Reactor component for thermogravimetry equipment and thermogravimetry equipment

A technology of reactors and components, applied in the field of reactor components and thermogravimetric equipment, can solve the problems of inaccurate measurement, incomplete contact between gas and solid samples, etc., and achieve the effect of sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

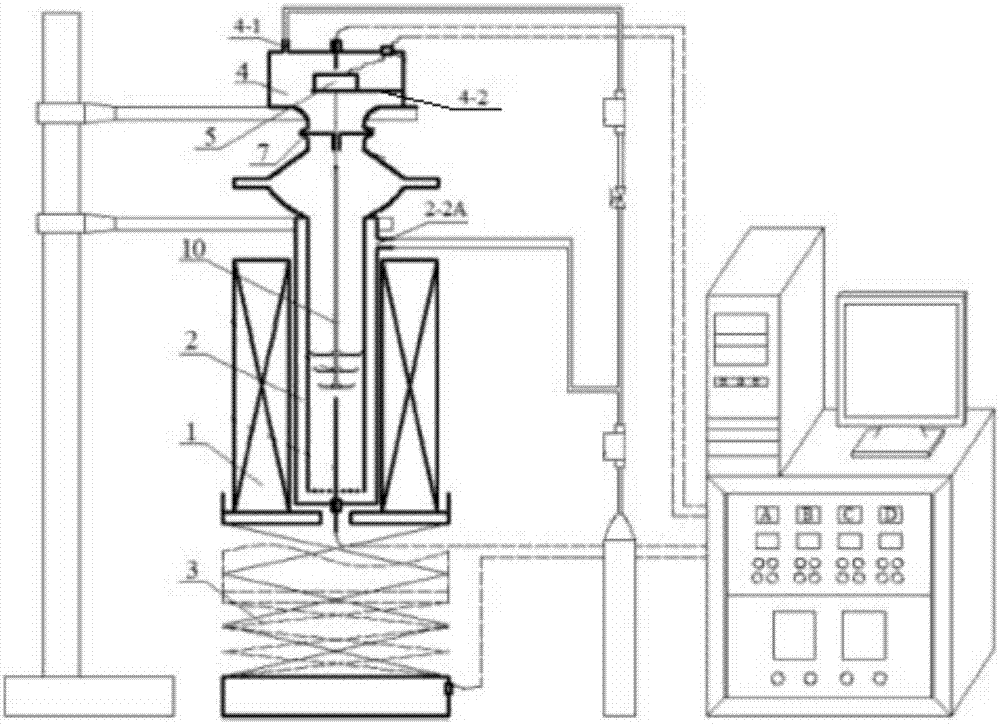

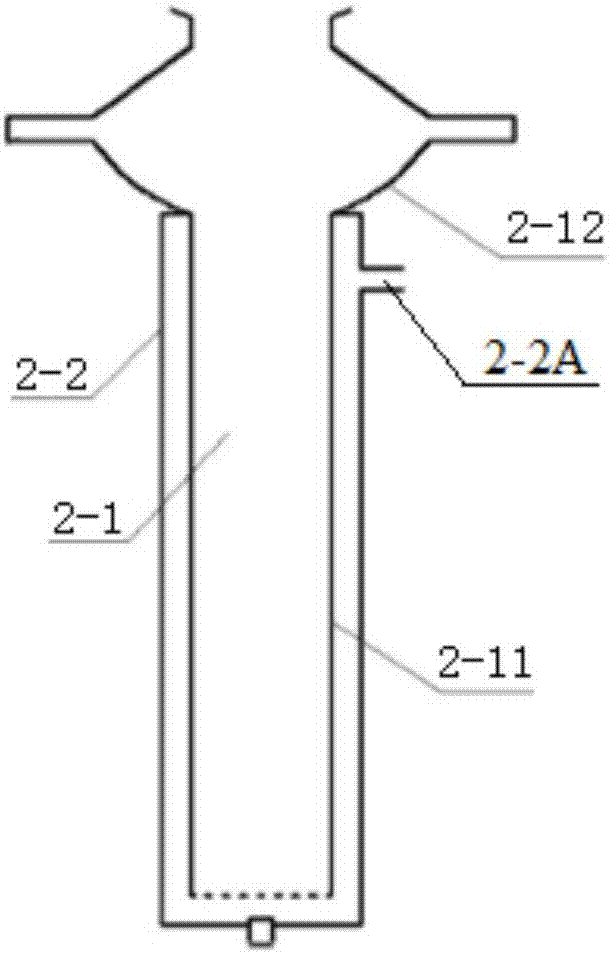

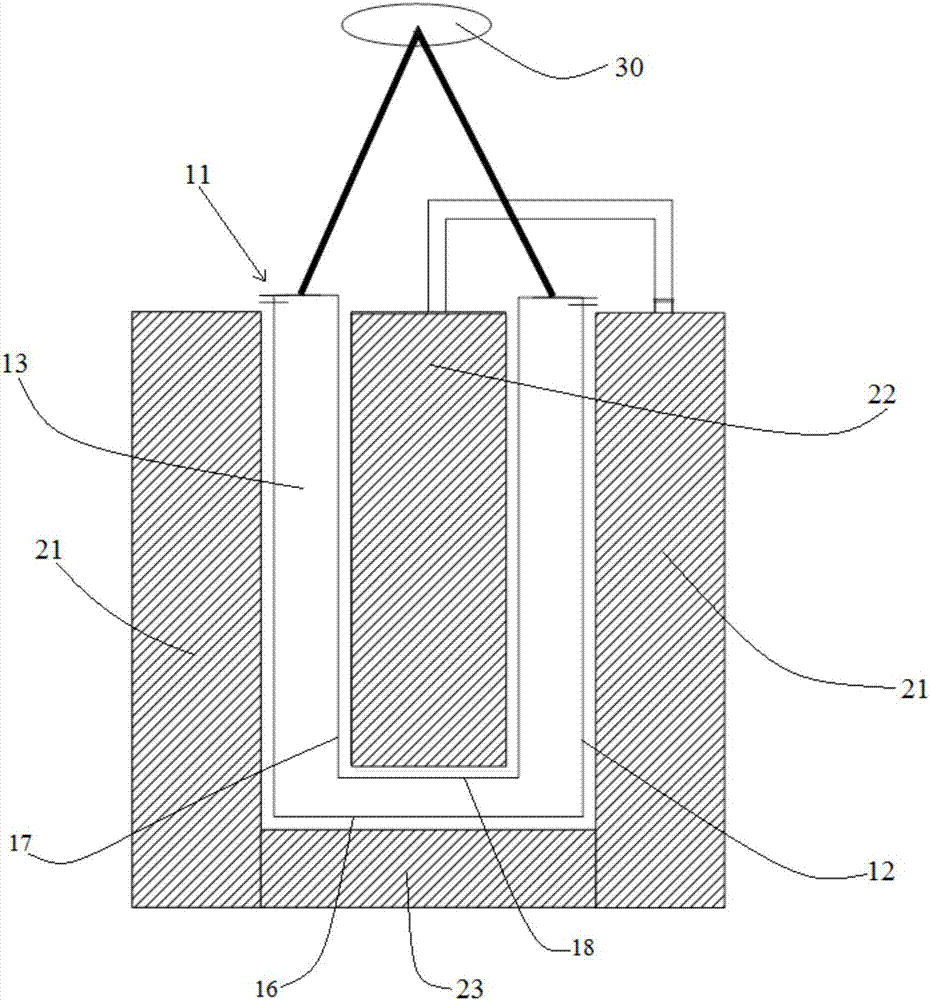

[0054] appropriate reference image 3 , in the present embodiment, the reactor assembly for thermogravimetric equipment provided by the present invention comprises the container 11 that has at least double wall, and the space 13 between the adjacent wall of this container 11 is sealable and is used for placing Sample to be tested.

[0055]Compared with the prior art, the place for placing the sample to be tested in the present invention is completely different from the prior art. In the present invention, by using a container 11 comprising at least double walls, the sample to be tested can be placed in a thin layer. The form is placed in the space 13, avoiding the problem of incomplete contact between the gas and the solid sample caused by stacking the samples to be tested together like the prior art, and it is also because the structure of the reactor assembly in the present invention is consistent with the actual There are different technologies, so that the present inventi...

Embodiment approach 2

[0083] One of the differences between this embodiment and Embodiment 1 is: the bottom of the inner side wall 17 is fixedly connected to the inner surface of the outer bottom wall 16. It can also be understood that the inner bottom wall 18 overlaps with the outer bottom wall 16. , the sealing of the space 13 formed by the container 11 only needs to be realized by an annular top cover. Meanwhile, in this embodiment, the above-mentioned gas distributor 50 may be an annular structure. Certainly, in this embodiment, the longitudinal cross-section of the pick-and-place part 40 along the reactor assembly may be concave, or the cross-section of the pick-and-place part 40 perpendicular to the longitudinal direction of the reactor assembly may be ring-shaped.

[0084] Other features in this embodiment are similar or identical to Embodiment 1, and will not be repeated here.

[0085] The thermogravimetric equipment provided by the present invention can be applicable to the situation that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com