Gas raising device applied to efficient absorption liquid separation of staged absorption tower

An absorption tower and absorption liquid technology, applied in the field of industrial graded absorption tower internals, can solve the problems of incomplete separation of absorption liquids, pollution of two-stage absorption liquids, and single function, saving labor and transportation costs, and shortening production. cycle, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

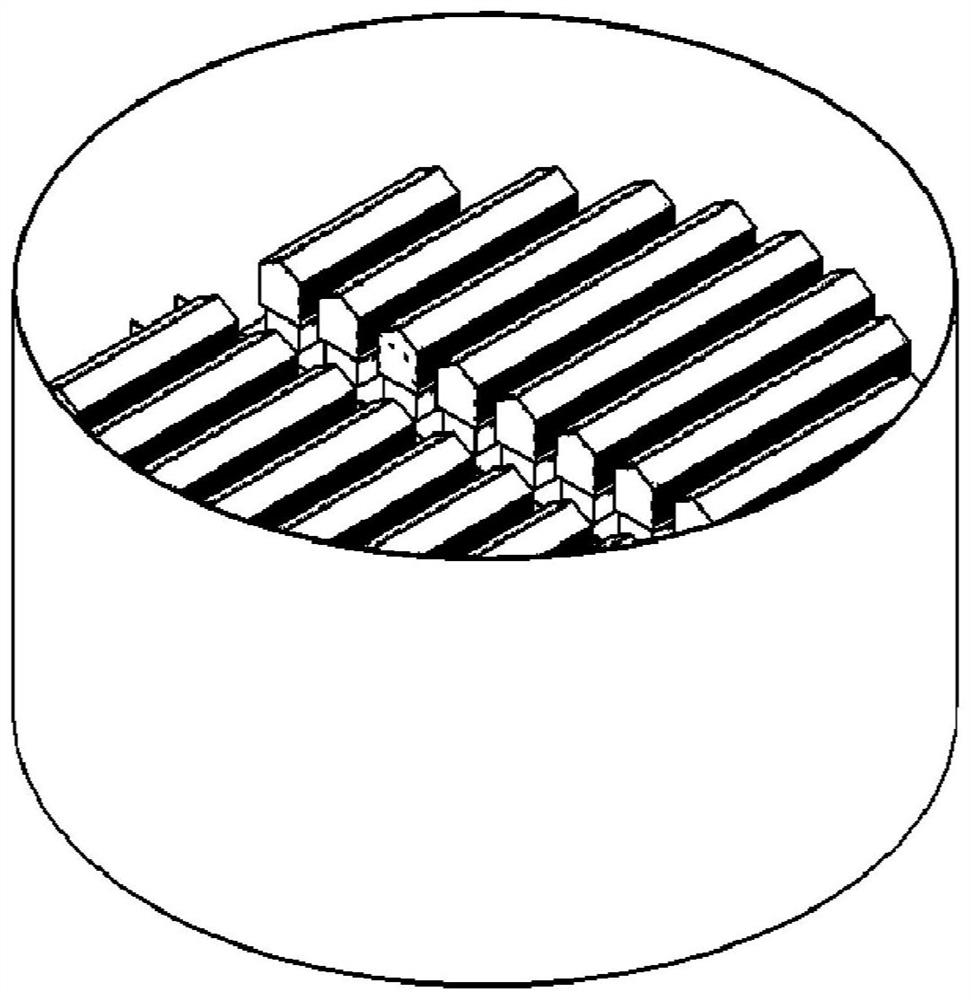

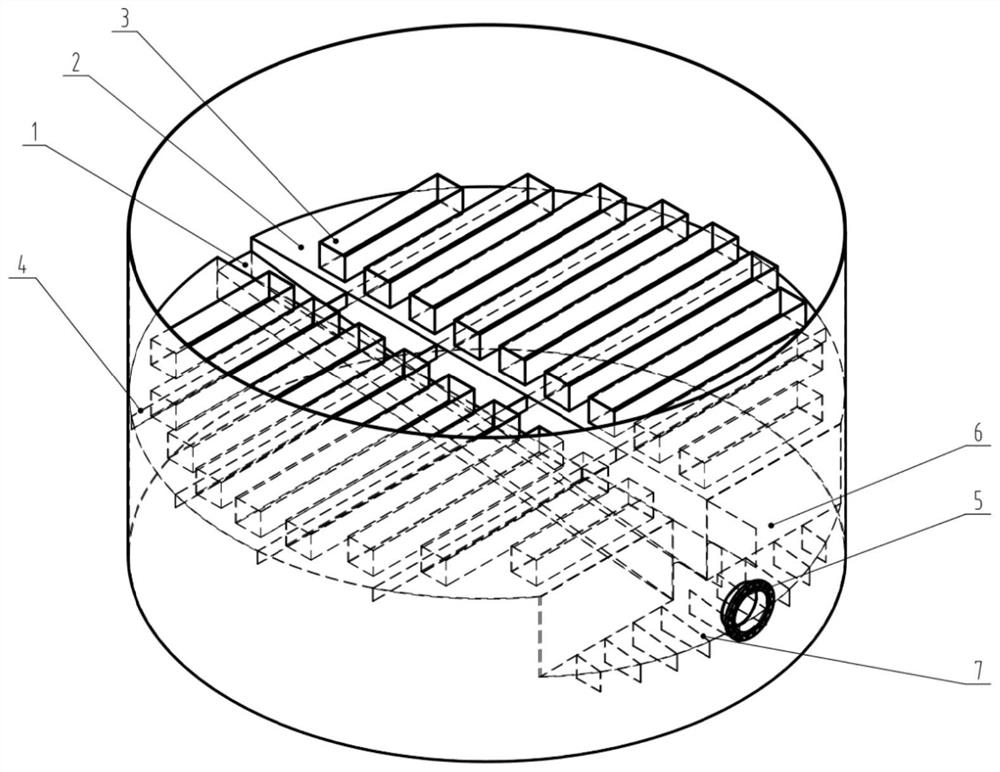

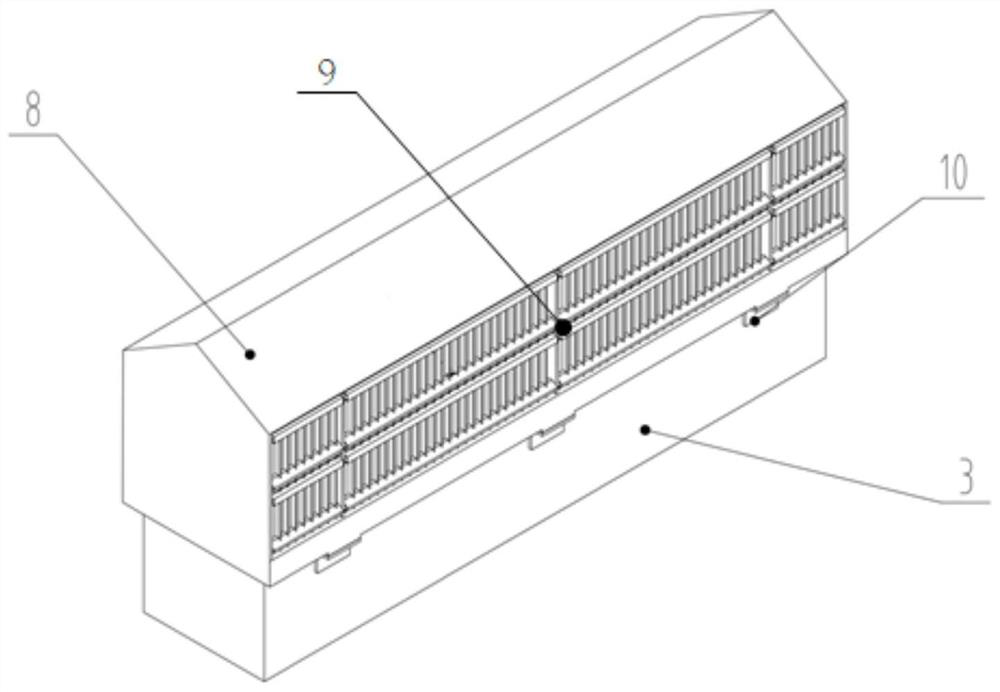

[0040] See attached figure 1 , 2 And 3, embodiment 1 provides a kind of gas-lifting device that is applied to the efficient separation of absorption liquid of staged absorption tower, comprises bottom plate 2, liquid-contacting parts, gas-lifting cylinder 3, gas-lifting cap assembly; Said gas-lifting cap assembly It includes a lift cap body 8, a baffle plate assembly, a fastener, and an installation base plate 10; the base plate 2 is arranged at the bottom of the lift device for efficient separation of absorption liquid applied to a staged absorption tower, and the lift cylinder 3 It is arranged on the upper part of the bottom plate 2; the air lifting cap assembly is installed on the upper part of the air lifting cylinder 3. The liquid-contacting parts include a liquid-contacting part flow tank 1, a liquid-contacting part buffer tank 6, and an external connecting pipe 5; the liquid-contacting part water tank 1 is arranged in the middle of the bottom plate 2, and the angle wit...

Embodiment 2

