Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Ethylene glycol monopropyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for intermediate epichlorophdrin of herbicide pretilachlor

InactiveCN101284768AEmission reductionEliminate potential safety hazardsOrganic chemistryOrganic compound preparationChemical reactionOrganic solvent

The invention relates to a method for preparing the designed herbicide pretilachlor intermediate chloride ether. Under the action of organic amine catalyst, the chloride ether can be obtained by ethylene glycol monopropyl ether and bis (trichloromethyl) hydroxyphenyl in the organic solvent through the following chemical equation: HOC2H4OC3H7+Cl3COCOOCCl3 arrow ClC2H4OC3H7+CO2+HCl. The method replaces the traditional chlorination reagent with the bis (trichloromethyl) hydroxyphenyl, such as, thionly chloride, phosphorus oxychloride and hydrogen chloride, etc., and the potential safety hazard can be eliminated from the process source by using the novel chlorination reagent. Simultaneously, the emissions of pollutants are greatly reduced, and the method is a cleaning process with mild reaction conditions, safe and reliable operating process and high product yield, and has good industrialization implementation value and social economic benefits.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Anti-condensation coating

The invention discloses an anti-condensation coating. The anti-condensation coating comprises the following components in parts by weight: 12-30 parts of zinc oxide, 8-16 parts of benzoyl peroxide, 10-20 parts of dibutyl phthalate, 10-20 parts of triphenyl phosphate, 2-10 parts of isopropyl acrylate, 20-80 parts of styrene, 120-200 parts of butyl acrylate, 40-120 parts of acrylic acid, 80-100 parts of methyl methacrylate, 10-20 parts of ammonium zinc carbonate, 20-40 parts of titanium dioxide, 10-20 parts of ethylene glycol monopropyl ether and 6-12 parts of ethyl acrylate. The anti-condensation coating provided by the invention is simple to prepare, adopts nontoxic production raw materials, has good using effects, is environment-friendly, can form tough coats and has lasting anti-condensation property and waterproofness.

Owner:范红梅

Anti-fogging coating

The invention discloses an anti-fogging coating which comprises the following components in parts by weight: 100-140 parts of styrene, 120-200 parts of butyl acrylate, 40-120 parts of acrylic acid, 80-100 parts of methyl methacrylate, 40-80 parts of ammonia zinc carbonate, 45-60 parts of titanium dioxide, 40-50 parts of ethylene glycol monopropyl ether and 20-40 parts of ethyl acrylate. The anti-fogging coating provided by the invention is easy to manufacture, the adopted production raw materials are non-toxic, the coating is good in using effect and environment-friendly, a tough coating can be formed, and the coating has lasting anti-fogging property and antistatic property.

Owner:姜云华

Automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling automobile engine

ActiveCN104877831AReduce fuel consumptionIncrease motivationSurface-active non-soap compounds and soap mixture detergentsCleansing AgentsCarbon deposit

The invention provides an automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling an automobile engine, relates to a carbon deposit cleaning agent and aims to solve the problem that the service life of an engine is shortened due to extremely high temperature in a cylinder when the conventional hydrogen method is used for removing carbon deposit. The automobile carbon deposit cleaning agent is formed by mixing dodecyl phenolsulfonic acid isopropylamine salt, nonylphenol polyglycol ether, ethylene glycol monopropyl ether, petroleum ether, petroleum hydrogenated light distillate, methenamine and deionized water. The cleaning agent has the advantages as follows: the automobile carbon deposit cleaning agent is gasified into nanoscale liquid drops through atomizing equipment to enter the engine along an engine gas inlet pipeline to achieve the purpose of cleaning, the interior of the engine, the pipeline and a three-element catalytic device can be cleaned without dismantling the engine. The invention is mainly used for preparing the automobile carbon deposit cleaning agent capable of being used for cleaning without dismantling the automobile engine.

Owner:HARBIN INST OF TECH

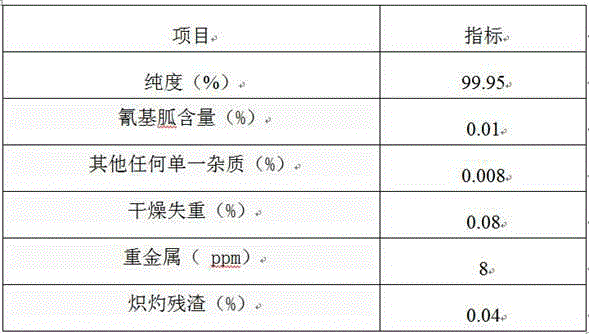

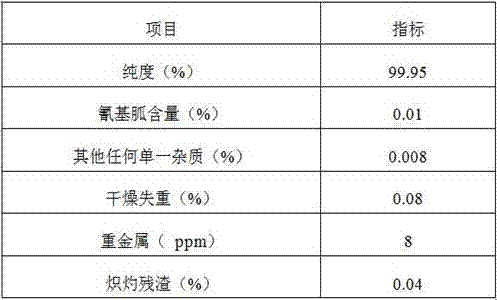

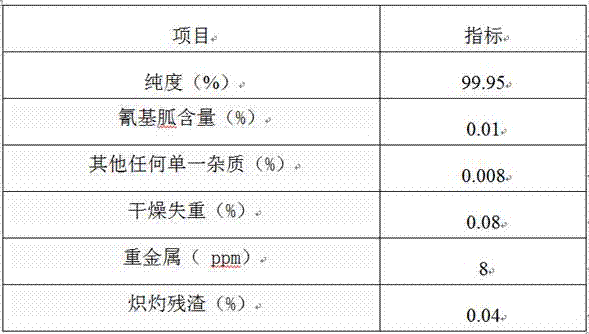

Method for preparation of high purity and high yield metformin hydrochloride by two-component solvent

ActiveCN104829495AHigh purityGood crystal shapeOrganic compound preparationAmino compound preparationMetformin hclMetformin hydrochloride product

The invention discloses a method for preparation of high purity and high yield metformin hydrochloride by a two-component solvent. The method includes: preparation of dimethylamine hydrochloride and preparation of metformin hydrochloride. During preparation of dimethylamine hydrochloride, dimethylamine gas and 31% hydrochloric acid are adopted as the raw materials to carry out reaction, through co-cooling of a cooler and a reaction kettle jacket, pumping circulating, spraying absorption of dimethylamine tail gas and absorption of dimethylamine tail gas by hydrochloric acid, the utilization rate of the raw materials is maximumly ensured, the loss of raw materials is reduced, and the product yield is improved. During preparation of metformin hydrochloride, dimethylformamide and ethylene glycol monopropyl ether two components are used as the solvent, the synergistic effect of the two solvents with different natures are utilized, and the prepared metformin hydrochloride product has yield of over 95% and purity of more than 99.90%.

