Method for producing metformin hydrochloride from complex solvents

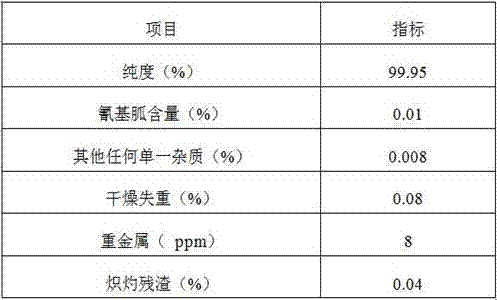

A technology of metformin hydrochloride and compound solvent, which is applied in chemical instruments and methods, preparation of organic compounds, preparation of amino compounds, etc., can solve problems such as side reactions, poor productivity of a single device, toxic solvents, etc., to ensure the distribution of crystal particles. , The process time is shortened, and the effect of ensuring the purity of the finished product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A method for preparing metformin hydrochloride with high purity and high yield by a two-component solvent, comprising the following steps:

[0054] (1) Preparation of dimethylamine hydrochloride

[0055] 1. Add part of hydrochloric acid and dimethylamine gas

[0056] Measure 920kg of hydrochloric acid with a concentration of 31% into the head tank, then put 560Kg of hydrochloric acid in the head tank into the salt-forming reaction kettle first, start stirring, and feed frozen brine into the jacket of the reaction kettle, and wait until the temperature of the kettle drops to 10 ℃, feed frozen brine to the shell side of the cooler, start feeding dimethylamine gas into the salt-forming reactor, adjust the feeding speed of dimethylamine gas, the amount of dimethylamine gas added is about 200Kg, and keep the temperature of the kettle at 20°C.

[0057] 2. The material enters the vent pipe

[0058] Turn on the circulation pump, and open the valve leading to the high end of t...

Embodiment 2

[0096] Through test, adopt the step of embodiment 1, adopt following process parameter:

[0097] (1) Preparation of dimethylamine hydrochloride

[0098] 1. Add part of hydrochloric acid and dimethylamine gas

[0099] Measure 31% hydrochloric acid into the high-level tank, put about 60% of the total amount of hydrochloric acid into the salt-forming reactor first, start stirring, feed frozen brine into the jacket of the reactor, wait until the temperature of the kettle drops to 10-20°C, Feed frozen brine into the shell side of the cooler, and start feeding dimethylamine gas into the salt-forming reaction kettle. The amount of dimethylamine gas added is about two-thirds of the total amount, and the feeding speed of dimethylamine gas is adjusted to keep the temperature of the kettle at 15 ~25°C.

[0100] Dimethylamine: 31% industrial hydrochloric acid (weight ratio) = 1: 2.75 to 2.98.

[0101] 2. The material enters the vent pipe

[0102] Turn on the circulation pump, and open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com