[0043] See attached figure 1 , 2 And 3, embodiment 1 provides a kind of gas-lifting device that is applied to the efficient separation of absorption liquid of staged absorption tower, comprises bottom plate 2, liquid-contacting parts, gas-lifting cylinder 3, gas-lifting cap assembly; Said gas-lifting cap assembly It includes a lift cap body 8, a baffle plate assembly, a fastener, and an installation base plate 10; the base plate 2 is arranged at the bottom of the lift device for efficient separation of absorption liquid applied to a staged absorption tower, and the lift cylinder 3 It is arranged on the upper part of the bottom plate 2; the air lifting cap assembly is installed on the upper part of the air lifting cylinder 3. The liquid-contacting parts include a liquid-contacting part flow tank 1, a liquid-contacting part buffer tank 6, and an external connecting pipe 5; the liquid-contacting part water tank 1 is arranged in the middle of the bottom plate 2, and the angle wit...

Embodiment 3

[0046] See attached figure 1 , 2 And 3, embodiment 1 provides a kind of gas-lifting device that is applied to the efficient separation of absorption liquid of staged absorption tower, comprises bottom plate 2, liquid-contacting parts, gas-lifting cylinder 3, gas-lifting cap assembly; Said gas-lifting cap assembly It includes a lift cap body 8, a baffle plate assembly, a fastener, and an installation base plate 10; the base plate 2 is arranged at the bottom of the lift device for efficient separation of absorption liquid applied to a staged absorption tower, and the lift cylinder 3 It is arranged on the upper part of the bottom plate 2; the air lifting cap assembly is installed on the upper part of the air lifting cylinder 3. The liquid-contacting parts include a liquid-contacting part flow tank 1, a liquid-contacting part buffer tank 6, and an external connecting pipe 5; the liquid-contacting part water tank 1 is arranged in the middle of the bottom plate 2, and the angle wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com