Owner:山西津华晖星制药有限公司

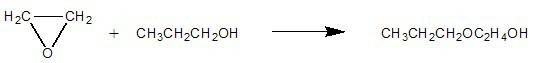

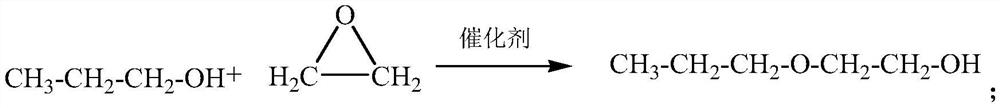

Method for preparing ethylene glycol monopropyl ether

InactiveCN102219654AHigh activityNarrow composition distributionOrganic-compounds/hydrides/coordination-complexes catalystsEther preparation from oxiranesPolymer scienceEthoxylation

The invention discloses a method for preparing ethylene glycol monopropyl ether. The method is mainly etherification reaction of n-propanol and ethylene oxide in the presence of methyl disulphonate serving as a catalyst. The catalyst for catalyzing the ethoxylation of the n-propanol is high in activity, products are in narrow distribution, the selectivity is high, the conversion rate of the ethylene oxide reaches 100 percent, and the yield of the ethylene glycol monopropyl ether is more than 95 percent.

Owner:南通德益化工有限公司

Concrete crack repairing additive, and preparation and use methods thereof

The invention relates to a concrete crack repairing additive, in particular to an organic silicon resin emulsion modified high-molecular polymer crack repairing additive, and a preparation method anda use method thereof. Every 100 parts by weight of the repairing additive contains 2-20 parts by weight of an organic silicon resin emulsion, 2-6 parts by weight of a coalescing agent, 1-7 parts by weight of a water reducing agent and 0.2-1 part by weight of a defoaming agent, with the balance being water, wherein the solid content of the organic silicon resin emulsion is 45%-55%, and the film-forming agent is at least one of selected from a group consisting of propylene glycol butyl ether, ethylene glycol monopropyl ether and propylene glycol methyl ether acetate. By controlling the organic silicon resin emulsion, the water reducing agent and the defoaming agent within the above ranges, the strength, coalescence, film-forming property and stability of the organic silicon resin emulsion are brought into full play, and the cement mortar prepared from the repairing additive has good strength performance and durability and is suitable for repairing fine concrete cracks with sizes of 0.3-2.5 mm.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

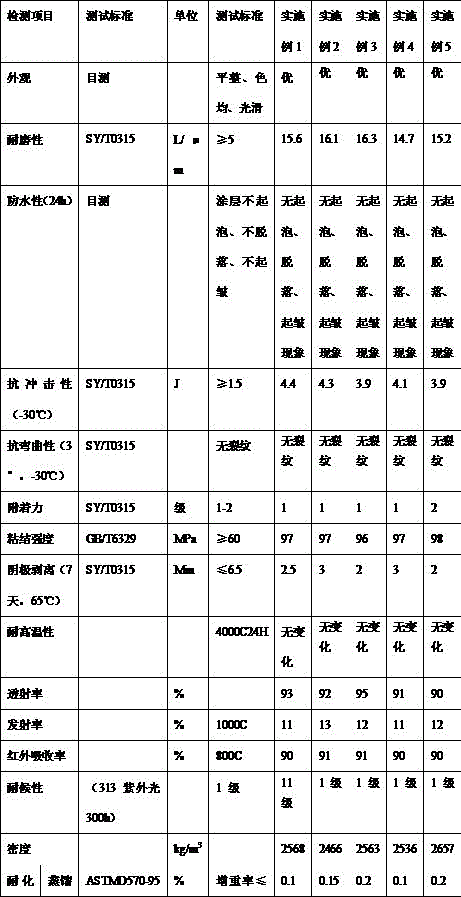

Modified polytetrafluoroethylene coating for centrifugal pump and preparation method thereof

The invention discloses a modified polytetrafluoroethylene coating for a centrifugal pump and a preparation method thereof and relates to the technical filed of coatings for centrifugal pumps. The modified polytetrafluoroethylene coating is prepared from the following raw materials in parts by mass: 90-100 parts of polytetrafluoroethylene, 50-60 parts of polyphenylene sulfide, 45-50 parts of organosilicone resin, 30-40 parts of ethylene glycol monopropyl ether, 25-30 parts of talc powder, 25-30 parts of quartz powder, 15-20 parts of fumed silica, 40-45 parts of epoxidized soybean oil, 10-15 parts of a titanate coupling agent, 18-22 parts of calcium carbonate, 15-20 parts of polydimethylsiloxane, 12-16 parts of dibutyl tin dilaurate, 10-15 parts of a toughening agent, 8-12 parts of an acrylic acid flatting agent, 5-10 parts of modified zinc phosphate, 5-10 parts of aluminum tripolyphosphate, 40-45 parts of methylisobutyl ketone and 20-25 parts of xylene. The coating prepared by the preparation method has good adhesion to the centrifugal pump and the formed coat has the advantages of very strong corrosion resistance, abrasion resistance and anti-aging property so that the service life of the centrifugal pump is prolonged.

