All-condition wet desulphurization exhaust gas dehumidifying and white smoke removing system and method

A technology of wet desulfurization and full working conditions, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of insufficient mixing air volume, inability to condense flue gas deeply, and large floor area, etc., and achieve zero water consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

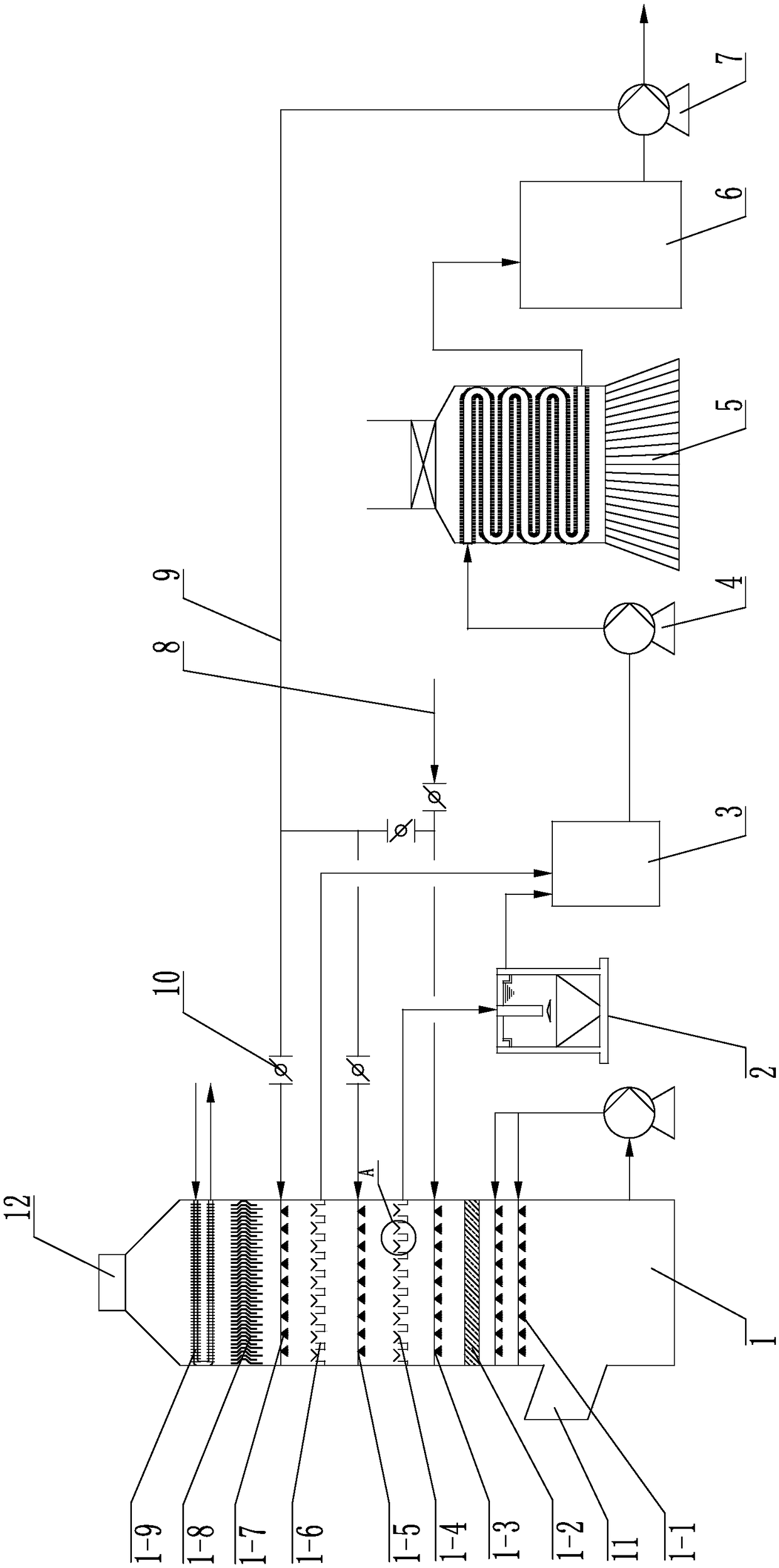

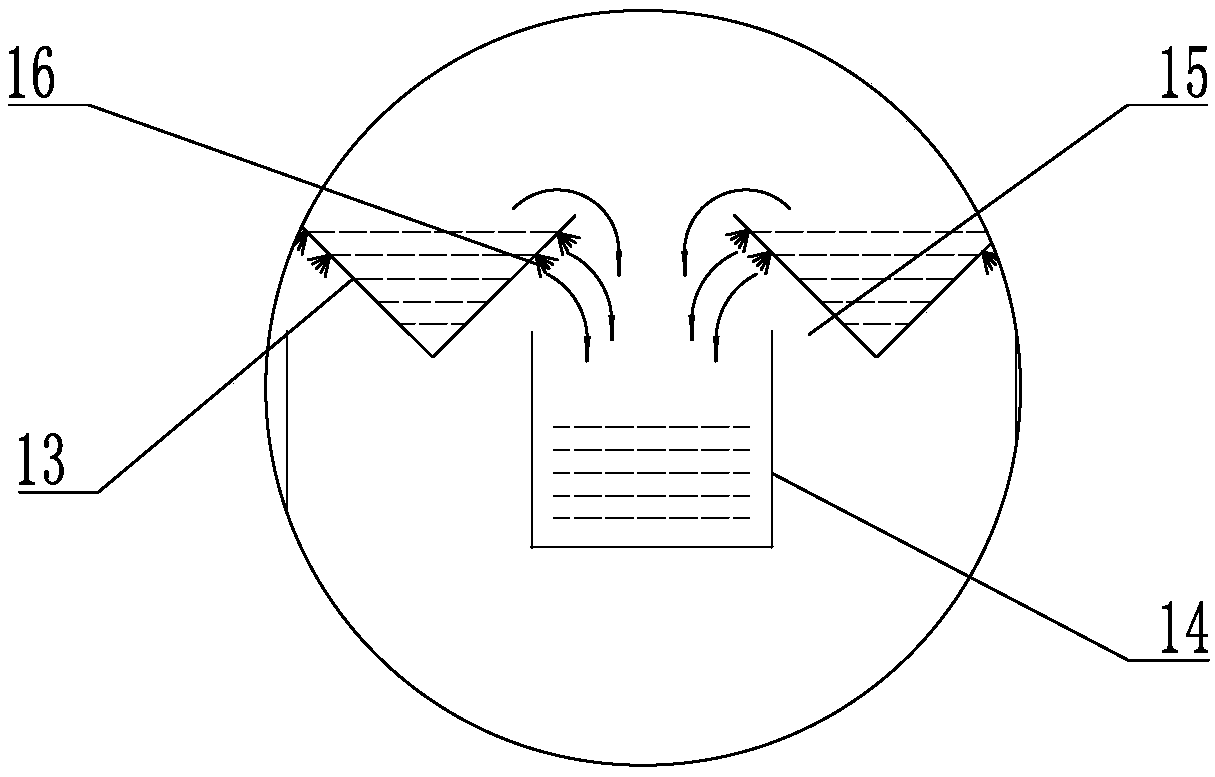

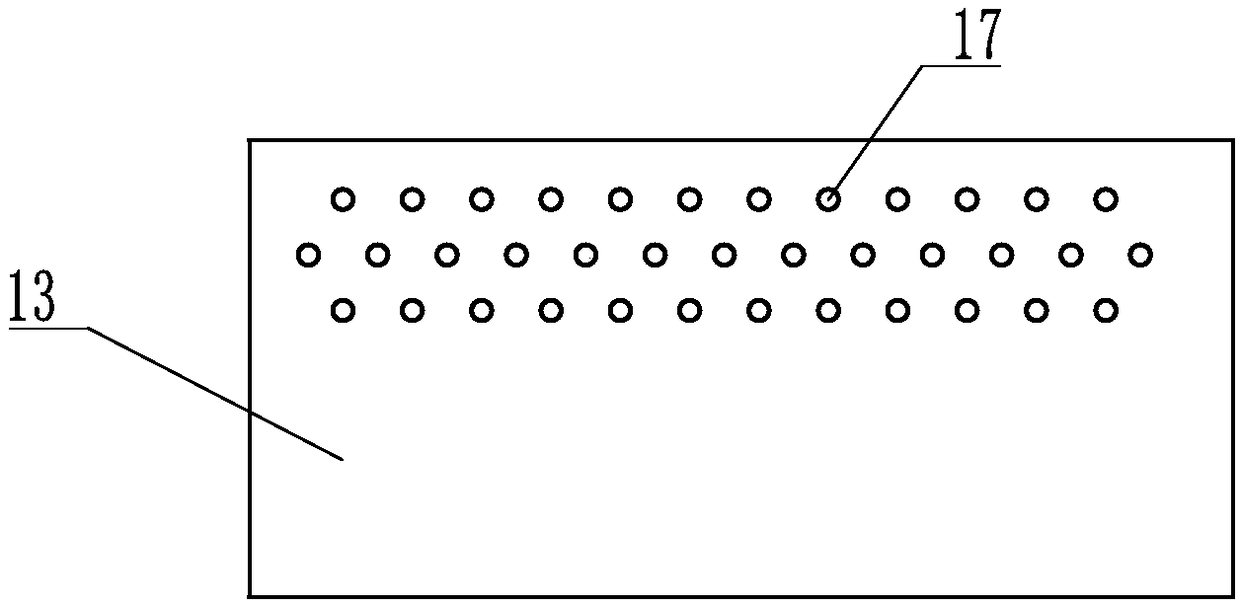

[0053] Embodiment 1: refer to Figure 1~3 , is a schematic structural diagram of Embodiment 1 of the present invention,

[0054] A full working condition wet desulfurization tail gas water collection and white smoke elimination system mainly includes a desulfurization tower 1, a sedimentation tank 2, a clean water tank 3, a