Deep extraction device for flue gas waste heat of thermal power plant

A flue gas waste heat and deep extraction technology, applied in the direction of exhaust gas equipment, heat exchanger type, climate sustainability, etc., can solve the problems of waste, heat loss, high equipment cost, etc., achieve low equipment cost, improve thermal efficiency, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

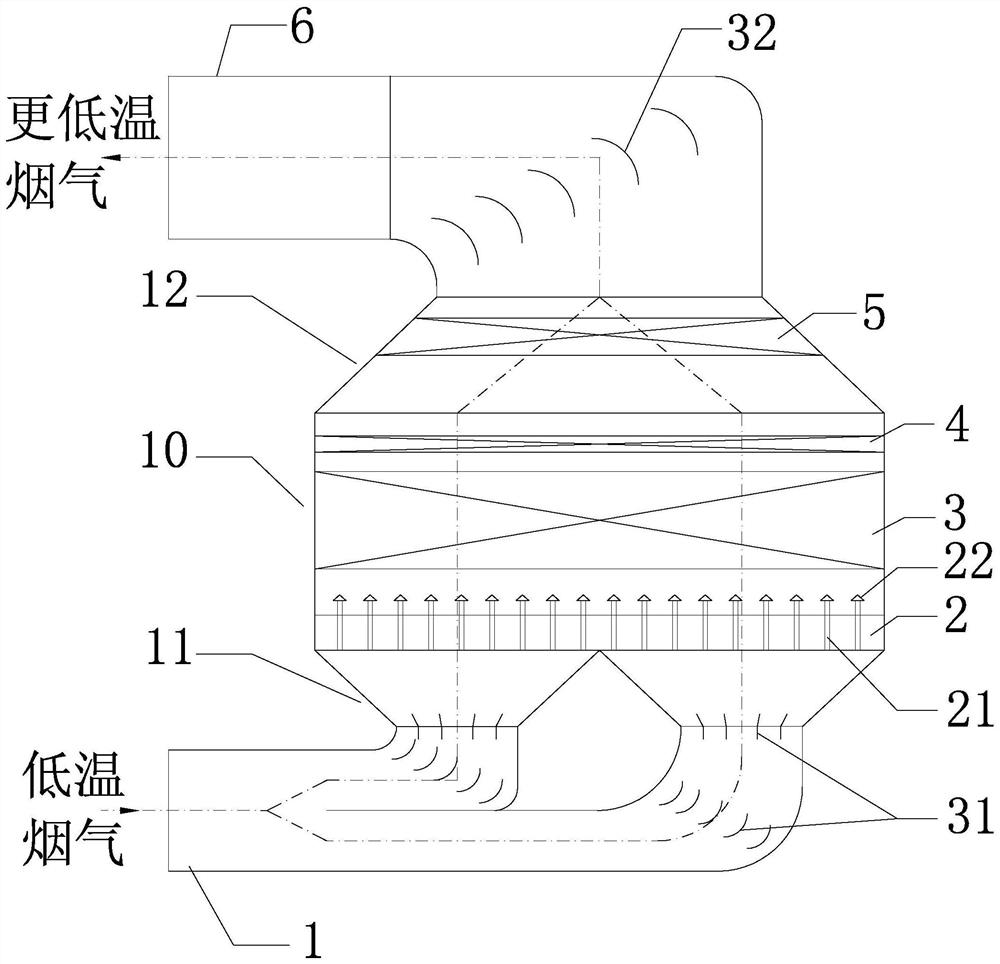

[0017] The invention belongs to a deep extraction device for flue gas waste heat in a thermal power plant, which is arranged at a low-temperature flue gas pipeline.

[0018] Specifically, the extraction device includes a hollow absorption tower 10, and the inlet flue 1 of the absorption tower 10 is connected to a low-temperature flue gas pipeline. The outlet of the inlet flue 1 can be as figure 1 As shown, it is divided into 2 paths, which are connected to the bottom of the absorption tower 10. The connecting part of the inlet flue 1 and the absorption tower 10 is the first variable diameter section 11, where the diameter gradually increases along the direction of the flue gas and is funnel-shaped. Several first deflectors 31 can be arranged at suitable positions in the inlet flue 1 , and the funnel-shaped arrangement cooperates with the first deflectors 31 so that the flue gas can enter the absorption tower 10 evenly.

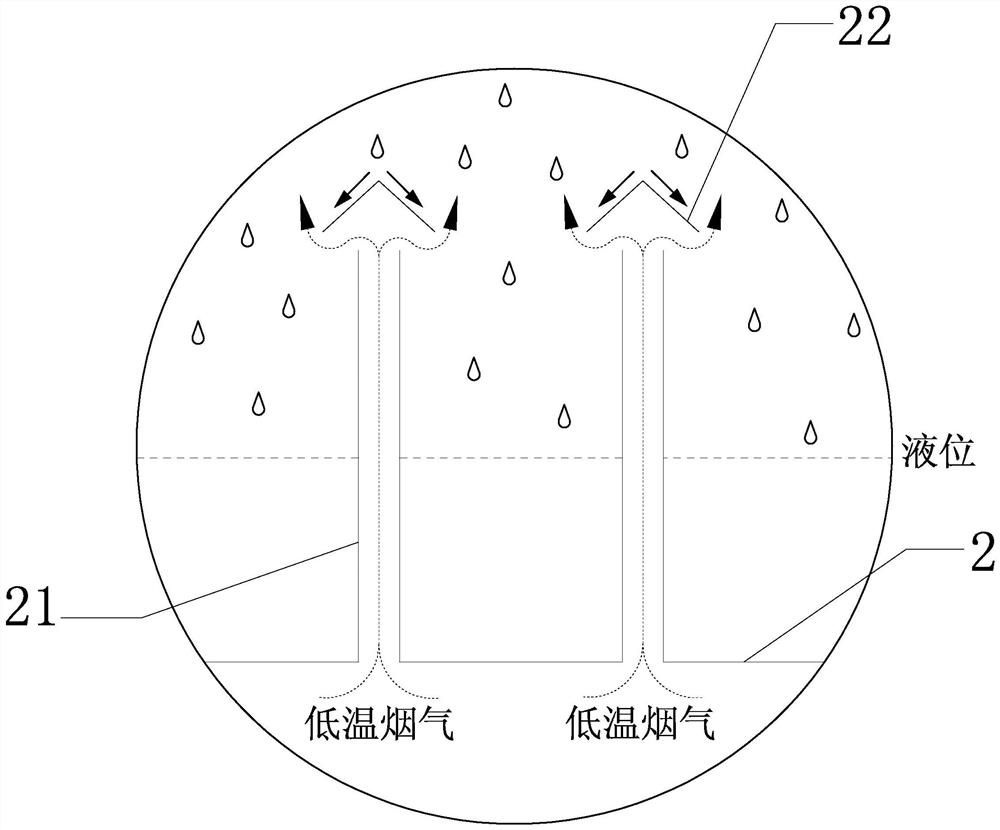

[0019] The bottom of the absorption tower 10 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com