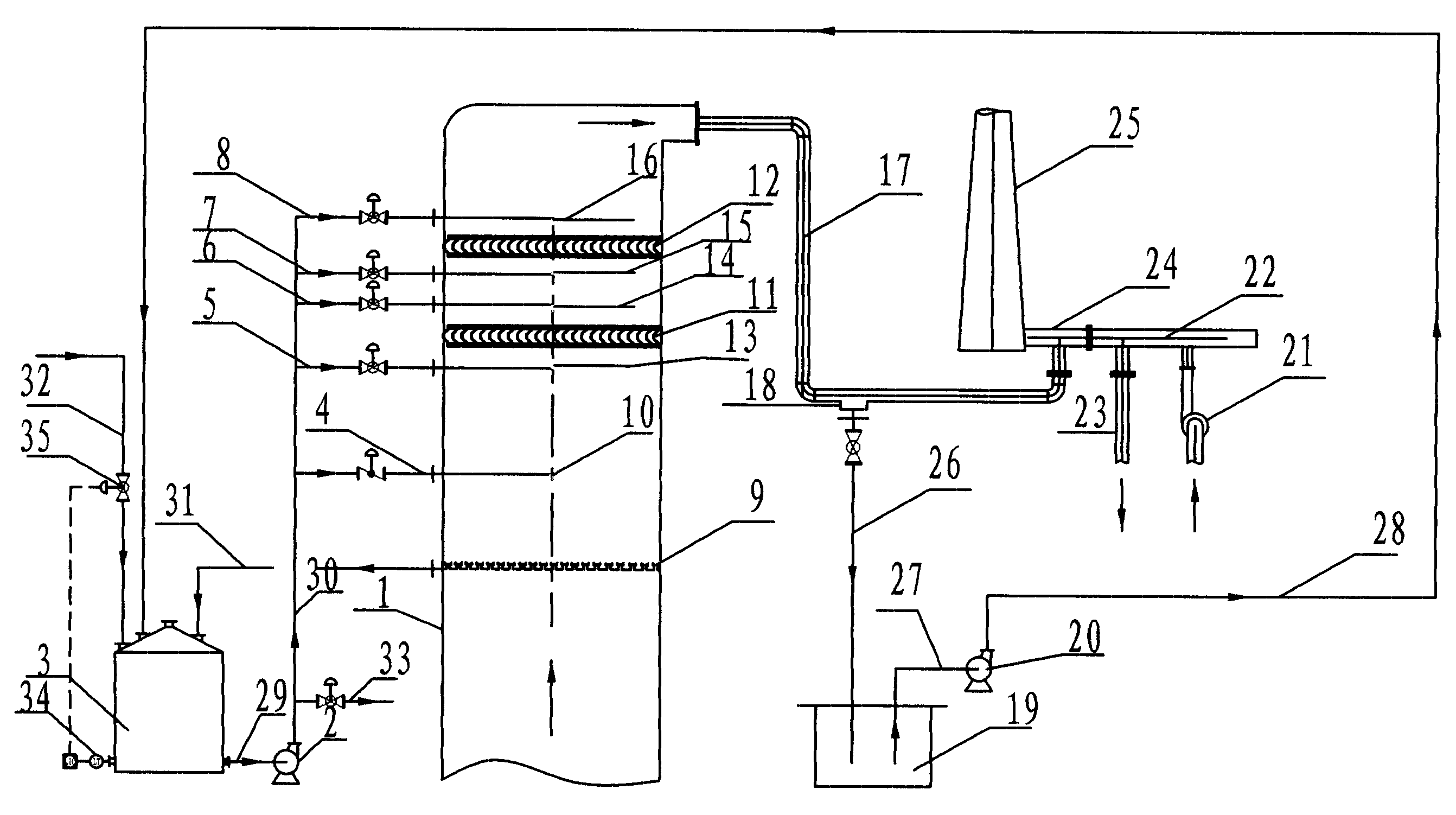

[0013] combine figure 1 The present invention is further described:

[0014] A dehumidification process for wet flue gas purification tail gas, the process flow is: the desulfurized flue gas enters the desulfurization tower, continues to lift the gas cap 9 into the washing section of the desulfurization tower at an empty tower flow rate of 3 to 4 m / s, and washes The washing liquid sprayed from the nozzle 10, the washing liquid is in contact with the desulfurized flue gas, and the washing liquid is sprayed to remove the SO escaping with the desulfurized flue gas 2 with NH 3 The flue gas sprayed by the spray pipe continues to rise and enters the two-stage baffle plate demister, and the two-stage baffle plate demister will remove the liquid droplets with a particle size greater than 5 microns in the flue gas sprayed by the spray pipe. The nozzles on the upper and lower sides of the first-stage baffle demister will wash away the inorganic salt and dust attached to the baffle dem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com