Owner:SANLIAN PUMP IND CO LTD

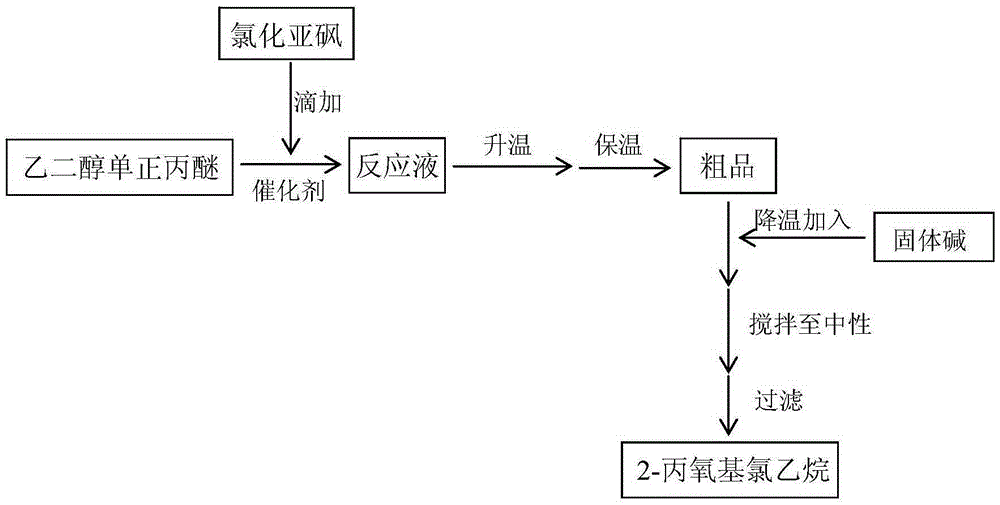

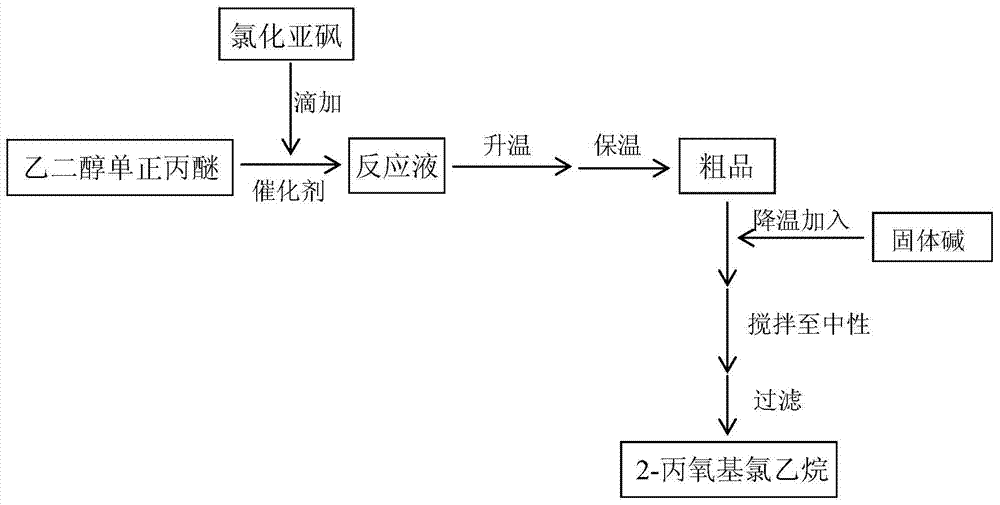

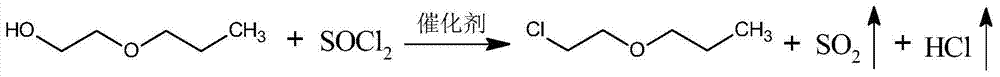

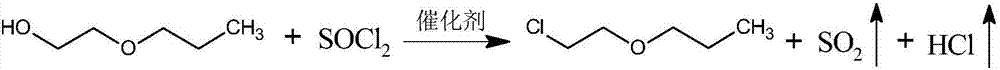

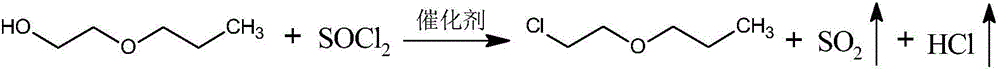

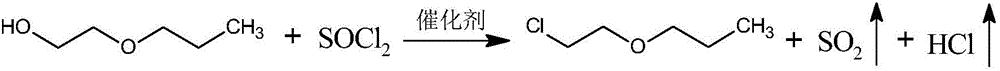

Method for compounding 1-(2-Chloroethoxy)propane

ActiveCN105348049AImprove efficiencyHigh yieldOrganic chemistryOrganic compound preparationOrganic synthesisReaction temperature

The invention belongs to the technical field of organic syntheses, and in particular relates to a method for compounding 1-(2-Chloroethoxy)propane. The method comprises the steps of taking ethylene glycol monopropyl ether and thionyl chloride as main raw materials under the synergistic action of a phase transfer catalyst; controlling the reaction temperature by dripping the thionyl chloride; obtaining a crude product through temperature rising and temperature preservation; directly adding solid alkali to decompose and neutralize the excessive thionyl chloride after cooling; finally obtaining the 1-(2-Chloroethoxy)propane through filtering. Compared with the prior art, the efficiency of the catalyst is higher, the technology is simple and convenient, safety and reliability are realized, the yield of the product is high, the quality is stable, the product content is more than 99.2 percent, the yield is greater than 98.6 percent, the production cost is lower, and the method is particularly suitable for industrial production.