cooling pump 4, a cooling tower 5, a circulating water tank 6 and a condensation pump 7. The desulfurization tower 1 is provided with an air inlet 11 and an air outlet 12, and the desulfurization tower 1 is provided with a desulfurization spray layer 1-1, a demister layer 1-2, and a demister flushing layer 1-3 in sequence from bottom to top , the first air lift plate 1-4, the first stage condensation spray layer 1-5, the second air lift plate 1-6, the second stage condensation spray layer 1-7, the defogging water collection layer 1-8 and the heater layer 1-9, the height of the demister flushing layer 1-3 from the mist eliminator layer 1-2 is 0.2m to 0.8m, ...

Embodiment 2

[0064] Embodiment 2: refer to figure 1 , is a schematic structural diagram of Embodiment 2 of the present invention,

[0065] A full working condition wet desulfurization tail gas water collection method for eliminating white smoke, comprising the following steps:

[0066] A. Preliminary purification of flue gas

[0067] After the flue gas enters the desulfurization tower 1, it is washed by the desulfurization spray layer 1-1 to remove most of the SO in the flue gas 2 and dust particles, the heat exchange between the flue gas and the desulfurization slurry reaches saturation, the temperature of the flue gas drops to 50-60°C, and the saturated wet flue gas after desulfurization carries a small amount of residual SO 2 and dust particles go upward through the demister layer 1-2 for demisting and desizing;

[0068] The flushing method of the mist eliminator is intermittent partition flushing, and the liquid-gas ratio of the flushing layer 1-3 of the mist eliminator is 0.1L / Nm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com