Three-dimensional film spraying and perforating tray

A technology of through-flow towers and three-dimensional membranes, applied in the field of three-dimensional membrane spray through-flow trays, which can solve the problems of liquid turbulence and mixed flow, affecting mass transfer efficiency, etc., to reduce material foam entrainment, increase flow time, and material foam entrainment Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

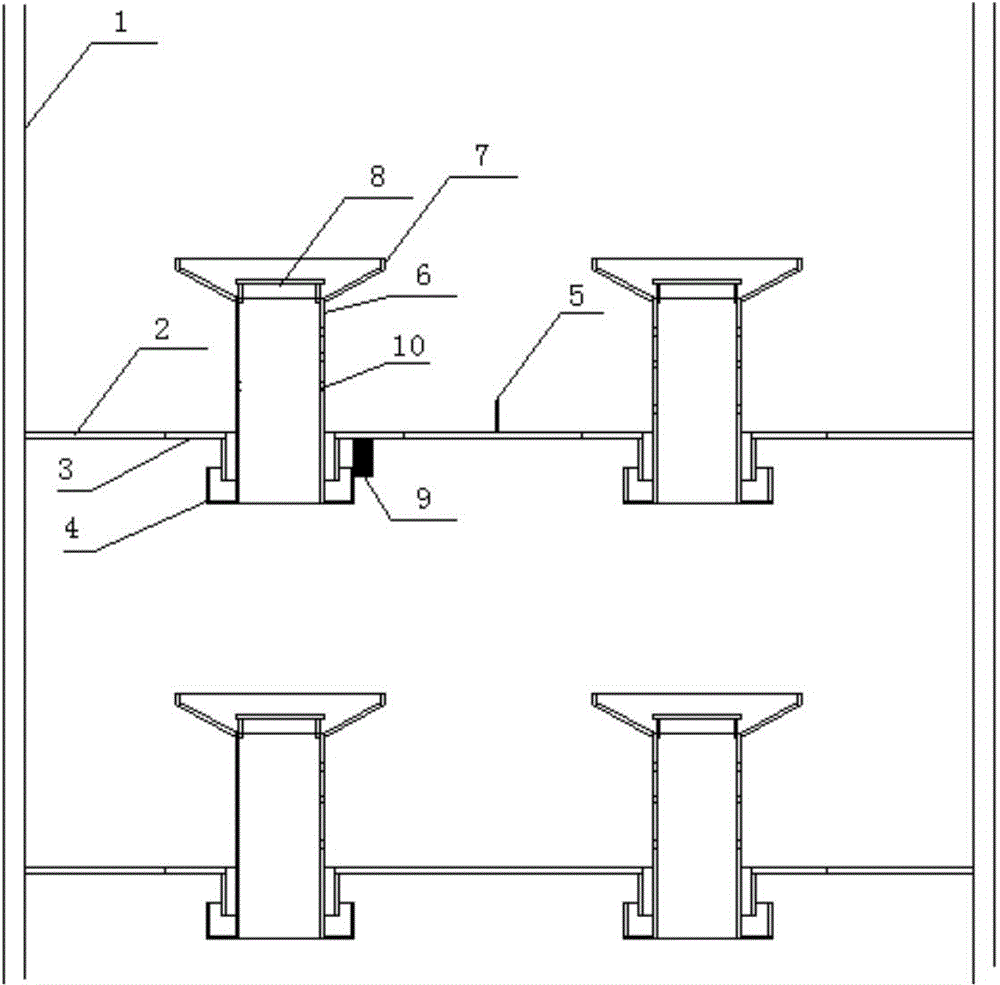

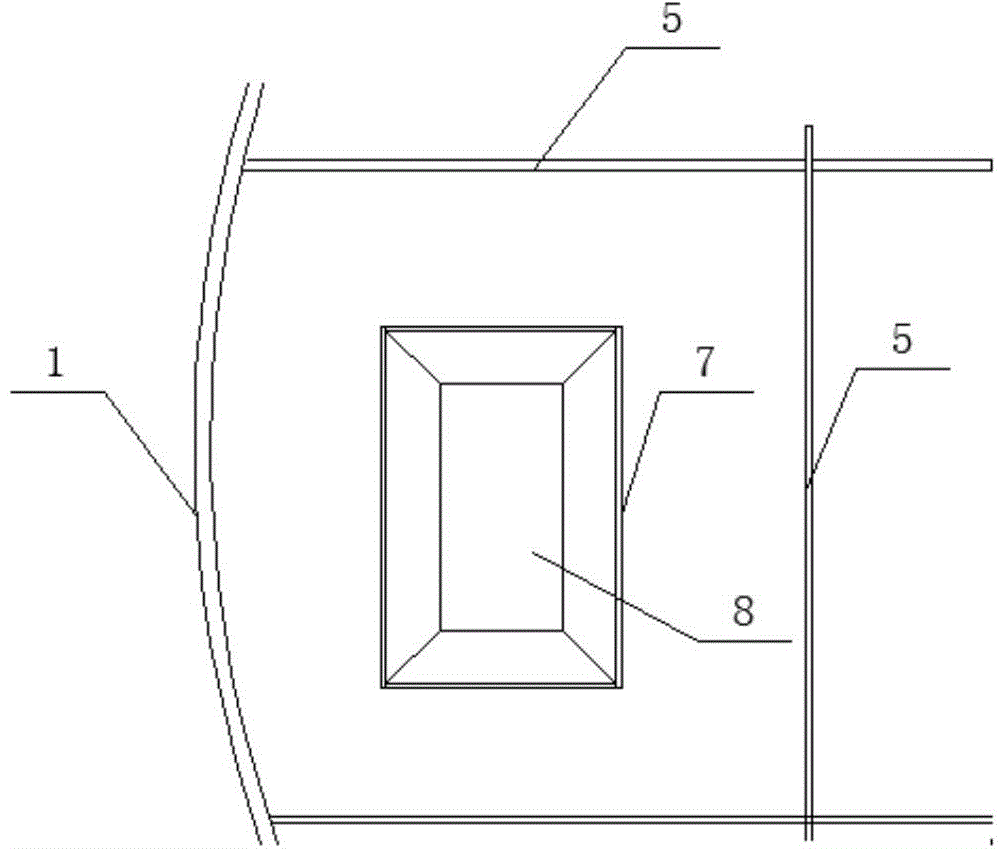

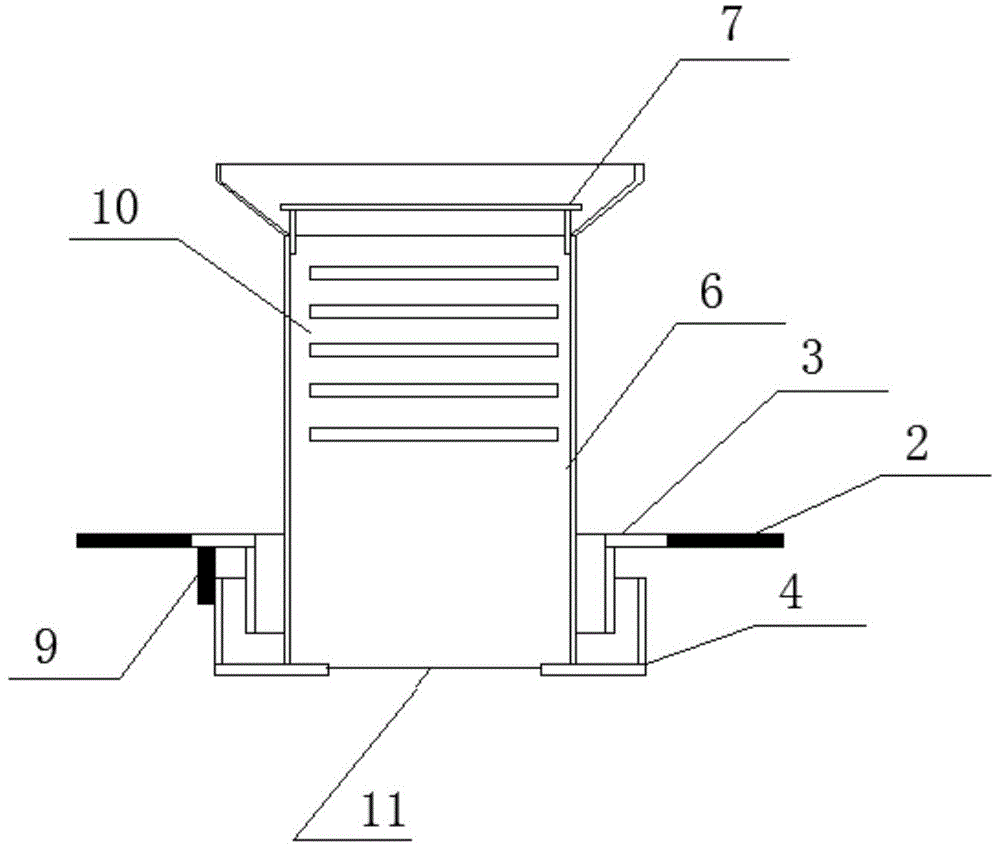

[0020] Such as Figure 2-3 As shown, the three-dimensional film sprays through the flow tray, including a tower body 1 and a tray 2 arranged inside the tower body 1, and a spray cover 6 arranged on the tray 2; the tray 2 is provided with a separator plate 5, and the The surface of the tray 2 is divided into several mutually isolated areas, and the mutually isolated areas are in the shape of a well. There are several fixing holes on the tower plate 2, and a guide tube 3 is fixed in each fixing hole, and the end face of the fixing hole is welded with the top cover of the guide tube 3; the outer ring of the side wall of the guide tube 3 is provided with a liquid seal The groove 4, the guide tube 3 and the liquid seal groove 4 are welded and fixed by the rib plate 9. The bottom of the liquid seal tank 4 is provided with a lift hole 11, the lift hole 11 is concentric with the fixing hole, the inner ring of the side wall of the guide tube 3 is provided with a spray cover 6, and the...

Embodiment 2

[0022] Such as Figure 4-5 As shown, the three-dimensional film sprays through the flow tray, including a tower body 1 and a tray 2 arranged inside the tower body 1, and a spray cover 6 arranged on the tray 2; the tray 2 is provided with a separator plate 5, and the The surface of the tray 2 is divided into several mutually isolated areas, and the mutually isolated areas are in the shape of a well. There are several fixing holes on the tower plate 2, and a guide tube 3 is fixed in each fixing hole, and the end face of the fixing hole is welded with the top cover of the guide tube 3; the outer ring of the side wall of the guide tube 3 is provided with a liquid seal The groove 4, the guide tube 3 and the liquid seal groove 4 are welded and fixed by the rib plate 9. The bottom of the liquid seal tank 4 is provided with a lift hole 11, the lift hole 11 is concentric with the fixing hole, the inner ring of the side wall of the guide tube 3 is provided with a spray cover 6, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com