Owner:SHANDONG KAISHENG NEW MATERIALS

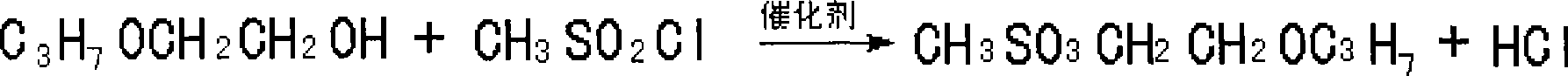

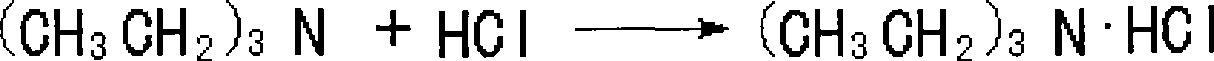

Circulation clean production method of N-propoxyl ethyl-2, 6-diethylaniline

ActiveCN101525298AEasy to recycleEasy to operateOrganic compound preparationAmino-hyroxy compound preparationSulfonyl chlorideAmidogen

The invention discloses a circulation clean production method of N-propoxyl ethyl-2, 6-diethylaniline. The circulation clean production method comprises the following steps: benzene sulfonyl chloride and propylcellosolve carry out esterification reaction to produce a benzene sulfonic acid (2-propoxyl group) ethyl ester, the benzene sulfonic acid (2-propoxyl group) ethyl ester and 2, 6-diethylaniline carry out N alkylation reaction to produce N-propoxyl ethyl 2, 6-diethylaniline, i.e. and rough amidogen ether, the rough amidogen ether is rectified to produce the N-propoxyl ethyl-2, 6-diethylaniline, i.e. fine amidogen ether. The invention has easy operation and clean processing. On one hand, the invention overcomes the shortage of the traditional technology by preferably selecting sulfonic acid chloride; on the other hand, salt obtained from the preferably selected sulfonic acid chloride through alkylation reaction is easy to recover, and the salt is back used for producing sulphonic acid ester again after being simply processed, thereby the invention greatly enhances the economic and the social benefits of the product.

Owner:NANTONG WEILIKE CHEM

Fireproof mould-proof coating rubber

InactiveCN105778697AEasy to makeEasy to useAntifouling/underwater paintsPaints with biocidesPolyesterEpoxy

The invention discloses fireproof mould-proof coating rubber which comprises the following components in parts by weight: 40-80 parts of isopropyl acrylate, 12-16 parts of epoxy resin, 40-50 parts of ethylene glycol monopropyl ether, 20-40 parts of ethyl acrylate, 12-24 parts of benzoyl peroxide, 10-20 parts of dibutyl phthalate, 8-16 parts of polyester, 20-30 parts of butanediol acrylate, 4-6 parts of trimethylolpropane, 10-20 parts of butanediol, 10-20 parts of methoxyphenol, 8-12 parts of acrylamide and 10-20 parts of styrene. The fireproof mould-proof coating rubber disclosed by the invention is simple to prepare; the adopted production raw materials are nontoxic, and the application effect of the coating rubber is good; and the coating rubber is environment-friendly and can form a firm bright film when acting on leather surface decoration.

Owner:黄金生

Heat-absorbing paint

PendingCN105694647AImprove waterproof performanceReduce hydrophilicityAnti-corrosive paintsRadiation-absorbing paintsPolymer scienceSolvent

The invention discloses a heat-absorbing paint which is prepared by the following steps: uniformly dispersing a light absorber, a film former, a solvent and aids by ball milling, adding a film forming aid, and mixing to obtain the solar heat-absorbing paint. The heat-absorbing paint is prepared from the following raw materials in parts by weight: 50-100 parts of film former, 10-30 parts of film forming, 35-55 parts of light absorber, 20-50 parts of solvent and 10-30 parts of aids. The film forming aid is hexanediol butyl ether acetate, ethanediol monopropyl ether or the like. The preparation method of the film former comprises the following steps: mixing casein and gelatin according to the weight ratio of (5-10):(2-3), adding water, immersing at 15-22 DEG C, transferring to a normal temperature environment, adding a mixed solution composed of ethyl acrylate and polydimethylsiloxane in a weight ratio of (1-2):(1-3), reacting, stirring, and carrying out ultraviolet irradiation for 10-15 minutes, thereby obtaining the modified casein-gelatin. The film former is modified and used as a critical raw material for preparing the paint, so that the prepared paint has favorable weather resistance and water resistance under outdoor conditions. The preparation technique is simple and understandable, and ensures the heat absorption efficiency of the heat-absorbing paint.

