TAIC anaerobic reactor

An anaerobic reactor and reaction chamber technology, which is applied in the field of anaerobic reactors, can solve the problems that the internal circulation return flow cannot be adjusted artificially, the biogas collection is incomplete, and the sludge cannot be mixed, etc., to achieve small footprint and impact resistance The effect of strong load capacity and low investment in infrastructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

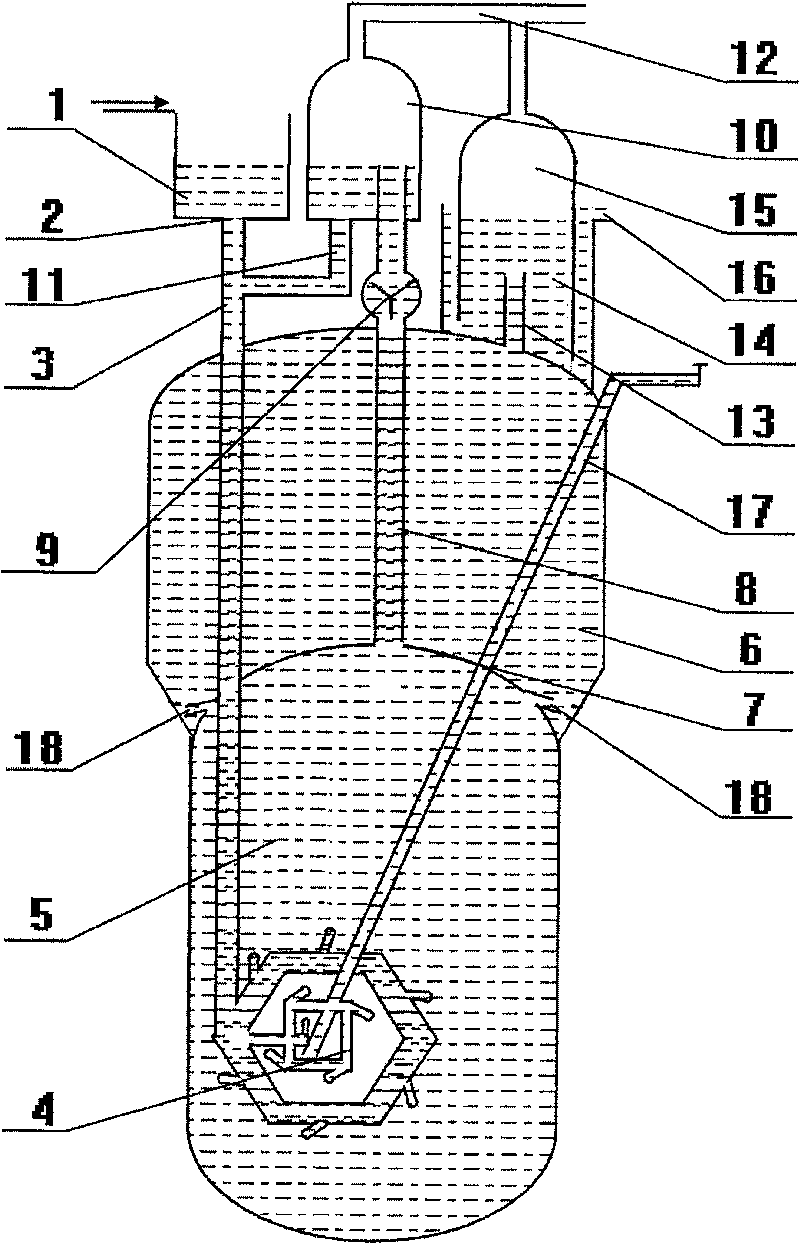

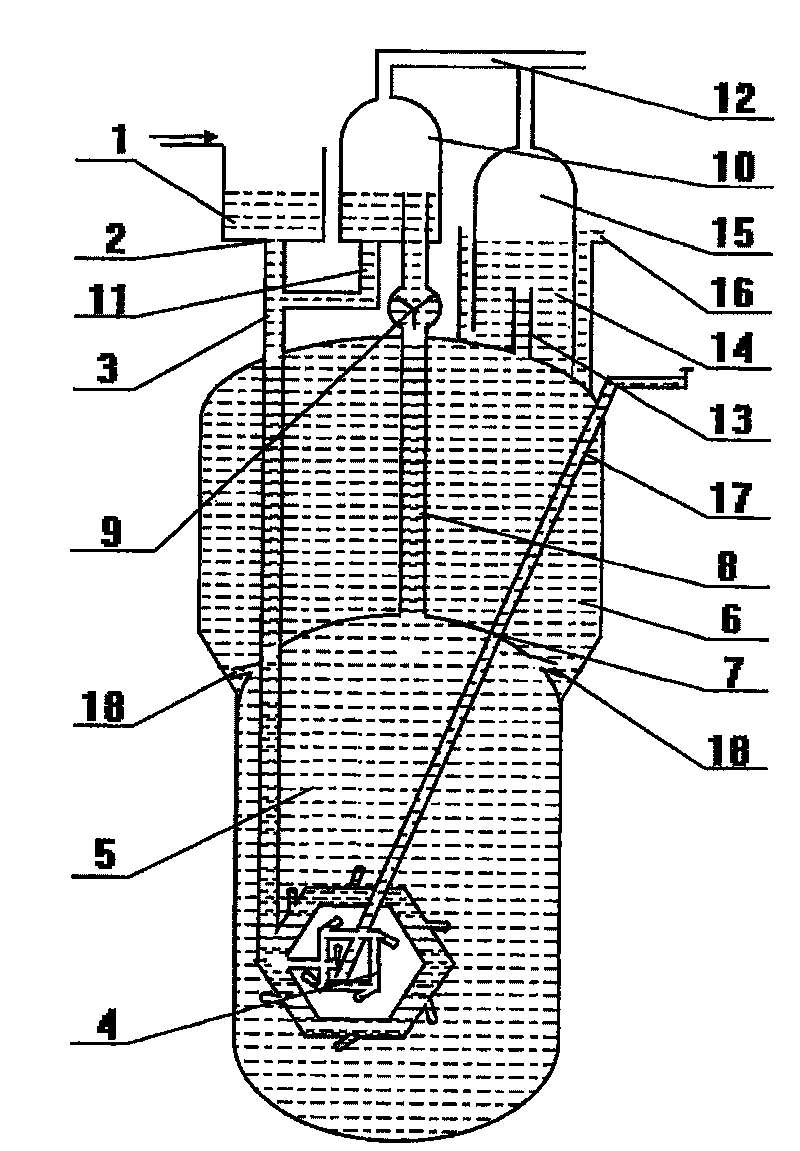

[0011] refer to figure 1 , the present invention consists of an automatic pressure-regulating feed tank 1, a feed port 2, a feed main pipe 3, a material distribution system 4, a first reaction chamber 5, a second reaction chamber 6, a three-phase separator 7, a riser 8, an adjustable Speed circulation return pump 9, first reaction chamber gas-liquid separator 10, sludge circulation return pipe 11, biogas air duct 12, second reaction chamber gas-liquid connection pipe 13, second reverse chamber gas-liquid separation tank 14, biogas Collecting cover 15, biogas slurry, biogas residue overflow pipe 16, bottom slag discharge pipe 17, inclined connecting pipe 18, the second reaction chamber 6 is superimposed on the first reaction chamber 5, and the three-phase separator 7 is arranged on the first On the top of the reaction chamber 5, the inclined connecting pipe 18 is arranged on both sides of the top of the first reaction chamber 5, and an adjustable speed circulating reflux pump...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com