Compound jet tower disk

A technology of tray and jet cover, applied in the field of composite jet tray, can solve problems such as difficulty in adapting to operating conditions, and achieve the effects of stable operation and high operating flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

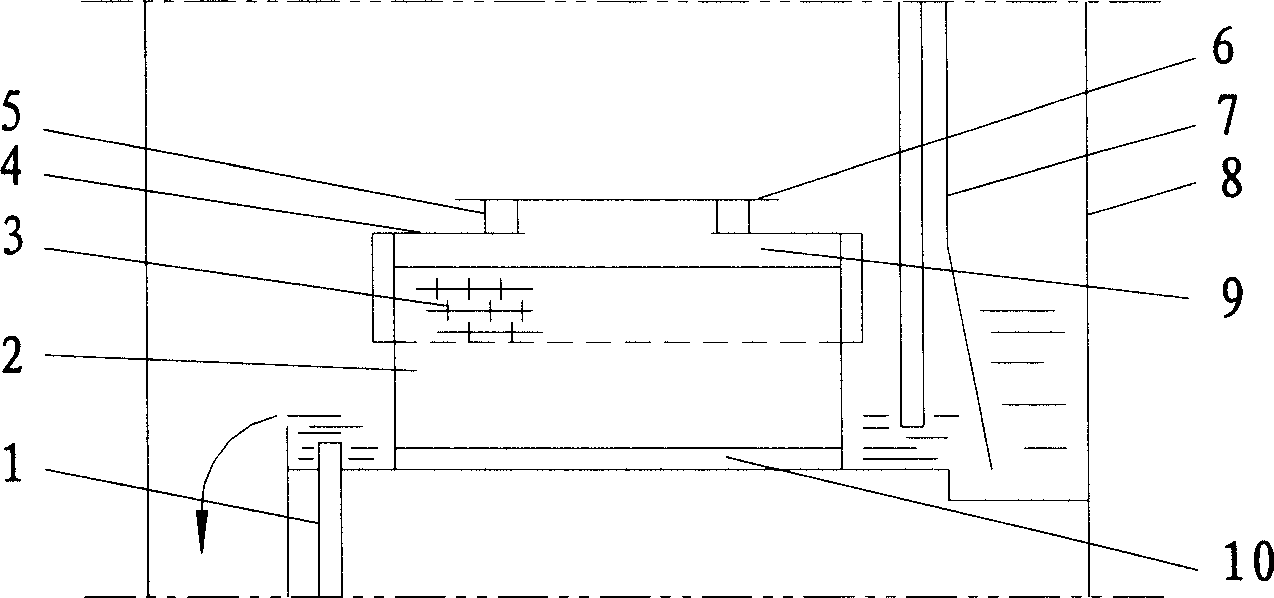

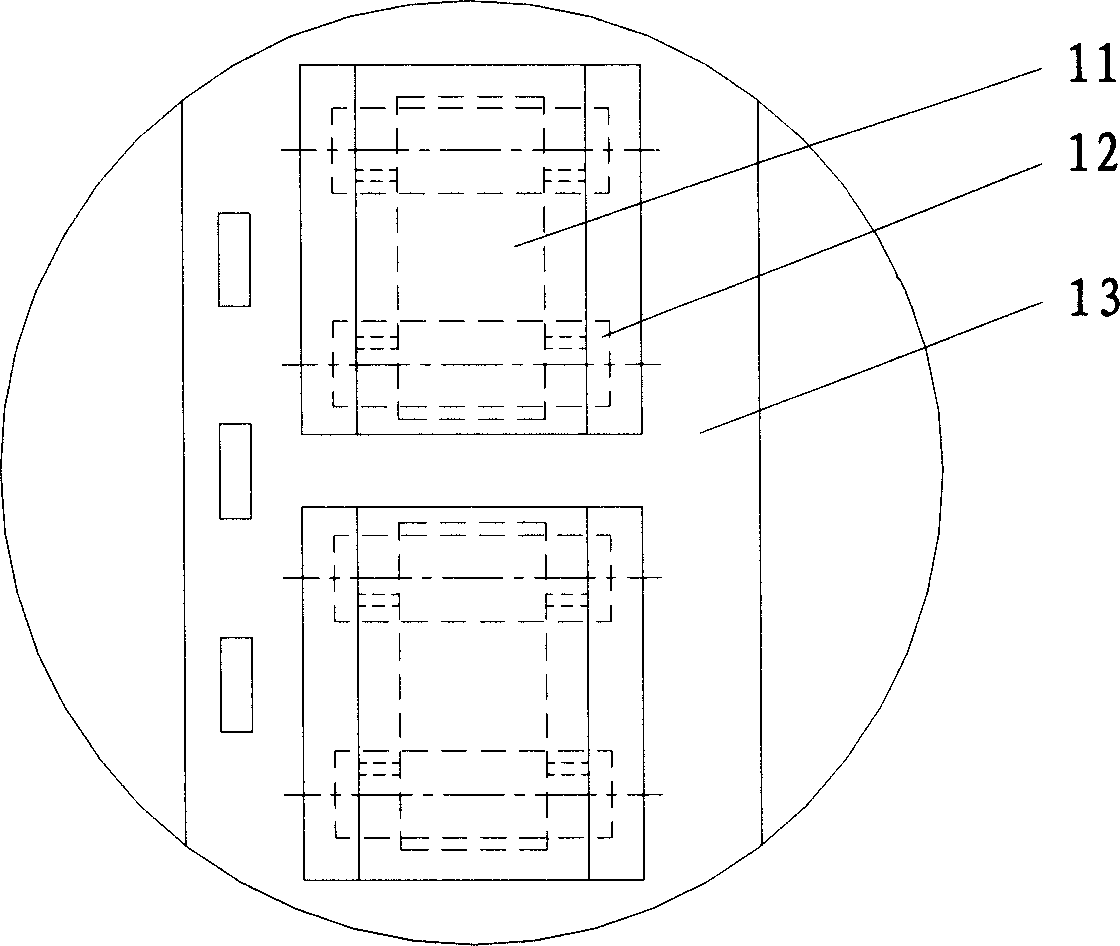

[0014] Embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0015] The working principle of the compound injection tray is: the liquid flows down from the overflow device and the auxiliary downcomer of the upper tray, and the gas enters the injection hood from the bottom of the tray through the air hole, and the gas enters the injection hood and rises at the same time , the liquid enters the spray hood through the bottom gap of the spray hood, and is blown into a thin liquid film by the gas. When the liquid film is lifted by the gas, it is broken into droplets under the action of surface tension. The gas-liquid mixed flow is ejected from the ejection hole and the ejection channel. Part of the gas-liquid mixed flow ejected from the top is sprayed on the gas-liquid separation plate of the lower layer, and the rest will be sprayed onto the gas-liquid separation plate of the upper layer through the air-lift holes on the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com