Owner:GUANGXI CHAOXING SOLAR ENERGY TECH

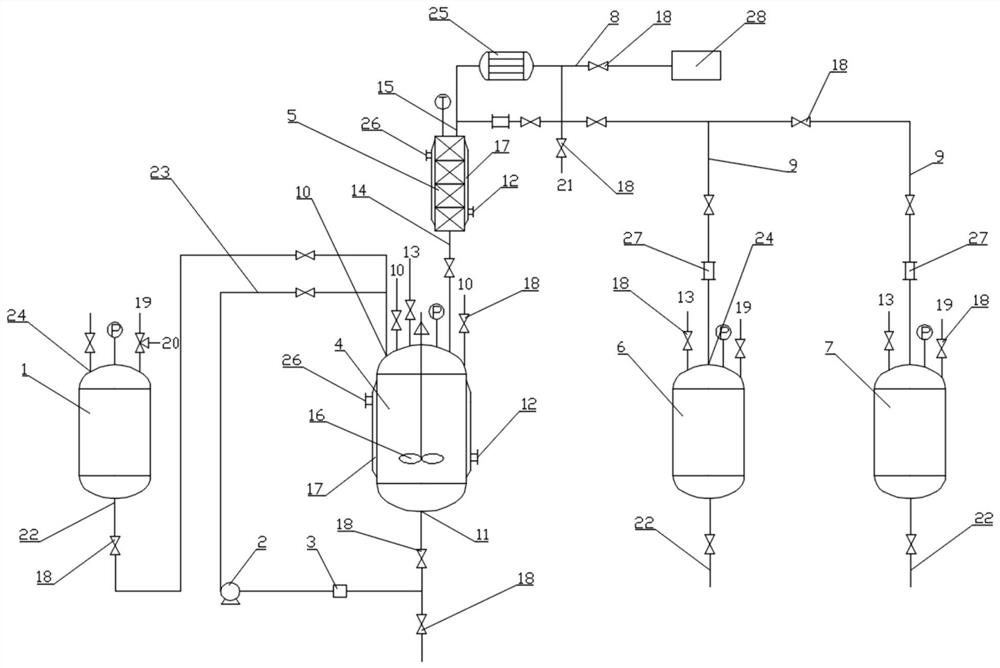

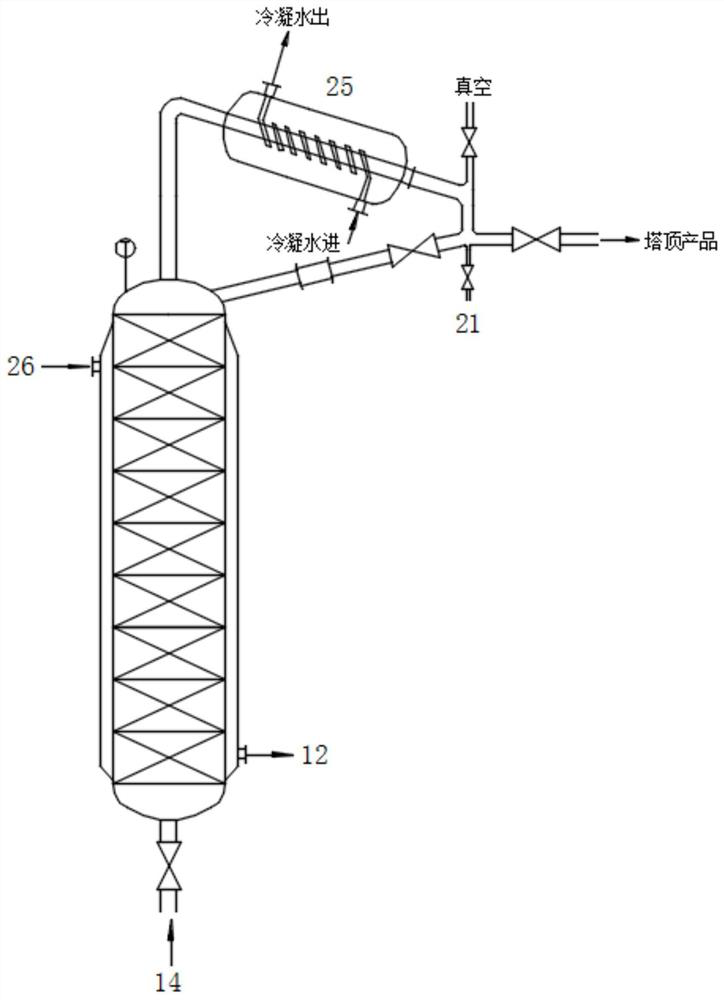

Preparation method and system of ethylene glycol monopropyl ether

ActiveCN111747828AHigh puritySimple processEther preparation from oxiranesChemical/physical/physico-chemical stationary reactorsPropanolPtru catalyst

The invention provides a preparation method and system of ethylene glycol monopropyl ether. The preparation method adopts the following reaction equations: n-propanol and ethylene oxide react under the action of a catalyst to synthesize an ethylene glycol monopropyl ether crude product; and rectification under vacuum is carried out on the crude product to obtain an ethylene glycol monopropyl etherfinished product. The preparation system comprises an addition and rectification integrated reaction kettle; the addition and rectification integrated reaction kettle comprises a reaction kettle mainbody; a rectification tower is connected above the reaction kettle main body; the reaction kettle main body comprises a reaction feed port, a reaction discharge port and a material steam outlet; thematerial steam outlet is connected with the rectification inlet of the rectification tower; the rectification tower is provided with the rectification inlet and a rectification outlet and is also connected with a vacuum device. The ethylene glycol monopropyl ether prepared by the method has high purity (more than or equal to 99.8%) and few byproducts.

Owner:ZHEJIANG HUANGMA TECH +3

Disinfector for domestic sewage

InactiveCN105994340AWith sterilizationSimple manufacturing methodBiocideDisinfectantsBetainePolyethylene glycol

A domestic sewage disinfectant, the composition is composed of the following weight ratios: 1 part of N-dihydroxyethylglycine, 9 parts of fatty acid glycerides, 10 parts of aminophenyl, 11 parts of propanol, 7 parts of nitrilotriacetic acid, poly 9 parts of hexamethylene guanidine, 10 parts of polyoxyethylene alcohol ester, 11 parts of polyethylene glycol, 4 parts of chlorhexidine, 8 parts of alkanolamide, 9 parts of ethylene glycol monopropyl ether, 10 parts of aminopropionic acid 11 parts of propylene glycol, 12 parts of p-chloro-m-xylenol, 14 parts of sodium alginate, 15 parts of polyhexamethylene biguanide, 16 parts of polyoxyethylene ether, 4 parts of polyvinylpyrrolidone, 6 parts of chlorhexidine salt, 7 parts of mucopolysaccharide, 8 parts of dextran, 9 parts of aldehyde phenyl, 10 parts of betaine, 14 parts of alkyl dimethyl ammonium salt.

