Production process of 2,6-diethyl-N-(2-propoxyethyl) acetanil

A technology of diethylaniline and propoxyethyl, which is applied in the preparation of carboxylic acid amides, the preparation of organic compounds, organic chemistry, etc., can solve the problems of low yield of finished products and few related reports, and achieve high yield of products, Raw materials are readily available and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

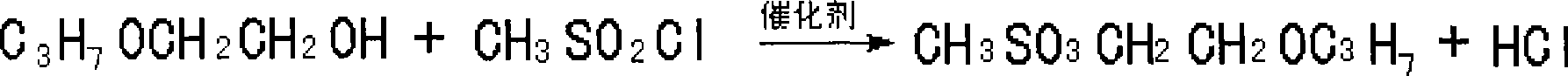

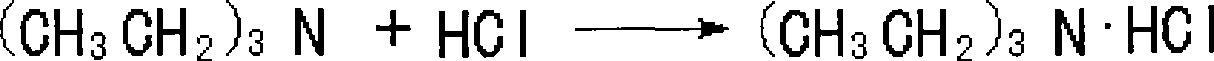

[0024] Mix 1 mole of ethylene glycol monopropyl ether, 1.5 moles of triethylamine and an appropriate amount of esterification catalyst to react and stir, and cool down to 0-5°C by freezing brine (for example: 0°C, 1°C, 2°C, 3°C, 4°C , 5°C,), slowly add 1.1 moles of methanesulfonyl chloride dropwise, and the dropwise addition is completed in about 5 hours. After the reaction is completed, add an appropriate amount of water and stir for 2 hours, leave to separate and separate, and the oil layer is subjected to vacuum distillation to obtain the product sulfonyl chloride Esterate 167 grams.

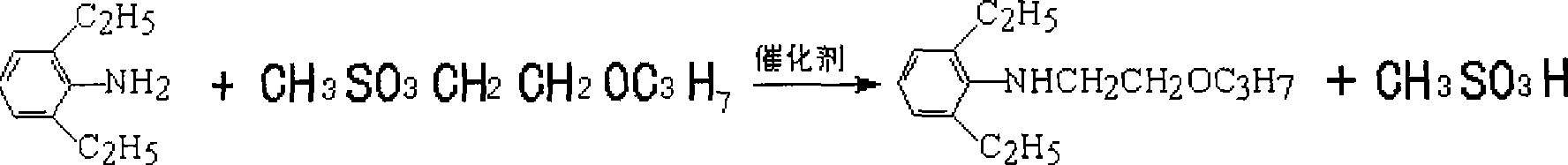

[0025] Add 1 mole of 2,6-diethylaniline, 1 mole of sulfonate and an appropriate amount of etherification catalyst into the autoclave, and heat to 165-180°C (for example, 165°C, 169°C, 170°C, 175°C, 180°C ), kept warm for 5 hours, after the reaction was finished, drop liquid caustic soda to neutralize, add water to wash and separate layers to obtain an oil layer, and obtain 2,6-diethyl-N-(2-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com