Owner:王兰英

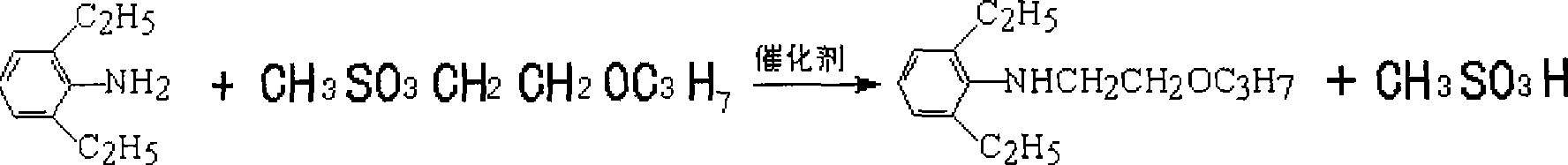

Production process of 2,6-diethyl-N-(2-propoxyethyl) acetanil

InactiveCN101475508ARaw materials are easy to getHigh yieldOrganic compound preparationCarboxylic acid amides preparationAnilineSolvent

The invention discloses technology for preparing 2,6-diethyl-N-(2-propoxyl ethyl)acetanilide, which comprises: firstly, performing esterification reaction on ethylene glycol monopropyl ether, triethylamine and proper amount of esterifying catalyst; secondly, adding 2,6-diethylaniline, esterified sulfonic acid ester and a catalyst into an autoclave, and performing heating reaction and etherification reaction; and thirdly, adding refined ether, a toluene solvent, sodium carbonate and water into an acylation reaction kettle, reducing the temperature, dripping acetyl chloride, and performing acylation reaction to prepare finished products. The method has the advantages of easily obtained raw materials, easy operation and high product yield.

Owner:南通德益化工有限公司

Method for producing metformin hydrochloride from complex solvents

ActiveCN107245042AHigh purityGood crystal shapeOrganic compound preparationAmino compound preparationMetformin HydrochlorideHydrochloride

The invention discloses a method for producing metformin hydrochloride from complex solvents. The method comprises the steps of dimethylamine hydrochloride preparation and metformin hydrochloride preparation, wherein the metformin hydrochloride preparation comprises the steps of adding raw materials and solvents, heating and warming, cooling, cooling secondarily, centrifuging, washing, crystallizing and drying; the heating and warming comprises the steps of introducing steam into an addition kettle jacket, heating, adjusting a stirring rotation speed to be 80 to 130 turns per minute, warming 30 to 50 minutes to raise kettle temperature to 110 to 115 DEG C, keeping 10 to 30 minutes, continuously warming 15 to 30 minutes to raise temperature to 118 to 125 DEG C and keeping warm to react for 1.5 to 2.5 hours. In the metformin hydrochloride preparation, double components of dimethyl formamide and ethylene glycol monopropyl ether are utilized as the solvents, the metformin hydrochloride can be prepared by using a synergistic effect of two solvents with different characters, product yield is greater than 95%, and purity is greater than 99.90%.

Owner:SUZHOU YUANCHUANG PHARM RES CO LTD

Method used for preparing pretilachlor

InactiveCN105272869AHigh yieldIncrease productivityOrganic compound preparationCarboxylic acid amides preparationAnilineCondensation reaction

The invention discloses a method used for preparing pretilachlor. The method comprises a step used for preparing pretilachlor. According to the method, ethylene glycol monopropyl ether is reacted with thionyl chloride so as to obtain chloric ether; chloric ether and aniline are subjected to condensation reaction so as to obtain a condensation product; the condensation product is subjected to rectification so as to obtain rectified N,N,N',N'-tetramethyl-2,2'-oxybis(ethylamine); and rectified N,N,N',N'-tetramethyl-2,2'-oxybis(ethylamine) is subjected to acylation so as to obtain pretilachlor. The method is capable of increasing production efficiency, reducing production cost, improving production environment, and increasing yield of pretilachlor obviously.

Owner:江苏汇丰科技有限公司

Circulation clean production method of N-propoxyl ethyl-2, 6-diethylaniline

ActiveCN101525298BEasy to recycleEasy to operateOrganic compound preparationAmino-hyroxy compound preparationSulfonyl chlorideBenzenesulfonyl chloride

The invention discloses a circulation clean production method of N-propoxyl ethyl-2, 6-diethylaniline. The circulation clean production method comprises the following steps: benzene sulfonyl chloride and propylcellosolve carry out esterification reaction to produce a benzene sulfonic acid (2-propoxyl group) ethyl ester, the benzene sulfonic acid (2-propoxyl group) ethyl ester and 2, 6-diethylaniline carry out N alkylation reaction to produce N-propoxyl ethyl 2, 6-diethylaniline, i.e. and rough amidogen ether, the rough amidogen ether is rectified to produce the N-propoxyl ethyl-2, 6-diethylaniline, i.e. fine amidogen ether. The invention has easy operation and clean processing. On one hand, the invention overcomes the shortage of the traditional technology by preferably selecting sulfonicacid chloride; on the other hand, salt obtained from the preferably selected sulfonic acid chloride through alkylation reaction is easy to recover, and the salt is back used for producing sulphonic acid ester again after being simply processed, thereby the invention greatly enhances the economic and the social benefits of the product.

Owner:NANTONG WEILIKE CHEM

Disinfectant for livestock and poultry shed

The invention discloses a disinfectant for livestock and poultry shed. The disinfectant comprises potassium permanganate, formalin, ethylene glycol monopropyl ether, ethylene diamine tetraacetic acid and water. The invention has a reasonable formula, good usage effect and low production cost.

Owner:吴建树

The method for synthesizing 2-propoxyl ethyl chloride

ActiveCN105348049BImprove efficiencyHigh yieldOrganic chemistryOrganic compound preparationOrganic synthesisReaction temperature

The invention belongs to the technical field of organic syntheses, and in particular relates to a method for compounding 1-(2-Chloroethoxy)propane. The method comprises the steps of taking ethylene glycol monopropyl ether and thionyl chloride as main raw materials under the synergistic action of a phase transfer catalyst; controlling the reaction temperature by dripping the thionyl chloride; obtaining a crude product through temperature rising and temperature preservation; directly adding solid alkali to decompose and neutralize the excessive thionyl chloride after cooling; finally obtaining the 1-(2-Chloroethoxy)propane through filtering. Compared with the prior art, the efficiency of the catalyst is higher, the technology is simple and convenient, safety and reliability are realized, the yield of the product is high, the quality is stable, the product content is more than 99.2 percent, the yield is greater than 98.6 percent, the production cost is lower, and the method is particularly suitable for industrial production.

Owner:SHANDONG KAISHENG NEW MATERIALS

Preparation process of 2-propoxy chloroethane

InactiveCN107056589AHigh catalytic efficiencySimple processOrganic chemistryOrganic compound preparationOrganic synthesisReaction rate

The invention relates to a preparation process of 2-propoxy chloroethane and belongs to the technical field of organic synthesis of fine chemical intermediates. The synthetic process comprises the following steps: by taking ethylene glycol monopropyl ether and excess thionyl chloride as raw materials and adopting a high efficiency composite catalyst, controlling the reaction rate through dropwise adding the thionyl chloride, raising the temperature and preserving the temperature to obtain a crude product, neutralizing, hydrolyzing, standing and layering to obtain the 2-propoxy chloroethane. Compared with the prior art, the preparation process disclosed by the invention has the advantages that the catalyst is higher in catalytic efficiency, low in price and easy to get; the process is simple, safe and reliable; the product is high in yield and stable in quality; the product content is up to above 99.0%; the yield is greater than 98.5%; catalysts used in the prior art easily react with little hydrochloric acid contained in the product to form complex salt which is a precipitate in the 2-propoxy chloroethane and then the product quality is influenced; and the preparation process is particularly suitable for industrial production.

Owner:SHANDONG KAISHENG NEW MATERIALS

A concrete crack repair additive and its preparation and use method

The invention relates to a concrete crack repair additive, in particular to a polymer crack repair additive modified by silicone resin emulsion and its preparation and use method. The restoration additive per 100 parts by weight contains 2-20 parts by weight of silicone resin emulsion, 2-6 parts by weight of film-forming aid, 1-7 parts by weight of water reducing agent and 0.2-1 part by weight of defoamer , the balance is water; the solid content of the silicone resin emulsion is 45% to 55%; the film-forming agent is at least one of propylene glycol butyl ether, ethylene glycol monopropyl ether, and propylene glycol methyl ether acetate. Through silicone resin emulsion, water reducer, defoamer, and controlled within the above range, the strength, coalescence, film-forming performance and stability of silicone resin emulsion are fully exerted, and the cement mortar prepared with this repair additive has With good strength performance and durability, it is suitable for the repair of 0.3-2.5mm concrete micro cracks.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

Production method of 2-propoxyethyl chloride

InactiveCN106831362AHigh catalytic efficiencySimple processOrganic chemistryOrganic compound preparationOrganic synthesisReaction rate

The invention relates to a production method of 2-propoxyethyl chloride and belongs to the technical field of fine chemical intermediate organic synthesis. The synthesis process comprises the following steps: preparing a crude product by taking ethylene glycol monopropyl ether and excessive sulfoxide chloride as main raw materials and adopting an efficient catalyst through heating and heat preservation, wherein the reaction rate is controlled by dropwise adding sulfoxide chloride; and performing neutralization, hydrolysis, and liquid separation after standingto obtain 2-propoxyethyl chloride. Compared with the existing process, the synthesis process has the advantages that the catalyst has higher catalytic efficiency and is cheap and easily available; the technological process is simple and convenient; the catalyst used in the existing process and hydrochloric acid in the crude product form a complex easily, so that the product has precipitates and the product yield is influenced; and the crude product prepared by the catalyst is clear and transparent, the product can be obtained without water washing, the quality is stable, the product content reaches above 99.5 percent, the yield is more than 99.0 percent, the production cost is lower, and the synthesis process is particularly suitable for industrialized production.

Owner:SHANDONG KAISHENG NEW MATERIALS

Production method for the intermediate methanesulfonic acid-2-propoxy ethyl ester of pretilachlor

The invention discloses a production method for the intermediate methanesulfonic acid-2- propoxy ethyl ester of pretilachlor. According to the method, glycol monopropyl ether reacts with methanesulfonyl chloride, and a metal halide is used as a catalyst for the reaction. The production method provided in the invention has the advantages of easy operation, simple equipment, a small amount of the three wastes (waste gas, waste water and industrial residue) and low cost, and the content and yield of the produced products are high.

Owner:NANTONG WEILIKE CHEM

Mildewproof coating

InactiveCN105949924AEasy to makeEasy to useAntifouling/underwater paintsPaints with biocidesPolyesterEpoxy

The invention discloses a mildewproof coating which comprises, by weight, 40-80 parts of acrylic isopropyl ester, 20-40 parts of epoxy resin, 20-28 parts of ethylene glycol monopropyl ether, 30-40 parts of ethyl acetate, 18-24 parts of benzoperoxide, 10-20 parts of dibutyl phthalate, 8-16 parts of polyester, 20-30 parts of butanediol acrylate, 4-6 parts of trimethylolpropane, 10-20 parts of butanediol, 10-20 parts of metoxyphenol, 20-40 parts of zinc ammonium carbonate and 10-20 parts of titanium dioxide. The mildewproof coating is simple to make, and nontoxic production raw materials are selected and adopted, so that using of the coating has good effect and is environment-friendly, and a solid shining film can be formed acting on coating the surface of leather.

Owner:陈金才

Synthesis process of 2-propoxyethyl chloride

InactiveCN106831368AHigh catalytic efficiencyReduce generationEther separation/purificationOrganic compound preparationReaction rateOrganic synthesis

The invention relates to a synthesis process of 2-propoxyethyl chloride and belongs to the technical field of fine chemical intermediate organic synthesis. The synthesis process comprises the following steps: preparing a crude product by taking ethylene glycol monopropyl ether and excessive sulfoxide chloride as main raw materials and adopting an efficient catalyst through heating and heat preservation, wherein the reaction rate is controlled by dropwise adding sulfoxide chloride; and performing neutralization, hydrolysis, and liquid separation after standing to obtain 2-propoxyethyl chloride. Compared with the existing process, the synthesis process has the advantages that the catalyst has higher catalytic efficiency; and the existing process needs 0.1 to 0.2 mol of excessive sulfoxide chloride, but the catalyst only needs 0.01 mol of excessive sulfoxide chloride, so fewer waste water and waste residues are generated when the crude product is treated, the product content reaches above 99.5 percent, the yield is more than 99.0 percent, the production cost is lower, and the synthesis process is suitable for industrialized production.

Owner:SHANDONG KAISHENG NEW MATERIALS

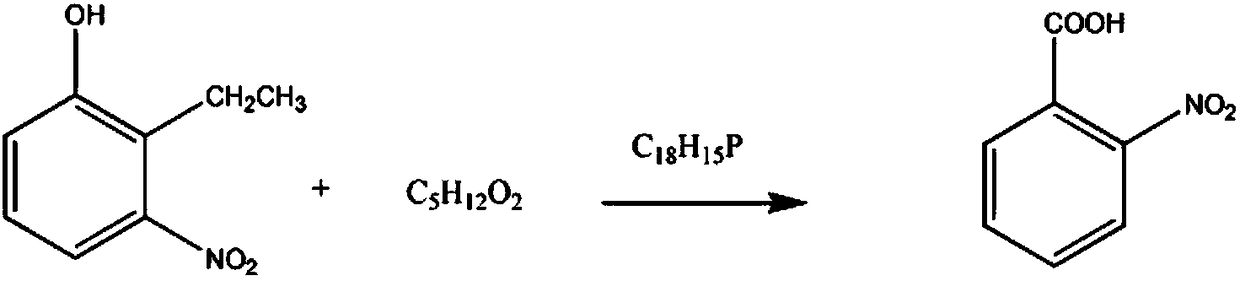

Synthesis method of antagonist medicine intermediate o-nitrobenzoic acid

InactiveCN108623464AReduce intermediate linksShort reaction timeOrganic chemistryOrganic compound preparationSynthesis methodsPropionic anhydride

The invention provides a synthesis method of an antagonist medicine intermediate o-nitrobenzoic acid. The method mainly comprises the following steps of adding 3mol of 2-ethyl-3-nitrophenol and 4 to 5mol of ethylene glycol monopropyl ether solution into a reaction container; raising the solution temperature to 30 to 35 DEG C; controlling the stirring speed being 150 to 170 rpm; maintaining the state for 30 to 50min; then, adding 6 to 7mol of triphenylphosphine powder; continuously performing reaction for 60 to 90min; lowering the solution temperature to 5 to 8 DEG C; separating out solid; performing filtering; sequentially using propionic anhydride solution for washing and triethylamine solution for washing; then, performing recrystallization in the 2-methyl pentane solution; performing dewatering by a dewatering agent; obtaining crystal o-nitrobenzoic acid.

Owner:CHENGDU ZHONGHENG HUATIE TECH CO LTD

Waterproof anti-condensation glue

The invention discloses waterproof anti-condensation glue. The waterproof anti-condensation glue comprises the following ingredient in parts by weight: 100-120 parts of epoxy resin, 80-120 parts of butyl acetate, 12-30 parts of zinc oxide, 8-16 parts of benzoyl peroxide, 10-20 parts of dibutyl phthalate, 10-20 parts of triphenyl phosphate, 2-10 parts of isopropyl acrylate, 20-80 parts of styrene, 10-20 parts of zinc ammonia carbonate, 20-40 parts of titanium dioxide, 10-20 parts of ethylene glycol monopropyl ether and 6-12 parts of ethyl acrylate. The waterproof anti-condensation glue is simple to manufacture, good in using effect, environmental-friendly, capable of forming tough coatings and durable in anti-condensation and waterproof performance. In addition, the producing raw materials are free of toxicity.

Owner:陈金才

A method for preparing metformin hydrochloride with high purity and high yield by two-component solvent

ActiveCN104829495BHigh purityGood crystal shapeOrganic compound preparationAmino compound preparationMetformin hydrochloride productDimethylformamide

The invention discloses a method for preparation of high purity and high yield metformin hydrochloride by a two-component solvent. The method includes: preparation of dimethylamine hydrochloride and preparation of metformin hydrochloride. During preparation of dimethylamine hydrochloride, dimethylamine gas and 31% hydrochloric acid are adopted as the raw materials to carry out reaction, through co-cooling of a cooler and a reaction kettle jacket, pumping circulating, spraying absorption of dimethylamine tail gas and absorption of dimethylamine tail gas by hydrochloric acid, the utilization rate of the raw materials is maximumly ensured, the loss of raw materials is reduced, and the product yield is improved. During preparation of metformin hydrochloride, dimethylformamide and ethylene glycol monopropyl ether two components are used as the solvent, the synergistic effect of the two solvents with different natures are utilized, and the prepared metformin hydrochloride product has yield of over 95% and purity of more than 99.90%.

Owner:山西津华晖星制药有限公司

Preparation method for intermediate epichlorophdrin of herbicide pretilachlor

InactiveCN101284768BEmission reductionEliminate potential safety hazardsOrganic chemistryOrganic compound preparationChemical reactionOrganosolv

The invention relates to a method for preparing a herbicide pretilachlor intermediate chloride ether, which comprises: under the action of an organic amine catalyst, the chloride ether can be obtained by reacting ethylene glycol monopropyl ether with bis (trichloromethyl) hydroxyphenyl in the organic solvent according to the following chemical equation: HOC2H4OC3H7+Cl3COCOOCCl3 - ClC2H4OC3H7+CO2+HCl. The method substitutes bis(trichloromethyl) hydroxyphenyl for traditional chlorination reagents, such as thionly chloride, phosphorus oxychloride and hydrogen chloride, etc., and the potential safety hazard can be eliminated from the process source by using the novel chlorination reagent. Simultaneously, the emissions of pollutants are greatly reduced; the method is a cleaning process with mild reaction conditions, safe and reliable operating process and high product yield, and has good industrialization implementation value and social economic benefits.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com